-

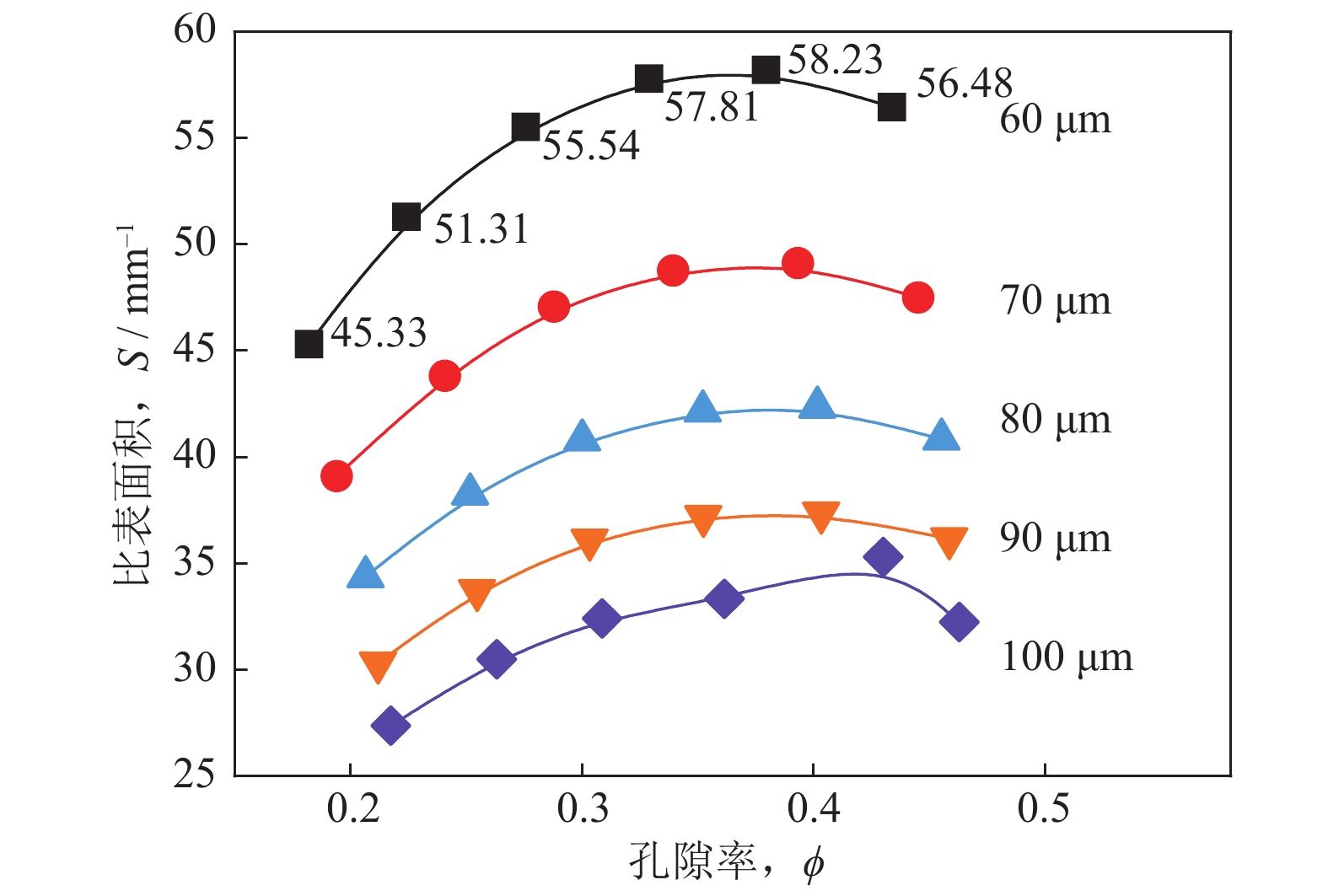

摘要: 在球体随机堆积模型的基础上,考虑实际平均配位数,利用离散建模软件EDEM对不可变形系数进行拟合,建立了球形粉末烧结多孔介质比表面积的理论模型。与传统模型相比,该模型的适用范围更广。以实际液体爬升实验为实证对象,将伯努利方程与所建模型耦合,对液体爬升高度进行了预测,发现方程计算结果与实验结果相吻合,说明所建模型具有较好的准确性和应用价值。Abstract: The theoretical model of the specific surface area for the porous media sintered by the spherical powders is established by discrete modeling software EDEM, considering the actual average coordination number and the impenetrability parameter, based on the theory of spheres random stacking model. Compared with the conventional model, the established model has a wider range of applications. Taking the actual capillary rise test as the empirical object, the capillary rise height is predicted by coupling Bernoulli equation with the established model, and the prediction results show the agree with the experimental results, indicating that the established model has the good accuracy and application value.

-

Key words:

- porous media /

- specific surface area /

- numerical simulation /

- powders /

- sintering

-

表 1 不同文献中液体爬升实验参数

Table 1. Experimental parameters of the actual capillary rise test in the different references

-

[1] Ren W. Property characterization of Mn–Si powder porous alloy for semiconductors prepared by solid phase sintering. Powder Metall Technol, 2019, 37(6): 456任伟. 固相烧结制备半导体用Mn‒Si粉末多孔合金的性能表征. 粉末冶金技术, 2019, 37(6): 456 [2] Xu P, Qiu S, Cai J, et al. A novel analytical solution for gas diffusion in multi-scale fuel cell porous media. J Power Sources, 2017, 362: 73 doi: 10.1016/j.jpowsour.2017.07.015 [3] Zhu M H, Huang J, Song M J, et al. Thermal performance of a thin flat heat pipe with grooved porous structure. Appl Therm Eng, 2020, 173: 115215 doi: 10.1016/j.applthermaleng.2020.115215 [4] Perez-Sanchez J F, Palacio-Perez A, Suarez-Dominguez E J, et al. Evaluation of surface tension modifiers for crude oil transport through porous media. J Pet Sci Eng, 2020, 192: 107319 doi: 10.1016/j.petrol.2020.107319 [5] Jang J, Sun Z, Santamarina J C. Capillary pressure across a pore throat in the presence of surfactants. Water Resour Res, 2016, 52(12): 9586 doi: 10.1002/2015WR018499 [6] Soldi M, Guarracino L, Jougnot D. A simple hysteretic constitutive model for unsaturated flow. Transp Porous Media, 2017, 120(2): 271 doi: 10.1007/s11242-017-0920-2 [7] Chen H, Chen K, Yang M H, et al. A fractal capillary model for multiphase flow in porous media with hysteresis effect. Int J Multiphase Flow, 2020, 125: 103208 doi: 10.1016/j.ijmultiphaseflow.2020.103208 [8] Zhang X. Coal-Gas Interaction and Its Influence on Gas Migration under Multi-Field Conditions [Dissertation]. Chongqing: Chongqing University, 2018张鑫. 多场条件下煤瓦斯相互作用及对瓦斯运移的影响[学位论文]. 重庆: 重庆大学, 2018 [9] Jiang L S, Liu H S, Wu D, et al. Numerical simulation of methane-air premixed combustion process in a randomly packed bed. J Northeast Univ Nat Sci, 2019, 40(7): 962 doi: 10.12068/j.issn.1005-3026.2019.07.010姜霖松, 刘宏升, 吴丹, 等. 随机堆积床内甲烷/空气预混燃烧过程的数值模拟. 东北大学学报(自然科学版), 2019, 40(7): 962 doi: 10.12068/j.issn.1005-3026.2019.07.010 [10] Zhao H. Research and development on the sintering techniques of molybdenum and molybdenum alloys. Powder Metall Technol, 2019, 37(5): 382 doi: 10.19591/j.cnki.cn11-1974/tf.2019.05.010赵虎. 钼及钼合金烧结技术研究及发展. 粉末冶金技术, 2019, 37(5): 382 doi: 10.19591/j.cnki.cn11-1974/tf.2019.05.010 [11] Li G Y. Research on Transport Properties of Liquid in Porous Media under Microgravity [Dissertation]. Changsha: National University of Defense Technology, 2016李光昱. 微重力条件下多孔介质中的液体输运特性研究[学位论文]. 长沙: 国防科学技术大学, 2016 [12] Blum L, Stell G. Polydisperse systems. I. Scattering function for polydisperse fluids of hard or permeable spheres. J Chem Phys, 1979, 71(1): 42 [13] Li S G. Study on Packing Density of Metal Powder Particles Used in Metal 3D Printing [Dissertation]. Beijing: North China Electric Power University, 2019李世广. 用于3D打印的金属粉末颗粒致密度研究[学位论文]. 北京: 华北电力大学, 2019 [14] El Khaldi K, Saleeby E G. On the tangent model for the density of lines and a Monte Carlo method for computing hypersurface area. Monte Carlo Methods Appl, 2017, 23(1): 13 doi: 10.1515/mcma-2017-0100 [15] Eisfeld B, Schnitzlein K. The influence of confining walls on the pressure drop in packed beds. Chem Eng Sci, 2001, 56(14): 4321 doi: 10.1016/S0009-2509(00)00533-9 [16] White L R. Capillary rise in powders. J Colloid Interface Sci, 1982, 90(2): 536 doi: 10.1016/0021-9797(82)90319-8 [17] Li G, Chen X, Huang Y. Contact angle determined by spontaneous imbibition in porous media: experiment and theory. J Dispersion Sci Technol, 2015, 36(6): 772 doi: 10.1080/01932691.2014.921627 [18] Zheng X H, Wang Y, Li H C, et al. Characterization of capillary performance of micro-nano scale wicks. Mater Sci Eng Powder Metall, 2016, 21(3): 488郑晓欢, 王野, 李红传, 等. 微纳尺度毛细芯吸液特性. 粉末烧结材料科学与工程, 2016, 21(3): 488 [19] Guo H, Ji X B, Xu J L. Effect of particle morphology and surface wettability on performance of porous wick and loop heat pipe. J Mech Eng, 2020, 56(14): 173 doi: 10.3901/JME.2020.14.173郭浩, 纪献兵, 徐进良. 颗粒形貌及表面润湿性对毛细芯及环路热管性能的影响. 机械工程学报, 2020, 56(14): 173 doi: 10.3901/JME.2020.14.173 [20] Huber P, Grüner S, Schfer C, et al. Rheology of liquids in nanopores: A study on the capillary rise of water, n-Hexadecane and n-Tetracosane in mesoporous silica. Eur Phys J Spec Top, 2007, 141(1): 101 doi: 10.1140/epjst/e2007-00024-0 -

下载:

下载: