Analysis on X-ray flaw detection stripe of tungsten infiltrated copper used in gas rudder

-

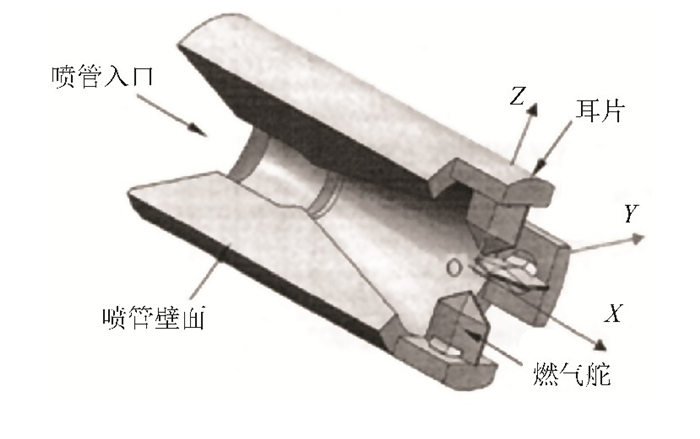

摘要: 以燃气舵用钨渗铜(W-7Cu)为研究对象,通过观察和检测X射线探伤底片、金相组织、断口显微形貌及力学性能,对产品在X射线探伤过程中出现的条纹现象进行分析。结果表明,燃气舵用钨渗铜X射线探伤出现的条纹现象由材料的组织结构和工艺特点所决定,条纹区域的组织属于钨渗铜材料的正常组织,不存在孔洞、裂纹和渗铜不均等结构缺陷;产品条纹区域的性能指标满足技术要求,与材料无条纹区域的性能无显著差别;提出了对燃气舵用钨渗铜X射线探伤进行分级的建议。Abstract: The stripe phenomenon of the tungsten infiltrated copper used in gas rudder (W-7Cu) during the X-ray flaw detection was analyzed by the observation and detection of the X-ray flaw detection negative, metallographic structure, fracture microstructure, and mechanical properties. The results show that, the stripe phenomenon during the X-ray flaw detection is caused by the structure and technological features of the tungsten infiltrated copper materials. The structure in the stripe region is the normal structure of the tungsten infiltrated copper materials without the structural defects of holes, cracks, and uneven infiltrated copper. The product properties in the stripe region meet the technical requirements, and there is no significant difference between the strip region and the non-striped region. The suggestion of grading the X-ray flaw detection for tungsten infiltrated copper used in gas rudder is proposed.

-

表 1 钨渗铜产品性能参数

Table 1. Product performance parameters of the tungsten infiltrated copper materials

Cu质量分数/% 钨骨架相对密度/% 钨渗铜材料密度/(g·cm-3) 钨渗铜材料相对密度/% 9.0 81.3 17.3 98.6 表 2 钨渗铜产品不同区域密度测量值

Table 2. Density data of the tungsten infiltrated copper products in the different regions

试样编号 区域 密度/(g·cm-3) 1# A 17.36 2# B 17.33 3# C 17.27 表 3 钨渗铜产品不同区域能谱分析结果

Table 3. EDS analysis results of the tungsten infiltrated copper products in the different regions

位置 Cu质量分数/% W质量分数/% 有条纹区〔A位置) 6.14 93.86 无条纹区〔C位置) 9.15 90.85 表 4 钨渗铜产品不同区域力学性能试验结果

Table 4. Mechanical properties of the tungsten infiltrated copper products in the different regions

区域 试样编号 室温抗拉强度/MPa 800 ℃抗拉强度/MPa 实际值 平均值 实际值 平均值 无条纹区(C位置) C-1 730 290 C-2 720 728 290 290 C-3 734 290 有条纹区(D位置) D-1 720 285 D-2 729 726 280 283 D-3 730 285 -

[1] Ye B. Parametric Design and Software Development of Gas Vane[Dissertation]. Nanjing: Nanjing University of Science and Technology, 2008叶彬. 燃气舵片参数化设计及其软件开发[学位论文]. 南京: 南京理工大学, 2008 [2] Yuan S Q, Zhang B Y, Chen Z M, et al. Current status and development of tungsten alloys using in warheads. China Tungsten Ind, 2015, 30(2): 49 https://www.cnki.com.cn/Article/CJFDTOTAL-ZGWU201502012.htm袁书强, 张保玉, 陈子明, 等. 战斗部用钨合金材料现状及发展状况. 中国钨业, 2015, 30(2): 49 https://www.cnki.com.cn/Article/CJFDTOTAL-ZGWU201502012.htm [3] Fan J L, Li P F, Liu T, et al. Advances in fine grained tungsten and tungsten alloys with high performance. China Tungsten Ind, 2015, 30(2): 41 https://www.cnki.com.cn/Article/CJFDTOTAL-ZGWU201502011.htm范景莲, 李鹏飞, 刘涛, 等. 高性能细晶钨及钨合金的研究进展. 中国钨业, 2015, 30(2): 41 https://www.cnki.com.cn/Article/CJFDTOTAL-ZGWU201502011.htm [4] Zhong J F. Development and application on gas rudder prepared by copper tungsten. Aerosp Manuf Technol, 1987(5): 1 https://www.cnki.com.cn/Article/CJFDTOTAL-HTGY198705000.htm钟景福. 钨渗铜燃气舵的研制和应用. 航天工艺, 1987(5): 1 https://www.cnki.com.cn/Article/CJFDTOTAL-HTGY198705000.htm [5] Ma H Q, Gan Y, Zhang W, et al. Radiographic inspection of common defects in superalloy blades. Fail Anal Prev, 2020, 15(3): 159 https://www.cnki.com.cn/Article/CJFDTOTAL-SXFX202003006.htm马海全, 甘勇, 张卫, 等. 高温合金叶片常见缺陷的射线检测. 失效分析与预防, 2020, 15(3): 159 https://www.cnki.com.cn/Article/CJFDTOTAL-SXFX202003006.htm [6] Dan X G, Fan Z K, Liang S H, et al. Investigation on the ultrasonic nondestructive test of infiltrated W-Cu alloy by multiple echo method. Powder Metall Technol, 2005, 23(3): 181 doi: 10.3321/j.issn:1001-3784.2005.03.005淡新国, 范志康, 梁淑华, 等. 熔渗CuW材料的超声无损探伤研究. 粉末冶金技术, 2005, 23(3): 181 doi: 10.3321/j.issn:1001-3784.2005.03.005 [7] Wang Z Y, Li J W, Tang G P, et al. The test block design to tungsten alloy bars. Nondestr Test, 2015, 37(7): 11 https://www.cnki.com.cn/Article/CJFDTOTAL-WSJC201507003.htm王增勇, 李建文, 汤光平, 等. 超声检测用钨合金棒材试块设计. 无损检测, 2015, 37(7): 11 https://www.cnki.com.cn/Article/CJFDTOTAL-WSJC201507003.htm [8] Chen W G, An F S. Anaylsis of ultrasonic nondestructive investigation of W-Cu powder metallurgical products. Electr Eng Mater, 2006(1): 14 doi: 10.3969/j.issn.1671-8887.2006.01.004陈文革, 安发顺. 钨铜合金的超声波无损检测分析. 电工材料, 2006(1): 14 doi: 10.3969/j.issn.1671-8887.2006.01.004 [9] Kang D, Zhang H, Ma Z G, et al. Water-immersion ultrasonic testing of copper infiltrated tungsten material used in aerospace. Aerosp Manuf Technol, 2018, 12(6): 22 doi: 10.3969/j.issn.1674-5108.2018.06.005康达, 张宏, 马兆光, 等. 航天用钨渗铜产品水浸超声检测研究. 航天制造技术, 2018, 12(6): 22 doi: 10.3969/j.issn.1674-5108.2018.06.005 [10] Xie D H, He W Y, Wang X L, et al. Ultrasonic testing and defect analysis of tungsten alloy shells. Nondestr Test, 2006, 28(12): 641 doi: 10.3969/j.issn.1000-6656.2006.12.008谢东华, 何文艳, 王秀龙, 等. 钨合金壳体的超声检测及缺陷分析. 无损检测, 2006, 28(12): 641 doi: 10.3969/j.issn.1000-6656.2006.12.008 [11] Xiao J, Yang X G, Lin X S. Materials and process techniques of copper infiltrated tungsten for thrust vector jet vane of airborne missile. Aero Weap, 2009(6): 61 doi: 10.3969/j.issn.1673-5048.2009.06.015肖军, 杨晓光, 林学书. 空空导弹推矢燃气舵用钨渗铜材料与工艺. 航空兵器, 2009(6): 61 doi: 10.3969/j.issn.1673-5048.2009.06.015 [12] Sun B S. Study on the properties of copper tungsten infiltrated material. J Solid Rocket Technol, 1990(1): 82 https://www.cnki.com.cn/Article/CJFDTOTAL-GTHJ199001017.htm孙百顺. 钨渗铜材料性能的研究. 固体火箭技术, 1990(1): 82 https://www.cnki.com.cn/Article/CJFDTOTAL-GTHJ199001017.htm [13] Lin J Q, Chen W G, Tao W J, et al. Research on the tungsten fiber reinforced W/Cu composite materials with high-copper content. Powder Metall Technol, 2012, 30(2): 125 doi: 10.3969/j.issn.1001-3784.2012.02.008李君强, 陈文革, 陶文俊, 等. W纤维增强高Cu含量W-Cu复合材料的研究. 粉末冶金技术, 2012, 30(2): 125 doi: 10.3969/j.issn.1001-3784.2012.02.008 [14] Gao H M, Chen W G, Lian K, et al. Relativity between grain size and tungsten copper alloy. Chin J Rare Met, 2018, 42(1): 59 https://www.cnki.com.cn/Article/CJFDTOTAL-ZXJS201801009.htm高红梅, 陈文革, 连凯, 等. 晶粒尺寸与钨铜合金相关性的研究. 稀有金属, 2018, 42(1): 59 https://www.cnki.com.cn/Article/CJFDTOTAL-ZXJS201801009.htm [15] Cui L Q, Han S L, Li D R, et al. The effects of W particle size on the structure and mechanical properties of tungsten-copper alloy strips prepared by warm powder rolling. Powder Metall Ind, 2019, 29(6): 1 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201906001.htm崔利群, 韩胜利, 李达人, 等. W粉粒度对粉末温轧制备钨铜合金板组织和性能的影响. 粉末冶金工业, 2019, 29(6): 1 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201906001.htm [16] Zhang B H, Zhang D H, Guo Y L. Study on ablation properties and mechanism of tungsten infiltrated copper composites. Powder Metall Ind, 2019, 29(6): 18 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201906005.htm张保红, 张丹华, 郭颖利. 钨渗铜复合材料烧蚀性能及机理研究. 粉末冶金工业, 2019, 29(6): 18 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201906005.htm [17] Chen W, Zhou W P, Kuang Y G, et al. Effect of granularity on W-skeleton of copper infiltrated tungsten. Powder Metall Ind, 2004, 14(2): 17 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG200402007.htm陈伟, 周武平, 邝用庚, 等. 粉末粒度对于高温钨渗铜材料骨架性能的影响. 粉末冶金工业, 2004, 14(2): 17 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG200402007.htm [18] Cun M M, Chen W G, Yan G J, et al. Influence of multiple sintering on microstructure and properties of W-Cu alloy. Powder Metall Technol, 2017, 35(4): 243寸敏敏, 陈文革, 颜国君, 等. 多次烧结对钨铜合金组织与性能的影响. 粉末冶金技术, 2017, 35(4): 243) Yang G Y, Liu N, Jia L, et al. Fabrication and compression property of tungsten skeleton for tungsten-copper composite. Mater Sci Eng Powder Metall, 2017, 22(5): 701(杨广宇, 刘楠, 贾亮, 等. 钨铜复合材料用钨骨架的制备与压缩性能. 粉末冶金材料科学与工程, 2017, 22(5): 701 -

下载:

下载: