-

摘要: 锂离子电池商用负极材料石墨比容量低,难以满足市场需求,金属有机骨架材料(metal-organic framework materials,MOFs)具有可调控的结构、较大的表面积和可调节的孔径,可用作下一代电化学储能器件,引起广泛研究。本文综述了金属(Fe、Co、Zn、Mn、Cu)基金属有机骨架及其衍生物的合成,重点介绍了以金属有机骨架材料为前驱体制备过渡金属氧化物(transition metal oxide,TMO)/C作为锂离子电池负极材料的研究进展,并对其发展方向进行了展望。Abstract: The graphite as the commercial anode material for lithium-ion batteries shows the low specific capacity, which is difficult to meet the market demand. The metal-organic framework materials (MOFs) have the tunable structure, large surface area, and adjustable pore size, which can be used as the next generation of electrochemical energy storage devices, causing the extensive research. The synthesis of the metal (Fe, Co, Zn, Mn, Cu)-based metal organic frameworks and the derivatives were introduced in this paper, the research progress on the preparation of transition metal oxide (TMO)/C as the anode materials for lithium-ion batteries was focused, using MOFs as the precursors, and the development direction was prospected.

-

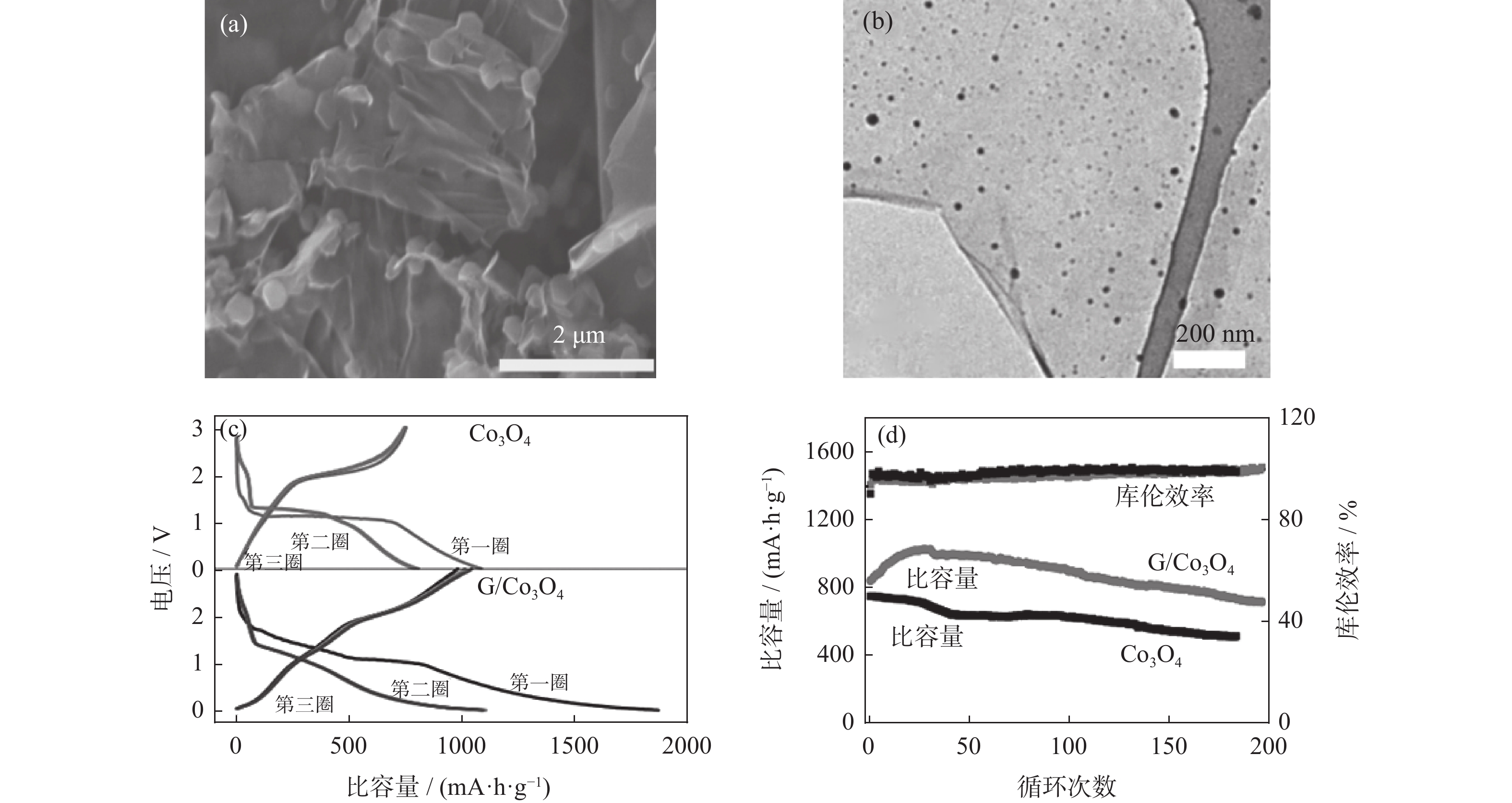

图 1 前驱体GO/ZIF-67(a)和G/Co3O4复合材料(b)显微形貌、G/Co3O4和Co3O4电极在100 mA·g−1电流密度下前三圈放电/充电曲线(c)以及在200 mA·g−1的循环图(d)[17]

Figure 1. Microstructures of GO/ZIF-67 precursor (a) and G/Co3O4 (b), the discharge/charge curves of G/Co3O4 and Co3O4 at the current density of 100 mA·g−1 for the first three cycles (c), and the cycling properties of G/Co3O4 and Co3O4 at 200 mA·g−1 (d)[17]

图 3 空心多孔ZnO/C制备工艺流程(a)、空心多孔ZnO/C显微形貌(b)以及在电流密度为100 mA·g−1时空心多孔ZnO/C、空心多孔ZnO和商用ZnO的循环性能(c)[20]

Figure 3. Schematic diagram of hollow porous ZnO/C preparation process (a), microstructure of hollow porous ZnO/C (b), and cycling properties of hollow porous ZnO/C, hollow porous ZnO, and commercial ZnO at 100 mA·g−1 (c)[20]

表 1 MOFs衍生锂离子电池负极材料

Table 1. MOFs-derived anode materials for lithium-ion batteries

MOFs前驱体 产物 电流密度 / (mA·g−1) 可逆容量 / (mA·h·g−1) 循环次数 参考文献 Co-MOF Co3O4/C 200 1052 60 [15] Co-MOF Co3O4/C 1000 601.0 500 [16] ZIF-67 G/Co3O4 200 714.0 200 [17] Fe-MOF C-Fe3O4 100 975.0 50 [18] Fe-ZIF Fe2O3@N-C 100 861.0 100 [19] MOF-5 ZnO/C 100 750.0 100 [20] Ppy-ZIF-8 ZnO/C 250 526.0 500 [21] Zn-BTC ZnO/C 100 919.0 100 [22] ZnO@ZIF-8 ZnO/C 2000 351.0 — [23] MOF-5 ZnO@C/CNT 100 758.0 100 [24] Mn-BTC MnO@C 3825 596.3 1000 [26] Mn-PBI MnO/C−N 300 1085.0 100 [27] Mn-BDC MnO/C@rGO 100 1536.4 100 [29] Cu-MOF CuOx-rGO 200 1490.0 220 [31] Cu-BTC CuO@C 100 1024.0 100 [32] [Cu(BTC)2]n-MOF CuO/C 100 510.5 200 [33] Cu-MOF CuO/C 100 789.0 200 [34] Cu-MOF CuO@C 1000 410.0 1000 [35] MIL-125@ZIF-67 Co3O4/TiO2 1000 838.6 600 [36] ZIF-67 Co3O4@Co3V2O8 100 948.0 100 [37] ZIF-67 Co3O4@TiO2 100 1057.0 100 [38] MOF-74-FeCo Co3O4-CoFe2O4 100 940.0 80 [39] ZnCo-MOF ZnO/ZnCo2O4/C 500 669.0 250 [40] GO/Zn-Co-ZIF/Ni rGO/ZnCo2O4-ZnO-C/Ni 100 1184.4 150 [42] -

[1] Xu G, Nie P, Dou H, et al. Exploring metal organic frameworks for energy storage in batteries and supercapacitors. Mater Today, 2017, 20(4): 191 doi: 10.1016/j.mattod.2016.10.003 [2] Yu S H, Lee S H, Lee D J, et al. Conversion reaction-based oxide nanomaterials for lithium ion battery anodes. Small, 2016, 12(16): 2146 doi: 10.1002/smll.201502299 [3] Kim T, Song W T, Son D Y, et al. Lithium-ion batteries: outlook on present, future, and hybridized technologies. J Mater Chem A, 2019, 7(7): 2942 doi: 10.1039/C8TA10513H [4] Zhao R, Liang Z B, Zou R Q, et al. Metal-organic frameworks for batteries. Joule, 2018, 2(11): 2235 doi: 10.1016/j.joule.2018.09.019 [5] Xie X C, Huang K J, Wu X. Metal-organic framework derived hollow materials for electrochemical energy storage. J Mater Chem A, 2018, 6(16): 6754 doi: 10.1039/C8TA00612A [6] Cook T R, Zheng Y R, Stang P J. Metal-organic frameworks and self-assembled supramolecular coordination complexes: comparing and contrasting the design, synthesis, and functionality of metal-organic materials. Chem Rev, 2013, 113(1): 734 doi: 10.1021/cr3002824 [7] Mehta J, Bhardwaj N, Bhardwaj S K, et al. Recent advances in enzyme immobilization techniques metal-organic frameworks as novel substrates. Coord Chem Rev, 2016, 322: 30 doi: 10.1016/j.ccr.2016.05.007 [8] Yaghi O M, Li H. Hydrothermal synthesis of a metal-organic framework containing large rectangular channels. J Am Chem Soc, 1995, 117: 10401 doi: 10.1021/ja00146a033 [9] Li B, Wen H, Cui Y, et al. Emerging multifunctional metal-organic framework materials. Adv Mater, 2016, 28(40): 8819 doi: 10.1002/adma.201601133 [10] Li T, Bai Y L, Wang Y, et al. Advances in transition-metal (Zn, Mn, Cu)-based MOFs and their derivatives for anode of lithium-ion batteries. Coord Chem Rev, 2020, 410: 213 [11] Xia W, Mahmood A, Zou R, et al. Metal-organic frameworks and their derived nanostructures for electrochemical energy storage and conversion. Energy Environ Sci, 2015, 8(7): 1837 doi: 10.1039/C5EE00762C [12] Zou F, Chen Y M, Liu K W, et al. Metal organic frameworks derived hierarchical hollow NiO/Ni/graphene composites for lithium and sodium storage. ACS Nano, 2016, 10(1): 377 doi: 10.1021/acsnano.5b05041 [13] Zheng M B, Tang H, Li L L, et al. Hierarchically nanostructured transition metal oxides for lithium-ion batteries. Adv Sci, 2018, 5(3): 1700592 doi: 10.1002/advs.201700592 [14] Cai Z X, Wang Z L, Kim J, et al. Hollow functional materials derived from metal-organic frameworks: synthetic strategies, conversion mechanisms, and electrochemical applications. Adv Mater, 2019, 31(11): 1804903.1 [15] Tian D, Zhou X L, Zhang Y H, et al. MOF-derived porous Co3O4 hollow tetrahedra with excellent performance as anode materials for lithium-ion batteries. Inorg Chem, 2015, 54(17): 8159 doi: 10.1021/acs.inorgchem.5b00544 [16] Ding Y C, Hu L H, He D C, et al. Design of multishell microsphere of transition metal oxides/carbon composites for lithium ion battery. Chem Eng J, 2020, 380: 122489 doi: 10.1016/j.cej.2019.122489 [17] Qu Q, Gao T, Zheng H, et al. Graphene oxides-guided growth of ultrafine Co3O4 nanocrystallites from MOFs as high-performance anode of Li-ion batteries. Carbon, 2015, 92: 119 doi: 10.1016/j.carbon.2015.03.061 [18] Li M, Wang W, Yang M, et al. Large-scale fabrication of porous carbon-decorated iron oxide microcuboids from Fe-MOF as high-performance anode materials for lithium-ion batteries. RSC Adv, 2015, 5(10): 7356 doi: 10.1039/C4RA11900B [19] Chen Y, Zheng L, Fu Y, et al. MOF-derived Fe3O4/carbon octahedral nanostructures with enhanced performance as anode materials for lithium-ion batteries. RSC Adv, 2016, 6(89): 85917 doi: 10.1039/C6RA19041C [20] Song Y, Chen Y, Wu J, et al. Hollow metal organic frameworks-derived porous ZnO/C nanocages as anode materials for lithium-ion batteries. J Alloys Compd, 2017, 694: 1246 doi: 10.1016/j.jallcom.2016.10.110 [21] Zhang J, Chu R, Chen Y, et al. MOF-derived transition metal oxide encapsulated in carbon layer as stable lithium ion battery anodes. J Alloys Compd, 2019, 797: 83 doi: 10.1016/j.jallcom.2019.04.162 [22] Yang T, Liu Y, Huang Z, et al. In situ growth of ZnO nanodots on carbon hierarchical hollow spheres as high-performance electrodes for lithium-ion batteries. J Alloys Compd, 2018, 735: 1079 doi: 10.1016/j.jallcom.2017.11.125 [23] Fu Y, Zhong B, Chen Y, et al. Porous ZnO@C core–shell nanocomposites as high performance electrode materials for rechargeable lithium-ion batteries. J Porous Mater, 2016, 24(3): 613 [24] Yue H, Shi Z, Wang Q, et al. In situ preparation of cobalt doped ZnO@C/CNT composites by the pyrolysis of a cobalt doped MOF for high performance lithium ion batteries. RSC Adv, 2015, 5(92): 75653 doi: 10.1039/C5RA14271G [25] Hou C, Tai Z, Zhao L, et al. High performance MnO@C microcages with a hierarchical structure and tunable carbon shell for efficient and durable lithium storage. J Mater Chem A, 2018, 6(20): 9723 doi: 10.1039/C8TA02863J [26] Cui Z, Liu Q, Xu C, et al. A new strategy to effectively alleviate volume expansion and enhance the conductivity of hierarchical MnO@C nanocomposites for lithium ion batteries. J Mater Chem A, 2017, 5(41): 21699 doi: 10.1039/C7TA05986H [27] Niu J L, Hao G X, Lin J, et al. Mesoporous MnO/C-N nanostructures derived from a metal-organic framework as high-performance anode for lithium-ion battery. Inorg Chem, 2017, 56(16): 9966 doi: 10.1021/acs.inorgchem.7b01486 [28] Maiti S, Pramanik A, Mahanty S. Electrochemical energy storage in Mn2O3 porous nanobars derived from morphology-conserved transformation of benzenetricarboxylate-bridged metal–organic framework. Cryst Eng Comm, 2016, 18(3): 450 doi: 10.1039/C5CE01976A [29] Tian X M, Zhao D L, Meng W J, et al. Highly porous MnO/C@rGO nanocomposite derived from MnBDC@rGO as high-performance anode material for lithium ion batteries. J Alloys Compd, 2019, 792: 487 doi: 10.1016/j.jallcom.2019.04.027 [30] Xu Y H, Jian G Q, Zachariah M R, et al. Nano-structured carbon-coated CuO hollow spheres as stable and high rate anodes for lithium-ion batteries. J Mater Chem A, 2013, 1: 15486 doi: 10.1039/c3ta13698a [31] Ramaraju B, Li C H, Prakash S, et al. Metal–organic framework derived hollow polyhedron metal oxide posited graphene oxide for energy storage applications. Chem Comm, 2016, 52(5): 946 doi: 10.1039/C5CC07621H [32] Xu Y, Chu K, Li Z, et al. Porous CuO@C composite as high-performance anode materials for lithium-ion batteries. Dalton Trans, 2020, 49(33): 11597 doi: 10.1039/D0DT02493G [33] Yin H, Yu X X, Li Q W, et al. Hollow porous CuO/C composite microcubes derived from metal-organic framework templates for highly reversible lithium-ion batteries. J Alloys Compd, 2017, 706: 97 doi: 10.1016/j.jallcom.2017.02.215 [34] Peng H J, Hao G X, Chu Z H, et al. Mesoporous spindle-like hollow CuO/C fabricated from a Cu-based metal-organic framework as anodes for high-performance lithium storage. J Alloys Compd, 2017, 727: 1020 doi: 10.1016/j.jallcom.2017.08.231 [35] Kang M S, Lee D H, Lee K J, et al. Porosity- and content-controlled metal/metal oxide/metal carbide@carbon (M/MO/MC@C) composites derived from MOFs: mechanism study and application for lithium-ion batteries. New J Chen, 2018, 42(23): 18678 doi: 10.1039/C8NJ04919J [36] Yang X, Wang Y, Hu Y Y, et al. Interior supported hierarchical TiO2@Co3O4 derived from MOF-on-MOF architecture with enhanced electrochemical properties for lithium storage. Chem Electro Chem, 2019, 6(14): 3657 [37] Lu Y, Yu L, Wu M H, et al. Construction of complex Co3O4@Co3V2O8 hollow structures from metal-organic frameworks with enhanced lithium storage properties. Adv Mater, 2018, 30(1): 1702875 doi: 10.1002/adma.201702875 [38] Ding H, Zhang X K, Fan J Q, et al. MOF-templated synthesis of Co3O4@TiO2 hollow dodecahedrons for high-storage-density lithium-ion batteries. ACS Omega, 2019, 4(8): 13241 doi: 10.1021/acsomega.9b01405 [39] Zhong M, Yang D H, Kong L J, et al. Bimetallic metal-organic framework derived Co3O4-CoFe2O4 composites with different Fe/Co molar ratios as anode materials for lithium ion batteries. Dalton Trans, 2017, 46(45): 15947 doi: 10.1039/C7DT03047A [40] Ge X, Li Z, Wang C, et al. Metal-organic frameworks derived porous core/shell structured ZnO/ZnCo2O4/C hybrids as anodes for high-performance lithium-ion battery. ACS Appl Mater Interfaces, 2015, 7(48): 26633 doi: 10.1021/acsami.5b08195 [41] Huang G, Yin D, Zhang F, et al. Yolk@shell or concave cubic NiO-Co3O4@C nanocomposites derived from metal-organic frameworks for advanced lithium-ion battery anodes. Inorg Chem, 2017, 56(16): 9794 doi: 10.1021/acs.inorgchem.7b01296 [42] Li Z, Yin L. Sandwich-like reduced graphene oxide wrapped MOF-derived ZnCo2O4-ZnO-C on nickel foam as anodes for high performance lithium ion batteries. J Mater Chem A, 2015, 3(43): 21569 doi: 10.1039/C5TA05733G -

下载:

下载: