-

摘要: 闭孔金属基复合泡沫材料是一种新型多孔复合材料,主要以空心微球和基体粉末为原料,将空心微球填充到金属或合金基体中复合而成;因其具有轻质、高强、良好的阻尼、吸能、隔热、隔音及电磁屏蔽等诸多优异性能,在减震、缓冲阻尼及防撞击等相关领域具有广泛的应用价值。本文主要介绍了利用空心微球制备闭孔金属基复合泡沫材料的方法,总结了其制备过程中存在的问题,并概述了闭孔金属基复合泡沫材料的应用。Abstract: Closed-cell metal matrix syntactic foam (MMSF) is a kind of new porous composite materials formed by embedding the hollow microspheres into the metal or alloy matrix, using the hollow microspheres and metal powders as the raw materials. Due to the lightweight, high strength, good damping, energy-absorbing capability, thermal insulation, sound absorption, electromagnetic shielding, and other excellent properties, the closed-cell metal matrix syntactic foams can be widely used in the fields of shock absorption, buffer damping, and impact prevention. The preparation method of the closed-cell metal matrix syntactic foams by hollow microspheres were introduced in this paper, some problems existing in the preparation process were summarized and the application of the closed-cell metal matrix foams were overviewed.

-

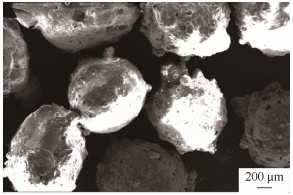

图 3 粉末冶金法制备闭孔金属基复合泡沫材料工艺流程[31]

Figure 3. Typical preparation process of the closed-cell metal matrix syntactic foams by powder metallurgy

-

[1] Yu M, Zhu P, Ma Y Q. Experimental study and numerical prediction of tensile strength properties and failure modes of hollow spheres filled syntactic foams. Comput Mater Sci, 2012, 63: 232 doi: 10.1016/j.commatsci.2012.06.024 [2] Májlinger K. Wear properties of hybrid AlSi12 matrix syntactic foams. Int J Mater Res, 2015, 106(11): 1165 doi: 10.3139/146.111290 [3] Wu G H, Dou Z Y, Sun D L, et al. Compression behaviors of cenosphere-pure aluminum syntactic foams. Scr Mater, 2007, 56(3): 221 doi: 10.1016/j.scriptamat.2006.10.008 [4] Matsunaga T, Kim J K, Hardcastle S, et al. Crystallinity and selected properties of fly ash particles. Mater Sci Eng A, 2002, 325: 333 doi: 10.1016/S0921-5093(01)01466-6 [5] Szlancsik A, Katona B, Kemeny A, et al. On the filler materials of metal matrix syntactic foams. Materials, 2019, 12(12): 2023 doi: 10.3390/ma12122023 [6] Braszczyńska-Malik K N, Kamieniak J. AZ91 magnesium matrix foam composites with fly ash cenospheres fabricated by negative pressure infiltration technique. Mater Charact, 2017, 128: 209 doi: 10.1016/j.matchar.2017.04.005 [7] Huang Z Q, Yu S R, LI M Q. Microstructures and compressive properties of AZ91D/fly-ash cenospheres composites. Trans Nonferrous Met Soc China, 2010, 20: 458 doi: 10.1016/S1003-6326(09)60162-X [8] Rajan T P D, Pillai R M, Pai B C, et al. Fabrication and characterisation of Al–7Si–0.35Mg/fly ash metal matrix composites processed by different stir casting routes. Compos Sci Technol, 2007, 67(15-16): 3369 doi: 10.1016/j.compscitech.2007.03.028 [9] Orbulov I, Májlinger K. On the microstructure of ceramic hollow microspheres. Period Polytech Mech Eng, 2010, 54(2): 89 doi: 10.3311/pp.me.2010-2.05 [10] Santa Maria J A, Schultz B F, Ferguson J B, et al. Effect of hollow sphere size and size distribution on the quasi-static and high strain rate compressive properties of Al–A380–Al2O3 syntactic foams. J Mater Sci, 2014, 49(3): 1267 doi: 10.1007/s10853-013-7810-y [11] Wu R B, Zhou K, Yue C Y, et al. Recent progress in synthesis, properties and potential applications of SiC nanomaterials. Prog Mater Sci, 2015, 72: 1 doi: 10.1016/j.pmatsci.2015.01.003 [12] Shcherban N D. Review on synthesis, structure, physical and chemical properties and functional characteristics of porous silicon carbide. J Ind Eng Chem, 2017, 50: 15 doi: 10.1016/j.jiec.2017.02.002 [13] Shunmugasamy V C, Zeltmann S E, Gupta N, et al. Compressive characterization of single porous SiC hollow particles. JOM, 2014, 66(6): 892 doi: 10.1007/s11837-014-0954-7 [14] Wang X P, Zhang L, Yang J J, et al. Preparation and characterization of SiC hollow spheres. Mater Rev. 2009, 23(14): 22 doi: 10.3321/j.issn:1005-023X.2009.14.007王雪平, 张磊, 杨久俊, 等. SiC空心球的制备与表征. 材料导报, 2009, 23(14): 22 doi: 10.3321/j.issn:1005-023X.2009.14.007 [15] Luong D D, Strbik Ⅲ O M, Hammond V H, et al. Development of high performance lightweight aluminum alloy/SiC hollow sphere syntactic foams and compressive characterization at quasi-static and high strain rates. J Alloys Compd, 2013, 550: 412 doi: 10.1016/j.jallcom.2012.10.171 [16] Lin Y F, Zhang Q, Ma X Y, et al. Mechanical behavior of pure Al and Al–Mg syntactic foam composites containing glass cenospheres. Composites Part A, 2016, 87: 194 doi: 10.1016/j.compositesa.2016.05.001 [17] Taherishargh M, Belova I V, Murch G E, et al. Pumice/aluminium syntactic foam. Mate Sci Eng A, 2015, 635: 102 doi: 10.1016/j.msea.2015.03.061 [18] Chen J M, Cui X M, Luo X, et al. The structure and property of Al matrix syntactic foam fabricated with ceramic microspheres prepared by vacuum casting method. Hunan Nonferrous Met, 2012, 28(3): 46 https://www.cnki.com.cn/Article/CJFDTOTAL-HNYJ201203015.htm陈健美, 崔学敏, 罗翔, 等. 真空吸铸法制备铝基空心陶瓷球泡沫材料的结构和性能. 湖南有色金属, 2012, 28(3): 46 https://www.cnki.com.cn/Article/CJFDTOTAL-HNYJ201203015.htm [19] Zhang L P, Zhao Y Y. Mechanical response of Al matrix syntactic foams produced by pressure infiltration casting. J Compos Mater, 2016, 41(17): 2105 http://adsabs.harvard.edu/abs/2007JCoMa..41.2105Z [20] Orbulov I N. Metal matrix syntactic foams produced by pressure infiltration — The effect of infiltration parameters. Mater Sci Eng A, 2013, 583: 11 doi: 10.1016/j.msea.2013.06.066 [21] Vogiatzis C A, Skolianos S M. On the sintering mechanisms and microstructure of aluminium–ceramic cenospheres syntactic foams produced by powder metallurgy route. Composites Part A, 2016, 82: 8 doi: 10.1016/j.compositesa.2015.11.037 [22] Kamieniak J, Braszczyńska-Malik K N. Problems fabricating cast magnesium matrix composites with aluminosilicate cenospheres. Compos Theory Pract, 2014, 14: 214 http://yadda.icm.edu.pl/yadda/element/bwmeta1.element.baztech-ac08e878-e1ff-48e2-94c3-1ce26e3a09c0 [23] Mondal D P, Das S, Ramakrishnan N, et al. Cenosphere filled aluminum syntactic foam made through stir-casting technique. Composites Part A, 2009, 40(3): 279 doi: 10.1016/j.compositesa.2008.12.006 [24] Rabiei A, O'Neill A T. A study on processing of a composite metal foam via casting. Mater Sci Eng A, 2005, 404(1-2): 159 doi: 10.1016/j.msea.2005.05.089 [25] Jia C C, Guo H. Composites Course. Beijing: Higher Education Press, 2010贾成厂, 郭宏. 复合材料教程. 北京: 高等教育出版社, 2010 [26] Wei L, Yao G C, Zhang X M, et al. Preparation of foam aluminium by powder metallurgy process. J Northeastern Univ Nat Sci, 2003, 24(11): 53 https://www.cnki.com.cn/Article/CJFDTOTAL-DBDX200311014.htm魏莉, 姚广春, 张晓明, 等. 粉末冶金法制备泡沫铝材料. 东北大学学报(自然科学版), 2003, 24(11): 53 https://www.cnki.com.cn/Article/CJFDTOTAL-DBDX200311014.htm [27] Neville B P, Rabiei A. Composite metal foams processed through powder metallurgy. Mater Des, 2008, 29(2): 388 doi: 10.1016/j.matdes.2007.01.026 [28] Cho Y J, Lee T S, Lee W, et al. Preparation and characterization of iron matrix syntactic foams with glass microspheres via powder metallurgy. Met Mater Int, 2019, 25(3): 794 doi: 10.1007/s12540-018-00215-w [29] Akinwekomi A D, Adebisi J A, Adediran A A. Compressive characteristics of aluminum-fly ash syntactic foams processed by microwave sintering. Metall Mater Trans A, 2019, 50(9): 4257 doi: 10.1007/s11661-019-05347-1 [30] Wang Q P, Min F F, Wu Y C, et al. Microstructures and friction and wear properties of fly ash/Al–Mg alloy composites. Chin J Nonferrous Met, 2012, 22(4): 1039 https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ201204009.htm王庆平, 闵凡飞. 吴玉程, 等. 粉煤灰/铝–镁合金复合材料的微观组织及摩擦磨损性能. 中国有色金属学报, 2012, 22(4): 1039 https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ201204009.htm [31] Lehmhus D, Weise J, Baumeister J, et al. Quasi-static and dynamic mechanical performance of glass microsphere- and cenosphere-based 316L syntactic foams. Proc Mater Sci, 2014, 4: 383 doi: 10.1016/j.mspro.2014.07.578 [32] Sudarshan, Surappa M K. Synthesis of fly ash particle reinforced A356 Al composites and their characterization. Mater Sci Eng A, 2007, 480(1-2): 117 http://www.sciencedirect.com/science/article/pii/S0921509307013858 [33] Manakari V, Parande G, Doddamani M, et al. Evaluation of wear resistance of magnesium/glass microballoon syntactic foams for engineering/biomedical applications. Ceram Int, 2019, 45(7): 9302 doi: 10.1016/j.ceramint.2019.01.207 [34] Banhart J. Aluminium foams for lighter vehicles. Int J Veh Des, 2005, 37(2-3): 114 http://www.ingentaconnect.com/content/ind/ijvd/2005/00000037/F0020002/art00001 -

下载:

下载: