Metal additive manufacturing technology for emergency maintenance of field equipment

-

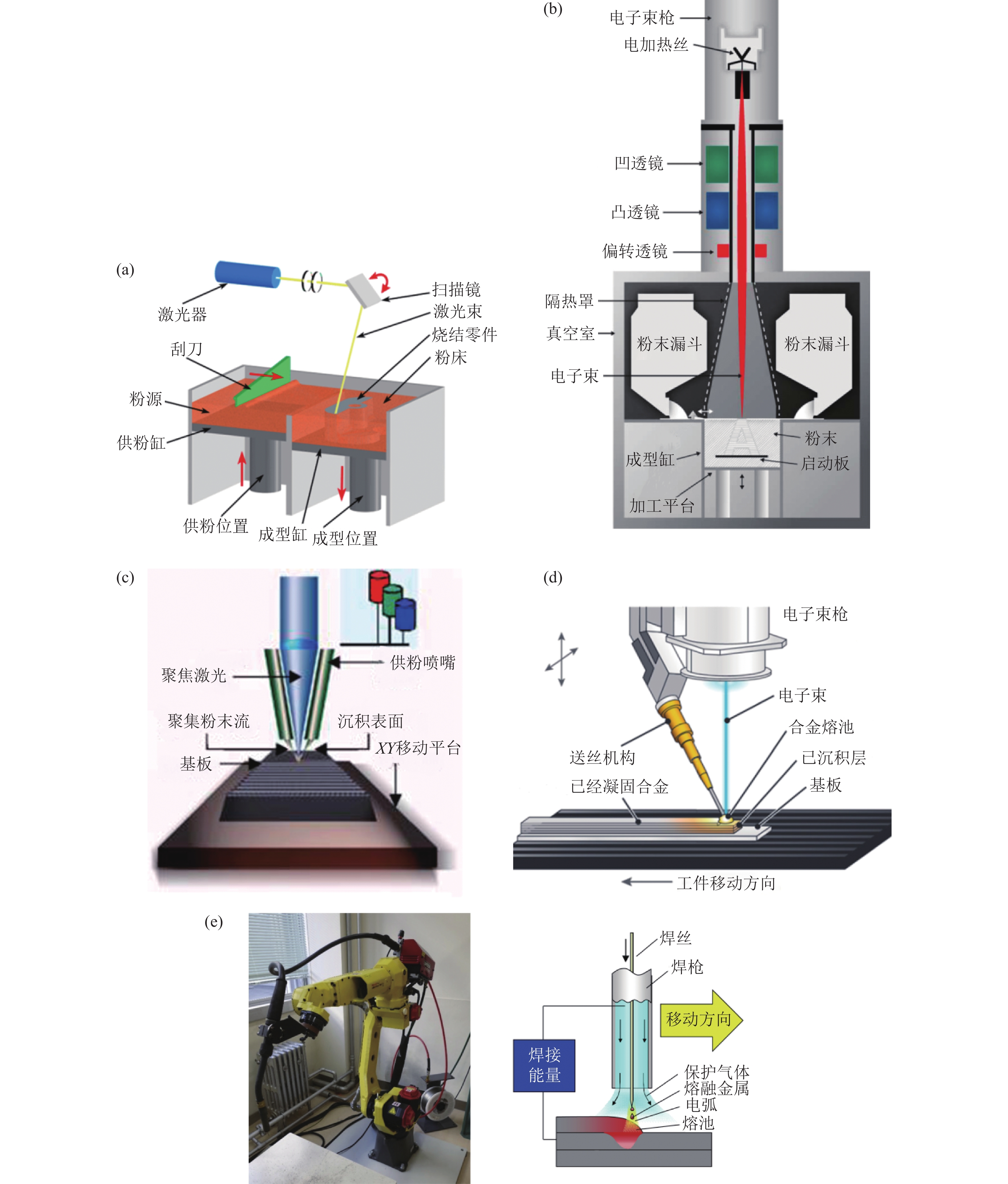

摘要: 金属增材制造技术具有利用率高、柔性高及快速性等特点,如果将其用于野外装备应急维修,将能有效克服传统装备应急维修方法的缺陷,提升野外装备的应急保障能力。本文对常见金属增材制造技术的成形效率、成形精度、力学性能进行对比,结合金属增材制造技术在国内外装备维修领域的应用现状以及野外装备应急维修的特点,从成形质量、成形能力、设备机动性以及抗干扰能力等几个方面展开分析,得出激光熔覆沉积以及电弧熔丝技术更适用于野外装备应急维修。最后就激光熔覆沉积以及电弧熔丝技术应用于野外装备应急维修亟待解决的问题以及今后发展趋势展开讨论。Abstract: Metal additive manufacturing technology can be used for the emergency maintenance of field equipment and shows the characteristics of high-usage, high flexibility, and rapidity, which may effectively overcome the defects of the traditional equipment emergency maintenance and improve the emergency support capability of field equipment. The forming efficiency, forming accuracy, and mechanical property of the common metal additive manufacturing technology were compared in this paper. Combined with the application status at home and aboard of the metal additive manufacturing technology in the field of equipment maintenance and the characteristics of the emergency maintenance of field equipment, the forming quality, forming ability, equipment mobility, and anti-jamming ability were analyzed. The conclusion was shown that the laser cladding deposition (LCD) and wire and arc additive manufacturing (WAAM) were more suitable for the emergency maintenance of field equipment. Finally, the existing problems and the future trends of LCD and WAAM used for the mergency maintenance of field equipment were discussed.

-

表 1 金属增材制造技术成形效率对比

Table 1. Comparison of the forming efficiency for the metal additive manufacturing techniques

表 2 金属增材制造技术成形精度对比

Table 2. Comparison of the forming precision for the metal additive manufacturing techniques

表 3 金属增材制造技术适用性分析

Table 3. Suitability analysis of metal additive manufacturing technology

工艺 成形质量 成形效率 成形能力 设备机动性 抗干扰能力 尺寸精度 粗糙度 力学性能 选择性激光熔化 A A A D C D D 激光熔覆沉积 C D B B A B B 电子束成形 B B B C C D D 电子束熔丝 D C C A B C A 电弧熔丝 D C C A A A A 注:“A”表示优异,“B”表示良好,“C”表示中等,“D”表示较差 -

[1] Shi A P, Zheng Z D, Chang Y J. Discussion on emergency maintenance of wartime equipment // Proceedings of the 12th National Mechanical Maintenance Conference. Huangshan, 2011: 124石安平, 郑振铎, 常永杰. 战时装备应急维修探讨//第十二次全国机械维修学术会议论文集. 黄山, 2011: 124 [2] Cao W B, Jia X S, Hu Q W, et al. Equipment battlefield damage assessment and repair decision-making modeling based on selective maintenance. Syst Eng Electron, 2018, 40(1): 98 doi: 10.3969/j.issn.1001-506X.2018.01.15曹文斌, 贾希胜, 胡起伟, 等. 基于选择性维修的装备战场抢修决策建模. 系统工程与电子技术, 2018, 40(1): 98 doi: 10.3969/j.issn.1001-506X.2018.01.15 [3] Zhao J F, Ma Z Y, Xie D Q, et al. Metal additive manufacturing technique. J Nanjing Univ Aeronaut Astronaut, 2014, 46(5): 675 doi: 10.3969/j.issn.1005-2615.2014.05.003赵剑峰, 马智勇, 谢德巧, 等. 金属增材制造技术. 南京航空航天大学学报, 2014, 46(5): 675 doi: 10.3969/j.issn.1005-2615.2014.05.003 [4] Zhu X C, Wei Q S, Sun C H. Study on microstructures and properties of S136 die steel formed by selective laser melting after heat treatment. Powder Metall Technol, 2019, 37(2): 83朱学超, 魏青松, 孙春华. 激光选区熔化成形S136模具钢热处理组织和性能研究. 粉末冶金技术, 2019, 37(2): 83 [5] Sun X, Yang H C, Shao W S, et al. Study on integrated fabrication of cathode-heater assembly by 3D printing. Powder Metall Technol, 2020, 38(4): 300孙信, 杨怀超, 邵文生, 等. 3D打印一体化制备阴极热子组件研究. 粉末冶金技术, 2020, 38(4): 300 [6] Wolf T, Fu Z W, Körner C. Selective electron beam melting of an aluminum bronze: Microstructure and mechanical properties. Mater Lett, 2019, 238: 241 doi: 10.1016/j.matlet.2018.12.015 [7] Liu Z C, Cong W L, Kim H, et al. Feasibility exploration of superalloys for AISI 4140 steel repairing using laser engineered net shaping. Procedia Manuf, 2017, 10: 912 doi: 10.1016/j.promfg.2017.07.080 [8] Guo Y Y, Pan H H, Ren L B, et al. Microstructure and mechanical properties of wire arc additively manufactured AZ80M magnesium alloy. Mater Lett, 2019, 247: 4 doi: 10.1016/j.matlet.2019.03.063 [9] Shu X, Chen G Q, Liu J P, et al. Microstructure evolution of copper/steel gradient deposition prepared using electron beam freeform fabrication. Mater Lett, 2018, 213: 374 doi: 10.1016/j.matlet.2017.11.016 [10] Yang W X, Yang Y Q, Liu Y, et al. Study on dimensional accuracy of typical geometric features manufactured by selective laser melting. Chin J Lasers, 2015, 42(3): 70杨文雄, 杨永强, 刘洋, 等. 激光选区熔化成型典型几何特征尺寸精度研究. 中国激光, 2015, 42(3): 70 [11] Wang H J, Cui Z W, Sun F, et al. Superalloy GH4169 complicated components prepared by selective laser melting forming technique. Powder Metall Technol, 2016, 34(5): 368 doi: 10.3969/j.issn.1001-3784.2016.05.009王会杰, 崔照雯, 孙峰, 等. 激光选区熔化成形技术制备高温合金GH4169复杂构件. 粉末冶金技术, 2016, 34(5): 368 doi: 10.3969/j.issn.1001-3784.2016.05.009 [12] Rodrigues T A, Duarte V, Avila J A, et al. Wire and arc additive manufacturing of HSLA steel: Effect of thermal cycles on microstructure and mechanical properties. Addit Manuf, 2019(27): 440 [13] Yang Q, Lu Z L, Huang F X, et al. Research on status and development trend of laser additive manufacturing. Aeronaut Manuf Technol, 2016(12): 26杨强, 鲁中良, 黄福享, 等. 激光增材制造技术的研究现状及发展趋势. 航空制造技术, 2016(12): 26 [14] Wang Q W, Zhu S, Chen C L, et al. Research progress of additive remanufacturing technology based on energy beam and energy field. China Surf Eng, 2018, 31(6): 1 doi: 10.11933/j.issn.1007-9289.20181017001王启伟, 朱胜, 陈春良, 等. 能束能场增材再制造技术的研究进展. 中国表面工程, 2018, 31(6): 1 doi: 10.11933/j.issn.1007-9289.20181017001 [15] Verhoef L A, Budde B W, Chockalingam C, et al. The effect of additive manufacturing on global energy demand: An assessment using a bottom-up approach. Energy Policy, 2018, 112: 349 doi: 10.1016/j.enpol.2017.10.034 [16] Yang X Y, Li Y, Zhao P K, et al. Research status and challenges of arc additive manufacturing technology in material preparation. Weld Join, 2018(8): 14杨笑宇, 李言, 赵鹏康, 等. 电弧增材制造技术在材料制备中的研究现状及挑战. 焊接, 2018(8): 14 [17] Ahmed N. Direct metal fabrication in rapid prototyping: A review. J Manuf Process, 2019, 42: 167 doi: 10.1016/j.jmapro.2019.05.001 [18] Huang C P, Huang S W, Liu F C. Metal materials additive manufacturing. Mach Met Form, 2016(2): 34黄春平, 黄硕文, 刘奋成. 金属材料增材制造技术. 金属加工(热加工), 2016(2): 34 [19] Xing X X, Pan L H, Wang Y, et al. Research status analysis of electron beam 3D printing technology. Weld Join, 2016(7): 22 doi: 10.3969/j.issn.1001-1382.2016.07.005邢希学, 潘丽华, 王勇, 等. 电子束选区熔化增材制造技术研究现状分析. 焊接, 2016(7): 22 doi: 10.3969/j.issn.1001-1382.2016.07.005 [20] Chen G Q, Shu X, Zhang B G, et al. State-of-arts of electron beam freeform fabrication technology. Trans China Weld Inst, 2018, 39(8): 123 doi: 10.12073/j.hjxb.2018390214陈国庆, 树西, 张秉刚, 等. 国内外电子束熔丝沉积增材制造技术发展现状. 焊接学报, 2018, 39(8): 123 doi: 10.12073/j.hjxb.2018390214 [21] Li Q, Wang F D, Wang G Q. Wire and arc additive manufacturing of lightweight metal components in aeronautics and astronautics. Aeronaut Manuf Technol, 2018, 61(3): 74李权, 王福德, 王国庆, 等. 航空航天轻质金属材料电弧熔丝增材制造技术. 航空制造技术, 2018, 61(3): 74 [22] Liu J C. Analysis of the state of the art and problems of metal additive manufacturing. Electromach Mould, 2018(2): 1 doi: 10.3969/j.issn.1009-279X.2018.02.001刘继常. 金属增材制造研究现状与问题分析. 电加工与模具, 2018(2): 1 doi: 10.3969/j.issn.1009-279X.2018.02.001 [23] Ding D H, Pan Z X, Cuiuri D. Wire-feed additive manufacturing of metal components: technologies, developments and future interests. Int J Adv Manuf Technol, 2015, 81(1-4): 465 doi: 10.1007/s00170-015-7077-3 [24] Yang Q Z, Wei Y P, Gao P, et al. Research progress of metal additive manufacturing technologies and related materials. Mater Rev, 2016, 30(Suppl 1): 107杨全占, 魏彦鹏, 高鹏, 等. 金属增材制造技术及其专用材料研究进展. 材料导报, 2016, 30(增刊1): 107 [25] Xu J Q, Zhu J, Fan J K, et al. Microstructure and mechanical properties of Ti‒6Al‒4V alloy fabricated using electron beam freeform fabrication. Vacuum, 2019, 167: 364 doi: 10.1016/j.vacuum.2019.06.030 [26] Jiang H L, Yao J K, Yin F L. Research status and application of wire arc additive manufacturing technology. Hot Working Technol, 2018, 47(18): 25江宏亮, 姚巨坤, 殷凤良. 丝材电弧增材制造技术的研究现状与应用. 热加工工艺, 2018, 47(18): 25 [27] Hao P, Morteza G K, Shan G, et al. Fast prediction of thermal distortion in metal powder bed fusion additive manufacturing: Part 2, a quasi-static thermo-mechanical model. Addit Manuf, 2018, 22: 869 [28] Afkhami S, Dabiri M, Alavi S H, et al. Fatigue characteristics of steels manufactured by selective laser melting. Int J Fatigue, 2019, 122: 72 doi: 10.1016/j.ijfatigue.2018.12.029 [29] Gao C, Zhang P P, Lin F. Research advances of electron beam selective melting additive manufacturing technology. Ind Technol Innov, 2017, 4(4): 6郭超, 张平平, 林峰. 电子束选区熔化增材制造技术研究进展. 工业技术创新, 2017, 4(4): 6 [30] Yang Y Q, Chen J, Song C H, et al. Current status and progress on technology of selective laser melting of metal parts. Laser Optoelectron Prog, 2018, 55(1): 9杨永强, 陈杰, 宋长辉, 等. 金属零件激光选区熔化技术的现状及进展. 激光与光电子学进展, 2018, 55(1): 9 [31] Li Y J, Dong S Y, Yan S X, et al. Microstructure evolution during laser cladding Fe‒Cr alloy coatings on ductile cast iron. Opt Laser Technol, 2018, 108: 255 doi: 10.1016/j.optlastec.2018.07.004 [32] Xu B S. Theory and Technology of Surface Engineering. Beijing: National Defense Industry Press, 2010徐滨士. 表面工程的理论与技术. 北京: 国防工业出版社, 2010 [33] Benjamin B, Rohan R, Richard K, et al. Systematic evaluation of process parameter maps for laser cladding and directed energy deposition. Addit Manuf, 2018, 21: 487 [34] Ran J T, Zhao H, Gao H B, Selective electron beam melting technique and its application. Aeronaut Manuf Technol, 2019, 62(Suppl 1): 46冉江涛, 赵鸿, 高华兵, 等. 电子束选区熔化成形技术及应用. 航空制造技术, 2019, 62(增刊1): 46 [35] Machry T, Eatock D, Meyer J, et al. Effect of microstructure on the tensile strength of Ti6Al4V specimens manufactured using additive manufacturing electron beam process. Powder Metall, 2016, 59(1): 41 doi: 10.1080/00325899.2015.1123800 [36] Zhang K, Liu W J, Shang X F, et al. Applications of rapid protyping on national defense science and technology field. Tool Eng, 2005(11): 4张凯, 刘伟军, 尚晓峰, 等. 快速原型技术在国防科技中的应用. 工具技术, 2005(11): 4 [37] Gady B R. Upgrading readiness: success and improvements of the mobile parts hospital // 2005 SAE World Congress. Detroit, 2005, 01-0592 [38] Zhang Y Z, Shi L K. Process on laser rapid manufacturing of high performance. Aeronaut Manuf Technol, 2010(8): 47 doi: 10.3969/j.issn.1671-833X.2010.08.006张永忠, 石力开. 高性能金属零件激光快速成形技术研究进展. 航空制造技术, 2010(8): 47 doi: 10.3969/j.issn.1671-833X.2010.08.006 [39] Kathuria Y P. Some aspects of laser surface cladding in the turbine industry. Surf Coat Technol, 2000, 132(2-3): 262 doi: 10.1016/S0257-8972(00)00735-0 [40] Shi W. Blisk structure of MTU company in Germany. Int Aviat, 1997(10): 57石文. 德国MTU公司研究的整体叶盘结构. 国际航空, 1997(10): 57 [41] Zhang J P. Maintenance technology of high pressure turbine blade for civil aviation engine of MTU company. Aeronaut Manuf Technol, 2004(10): 70 doi: 10.3969/j.issn.1671-833X.2004.10.003张建平. 德国MTU公司民用航空发动机高压涡轮叶片维修技术. 航空制造技术, 2004(10): 70 doi: 10.3969/j.issn.1671-833X.2004.10.003 [42] Busachi A, Erkoyuncu J, Colegrove P, et al. Designing a WAAM based manufacturing system for defence applications. Procedia CIRP, 2015, 37: 48 doi: 10.1016/j.procir.2015.08.085 [43] Wilson J M, Piya C, Shin Y C, et al. Remanufacturing of turbine blades by laser direct deposition with its energy and environmental impact analysis. J Clean Prod, 2014, 80: 170 doi: 10.1016/j.jclepro.2014.05.084 [44] Gäumann M, Bezençon C, Canalis P, et al. Single-crystal laser deposition of superalloys: processing-microstructure maps. Acta Mater, 2001, 49(6): 1051 doi: 10.1016/S1359-6454(00)00367-0 [45] Liu Z C, Jiang Q H, Li T, et al. Environmental benefits of remanufacturing: A case study of cylinder heads remanufactured through laser cladding. J Clean Prod, 2016, 133: 1027 doi: 10.1016/j.jclepro.2016.06.049 [46] Ren W B, Dong S Y, Xu B S, et al. Process optimization and forming repair of laser remanufacturing for FV520(B) steel blade simulator. J Mater Eng, 2015, 43(1): 6 doi: 10.11868/j.issn.1001-4381.2015.01.002任维彬, 董世运, 徐滨士, 等. FV520(B)钢叶片模拟件激光再制造工艺优化及成形修复. 材料工程, 2015, 43(1): 6 doi: 10.11868/j.issn.1001-4381.2015.01.002 [47] Xu L D. Study on Microstructure and Properties of Welding Joint of Laser Repair of High-Strength Aluminum Alloy [Dissertation]. Chengdu: Southwest Jiaotong University, 2018徐力栋. 高强度铝合金焊接结构激光修复接头组织与性能研究[学位论文]. 成都: 西南交通大学, 2018 [48] Sun Y F. Research on Path Planning of Arc Additive Manufacturing for Repairing Large Defects of Casting [Dissertation]. Harbin: Harbin Institute of Technology, 2018孙云飞. 铸件大缺陷电弧增材修复的路径规划研究[学位论文]. 哈尔滨: 哈尔滨工业大学, 2018 [49] Wang K, Chen Y J, Lu L, et al. On line arc additive remanufacturing technology for nuclear flange. Mach Met Form, 2020(7): 2王凯, 陈英杰, 鲁立, 等. 核级法兰面在线电弧增材再制造技术研究. 金属加工(热加工), 2020(7): 2 [50] Zhang S X, Qian H F. Characteristics and personnel training of equipment battlefield emergency maintenance. J Sichuan Ordnan, 2009, 30(9): 149张树祥, 钱海峰. 装备战场应急维修特点和人才培养. 四川兵工学报, 2009, 30(9): 149 [51] Qiang T, Zhu B. The study on the application of pit-stop in battlefield emergency maintenance. Value Eng, 2011, 30(10): 190 doi: 10.3969/j.issn.1006-4311.2011.10.142强弢, 朱斌. 赛车快速维修在装备战场应急维修中应用研究. 价值工程, 2011, 30(10): 190 doi: 10.3969/j.issn.1006-4311.2011.10.142 [52] Ma S N, Liu Q, Sun X F. Research on emergency maintenance technique of equipments. China Surf Eng, 2003, 16(3): 7马世宁, 刘谦, 孙晓峰. 装备应急维修技术研究. 中国表面工程, 2003, 16(3): 7 -

下载:

下载: