-

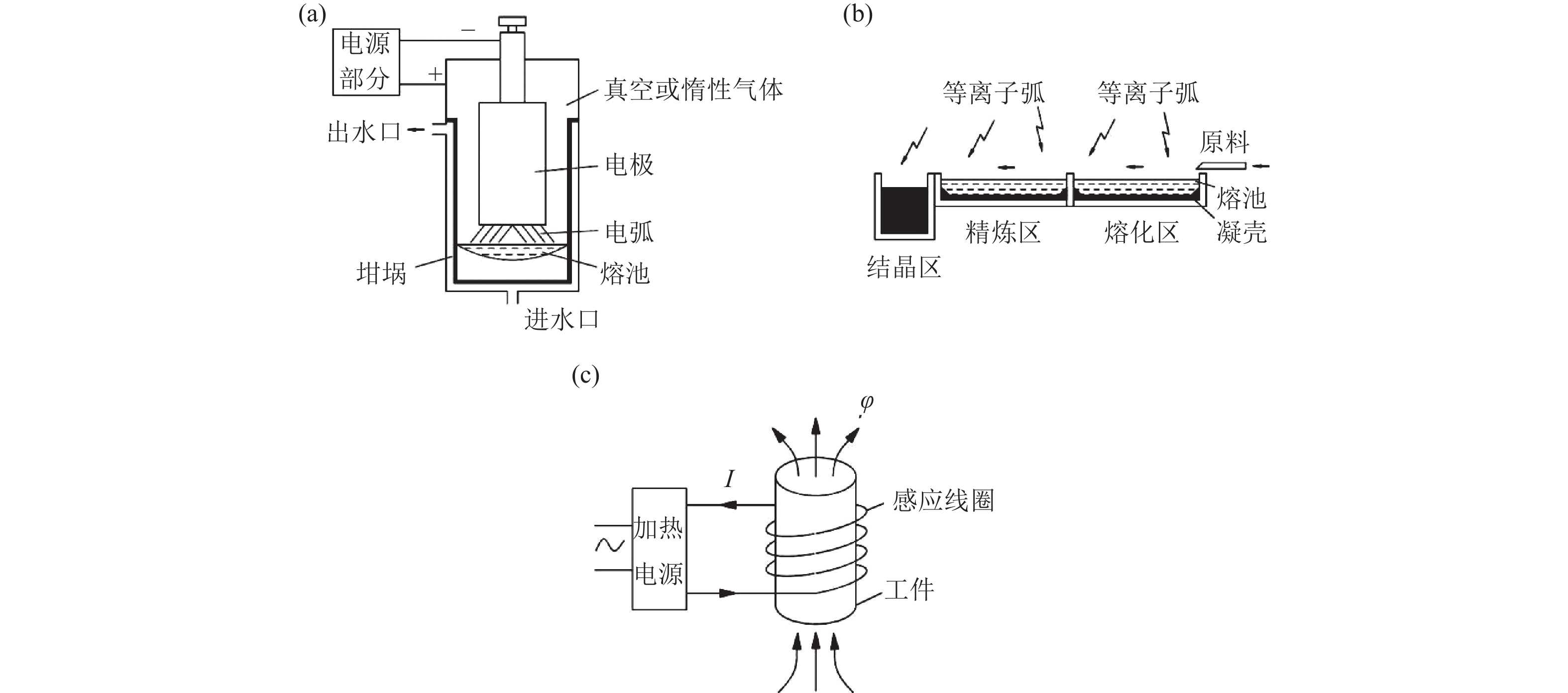

摘要: 金属增材制造技术正朝着产业化的方向发展,钛粉是金属增材制造领域的主流原料之一。本文概述了钛及钛合金的熔炼技术,重点介绍了感应熔炼,并对目前主流的钛粉制备技术进行了对比和分析,包括基本原理、优缺点和影响粉末特性的因素等。此外,还介绍了数值模拟在钛粉制备上的应用,并对钛粉制备工艺在金属增材制造领域的发展做出了展望。Abstract: Metal additive manufacturing technology is now developing in the direction of industrialization, and the titanium powders are one of the mainstream raw materials used for metal additive manufacturing. The smelting technology of titanium and its alloys was summarized in this paper, the induction smelting was emphasized, and the main technology of titanium powder preparation was analyzed and compared, including the basic principles, the characteristics, and the factors affecting the powder characteristics. In addition, the application of numerical simulation on the titanium powder preparation was also introduced, and the development of titanium powder preparation technology used in the field of metal additive manufacturing was prospected.

-

Key words:

- metal additive manufacturing /

- smelting /

- titanium powders /

- numerical simulation

-

表 1 不同熔炼方法对比

Table 1. Comparison of the different smelting methods

熔炼方法 热源 杂质元素 效率 成本 真空自耗电弧熔炼 电弧 多 低 高 电子束冷床熔炼 电子束 少 高 低 感应熔炼 电磁加热 少 高 最低 等离子旋转电极技术 工作转速 / (r·min‒1) 生产效率 细粉收得率 粉末中位粒径 / μm 自耗电极直径 / mm PREP 14000~16000 低 低 120 75 SL-PREP 18000 高 高 90 100 SS-PREP 33000 最高 最高 45 50~80 表 3 几种钛粉制备方法对比

Table 3. Comparison of the several preparation methods for the titanium powders

制粉方法 粒度分布范围 效率 球形度 细粉收得率 生产成本 空心率 PREP 窄 低 高 低 很高 几乎没有 PA 窄 低 高 低 高 低 VIGA 宽 高 低 高 低 高 EIGA 宽 低 低 高 高 高 表 4 Ansys和Comsol数值模拟软件对比

Table 4. Comparison of Ansys and Comsol

数值模拟软件 发展时间 物理场选择 网格划分 上手难度 主要应用范围 Ansys 长 主要是单相物理场 强 难 工业 Comsol 短 任意多物理场耦合 弱 容易 学术 -

[1] Neikter M, Åkerfeldt P, Pederson R, et al. Microstructural characterization and comparison of Ti‒6Al‒4V manufactured with different additive manufacturing processes. Mater Charact, 2018, 143: 68 doi: 10.1016/j.matchar.2018.02.003 [2] Xu W, Brandt M, Sun S, et al. Additive manufacturing of strong and ductile Ti–6Al–4V by selective laser melting via in situ martensite decomposition. Acta Mater, 2015, 85: 74 doi: 10.1016/j.actamat.2014.11.028 [3] Yang J J, Yu H C, Yin J, et al. Formation and control of martensite in Ti‒6Al‒4V alloy produced by selective laser melting. Mater Des, 2016, 108: 308 doi: 10.1016/j.matdes.2016.06.117 [4] Thijs L, Verhaeghe F, Craeghs T, et al. A study of the microstructural evolution during selective laser melting of Ti–6Al–4V. Acta Mater, 2010, 58(9): 3303 doi: 10.1016/j.actamat.2010.02.004 [5] Li A, Liu S F, Wang B J, et al. Research progress on preparation of metal powder for 3D printing. J Iron Steel Res, 2018, 30(6): 419李安, 刘世锋, 王伯健, 等. 3D打印用金属粉末制备技术研究进展. 钢铁研究学报, 2018, 30(6): 419 [6] Wen Y, Jiang T, Wu G H, et al. Research status on microstructures and properties of two-phase titanium alloys by 3D printing. Fail Anal Prev, 2016, 11(1): 42 doi: 10.3969/j.issn.1673-6214.2016.01.009文艺, 姜涛, 邬冠华, 等. 3D打印两相钛合金组织性能研究现状. 失效分析与预防, 2016, 11(1): 42 doi: 10.3969/j.issn.1673-6214.2016.01.009 [7] Ellyson B, Brochu M, Brochu M. Characterization of bending vibration fatigue of SLM fabricated Ti‒6Al‒4V. Int J Fatigue, 2017, 99: 25 doi: 10.1016/j.ijfatigue.2017.02.005 [8] Ren Y M, Lin X, Fu X, et al. Microstructure and deformation behavior of Ti‒6Al‒4V alloy by high-power laser solid forming. Acta Mater, 2017, 132: 82 doi: 10.1016/j.actamat.2017.04.026 [9] Tang H P, Qian M, Liu N, et al. Effect of powder reuse times on additive manufacturing of Ti‒6Al‒4V by selective electron beam melting. JOM, 2015, 67(3): 555 doi: 10.1007/s11837-015-1300-4 [10] Huang C S. Study on the Preparation of Ti‒6Al‒4V Powders by EIGA Method and the Microstructure and Properties of Selective Laser Melted Parts [Dissertation]. Guangzhou: South China University of Technology, 2019黄传收. EIGA法制备Ti‒6Al‒4V粉末及其SLM组织与性能研究[学位论文]. 广州: 华南理工大学, 2019 [11] Ding X. My country's 3D printing development is facing the dual bottleneck of materials and industrial innovation. Adv Mater Ind, 2015(4): 68 doi: 10.3969/j.issn.1008-892X.2015.04.014丁雪. 我国3D打印发展面临材料与产业创新双重瓶颈. 新材料产业, 2015(4): 68 doi: 10.3969/j.issn.1008-892X.2015.04.014 [12] Zhang F, Gao Z J, Ma T, et al. Metal powder materials for additive manufacturing and their preparation methods. Ind Technol Innov, 2017, 4(4): 59张飞, 高正江, 马腾, 等. 增材制造用金属粉末材料及其制备技术. 工业技术创新, 2017, 4(4): 59 [13] Sun J F, Yang Y Q, Wang D. Parametric optimization of selective laser melting for forming Ti6Al4V samples by taguchi method. Opt Laser Technol, 2013, 49: 118 doi: 10.1016/j.optlastec.2012.12.002 [14] Mitchell A. The electron beam melting and refining of titanium alloys. Mater Sci Eng A, 1999, 263(2): 217 doi: 10.1016/S0921-5093(98)01177-0 [15] Yuan W. Comparative analysis on melting process of TC4 titanium alloy. Nonferrous Met Process, 2018, 47(2): 23 doi: 10.3969/j.issn.1671-6795.2018.02.006袁蔚. TC4钛合金熔炼工艺的对比分析. 有色金属加工, 2018, 47(2): 23 doi: 10.3969/j.issn.1671-6795.2018.02.006 [16] Liu Q L, Li X M, Jiang Y H. Research progress of electron beam clod hearth melting for titanium and titanium alloys. Hot Working Technol, 2016, 45(9): 9刘千里, 李向明, 蒋业华. 电子束冷床熔炼钛及钛合金的研究进展. 热加工工艺, 2016, 45(9): 9 [17] Yue X, Yang G Q, Li W Q, et al. Effect of melting method on chemical composition and microstructure homogeneity of TC17 titanium alloy ingots and bars. Titanium Ind Prog, 2016, 33(5): 11岳旭, 杨国庆, 李渭清, 等. 熔炼方式对TC17钛合金铸锭化学成分及棒材组织均匀性的影响研究. 钛工业进展, 2016, 33(5): 11 [18] Yu J. On the development and future trend of vacuum induction melting technology. Sci Technol, 2016, 26(33): 100 doi: 10.3969/j.issn.1672-8289.2016.33.085俞杰. 浅谈真空感应熔炼技术的发展及未来动向. 科技展望, 2016, 26(33): 100 doi: 10.3969/j.issn.1672-8289.2016.33.085 [19] Zhang Y H. Research on the Numerical Simulation of Temperature Field in Induction Heating [Dissertation]. Wuxi: Jiangnan University, 2008张月红. 感应加热温度场的数值模拟[学位论文]. 无锡: 江南大学, 2008 [20] Chen Y Y, Xiao S L, Kong F T. Application and investment casting of high temperature titanium alloys and TiAl intermetallics // The 11th National Titanium and Titanium Alloy Academic Exchange Conference. Baoji, 2002: 39陈玉勇, 肖树龙, 孔凡涛. 高温钛合金及TiAl金属间化合物的精密铸造技术及应用前景//第十一届全国钛及钛合金学术交流会议. 宝鸡, 2002: 39 [21] Song Q Z, Dong H, E D M, et al. Development of electromagnetic levitation vacuum melting casting technology. Vacuum, 2019, 56(6): 43宋青竹, 董辉, 鄂东梅, 等. 电磁悬浮真空熔铸技术进展. 真空, 2019, 56(6): 43 [22] Zhou Z M, Wang Y P, Xia H, et al. Research development of manufacture processing of Cu‒Cr alloy. Mater Rep, 2008, 22(3): 44 doi: 10.3321/j.issn:1005-023X.2008.03.011周志明, 王亚平, 夏华, 等. Cu‒Cr合金制备技术的研究进展. 材料导报, 2008, 22(3): 44 doi: 10.3321/j.issn:1005-023X.2008.03.011 [23] Zhao C F, Wu B, Yang S J, et al. Effect of heat treatment on microstructure and hardness of AlCoCrFeNiTi0.5 high entropy alloy. J Guangxi Univ Nat Sci, 2014, 39(2): 407赵春凤, 吴波, 杨上金, 等. 热处理工艺对AlCoCrFeNiTi0.5高熵合金的显微组织和硬度的影响. 广西大学学报:自然科学版, 2014, 39(2): 407 [24] He Y L, Zhang Z Y, Zhang F L, et al. Development and application of key technology and equipment of the vacuum induction levitation furnace // 2018 China Foundry Congress. Suzhou, 2008: 557何永亮, 张志勇, 张福利, 等. 真空感应悬浮炉关键技术及装备的发展与应用//2018中国铸造活动周. 苏州, 2018: 557 [25] Wei M W, Chen S Y, Guo K K, et al. Preparation of TA15 titanium alloy powder by EIGA for laser 3D printing. Mater Rev, 2017, 31(12): 64 doi: 10.11896/j.issn.1005-023X.2017.012.014魏明炜, 陈岁元, 郭快快, 等. EIGA法制备激光3D打印用TA15钛合金粉末. 材料导报, 2017, 31(12): 64 doi: 10.11896/j.issn.1005-023X.2017.012.014 [26] Gao C F, Yu W Y, Zhu Q L, et al. Performance characteristics and research progress of metal powders for 3D printing. Powder Metall Ind, 2017, 27(5): 53高超峰, 余伟泳, 朱权利, 等. 3D打印用金属粉末的性能特征及研究进展. 粉末冶金工业, 2017, 27(5): 53 [27] Yang Q Z, Wei Y P, Gao P, et al. Research progress of metal additive manufacturing technologies and related materials. Mater Rev, 2016, 30(Suppl 1): 107杨全占, 魏彦鹏, 高鹏, 等. 金属增材制造技术及其专用材料研究进展. 材料导报, 2016, 30(增刊1): 107 [28] Zhou H P, Li S K, Li B, et al. Development status of preparation technology of metal powder for 3D printing. China Met Bull, 2016(8): 88邹海平, 李上奎, 李博, 等. 3D打印用金属粉末的制备技术发展现状. 中国金属通报, 2016(8): 88 [29] Le G M, Li Q, Dong X F, et al. Fabrication techniques of spherical-shaped metal powders suitable for additive manufacturing. Rare Met Mater Eng, 2017, 46(4): 1162乐国敏, 李强, 董鲜峰, 等. 适用于金属增材制造的球形粉体制备技术. 稀有金属材料与工程, 2017, 46(4): 1162 [30] He W W, Tang H P, Chen B K, et al. Study on process and particle size prediction on high-Nb TiAl powder produced by PREP. Titanium Ind Prog, 2019, 36(3): 26贺卫卫, 汤慧萍, 陈斌科, 等. PREP法制备高铌TiAl粉末工艺研究及粒度预测. 钛工业进展, 2019, 36(3): 26 [31] Chen Y Y, Xiao Z Y, Li S K, et al. Research progress on the preparation methods of metal powder for 3D printing. Powder Metall Ind, 2018, 28(4): 56陈莹莹, 肖志瑜, 李上奎, 等. 3D打印用金属粉末的制备技术及其研究进展. 粉末冶金工业, 2018, 28(4): 56 [32] Guo W M, Chen S D, Feng D. Study on process on nickel superalloy powder by the plasmarotationelectrode. Aviat Maint Eng, 1999(5): 44国为民, 陈生大, 冯涤. 等离子旋转电极法制取镍基高温合金粉末工世的研究. 航空工程与维修, 1999(5): 44 [33] Huang K, Zhao Y, Zhang C S, et al. Properties characterization of spherical CuAl10Fe3 copper alloy powders prepared by plasma rotating electrode processing. Mater Rep, 2019, 33(22): 3783 doi: 10.11896/cldb.18080057黄柯, 赵阳, 张昌松, 等. PREP法制备球形CuAl10Fe3铜合金粉末的性能表征. 材料导报, 2019, 33(22): 3783 doi: 10.11896/cldb.18080057 [34] Sun N G, Chen B K, Xiang C S, et al. The plasma rotating electrode processing machine for high quality 3D printing powder production. Heavy Mach, 2019(5): 36 doi: 10.3969/j.issn.1001-196X.2019.05.007孙念光, 陈斌科, 向长淑, 等. 3D打印粉末生产用等离子旋转电极雾化制粉机. 重型机械, 2019(5): 36 doi: 10.3969/j.issn.1001-196X.2019.05.007 [35] Zhao X H, Wang C, Pan F F, et al. A review on the methods and additive manufacturing application of spherical titanium alloy powder. Powder Metall Ind, 2019, 29(6): 71赵霄昊, 王晨, 潘霏霏, 等. 球形钛合金粉末制备技术及增材制造应用研究进展. 粉末冶金工业, 2019, 29(6): 71 [36] Lei N Z. Study on Processing and Properties of Spherical Metal Powder Prepared by Plasma Rotating Electrode Process [Dissertation]. Xi’ an: Xi’ an University of Technology, 2019雷囡芝. 等离子旋转电极雾化法制备球形金属粉末的工艺及性能研究[学位论文]. 西安: 西安理工大学, 2019 [37] Liu J X, Yu Q B, Guo Q. Experimental investigation of liquid disintegration by rotary cups. Chem Eng Sci, 2012, 73: 44 doi: 10.1016/j.ces.2012.01.010 [38] Frost A R. Rotary atomization in the ligament formation mode. J Agric Eng Res, 1981, 26(1): 63 doi: 10.1016/0021-8634(81)90127-X [39] Yang T, Yin Z X, Qiu J E, et al. Research on the static and dynamic behavior on the plasma torch used for plasma atomization. Vacuum, 2021, 58(5): 66杨彤, 尹政鑫, 邱吉尔, 等. 等离子体雾化用等离子体发生器动静态特性研究. 真空, 2021, 58(5): 66 [40] Liao X J, Lai Q, Zhang S L. Current situation and development prospect of preparation technologies for spherical titanium and titanium alloy powder. Iron Steel Vanadium Titanium, 2017, 38(5): 1 doi: 10.7513/j.issn.1004-7638.2017.05.001廖先杰, 赖奇, 张树立. 球形钛及钛合金粉制备技术现状及展望. 钢铁钒钛, 2017, 38(5): 1 doi: 10.7513/j.issn.1004-7638.2017.05.001 [41] Liang Y R, Wu Y J. Production technology of titanium and its alloy spherical powders used in 3D printing. World Nonferrous Met, 2016(12): 150梁永仁, 吴引江. 3D打印用钛及钛合金球形粉末制备技术. 世界有色金属, 2016(12): 150 [42] Herzog D, Seyda V, Wycisk E, et al. Additive manufacturing of metals. Acta Mater, 2016, 117: 371 doi: 10.1016/j.actamat.2016.07.019 [43] Chen G, Zhao S Y, Tan P, et al. A comparative study of Ti‒6Al‒4V powders for additive manufacturing by gas atomization, plasma rotating electrode process and plasma atomization. Powder Technol, 2018, 333: 38 doi: 10.1016/j.powtec.2018.04.013 [44] Dai Y, Li L. Current status and development trend of metal-based 3D printing powder materials preparation technology. Adv Mater Ind, 2016(6): 23 doi: 10.3969/j.issn.1008-892X.2016.06.005戴煜, 李礼. 金属基3D打印粉体材料制备技术现状及发展趋势. 新材料产业, 2016(6): 23 doi: 10.3969/j.issn.1008-892X.2016.06.005 [45] Sun S J. Canada PyroGenesis Co., Ltd. has developed a new plasma atomization technology for producing fine metal powder. Powder Metall Ind, 2017, 27(6): 75孙世杰. 加拿大PyroGenesis有限公司开发出新的生产细颗粒金属粉末的等离子雾化技术. 粉末冶金工业, 2017, 27(6): 75 [46] Dai Y, Li L. Technical analysis of preparation of titanium alloy powder for metal 3D printing by plasma torch atomization. Adv Mater Ind, 2018(11): 55戴煜, 李礼. 等离子火炬雾化制备金属3D打印专用钛合金粉体技术分析. 新材料产业, 2018(11): 55 [47] Liu Y, You Q S, Zhu H M, et al. Preparation of new high hardness martensitic iron-based alloy powders by electrode induction gas atomization. Powder Metall Technol, 2021, 39(6): 537刘艳, 尤齐燊, 朱红梅, 等. 电极感应气雾化法制备新型高硬度马氏体铁基合金粉末. 粉末冶金技术, 2021, 39(6): 537 [48] Wang C J, Zhang M X, Chen Q M, et al. Characterization of high strength PH13-8Mosteel powders prepared by vacuum induction melting gas atomization method. Mater Heat Treat, 2020, 41(1): 94王长军, 张梦醒, 陈清明, 等. 真空感应熔炼气雾化法制备高强度PH13-8Mo钢粉末的特性表征. 材料热处理学报, 2020, 41(1): 94 [49] Gao Z J, Zhou X L, Li J H, et al. A review: high-performance spherical metal powder preparation methods. Therm Spray Technol, 2018, 10(3): 1 doi: 10.3969/j.issn.1674-7127.2018.03.001高正江, 周香林, 李景昊, 等. 高性能球形金属粉末制备技术进展. 热喷涂技术, 2018, 10(3): 1 doi: 10.3969/j.issn.1674-7127.2018.03.001 [50] Zhao S Y, Chen G, Tan P, et al. Characterization of spherical TC4 powders by gas atomization and its interstitial elemental control. Chin J Nonferrous Met, 2016, 26(5): 980赵少阳, 陈刚, 谈萍, 等. 球形TC4粉末的气雾化制备、表征及间隙元素控制. 中国有色金属学报, 2016, 26(5): 980 [51] Liu C. Research on Flow and Heat Transfer Mechanism of Liquid Metals in Melt Delivery Nozzle During Gas Atomization Process [Dissertation]. Harbin: Harbin Institute of Technology, 2020刘畅. 气体雾化制粉过程中金属熔体在导流管内的流动与传热机理研究[学位论文]. 哈尔滨: 哈尔滨工业大学, 2020 [52] Tian C, Chen Z, Liu B T, et al. Preparation process optimization of TC4 titanium alloy powder for additive manufacturing. J Heilongjiang Univ Sci Technol, 2020, 30(2): 214 doi: 10.3969/j.issn.2095-7262.2020.02.018田操, 陈卓, 刘邦涛, 等. 增材制造用TC4钛合金粉末制备工艺的优化. 黑龙江科技大学学报, 2020, 30(2): 214 doi: 10.3969/j.issn.2095-7262.2020.02.018 [53] Zhang N, Chen S Y, Yu X, et al. Preparation of TC4 alloy powder for laser 3D printing. J Mater Metall, 2016, 15(4): 277张宁, 陈岁元, 于笑, 等. 激光3D打印TC4球形合金粉末的制备. 材料与冶金学报, 2016, 15(4): 277 [54] He W W, Jia W P, Yang G Y, et al. Research progress in preparation of TiAl pre-alloyed powder. Titanium Ind Prog, 2012, 29(4): 1 doi: 10.3969/j.issn.1009-9964.2012.04.001贺卫卫, 贾文鹏, 杨广宇, 等. TiAl预合金粉末制备的研究进展. 钛工业进展, 2012, 29(4): 1 doi: 10.3969/j.issn.1009-9964.2012.04.001 [55] Lubanska H. Correlation of spray ring data for gas atomization of liquid metals. JOM, 1970, 22: 45 [56] Long Q L, Wu W H, Lu L, et al. Effect of powder on properties of Ti‒6Al‒4V alloy powder prepared by EIGA process. China Powder Sci Technol, 2018, 24(4): 49龙倩蕾, 吴文恒, 卢林, 等. 熔炼功率对EIGA制备Ti‒6Al‒4V合金粉末特性的影响. 中国粉体技术, 2018, 24(4): 49 [57] Zhou K, Wei B. Determination of the thermophysical properties of liquid and solid Ti–6Al–4V alloy. Appl Phys A, 2016, 122: 248 doi: 10.1007/s00339-016-9783-6 [58] Paradis P F, Ishikawa T, Yoda S. Non-contact measurements of surface tension and viscosity of niobium, zirconium, and titanium using an electrostatic levitation furnace. Int J Thermophys, 2002, 23(3): 825 doi: 10.1023/A:1015459222027 [59] Guo K K, Liu C S, Chen S Y, et al. High pressure EIGA preparation and 3D printing capability of Ti‒6Al‒4V powder. Trans Nonferrous Met Soc China, 2020, 30(1): 147 doi: 10.1016/S1003-6326(19)65187-3 [60] Lu H, Li S J, Du H Z, et al. Secondary breakup characteristics and mechanism of single electrified Al/N-Decanenanofluid fuel droplet in electrostatic field. Appl Sci, 2020, 10(15): 5332 doi: 10.3390/app10155332 [61] Soni S K, Kirar P K, Kolhe P, et al. Deformation and breakup of droplets in an oblique continuous air stream. Int J Multiph Flow, 2020, 122: 103141 doi: 10.1016/j.ijmultiphaseflow.2019.103141 [62] Stefanitsis D, Strotos G, Nikolopoulos N, et al. Improved droplet breakup models for spray applications. Int J Heat Fluid Flow, 2019, 76: 274 doi: 10.1016/j.ijheatfluidflow.2019.02.010 [63] Zheng M Y. Gas Atomization Technology Research of Titanium Alloy Powders for Additive Manufacturing [Dissertation]. Beijing: University of Science and Technology Beijing, 2019郑明月. 气雾化法制备增材制造用钛合金粉末研究[学位论文]. 北京: 北京科技大学, 2019 [64] Mao X H, Liu X, Xie H W, et al. Effects of preparation methods on the properties of Ti‒6Al‒4V alloys powders for 3D printing. Mater Res Appl, 2017, 11(1): 13 doi: 10.3969/j.issn.1673-9981.2017.01.004毛新华, 刘辛, 谢焕文, 等. 制备方法对3D打印用Ti‒6Al‒4V合金粉体特性的影响. 材料研究与应用, 2017, 11(1): 13 doi: 10.3969/j.issn.1673-9981.2017.01.004 [65] Ma C Y. Numerical Simulation of Electromagnetic Field in Vacuum Induction Melting [Dissertation]. Shenyang: Northeastern University, 2013马长勇. 真空感应熔炼电磁场的数值模拟[学位论文]. 沈阳: 东北大学, 2013 [66] Ouyang H W, Wang Q, Liu Z M. Numerical study on abrupt change of flow field in close-coupled gas atomization. Mater Sci Eng Powder Metall, 2010, 15(2): 96 doi: 10.3969/j.issn.1673-0224.2010.02.002欧阳鸿武, 王琼, 刘卓民. 紧耦合气雾化流场结构突变过程的数值模拟. 粉末冶金材料科学与工程, 2010, 15(2): 96 doi: 10.3969/j.issn.1673-0224.2010.02.002 [67] Guo K K, Chen J, Liu C S, et al. Numerical simulation of the intersection angle influence on atomization process of powders produced by VIGA. J Northeastern Univ Nat Sci, 2020, 41(5): 729 doi: 10.12068/j.issn.1005-3026.2020.05.020郭快快, 陈进, 刘常升, 等. 数值模拟喷射夹角对VIGA制粉雾化过程的影响. 东北大学学报(自然科学版), 2020, 41(5): 729 doi: 10.12068/j.issn.1005-3026.2020.05.020 [68] Tanaka M, Ushio M, Lowke J J. Numerical study of gas tungsten arc plasma with anode melting. Vacuum, 2004, 73(3-4): 381 doi: 10.1016/j.vacuum.2003.12.058 [69] Wang S H, Cui S P, Zhao D G, et al. Numerical simulation of superheat in atomization of SmFemelt. Nonferrous Met Extr Metall, 2018(1): 59王书桓, 崔少璞, 赵定国, 等. 高温熔体雾化过程中过热度的数值模拟. 有色金属(冶炼部分), 2018(1): 59 [70] Bojarevics V, Roy A, Pericleous K. Numerical model of electrode induction melting for gas atomization. COMPEL, 2011, 30(5): 1455 doi: 10.1108/03321641111152612 [71] Iatcheva I I, Stancheva R, Tahrilov H, et al. Coupled electromagnetic-thermal field investigation in induction heating device. Solid State Phenom, 2009, 152-153: 407 doi: 10.4028/www.scientific.net/SSP.152-153.407 [72] Shan F, Xia M, Ge C C. An EIGA driven coupled of electromagnetic-thermal field modeling in the induction melting process. Int J Mater Form, 2019, 12(4): 615 doi: 10.1007/s12289-018-1438-z [73] Heidloff A, Rieken J, Anderson I, et al. Advancements in Ti alloy powder production by close-coupled gas atomization // Powder Metall. SanFrancisco, 2011: 1 [74] Xia M, Wang P, Zhang X H, et al. Computational fluid dynamic investigation of the primary and secondary atomization of the free-fall atomizer in electrode induction melting gas atomization process. Acta Phys Sin, 2018, 67(17): 41夏敏, 汪鹏, 张晓虎, 等. 电极感应熔化气雾化制粉技术中非限制式喷嘴雾化过程模拟. 物理学报, 2018, 67(17): 41 [75] Wang J J, Hao J J, Guo Z M, et al. Numerical simulation on preparation of spherical powder by RF induction plasma. China Sciencepaper, 2015, 10(22): 2642 doi: 10.3969/j.issn.2095-2783.2015.22.014王建军, 郝俊杰, 郭志猛, 等. 射频等离子体制备球形粉末的数值模拟. 中国科技论文, 2015, 10(22): 2642 doi: 10.3969/j.issn.2095-2783.2015.22.014 [76] Zheng H. Experimentation and Numerical Simulation Study on Spheroidization of Titanium Powder in Inductively Coupled Plasma [Dissertation]. Nanchang: East China Jiaotong University, 2016郑华. 感应耦合热等离子体球化钛粉的数值模拟与试验研究[学位论文]. 南昌: 华东交通大学, 2016 -

下载:

下载: