Microstructure and mechanical properties of TiC particle enhanced high chromium iron

-

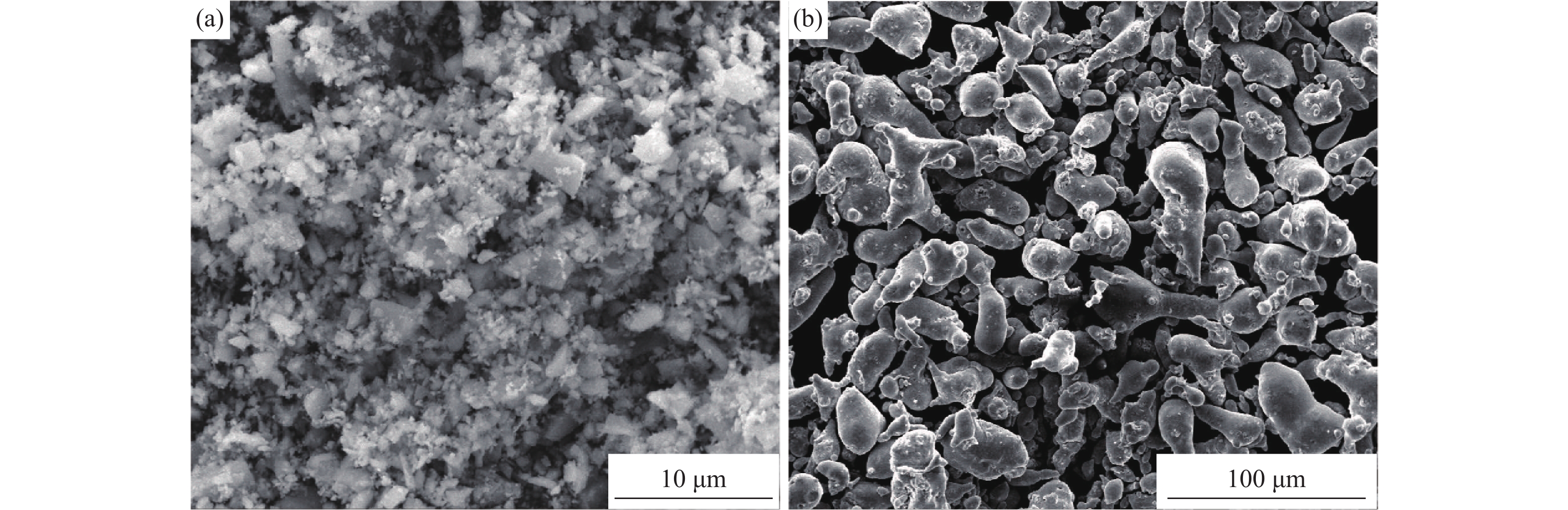

摘要: 采用粉末冶金法(powder metallurgy,PM)和超固相线液相烧结技术(super solid phase line liquid phase sintering,SLPS)制备出TiC颗粒增强(TiCP)+含质量分数20%Cr的烧结高铬铸铁(high chromium cast iron,HCCI)复合材料。利用光学显微镜、扫描电子显微镜(scanning electron microscope,SEM)和X射线衍射仪(X-ray diffraction,XRD)研究了TiC颗粒增强相含量(质量分数)对TiCP/HCCI复合材料物相组成、显微组织和力学性能的影响,并开展了后续热处理研究。结果表明:超固相线液相烧结技术制备出的TiCP/HCCI复合材料相对密度均达97%以上,其物相组成为马氏体、奥氏体、M7C3碳化物和TiC。TiC颗粒主要沿着高铬铸铁中金属基体/碳化物界面分布,随着TiC含量增加,复合材料的硬度显著增加,达到HRC 67.2,但冲击韧性却逐步降低,合金断裂机制也由准解理性断裂向沿晶完全解理性断裂转变。经淬火处理后,该类TiCP/HCCI复合材料的硬度可进一步提升至HRC 69.3,有望成为硬度介于高铬铸铁和硬质合金之间的优秀耐磨材料。Abstract: TiC particle (TiCP) reinforced-sintered high chromium cast iron (HCCI) composites containing 20% Cr by mass were prepared by powder metallurgy (PM) and super solid phase line liquid phase sintering (SLPS). The effect of TiC particle content (mass fraction) on the phase composition, microstructure, and mechanical properties of the TiCP/HCCI composites was systematically studied by means of optical microscope, scanning electron microscope (SEM), and X-ray diffraction (XRD). The subsequent heat treatment research was also carried out. The results show that, the relative density of the TiCP/HCCI composites prepared by SLPS is above 97%, and the phase composition is composed of martensite, austenite, M7C3 carbide, and TiC. The TiC particles mainly distribute along the interface between the metal matrix and carbide in HCCI. With the increase of TiC content, the hardness of the composites increases to HRC 67.2, while the impact toughness decreases gradually. The fracture mechanism of the composites changes from the quasi cleavage fracture to the inter-granular cleavage fracture. After the quenched treatment, the hardness of the TiCP/HCCI composites can be further increased to HRC 69.3, which are expected to be the excellent wear-resistant materials with the hardness between HCCI and cemented carbide.

-

Key words:

- TiC particles /

- high chromium cast iron /

- powder metallurgy /

- microstructure /

- mechanical properties /

- composites

-

表 1 烧结高铬铸铁主要化学成分(质量分数)

Table 1. Chemical composition of the sintered high chromium cast iron

% C Cr Mo Si Ni Fe 2.50 19.28 1.58 0.68 0.96 余量 表 2 TiC增强颗粒粉末特性参数

Table 2. Characteristic parameters of the TiC reinforced powders

成分 特性参数 TiC粉 疏松海绵状,氧含量(质量分数)0.13%,游离

碳含量(质量分数)<0.26%,D50=430 nm表 3 淬火前后TiC颗粒强化烧结高铬铸铁硬度和力学性能

Table 3. Hardness and mechanical properties of the TiC particles enhanced sintered HCCI before and after the quenched treatment

TiC质量分数/

%处理状态 硬度,

HRC冲击韧性/

(J·cm−2)抗弯强度/

MPa0 烧结态 56.7 9.6 2017.8 淬火态 60.2 5.6 1577.1 5 烧结态 61.4 2.8 1334.2 淬火态 65.2 1.6 1149.8 10 烧结态 63.3 2.2 1077.5 淬火态 67.0 1.4 1095.0 15 烧结态 64.0 1.8 1053.2 淬火态 66.6 1.4 1089.7 20 烧结态 67.2 1.5 1049.0 淬火态 69.3 1.4 1028.8 -

[1] Armstrong R W. The hardness and strength properties of WC−Co composite. Materials, 2011, 4(7): 1287 doi: 10.3390/ma4071287 [2] Bose A. A perspective on the earliest commercial PM metal-ceramic composite. Int J Powder Metall, 2011, 47(2): 31 [3] Kambakas K, Tsakiropoulos P. Solidification of high-Cr white cast iron WC particle reinforce steel matrix composites. Mater Sci Eng A, 2005, 413-414: 538 doi: 10.1016/j.msea.2005.08.215 [4] Li Y F, Gao Y M, Wang B H, et al. Fabrication and interface property of WC−TiC−Co/Cr20 composites. Rare Metal Mat Eng, 2010, 39(4): 715李烨飞, 高义民, 王必辉, 等. WC− TiC− Co/Cr20复合材料的制备与界面特性. 稀有金属材料与工程, 2010, 39(4): 715 [5] Gu J H, Xiao P A, Song J Y, et al. Sintering of a hypoeutectic high chromium cast iron as well as its microstructure and properties. J Alloys Compd, 2018, 740: 485 doi: 10.1016/j.jallcom.2017.11.189 [6] Li Z T, Xiao P A, Gu J H, et al. Study on microstructure and mechanical properties of Cr15 sintered high chromium cast iron. Mater Sci Technol, 2020, 28(1): 7 doi: 10.11951/j.issn.1005-0299.20180208李忠涛, 肖平安, 顾景洪, 等. 烧结Cr15高铬铸铁组织与性能的研究. 材料科学与工艺, 2020, 28(1): 7 doi: 10.11951/j.issn.1005-0299.20180208 [7] Lu R Q, Xiao P A, Song J Y, et al. Impact abrasive wear resistance of a new type of sintered high chromium cast iron. Mater Sci Eng Powder Metall, 2018, 23(1): 70 doi: 10.3969/j.issn.1673-0224.2018.01.010卢瑞青, 肖平安, 宋建勇, 等. 新型烧结高铬铸铁的冲击磨粒磨损性能. 粉末冶金材料科学与工程, 2018, 23(1): 70 doi: 10.3969/j.issn.1673-0224.2018.01.010 [8] Wang Y S, Zhang X Y, Li F C, et al. Study on an Fe−TiC surface composite produced in situ. Mater Des, 1999, 20(5): 233 doi: 10.1016/S0261-3069(98)00049-1 [9] Jiang J P, Li S B, Li H L, et al. Effect of in situ formed TiCx grains on the microstructural modification of high chromium white iron. J Alloys Compd, 2017, 726: 430 doi: 10.1016/j.jallcom.2017.07.274 [10] Jiang J P, Li S B, Hu S L, et al. Effects of in situ formed TiCx on the microstructure, mechanical properties and abrasive wear behavior of a high chromium white iron. Mater Chem Phys, 2018, 214: 80 doi: 10.1016/j.matchemphys.2018.04.041 [11] Ma S Q, Xing J D, He Y L, et al. Microstructure and crystallography of M7C3 carbide in chromium cast iron. Mater Chem Phys, 2015, 161: 65 doi: 10.1016/j.matchemphys.2015.05.008 [12] Karantzalis A E, Lekatou A, Mavros H. Microstructural modifications of as-cast high-chromium white iron by heat treatment. J Mater Eng Perform, 2009, 18(2): 174 doi: 10.1007/s11665-008-9285-6 [13] Wang J, Li C, Liu H H, et al. The precipitation and transformation of secondary carbides in a high chromium cast iron. Mater Charact, 2006, 56(1): 73 doi: 10.1016/j.matchar.2005.10.002 [14] Liu H H, Wang J, Yang H S, et al. Effect of cryogenic treatment on property of 14Cr2Mo2V high chromium cast iron subjected to subcritical treatment. J Iron Steel Res, 2006, 13(6): 43 doi: 10.1016/S1006-706X(06)60108-8 [15] Carpenter S D, Carpenter D, Pearce J T H. XRD and electron microscope study of a heat treated 26.6% chromium white iron microstructure. Mater Chem Phys, 2007, 101(1): 49 doi: 10.1016/j.matchemphys.2006.02.013 -

下载:

下载: