Effect of powder sintering on microstructure and mechanical properties of magnesium‒scandium alloys

-

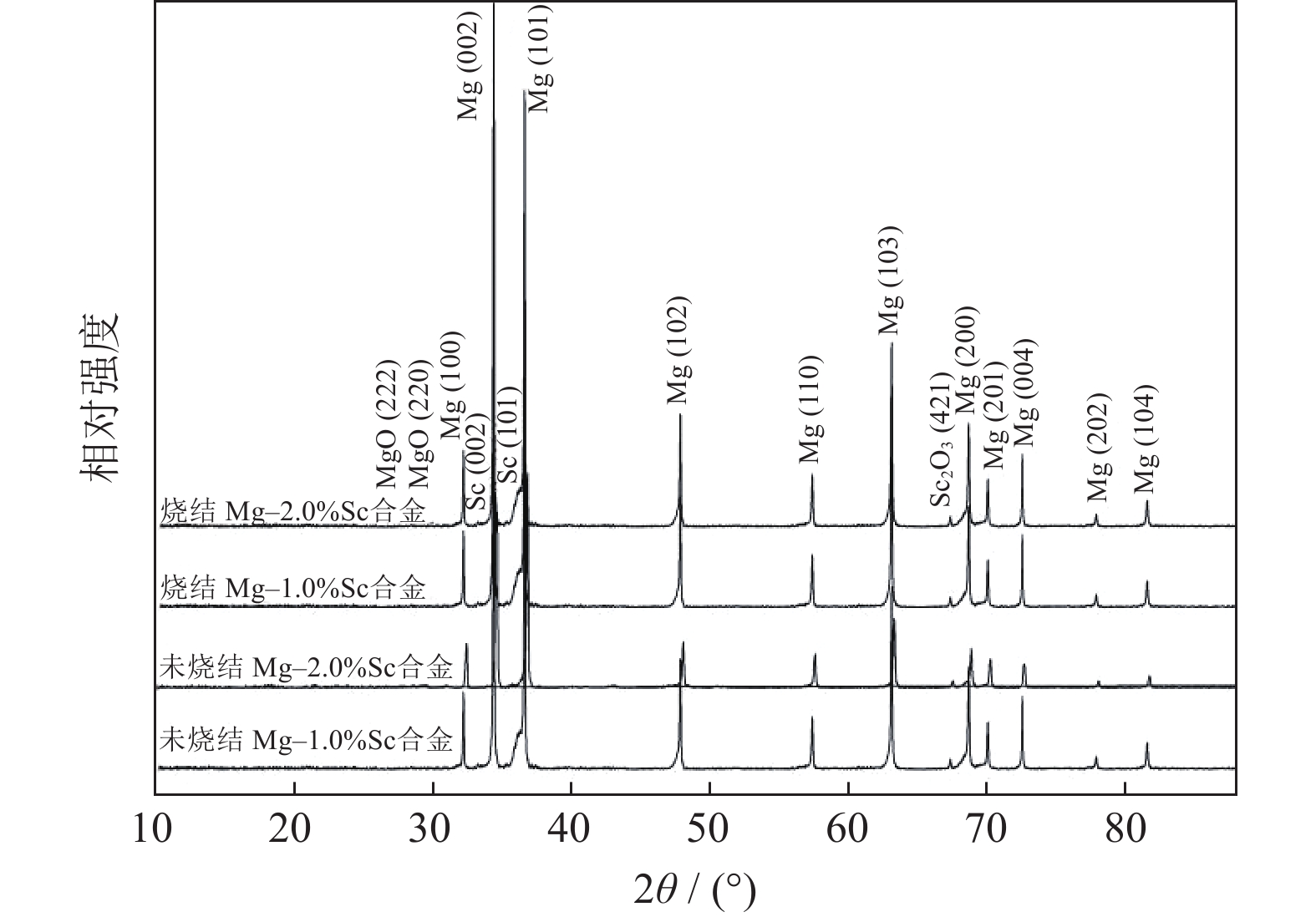

摘要: 在惰性气氛下,经500 ℃烧结2 h和300 ℃挤压制得镁钪合金,并对其进行微观组织观察和力学性能测试。结果表明:粉末烧结镁钪合金的相组成主要为基体Mg相,未发现Mg‒Sc相生成。在粉末烧结过程中,钪元素在镁基体中发生扩散,明显改善界面结合形式,提高了镁钪界面的结合性。当钪质量分数为1.0%时,镁钪合金的伸长率达到10.37%,提高了61%。在拉伸试样断口处发现大量韧窝存在,说明烧结处理可明显提高镁钪合金的韧性。Abstract: Magnesium‒scandium (Mg‒Sc) alloys were prepared by powder sintering at 500 ℃ for 2 h and extrusion at 300 ℃ under the inert atmosphere. The microstructure and mechanical properties of the Mg‒Sc alloys were investigated. The results show that, the phase composition of the Mg‒Sc alloys is mainly Mg phase, and no Mg‒Sc phase is detected. Due to the diffusion of Sc element in the Mg matrix during the sintering process, the interfacial combination is significantly improved, and the interface bonding between Mg and Sc particles is increased. The elongation of the sintered Mg‒Sc alloys with the Sc mass fraction of 1.0% is 10.37%, which is increased by 61%. In addition, a large number of dimples are observed at the tensile fracture, indicating that sintering can improve the toughness of the Mg‒Sc alloys.

-

Key words:

- Mg−Sc alloys /

- powder sintering /

- microstructure /

- mechanical properties

-

表 1 实验原料纯度及尺寸

Table 1. Purity and size of the raw materials in the experiment

原材料 纯度,质量分数 / % 尺寸 / μm 镁粉 >99.9 20~60 钪粉 >99.95 120~160 表 2 镁钪合金试样元素成分(质量分数)

Table 2. Element composition of the Mg‒Sc alloy samples %

工艺 Mg‒Sc合金 Sc Mg 未烧结 Mg‒1.0%Sc 0.98 余量 Mg‒2.0%Sc 1.98 余量 烧结 Mg‒1.0%Sc 0.96 余量 Mg‒2.0%Sc 2.01 余量 -

[1] Li W X. Magnesium and Magnesium Alloys. Changsha: Central South University Press, 2005黎文献. 镁及镁合金. 长沙: 中南大学出版社, 2005 [2] Yu Y, Zhang W C, Duan X R. Study on microstructure and properties of thin tube of AZ31 magnesium alloy by extrusion technology. Powder Metall Technol, 2013, 31(3): 201于洋, 张文丛, 段祥瑞. AZ31镁合金细管静液挤压工艺及组织性能分析. 粉末冶金技术, 2013, 31(3): 201 [3] Song J F, She J, Chen D L, et al. Latest research advances on magnesium and magnesium alloys worldwide. J Magnesium Alloys, 2020, 8(1): 1 doi: 10.1016/j.jma.2020.02.003 [4] Liu D X, Yang D L, Li X L, et al. Mechanical properties, corrosion resistance and biocompatibilities of degradable Mg‒RE alloys: A review. J Mater Res Technol, 2019, 8(1): 1538 doi: 10.1016/j.jmrt.2018.08.003 [5] Zhang J H, Liu S J, Wu R Z, et al. Recent developments in high-strength Mg‒RE-based alloys: Focusing on Mg‒Gd and Mg‒Y systems. J Magnesium Alloys, 2018, 6: 277 doi: 10.1016/j.jma.2018.08.001 [6] Lü Z, Zhou J, Sun Z M, et al. Effect of rare earth elements on the structures and mechanical properties of magnesium alloys. Chin Sci Bull, 2013, 58: 816 doi: 10.1007/s11434-012-5617-x [7] Tan X H, Chee K H W, Chan K W J, et al. Effect of homogenization on enhancing the failure strain of high strength quaternary LPSO Mg‒Y‒Zn‒Al alloy. Mater Sci Eng A, 2015, 644: 405 doi: 10.1016/j.msea.2015.07.079 [8] Li G L, Wen J B, He J G, et al. Effect of Nd addition on microstructure and corrosion resistance of AZ80 magnesium alloys. Trans Mater Heat Treat, 2013, 34(12): 53李高林, 文九巴, 贺俊光, 等. 稀土元素Nd对AZ80镁合金组织及耐蚀性能的影响. 材料热处理学报, 2013, 34(12): 53 [9] Liu J H, Song Y W, Shan D Y, et al. Comparative study on corrosion behavior of cast and forged Mg‒5Y‒7Gd‒1Nd‒0.5Zr alloys. Acta Metall Sinica, 2018, 54(8): 1141刘金辉, 宋影伟, 单大勇, 等. 铸态和锻造态Mg‒5Y‒7Gd‒1Nd‒0.5Zr合金腐蚀行为对比研究. 金属学报, 2018, 54(8): 1141 [10] Yang Y L, Liu C, Ma Y Z, et al. Effects of rare earth element Y on the microstructure and mechanical properties of 2A12 aluminum alloy prepared by powder metallurgy method. Powder Metall Technol, 2020, 38(1): 3杨玉玲, 刘超, 马运柱, 等. 稀土元素Y对粉末冶金2A12铝合金组织和力学性能的影响. 粉末冶金技术, 2020, 38(1): 3 [11] Liu Y H, Wang Z H, Liu K, et al. Effects of Er on hot cracking susceptibility of Mg‒5Zn‒xEr magnesium alloys. Acta Metall Sinica, 2019, 55(3): 389刘耀鸿, 王朝辉, 刘轲, 等. Er对Mg‒5Zn‒xEr镁合金热裂敏感性的影响. 金属学报, 2019, 55(3): 389 [12] Pan F S, Yang M B, Chen X H. A review on casting magnesium alloys: modification of commercial alloys and development of new alloys. J Mater Sci Technol, 2016, 32(12): 1211 doi: 10.1016/j.jmst.2016.07.001 [13] Luo K, Zhang L, Wu G H, et al. Effect of Y and Gd content on the microstructure and mechanical properties of Mg‒Y‒RE alloys. J Magnesium Alloys, 2019, 7(2): 345 doi: 10.1016/j.jma.2019.03.002 [14] Li S B, Li R J, Wang Z H, et al. Creep resistance of as-extruded Mg‒8Gd‒1Er‒0.5Zr alloy. Rare Met Mater Eng, 2019, 48(2): 545李淑波, 李瑞静, 王朝辉, 等. 挤压态Mg‒8Gd‒1Er‒0.5Zr合金的抗蠕变性能. 稀有金属材料与工程, 2019, 48(2): 545 [15] Kula A, Silva C J, Niewczas M. Grain size effect on deformation behaviour of Mg‒Sc alloys. J Alloys Compd, 2017, 727(15): 642 [16] Lin H, Yang M, Tang H, et al. Effect of minor Sc on the microstructure and mechanical properties of AZ91 magnesium alloy. Prog Nat Sci Mater Int, 2018, 28(1): 66 doi: 10.1016/j.pnsc.2018.01.006 [17] Munir K, Lin J, Wen C, et al. Mechanical, corrosion, and biocompatibility properties of Mg‒Zr‒Sr‒Sc alloys for biodegradable implant applications. Acta Biomater, 2020, 102: 493 doi: 10.1016/j.actbio.2019.12.001 [18] Liu J N, Lin Y L, Bian D, et al. In vitro and in vivo studies of Mg‒30Sc alloys with different phase structure for potential usage within bone. Acta Biomater, 2019, 98: 50 doi: 10.1016/j.actbio.2019.03.009 [19] Andon D, Ogawa Y, Suzuki T, et al. Age-hardening effect by phase transformation of high Sc containing Mg alloy. Mater Lett, 2015, 161(15): 5 [20] Liu X, Wang W, Yuan L L, et al. Superfast preparation of Al‒Sc alloys with high Sc content by spark plasma sintering. Powder Metall Technol, 2020, 38(2): 126柳旭, 王炜, 元琳琳, 等. 放电等离子烧结快速制备高钪含量铝钪合金. 粉末冶金技术, 2020, 38(2): 126 [21] Zhuang T Y, Zhang J L, Wang F, et al. Research progress on the microwave sintering mechanism of metal powders. Powder Metall Technol, 2019, 37(5): 392庄天涯, 张际亮, 王霏, 等. 金属粉末微波烧结机理研究进展. 粉末冶金技术, 2019, 37(5): 392 [22] Ren F Y, Xu L, Li C Y, et al. Research progress in the preparation of particle-reinforced magnesium matrix composites by powder metallurgy. Powder Metall Technol, 2020, 38(1): 66任峰岩, 许磊, 历长云, 等. 粉末冶金法制备颗粒增强镁基复合材料的研究进展. 粉末冶金技术, 2020, 38(1): 66 [23] Silva C J, Kula A, Mishra R K, et al. Mechanical properties of Mg‒Sc binary alloys under compression. Mater Sci Eng A, 2017, 692: 199 doi: 10.1016/j.msea.2017.03.053 -

下载:

下载: