Microstructure and properties of UNS S32750 super-duplex stainless steels processed by hot isostatic pressing

-

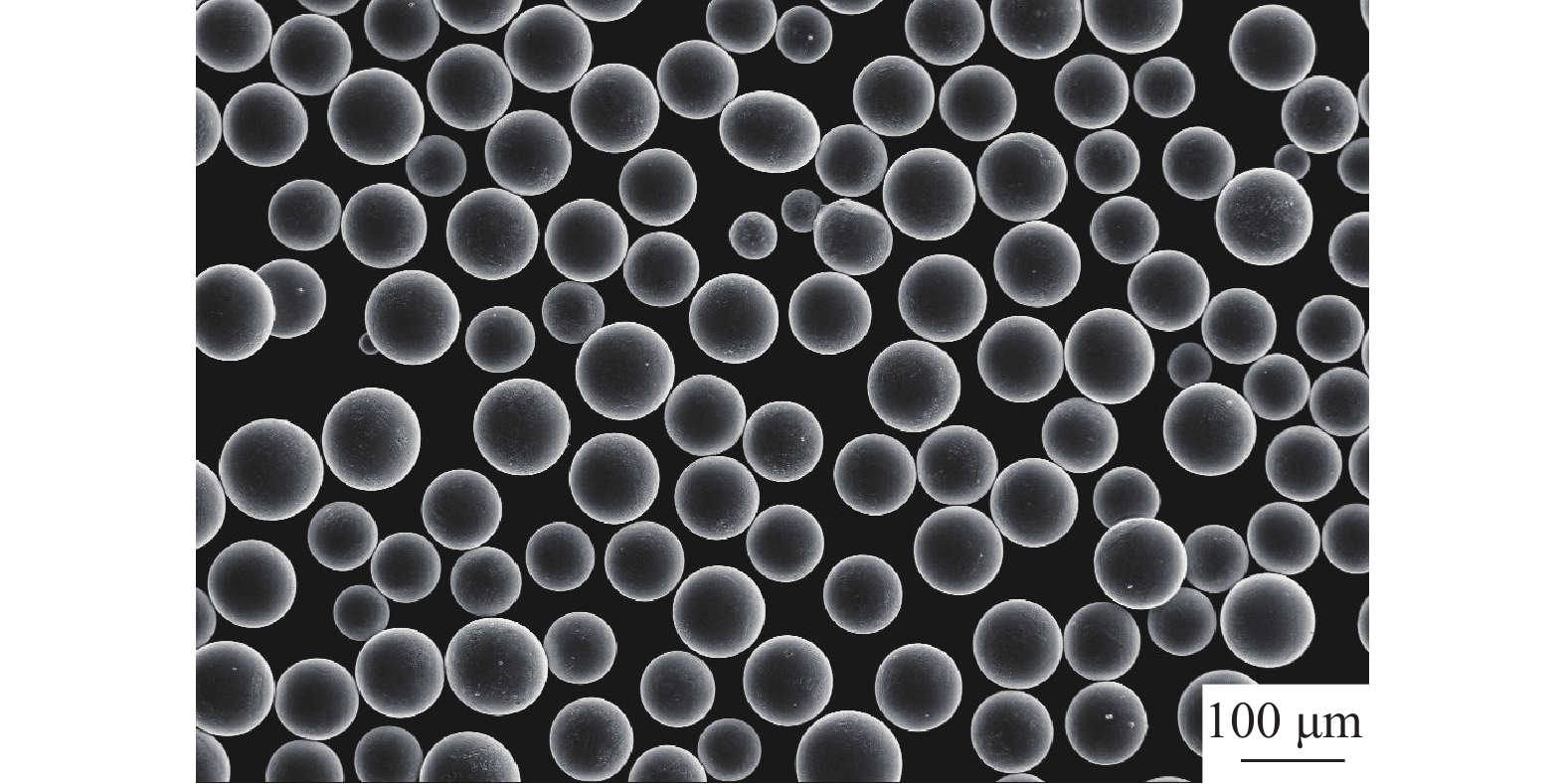

摘要: 采用等离子旋转电极雾化-热等静压工艺制备了UNS S32750超级双相不锈钢。利用光学显微镜、扫描电子显微镜、电子背散射衍射、万能试验机等手段研究了热等静压UNS S32750超级双相不锈钢固溶处理前后的显微组织和力学性能。结果表明:采用等离子旋转电极雾化制备的UNS S32750超级双相不锈钢粉末在150 MPa 压力下,经1200 ℃×3 h热等静压烧结后实现了致密化,相对密度为99.7%。随炉缓冷过程中,烧结件中析出的σ相导致材料韧性显著下降。经1035 ℃×1 h固溶处理后水淬,σ相完全溶解,材料韧性显著提高,显微组织为α和γ两相组织,体积比为65:35,抗拉强度791 MPa,屈服强度586 MPa,断后伸长率38%,冲击吸收功236 J。Abstract: The UNS S32750 super-duplex stainless steels were prepared by plasma rotating electrode processing and hot isostatic pressing in this study. The microstructure and mechanical properties of the steels before and after the solution treatment were investigated by optical microscope (OM), scanning electron microscope (SEM), electron back scattering diffraction (EBSD), and electronic material testing machine. The results indicate that the UNS S32750 super-duplex stainless steel powders prepared by plasma rotary electrode processing can be densified by hot isostatic pressing sintering at 1200 ℃ for 3 h at 150 MPa, and the relative density of the sintered parts is 99.7%. The σ phases precipitate in the sintered parts during the furnace slow cooling process, significantly undermining the impact toughness. In contrast, the σ phases are dissolved completely after the solution treatment at 1035 ℃ for 1 h followed by the water quenching, leading to a notable increase in the impact toughness. A duplex structure of the α and γ phases is identified, which significantly affects the properties of the specimens. In detail, the volume ratio between the α and γ phases is 65:35, the tensile strength and yield strength of the specimens are 791 MPa and 586 MPa, respectively, the elongation is approximately 38%, and the impact absorbing energy is 236 J.

-

表 1 UNS S32750双相不锈钢粉末化学成分(质量分数)

Table 1. Chemical composition of the UNS S32750 duplex stainless steel powders

% Cr Ni Mo N Si Mn S P C O Fe 25.7100 6.0800 3.5600 0.2000 0.4500 0.7200 0.0040 0.0300 0.0280 0.0057 余量 表 2 UNS S32750双相不锈钢热处理工艺

Table 2. Heat treatment of the UNS S32750 super-duplex stainless steels

试样编号 加工工艺 S1 热等静压(1200 ℃ × 3 h、150 MPa)+ 炉冷 S2 热等静压(1200 ℃ × 3 h、150 MPa)+ 炉冷 + 固溶处理(1000 ℃ × 1 h)+ 水冷 S3 热等静压(1200 ℃ × 3 h、150 MPa)+ 炉冷 + 固溶处理(1035 ℃ × 1 h)+ 水冷 S4 热等静压(1200 ℃ × 3 h、150 MPa)+ 炉冷 + 固溶处理(1070 ℃ × 1 h)+ 水冷 S5 热等静压(1200 ℃ × 3 h、150 MPa)+ 炉冷 + 固溶处理(1100 ℃ × 1 h)+ 水冷 表 3 不同固溶处理试样中α和γ两相体积比

Table 3. Volume ratio of α and γ phases in the specimens after the different solution treatments

试样编号 α与γ体积比 S1 52:44 S3 65:35 S4 65:35 S5 71:29 表 4 不同加工工艺试样的力学性能

Table 4. Mechanical properties of the specimens treated by the different processing technologies

试样编号 抗拉强度 / MPa 屈服强度 / MPa 断后伸长率 / % 冲击吸收功 / J 硬度,HV S1 830 572 36 8 231 S3 791 586 38 236 188 铸态[17] 790 530 36 155 — -

[1] Chail G, Kangas P. Super and hyper duplex stainless steels: structures, properties and applications. Procedia Struct Integrity, 2016, 2: 1755 doi: 10.1016/j.prostr.2016.06.221 [2] Jia C C, Kuang C J. Development of powder metallurgy high nitrogen stainless steels. Met World, 2015(1): 23 doi: 10.3969/j.issn.1000-6826.2015.01.08贾成厂, 况春江. 粉末冶金高氮不锈钢的发展历程. 金属世界, 2015(1): 23 doi: 10.3969/j.issn.1000-6826.2015.01.08 [3] Zhang Z Q, Jing H Y, Xu L Y, et al. Research progress on microstructure and properties of welded joint of ferrite/austenite duplex stainless steel. Trans Mater Heat Treat, 2020, 41(5): 13张志强, 荆洪阳, 徐连勇, 等. 铁素体/奥氏体双相不锈钢焊接接头组织和性能的研究进展. 材料热处理学报, 2020, 41(5): 13 [4] Xie X F, Li J W, Jiang W C, et al. Nonhomogeneous microstructure formation and its role on tensile and fatigue performance of duplex stainless steel 2205 multi-pass weld joints. Mater Sci Eng A, 2020, 786: 139426 doi: 10.1016/j.msea.2020.139426 [5] Li H, Zhou E, Zhang D, et al. Microbiologically influenced corrosion of 2707 hyper-duplex stainless steel by marine pseudomonas aeruginosa biofilm. Sci Rep, 2016, 6: 20190 doi: 10.1038/srep20190 [6] Xiang H L, Liu C Y, Wang Y X, et al. Cavitation corrosion resistance of copper-bearing antibacterial duplex stainless steel. Spec Cast Nonferrous Alloys, 2018, 38(8): 816向红亮, 刘春育, 王永霞, 等. 含Cu抗菌双相不锈钢的空蚀行为研究. 特种铸造及有色合金, 2018, 38(8): 816 [7] Qi M H, Ren S B, Zhang G Z, et al. Effects of solution treatment on microstructure and mechanical properties of hot isostatic pressing SAF3207. Powder Metall Technol, 2017, 35(5): 328齐美欢, 任淑彬, 张公桢, 等. 固溶处理对热等静压SAF3207的组织与性能影响. 粉末冶金技术, 2017, 35(5): 328 [8] Pan M M, Zhang X M, Chen P, et al. The effect of chemical composition and annealing condition on the microstructure and tensile properties of a resource-saving duplex stainless steel. Mater Sci Eng A, 2020, 788: 139540 doi: 10.1016/j.msea.2020.139540 [9] Holländer Pettersson N, Lindell D, Lindberg F, et al. Formation of chromium nitride and intragranular austenite in a super duplex stainless steel. Metall Mater Trans A, 2019, 50: 5594 doi: 10.1007/s11661-019-05489-2 [10] Li J Y, Yang Z H. Thermo-plasticity and high-temperature microstructure evolution of hyper duplex stainless steel 00Cr32Ni7Mo3.5N. Forg Stamp Technol, 2013, 38(6): 122李静媛, 杨智辉. 超级双相不锈钢00Cr32Ni7Mo3.5N的热塑性及高温组织演变. 锻压技术, 2013, 38(6): 122 [11] He F S, Xiang H L, Gu X, et al. Cavitation erosion behavior of Cr32Ni7Mo3N hyper duplex stainless steel. Chin J Eng, 2014, 36(8): 1060何福善, 向红亮, 顾兴, 等. Cr32Ni7Mo3N特级双相不锈钢的空蚀行为. 工程科学学报, 2014, 36(8): 1060 [12] Davidson K P, Singamneni S. Magnetic characterization of selective laser-melted S32750 duplex stainless steel. JOM, 2017, 69(3): 569 doi: 10.1007/s11837-016-2193-6 [13] Davidson K P, Singamneni S. Selective laser melting of duplex stainless steel powders: An investigation. Mater Manuf Process, 2016, 31(12): 1543 doi: 10.1080/10426914.2015.1090605 [14] Sotomayor M E, Cervera A, Várez A, et al. Duplex stainless steel self-ligating orthodontic brackets by micro-powder injection moulding. Int J Eng Res Sci, 2016, 2(4): 184 [15] Zucato I, Moreira M, Machado I, et al. Microstructural characterization and the effect of phase transformations on toughness of the UNS S31803 duplex stainless steel aged treated at 850 ℃. Mater Res, 2002, 5(3): 385 doi: 10.1590/S1516-14392002000300026 [16] Wang X F. Research on Microstructures and Properties of 00Cr25Ni7Mo4N Super Duplex Stainless Steel [Dissertation]. Beijing: University of Science and Technology Beijing, 2009王晓峰. 00Cr25Ni7Mo4N超级双相不锈钢组织及性能的研究[学位论文]. 北京: 北京科技大学, 2009 [17] Li S J. The Effect of Content on Microstructure and Mechanical Properties of 00Cr25Ni7Mo3N Super Duplex Stainless Steel [Dissertation]. Kunming: Kunming University of Science and Technology, 2011李树健. 成分对00Cr25Ni7Mo3N双相不锈钢组织及性能的影响[学位论文]. 昆明: 昆明理工大学, 2011 -

下载:

下载: