Research status and application of BaTiO3-based positive temperature coefficient thermal ceramics

-

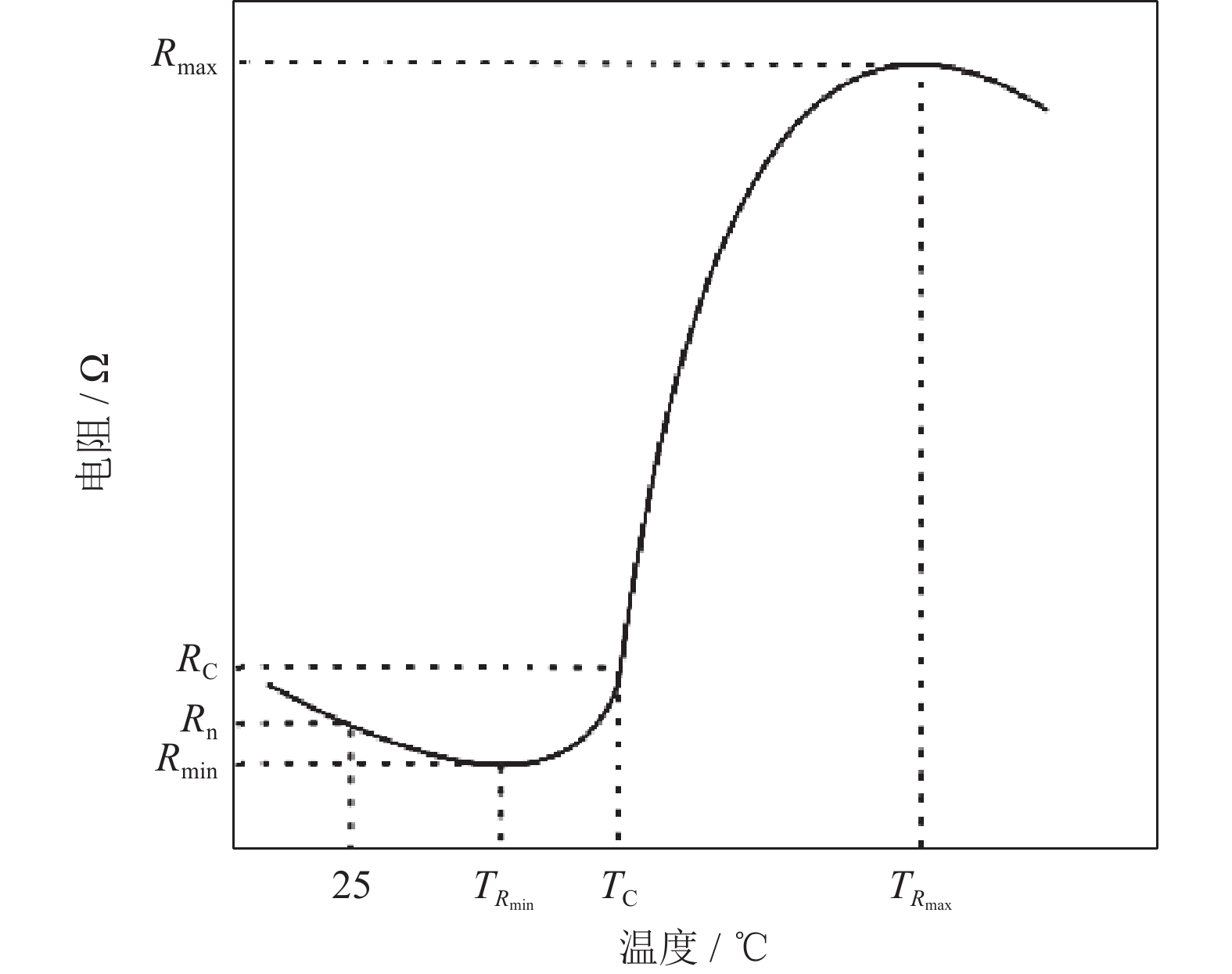

摘要: 正温度系数(positive temperature coefficient,PTC)热敏陶瓷是一类关键电子功能陶瓷,因其优异的特性在加热元件、传感器、电路保护器、温度控制器、电器消磁等领域都有广泛的应用。BaTiO3作为主体材料制备的正温度系数热敏电阻(positive temperature coefficient thermistor,PTCR)是目前用量较大的一类正温度系数元件,具有重要的研究意义。本文阐述了正温度系数热敏材料的分类及其优缺点,介绍了正温度系数效应、热敏机理及BaTiO3基正温度系数材料的半导化原理,综述了BaTiO3基正温度系数热敏陶瓷国内外研究现状,分析了移峰剂、施主掺杂、受主掺杂、烧结工艺等因素对BaTiO3基正温度系数热敏陶瓷的影响,总结了正温度系数热敏元器件的应用原理及其在相关领域的应用,并对正温度系数热敏陶瓷的无铅化进行了展望。Abstract: Positive temperature coefficient (PTC) thermal ceramics are a kind of key electronic functional ceramics, which are widely used in heating elements, sensors, circuit protectors, temperature controllers, and electrical demagnetization, because of the excellent characteristics. The positive temperature coefficient thermistor (PTCR) prepared by using BaTiO3 as the host materials is a type of PTC elements with a large amount at present, showing the important research significance. The classification and advantages-disadvantages of the PTC heat-sensitive materials were elaborated in the article, the PTC effect, heat-sensitive mechanism, and semiconductivity principle of the BaTiO3-based PTC materials were introduced, and the research status of the BaTiO3-based PTC heat-sensitive ceramics was summarized at home and abroad. The effects of peak shifting agent, donor doping, acceptor doping, and sintering process on the BaTiO3-based PTC thermal ceramics were analyzed. The application principle and application of the PTC thermal components were summarized in the related fields, and the lead-free PTC thermal ceramics were looked forward.

-

Key words:

- positive temperature coefficient /

- thermal ceramics /

- BaTiO3 /

- research status

-

表 1 正温度系数材料种类

Table 1. Types of the PTC materials

类别 产生正温度系数效应机理 特点 高分子类正温度系数复合材料 20世纪80年代开发成功的新型功能材料。由绝缘聚合物基体混合炭黑、金属等导电粒子构成。在某一温度点基体材料由半导体(或导体)转变为绝缘体。这是由于基体材料随着温度的升高而膨胀,导电粒子失去联系,电阻率急剧提高。 优点:容易加工成各种形状,电阻温度系数大,室温电导率大,升阻比大,可以消除负温度系数现象。缺点:居里点可改范围小,响应时间慢,耐高温性差,易老化失效。 V2O3系正温度系数材料 20世纪80年代发展起来的新型功能材料。随着温度升高,材料内部发生体效应(金属相→半导体或绝缘体),产生正温度系数效应。金属相的电阻率一般很低,绝缘体具有很高的电阻率,因此,lg(Rmax/Rmin)很大,具有一定升阻比。 优点:电阻温度系数与升阻不受频率电压影响,室温电阻率低,耐电压性强,通流能力强。缺点:居里温度不易改变,升阻比小,相变时存在体积膨胀。 钛酸钡基正温度系数材料 由20世纪50年代荷兰Philips公司发现,在BaTiO3中掺入少量稀土元素,其室温电导率会大幅提高,在居里点电阻呈阶跃式上升(可增大5~8个数量级),具有正温度系数效应。这类材料正温度系数效应可用晶界效应来解释。 优点:居里温度容易调整,电阻温度系数大,耐电压冲击能力强。缺点:室温电阻率较大,电阻温度系数、升阻比易受频率和电压影响。 表 2 BNT对正温度系数性能的影响

Table 2. Influence of BNT on the PTC performance

BNT摩尔分数 / % ρ25 / (Ω·m) lg(∆β) TC / ℃ 6 68.20 2.19 210.3 8 381.79 2.03 225.7 10 1055.77 1.69 237.1 15 3337.18 1.08 242.8 注:ρ25为室温电阻率,lg(∆β)为升阻比,TC为居里温度。 表 3 常见施主掺杂离子

Table 3. Common donor doped ions

掺入位置 掺杂离子 Ba位 La3+、Y3+、Nd3+、Sb3+、Bi3+ Ti位 Nb5+、Ta5+、Sb5+、V5+、W5+ 表 4 CuO对正温度系数性能的影响

Table 4. Influence of CuO on the performance of PTC

CuO摩尔分数 / % ρRT / (Ω·cm) ρmax / (Ω·cm) lg(ρmax/ρmin) TC / ℃ c/a 0 871.46 3.95×103 0.66 134.2 1.0042 0.05 2085.89 3.01×105 2.16 136.4 1.0056 0.10 3104.22 1.40×106 2.65 137.3 1.0061 0.15 10055.06 3.91×106 2.59 138.6 1.0073 0.20 136114.29 9.76×106 1.86 139.7 1.0082 注:ρRT为室温电阻率,ρmax为最大电阻率,ρmin为最小电阻率,lg(ρmax/ρmin)=lg(∆β)为升阻比,TC为居里温度,c/a为四方率。 -

[1] Wu W F. Study on Preparation and Application of the PTC Materials with Room Temperature Curie Point [Dissertation]. Hefei: University of Science and Technology of China, 2013吴万范. 室温居里点PTC材料的制备及应用研究[学位论文]. 合肥: 中国科学技术大学, 2013 [2] Song J L. Study on PTC Thermal Control Material at Room Temperature and Its ThermaI ControI Method [Dissertation]. Hefei: University of Science and Technology of China, 2016宋嘉梁. 常温PTC热控材料及其热控方法研究[学位论文]. 合肥: 中国科学技术大学, 2016 [3] Liu H G. Study on PTCR Thermistor for High Voltage Overcurrent Protection [Dissertation]. Chengdu: University of Electronic Science and Technology of China, 2012刘宏刚. 高耐压过流保护用PTCR热敏电阻器的研究[学位论文]. 成都: 电子科技大学, 2012 [4] Zhai J, Li L Y, Ouyang Y F. First-principle study of thermophysical properties of perovskite BaTiO3. J Guangxi Normal Univ Nation, 2012, 29(3): 39 doi: 10.3969/j.issn.1674-8891.2012.03.013翟娟, 李兰英, 欧阳义芳. 钙钛矿结构BaTiO3的热物理性能的第一原理研究. 广西民族师范学院学报, 2012, 29(3): 39 doi: 10.3969/j.issn.1674-8891.2012.03.013 [5] Ren Y J. Study on Preparation and Properties of BaTiO3 PTC Heat Sensitive Ceramics [Dissertation]. Taiyuan: Taiyuan University of Technology, 2006任伊锦. 钛酸钡系PTC热敏陶瓷材料的制备与性能研究[学位论文]. 太原: 太原理工大学, 2006 [6] Xi B F, Liu F Y, Xu C X, et al. The advance in theory research of PTC properties of polymer/carbon black composites. Polym Mater Sci Eng, 1999, 15(6): 25 doi: 10.16865/j.cnki.1000-7555.1999.06.007席保锋, 刘辅宜, 徐传骧, 等. 聚合物/炭黑复合材料PTC特性的理论研究进展. 高分子材料科学与工程, 1999, 15(6): 25 doi: 10.16865/j.cnki.1000-7555.1999.06.007 [7] Xu Q, Chen W, Zhou J, et al. Study and improvement of doped V2O3 PTC ceramics. Adv Ceram, 1997, 18(2): 26徐庆, 陈文, 周静, 等. 掺杂V2O3系PTC陶瓷的研究现状及进展. 现代陶瓷技术, 1997, 18(2): 26 [8] Heywang W. Barium titanate as a semiconductor with blocking layers. Solid State Electron, 1961, 3(1): 51 doi: 10.1016/0038-1101(61)90080-6 [9] Liang Y H, Wang J F, Pu Y P, et al. Effect of atmosphere sintering on lead-free PTCR ceramics. China Ceram, 2009, 45(7): 23梁云鹤, 王瑾菲, 蒲永平, 等. 含铋BaTiO3基PTC陶瓷半导化研究. 中国陶瓷, 2009, 45(7): 23 [10] Jiang S L, Gong S P, Zhou L, et al. Study on semiconductor ceramic materials: Double donor doping BaTiO3. Piezoelectr Acoust, 2000, 22(6): 392 doi: 10.3969/j.issn.1004-2474.2000.06.013姜胜林, 龚树萍, 周莉, 等. 双施主掺杂BaTiO3半导体陶瓷材料的研究. 压电与声光, 2000, 22(6): 392 doi: 10.3969/j.issn.1004-2474.2000.06.013 [11] Li T, Chang F G, Ge Y X, et al. PAT studies of donor-doped BaTiO3 ceramics. J Henan Normal Univ Nat Sci, 2006, 34(1): 43李涛, 常方高, 葛永霞, 等. Ho掺杂BaTiO3陶瓷的制备及其正电子湮没研究. 河南师范大学学报(自然科学版), 2006, 34(1): 43 [12] Hu Y, Chen Y Y, Su W Y, et al. Study on PTCR material of high Curie point and low resistivity. Electron Compon Mater, 2006, 6(6): 61 doi: 10.3969/j.issn.1001-2028.2006.06.020胡毅, 陈亿裕, 苏卫彦, 等. 低电阻率高居里点PTCR材料的研究. 电子元件与材料, 2006, 6(6): 61 doi: 10.3969/j.issn.1001-2028.2006.06.020 [13] Kang J N. Study on the Lead-Free High Curie Temperature BaTiO3 Based Materials [Dissertation]. Tianjin: Tianjin University, 2010康健宁. 无铅高居里点BaTiO3基PTC材料的研究[学位论文]. 天津: 天津大学, 2010 [14] Liu M L. Study on the Preparation of BaTiO3-Based Lead-Free High Curie-Point Positive Temperature Coefficient Ceramics [Dissertation]. Tianjin: Tianjin University, 2010刘明龙. BaTiO3基无铅高居里温度PTCR材料的制备研究[学位论文]. 天津: 天津大学, 2010 [15] Mächler D, Töpfer J. Effect of SiO2 sintering additive on the positive temperature coefficient of resistivity (PTCR) behavior of (Bi1/2Na1/2)0.10Ba0.90TiO3+CaO ceramics. Mater Res Bull, 2017, 89: 217 doi: 10.1016/j.materresbull.2017.02.005 [16] Kola L, Swain A B, Rath M, et al. Impedance characteristics and PTCR effect in lead free BaTi1‒xSnxO3 piezoceramics. Mater Res Bull, 2018, 106: 371 doi: 10.1016/j.materresbull.2018.06.021 [17] Matsuura K, Hoshina T, Takeda H, et al. Effects of Ca substitution on room temperature resistivity of donor-doped barium titanate based PTCR ceramics. J Ceram Soc Jpn, 2014, 122(1426): 402 doi: 10.2109/jcersj2.122.402 [18] Lei J. Study of the NTC Effect in Barium Titanate Based PTC Ceramics [Dissertation]. Guangzhou: South China University of Technology, 2018雷佳. 钛酸钡基PTC陶瓷NTC效应研究[学位论文]. 广州: 华南理工大学, 2018 [19] Guo C. Effect of Donor and Na0.5Bi0.5TiO3 (NBT) Dopants on Element’ s Curie Temperature of PTCR [Dissertation]. Xi′an: Xidian University, 2014郭晨. 施主掺杂和Na0.5Bi0.5TiO3对钛酸钡系PTCR居里温度的影响[学位论文]. 西安: 西安电子科技大学, 2014 [20] Wang X, Liu S J, Zhang L X, et al. Influence of sintering time and donor concentration on the PTCR effect of La-doped BaTiO3-Na0.5Bi0.5TiO3 ceramics. Ceram Int, 2018, 44(Suppl 1): S216 [21] Takeuchi N, Fujishita Y, Kobayashi H. Fabrication of high Curie-point PTCR materials using Gd-doped BaTiO3-(Bi1/2Na1/2)TiO3 system. J Soc Mater Sci Jpn, 2018, 67(4): 474 doi: 10.2472/jsms.67.474 [22] Cheng X X, Cui H N, Li X X, et al. Investigation of PTCR effect and microdefects in Nb2O5-doped BaTiO3-based ceramics by positron annihilation techniques. Int J Mod Phys B, 2017, 31: 1744060 doi: 10.1142/S021797921744060X [23] Teichmann C, Töpfer J. Low-temperature sintering of BaTiO3 positive temperature coefficient of resistivity (PTCR) ceramics. J Mater Sci Mater Electron, 2018, 29: 17881 doi: 10.1007/s10854-018-9903-5 [24] Mächler D, Schmidt R, Töpfer J, et al. Synthesis, doping and electrical bulk response of (Bi1/2Na1/2)xBa1‒xTiO3+CaO-based ceramics with positive temperature coefficient of resistivity (PTCR). J Alloys Compd, 2018, 762: 209 doi: 10.1016/j.jallcom.2018.05.049 [25] Zhao J J, Pu Y P, Wu Y R, et al. PTCR behavior of CuO-doped Ba0.96(Bi0. 5K0.5)0.04TiO3 ceramics. Ferroelectrics, 2016, 492(1): 117 doi: 10.1080/00150193.2015.1071145 [26] Zhao J J, Pu Y P, Wu Y R, et al. Influence of SiO2 addition on the PTCR characteristics of Ba0.92(Bi0.5K0.5)0.08TiO3 ceramics. J Mater Sci Mater Electron, 2015, 26(8): 6051 doi: 10.1007/s10854-015-3182-1 [27] Liu J Q, Gong S P, Quan L, et al. Effects of SiO2 addition on Ba excessive barium titanate ceramics sintered in reducing atmosphere for laminated PTCR thermistors. Mater Res Innovations, 2014, 18(Suppl 2): 172 [28] Cheng X X, Li X X, Chen X M, et al. Influence of sintering process on electrical properties and PTCR effect of laminated Ba1.005(Ti1‒xNbx)O3 ceramics fired in a reducing atmosphere. Int J Mod Phys B, 2017, 31: 1744061 doi: 10.1142/S0217979217440611 [29] Cheng X, Zhou D, Fu Q, et al. Influence of the sintering process on the PTCR effect of chip-type Ba1.022–xSmxTiO3 ceramics prepared by the reduction sintering-reoxidation method. J Mater Sci Mater Electron, 2014, 25(2): 1105 doi: 10.1007/s10854-013-1695-z [30] Zhang H L. Preparation and Research of Positive Temperature Coefficient Thermosensitive Material [Dissertation]. Nanjing: Nanjing University of Science and Technology, 2019张宏亮. 正温度系数热敏材料的制备与研究[学位论文]. 南京: 南京理工大学, 2019 [31] Ding S W, Pan B, Chuo Y M, et al. Influence of sintering process on the properties of BaTiO3-based PTCR ceramics. J Hebei Univ Nat Sci, 2011, 31(5): 486丁士文, 潘彬, 啜艳明, 等. 烧结工艺对BaTiO3基PTC热敏电阻材料性能的影响. 河北大学学报(自然科学版), 2011, 31(5): 486 [32] Cheng X, Chen X, Li X, et al. Influence of Ba/Ti ratio on PTCR effect of Bam(Ti1‒xNbx)O3 ceramics prepared by the reduction sintering-reoxidation method. Mod Phy Lett B, 2019, 32: 1840071 [33] Huang H, Chen Y, Li Z, et al. The influences of controlling sintering mechanism on electrical properties of multilayer PTCR chip. J Wuhan Univ Technol Mater Sci, 2015, 30(4): 674 doi: 10.1007/s11595-015-1210-x [34] Cao M H, Yuan J, Gong S P, et al. The abnormal effect of cooling rate on the room temperature resistivity of Ba0.92Ca0.08TiO3 PTCR ceramics. J Chin Ceram Soc, 2003, 31(6): 604 doi: 10.3321/j.issn:0454-5648.2003.06.016曹明贺, 袁俊, 龚树萍, 等. 降温速率对Ba0.92Ca0.08TiO3 PTCR陶瓷室温电阻率反常现象的影响. 硅酸盐学报, 2003, 31(6): 604 doi: 10.3321/j.issn:0454-5648.2003.06.016 -

下载:

下载: