Analysis of microstructure and friction property on 316L steels coated with Fe-based powders by high velocity oxy-fuel

-

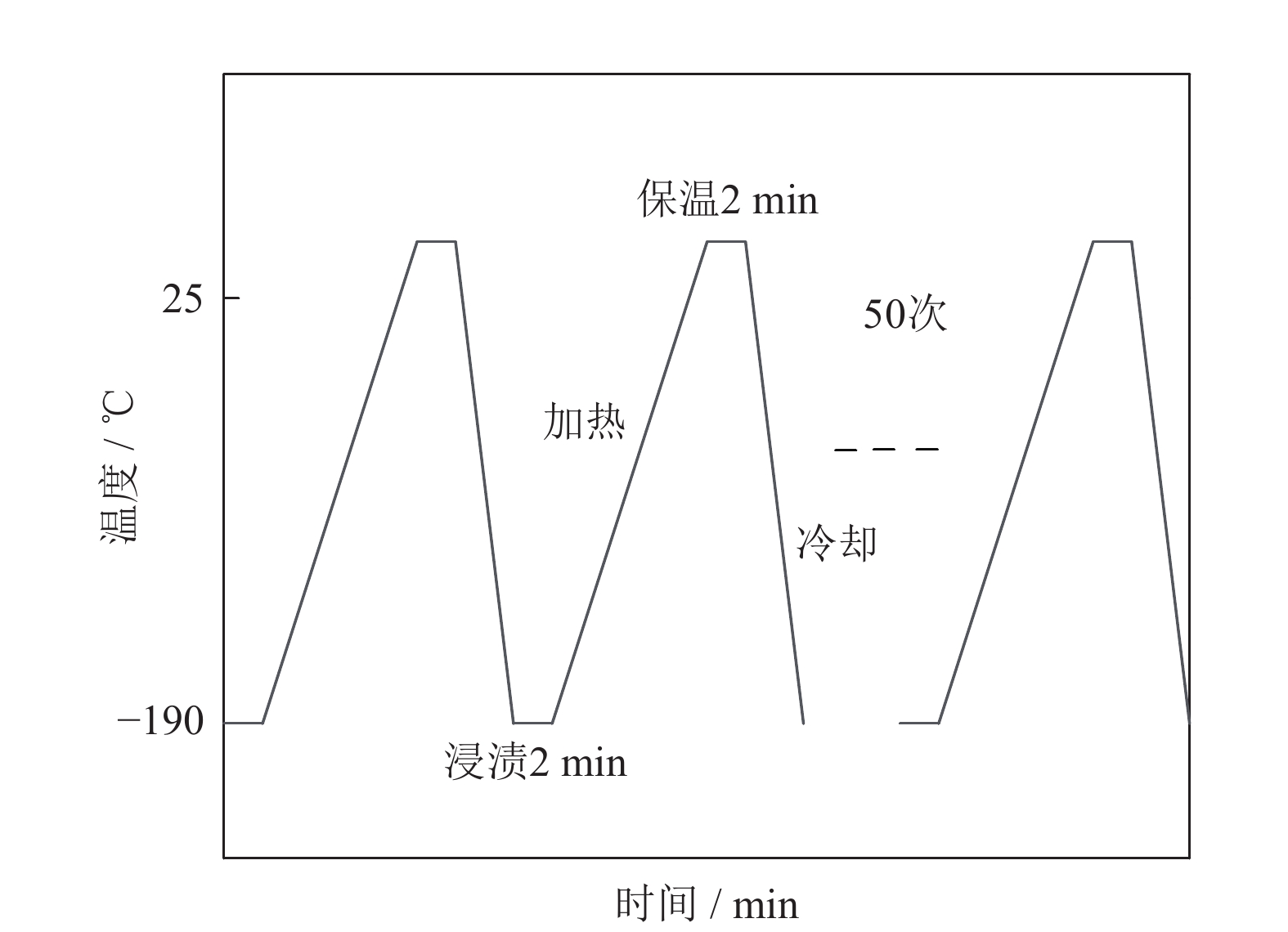

摘要: 经过液氮循环工艺获得了塑韧性更优的Fe基粉末,通过超音速火焰喷涂(high velocity oxy-fuel,HVOF)法对建筑用316L钢基体表面造成高速撞击生成Fe基粉末涂层,分析涂层摩擦学特性与液氮循环工艺间的关系。研究结果表明:液氮循环处理粉末和未处理原始粉末都属于非晶态,粉末外观形貌都属于椭球形,没有开裂或破碎。在液氮循环处理粉末涂层组织中只存在少量的未铺展颗粒,孔隙率也发生了明显减小,形成了更致密组织。采用液氮循环方法来改善粉末塑性,使粉末以更好的铺展状态完成沉积过程。经过液氮循环处理的粉末涂层可以获得更稳定的摩擦学性能,形成了更致密的组织,孔隙与裂纹数量明显降低,摩擦系数明显减小,主要发生氧化磨损,表现出更低的磨痕深度与磨损率误差。Abstract: The Fe-based powders with the better plasticity and toughness were obtained by liquid nitrogen cycling, the Fe-based powder coatings were generated by high-speed impact on the substrate surface of 316L steels used for building using the high velocity oxy-fuel method, and the relationship between the coating tribological characteristics and the liquid nitrogen cycling was analyzed. The results show that, both the powders treated by liquid nitrogen cycling and the untreated original powders are amorphous, and the appearance morphology of the powders belongs to ellipsoid without the causing cracking or crushing. After the liquid nitrogen cycle treatment, only a small number of the undispersed particles exist in the powder coating tissues, and the porosity also decreases significantly, forming a denser tissue. The liquid nitrogen cycle method can be used to improve the plasticity of powders, and the powders can be deposited in a better spreading state. The powder coatings after the liquid nitrogen cycle treatment can obtain the more stable tribological properties and show the denser structure, the number of pores and cracks reduces significantly, the friction coefficient decreases obviously, the oxidation wear mainly occurs, and the wear depth and the wear rate error are lower.

-

Key words:

- Fe-based coatings /

- liquid nitrogen cycle /

- high velocity oxy-fuel /

- microstructure /

- friction

-

图 4 液氮循环处理前后Fe基粉末超音速火焰喷涂制备涂层的表面和截面显微形貌:(a)液氮循环处理前涂层表面;(b)液氮循环处理前涂层截面;(c)液氮循环处理后涂层表面;(d)液氮循环处理后涂层截面

Figure 4. SEM images of the Fe-based powder coating surface and cross section prepared by HVOF before and after the liquid nitrogen cycling treatment: (a) coating surface before the liquid nitrogen cycling treatment; (b) coating cross section before the liquid nitrogen cycling treatment; (c) coating surface after the liquid nitrogen cycling treatment; (d) coating cross section after the liquid nitrogen cycling treatment

图 7 液氮循环处理前后Fe基粉末超音速火焰喷涂制备涂层的磨痕及对应的磨屑显微形貌:(a)液氮循环处理前磨痕;(b)液氮循环处理前磨屑;(c)液氮循环处理后磨痕;(d)液氮循环处理后磨屑

Figure 7. Wear marks and the corresponding abrasive debris of the Fe-based powder coatings prepared by HVOF before and after the liquid nitrogen cycling treatment: (a) wear marks before the liquid nitrogen cycling treatment; (b) abrasive debris before the liquid nitrogen cycling treatment; (c) wear marks after the liquid nitrogen cycling treatment; (d) abrasive debris after the liquid nitrogen cycling treatment

表 1 超音速火焰喷涂工艺参数

Table 1. Technological parameters of the high velocity oxy-fuel

O2气流量 / (m3·h‒1) Ac气流量 / (m3·h‒1) N2气流量 / (m3·h‒1) 喷涂频率 / Hz 喷涂距离 / mm 0.50 0.23 0.05 3.9 140 表 2 液氮循环处理前后Fe基粉末超音速火焰喷涂制备涂层的磨损参数

Table 2. Wear parameters of the Fe-based powder coatings prepared by HVOF before and after the liquid nitrogen cycling treatment

液氮循环 摩擦系数 磨损率 / (10‒6mm3·N‒1m‒1) 宽度 / mm 深度 / μm 处理前 0.656 6.85 4.83 5.16 处理后 0.583 6.32 4.12 4.63 -

[1] Huang Y, Ding Z X, Yu Z K, et al. Research on slurry erosion resistance of micro-nano WC‒10Co4Cr coatings in NaCl solution. Therm Spray Technol, 2019, 11(4): 16 doi: 10.3969/j.issn.1674-7127.2019.04.003黄炎, 丁彰雄, 喻仲昆, 等. 微纳米WC‒10Co4Cr涂层在NaCl介质中的抗泥沙冲蚀性能研究. 热喷涂技术, 2019, 11(4): 16 doi: 10.3969/j.issn.1674-7127.2019.04.003 [2] Henao J, Concustell A, Dosta S, et al. Influence of the substrate on the formation of metallic glass coatings by cold gas spraying. J Therm Spray Technol, 2016, 25(5): 992 doi: 10.1007/s11666-016-0419-3 [3] Yang E J, Li Y, Li W, et al. Effects of fuel type and spraying parameters on microstructure and mechanical properties of HVOF sprayed WC‒10Co4Cr coatings. China Surf Eng, 2019, 32(5): 136 doi: 10.11933/j.issn.1007-9289.20190405001杨二娟, 李勇, 李巍, 等. 燃料类型及喷涂参数对HVOF喷涂WC‒10Co4Cr涂层的组织及力学性能的影响. 中国表面工程, 2019, 32(5): 136 doi: 10.11933/j.issn.1007-9289.20190405001 [4] Ketov S V, Sun Y H, Nachum S, et al. Rejuvenation of metallic glasses by non-affine thermal strain. Nature, 2015, 524(7564): 200 doi: 10.1038/nature14674 [5] Liao Z, Hua N, Chen W, et al. Correlations between the wear resistance and properties of bulk metallic glasses. Intermetallics, 2018, 93: 290 doi: 10.1016/j.intermet.2017.10.008 [6] Hu S S, Wang W B, Wang K, et al. Comparison of structure and properties between supersonic flame spraying WC‒17CO coating and electroplating hard Cr layer. China Sci Technol Inf, 2019(19): 76胡生双, 王文博, 王柯, 等. 超音速火焰喷涂WC‒17Co涂层与电镀硬Cr层结构及性能对比. 中国科技信息, 2019(19): 76 [7] Cao Y, Zhang P L, Niu X M, et al. Research on thermal barrier and thermal shock resistance of NiCr‒mullite composite ceramic coating. Powder Metall Technol, 2021, 39(2): 135曹洋, 张鹏林, 牛显明, 等. 镍铬‒莫来石复合陶瓷涂层热障及热震性能的研究. 粉末冶金技术, 2021, 39(2): 135 [8] Wang Y M, Min X B, Xiong X, et al. Study on the high-quality molybdenum target fabricated by low pressure plasma spraying. Powder Metall Technol, 2017, 35(4): 284王跃明, 闵小兵, 熊翔, 等. 高品质钼靶材低压等离子喷涂成形技术研究. 粉末冶金技术, 2017, 35(4): 284 [9] Koga G Y, Schulz R, Savoie S, et al. Microstructure and wear behavior of Fe-based amorphous HVOF coatings produced from commercial precursors. Surf Coat Technol, 2017, 309: 938 doi: 10.1016/j.surfcoat.2016.10.057 [10] Liu M T, Zhong X C, Liu Z W, et al. Structure and properties of MoSi2‒CoNiCrAlY Nano-composite coating by plasma spraying. J Mater Eng, 2014(5): 17 doi: 10.11868/j.issn.1001-4381.2014.05.004刘名涛, 钟喜春, 刘仲武, 等. 等离子喷涂制备MoSi2‒CoNiCrAlY纳米复合涂层的结构与性能. 材料工程, 2014(5): 17 doi: 10.11868/j.issn.1001-4381.2014.05.004 [11] Chu Z H, Wei F S, Zheng X W, et al. Microstructure and properties of TiN/Fe-based amorphous composite coatings fabricated by reactive plasma spraying. J Alloys Compd, 2019, 785: 206 doi: 10.1016/j.jallcom.2019.01.171 [12] Liu Q N, Liu Y, Li F, et al. Effect of heat treatment on micro-structure and wear behaviors of iron-base amorphous alloy coatings. Mater Sci Eng Powder Metall, 2012, 17(5): 586 doi: 10.3969/j.issn.1673-0224.2012.05.007刘倩楠, 刘咏, 李飞, 等. 热处理对Fe基粉末涂层的相组成及摩擦磨损行为的影响. 粉末冶金材料科学与工程, 2012, 17(5): 586 doi: 10.3969/j.issn.1673-0224.2012.05.007 [13] Jang B T, Kim S S, Yi S. Wear behaviors of a Fe-based amorphous alloy in ambient atmosphere and in distilled water. Met Mater Int, 2014, 20(1): 55 doi: 10.1007/s12540-014-1034-9 [14] Gao H, Wei X S, Liang D D, et al. Friction and wear properties of HVAF sprayed Fe-based amorphous alloy coatings. Surf Technol, 2008, 47(2): 55高涵, 魏先顺, 梁丹丹, 等. 超音速火焰喷涂Fe基非晶合金涂层材料的摩擦磨损性能研究. 表面技术, 2008, 47(2): 55 [15] Han J J, Gao Z, Lu Y, et al. Structure and corrosion resistant of Fe base amorphous coating by HVOF. Hot Working Technol, 2015, 44(14): 187韩建军, 高振, 鲁元, 等. 超音速火焰喷涂制备Fe基非晶涂层的组织结构及耐蚀性. 热加工工艺, 2015, 44(14): 187 -

下载:

下载: