Influence of inclination parameters for axial‒radial combined structure on silicon nitride particles mixing prepared by dry method

-

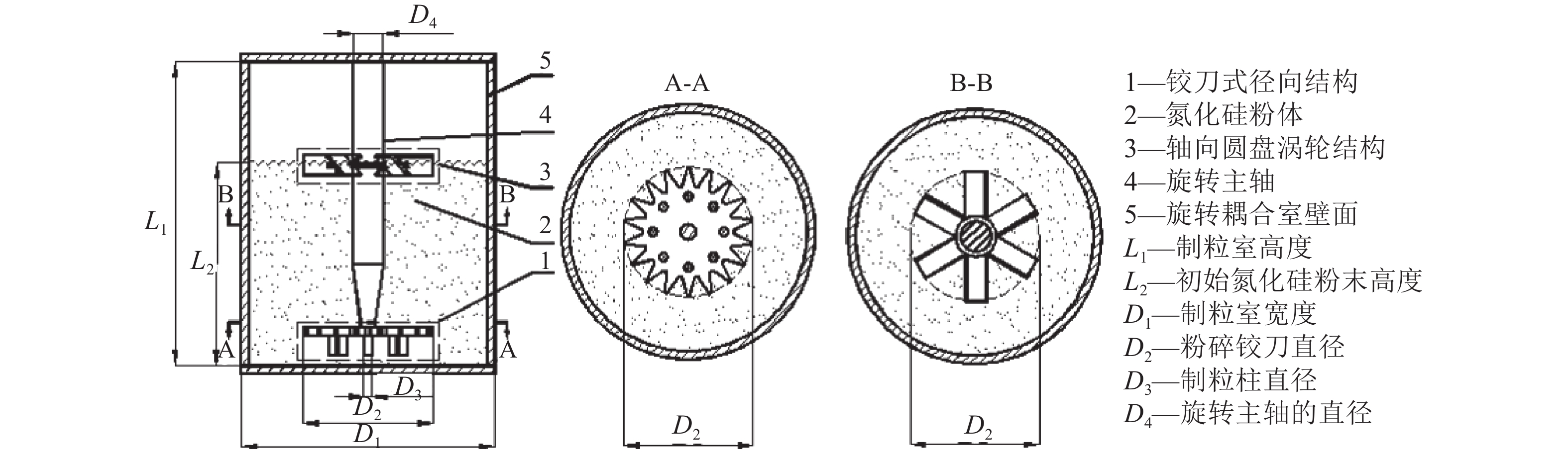

摘要: 针对干法制粒氮化硅室内混合效果不佳、颗粒球形度较差等问题,研究了开启涡轮式轴-径组合结构倾角参数对干法制备氮化硅颗粒混合效果的影响,建立了欧拉‒欧拉气固两相流数学模型并简化轴‒径组合结构制粒室物理模型,采用计算流体力学方法分析了轴向结构在不同倾斜角度下制粒室内氮化硅颗粒的体积分布与速度场,通过实验检测了氮化硅颗粒球形度,从侧面验证了数值模拟结果的准确性。数值模拟结果表明,当倾角为45°时,氮化硅颗粒体积分数处于0.3~0.7之间(占比28%),相比于倾角为30°、60°时,有较好的循环流动性,混合效果最佳。实验结果证实,当轴‒径组合结构倾角为45°时,氮化硅颗粒平均球形度最佳为0.72,能够有效提高氮化硅颗粒混合效果。Abstract: To solve the problems of poor mixing effect and poor sphericity for the silicon nitride particles in the dry granulation chamber, the influence of the inclination parameters for the open turbine typed axial‒radial combined structure on the mixing effect of silicon nitride particles prepared by dry method was studied. The mathematical model of Eulerian‒Eulerian gas‒solid two phase flow was established, and the physical model of the axial‒diameter combined structure granulation chamber was simplified. The computational fluid dynamics (CFD) method was used to analyze the volume distribution and velocity field of silicon nitride particles in granulation chamber in the axial structure under the different inclined angles. The sphericity of silicon nitride particles was tested by experiments, and the accuracy of numerical simulation results was verified. The numerical analysis results show that, when the inclination angle is 45°, the volume fraction of silicon nitride particles is 0.3~0.7 (accounting for 28%), showing the better circulating fluidity and the best mixing effect, compared with the inclination angle of 30° and 60°. The experimental results show that, the best average sphericity of the silicon nitride particles is 0.72 when the inclination angle of the axis‒diameter combined structure is 45°, which can effectively improve the mixing effect of silicon nitride particles.

-

表 1 制粒室几何参数

Table 1. Geometric parameter of the granulation chamber

L1 / mm L2 / mm D1 / mm D2 / mm D3 / mm D4 / mm 300 200 ϕ235 ϕ128 ϕ8 ϕ30 表 2 实验用料配比(质量分数)

Table 2. Experimental composition of the raw materials

% 实验原料 造粒添加剂 Si3N4(细粉) Si3N4(微粉) 邻苯二甲酸二丁酯 聚甲基丙烯酸甲酯 聚乙烯醇 聚丙烯酰胺 海藻酸钠 水 50 50 6 3 5 6 5 75 表 3 轴‒径组合结构倾角与球形度关系

Table 3. Relationship between the inclination angle and sphericity of the axial‒radial combined structure

角度 / (°) 球形度 30 0.57 45 0.72 60 0.43 -

[1] Wang M, Xie C, He R J, et al. Polymer-derived silicon nitride ceramics by digital light processing based additive manufacturing. J Am Ceram Soc, 2019, 102(9): 5117 doi: 10.1111/jace.16389 [2] Hyuga H. Development of efficient fabrication processes for highly functional silicon nitride ceramics: a review. J Ceram Soc Jpn, 2018, 126(12): 968 doi: 10.2109/jcersj2.18097 [3] Deng Q, Kong Z, Wu X, et al. Cloning of a COBL gene determining brittleness in diploid wheat using a MapRseq approach. Plant Sci, 2019, 285: 141 doi: 10.1016/j.plantsci.2019.05.011 [4] Zhang G, Sakai H, Noda N A, et al. Generation mechanism of driving out force of the shaft from the shrink fitted ceramic roll by introducing newly designed stopper. ISIJ Int, 2019, 59(2): 293 doi: 10.2355/isijinternational.ISIJINT-2018-615 [5] Zhou T, Zhu J B. Identification of a suitable 3D printing material for mimicking brittle and hard rocks and its brittleness enhancements. Rock Mech Rock Eng, 2018, 51(3): 765 doi: 10.1007/s00603-017-1335-7 [6] Varano E, Zhou M, Lanham S, et al. Developing toughened bismaleimide-clay nanocomposites: Comparing the use of platelet and rod-like nanoclays. React Funct Polym, 2019, 134: 10 doi: 10.1016/j.reactfunctpolym.2018.10.006 [7] Liu X H, Bao Y Y, Li Z P, et al. Particle image velocimetry study of turbulence characteristics in a vessel agitated by a dual Rushton impeller. Chin J Chem Eng, 2008, 16(5): 700 doi: 10.1016/S1004-9541(08)60143-3 [8] Sun C X, Wang L Z, Zhou Y J, et al. Numerical simulation of flow field characteristics in a double side-entery stirred tank. Pet Chem Equip, 2019, 48(4): 44 doi: 10.3969/j.issn.1000-7466.2019.04.008孙存旭, 王垒智, 周勇军, 等. 双层侧进式搅拌槽内流场特性数值模拟. 石油化工设备, 2019, 48(4): 44 doi: 10.3969/j.issn.1000-7466.2019.04.008 [9] Li L C, Wang J J, Gu X P, et al. Local gas-liquid dispersion properties in a dual-impeller stirred vessel. Chem Eng, 2009, 37(8): 24 doi: 10.3969/j.issn.1005-9954.2009.08.007李良超, 王嘉骏, 顾雪萍, 等. 双层组合桨搅拌槽内气液微观分散特性. 化学工程, 2009, 37(8): 24 doi: 10.3969/j.issn.1005-9954.2009.08.007 [10] Wang L L, Zhou Y J, Bao S Y, et al. PIV experiments on flow field of stirred tank with improved INTER-MIG impeller. J Process Eng, 2017, 17(3): 447 doi: 10.12034/j.issn.1009-606X.216263王璐璐, 周勇军, 鲍苏洋, 等. 改进型INTER-MIG桨搅拌槽内流场的PIV实验. 过程工程学报, 2017, 17(3): 447 doi: 10.12034/j.issn.1009-606X.216263 [11] Zhang Z, Liao R Q, Zhao Y R, et al. Influence of guide vane number and arrangement pattern on performance of downhole vortex tools. J Xi’ an Shiyou Univ Nat Sci, 2018, 33(5): 42张昭, 廖锐全, 赵亚睿, 等. 导流叶片数量及排布方式对涡流工具性能的影响. 西安石油大学学报(自然科学版), 2018, 33(5): 42 [12] Yang X, Mao Z H, Wu Y Y, et al. Compare mixed performance of vertical circulative impinging stream reactor (VCISR) with blade with inclinations. Chem Eng Mach, 2011, 38(3): 331 doi: 10.3969/j.issn.0254-6094.2011.03.022杨侠, 毛志慧, 吴艳阳, 等. 立式循环撞击流反应器不同倾角桨叶的混合性能比较. 化工机械, 2011, 38(3): 331 doi: 10.3969/j.issn.0254-6094.2011.03.022 [13] Gao Y, Hao H D, Dang R, et al. Characteristics of gas holdup in double-impeller self-inspirating reactor. Petrochem Technol, 2019, 48(5): 496 doi: 10.3969/j.issn.1000-8144.2019.05.012高勇, 郝惠娣, 党睿, 等. 双层桨自吸式反应器的气含率特性. 石油化工, 2019, 48(5): 496 doi: 10.3969/j.issn.1000-8144.2019.05.012 [14] Zhao L J, Yu Z L, Xu P J, et al. Influence of number and arrangement pattern of reversing blade on mixing uniformity of concrete. J Chang’ an Univ Nat Sci, 2016, 36(4): 103 doi: 10.19721/j.cnki.1671-8879.2016.04.014赵利军, 余志龙, 徐鹏杰, 等. 返回叶片数量及排布方式对混凝土搅拌均匀性的影响. 长安大学学报(自然科学版), 2016, 36(4): 103 doi: 10.19721/j.cnki.1671-8879.2016.04.014 [15] Gopaul C, Andrews R. The effect of atmospheric turbulence on entangled orbital angular momentum states. New J Phys, 2007, 9(4): 94 doi: 10.1088/1367-2630/9/4/094 [16] Clausen P, Wicke M, Shewchuk J R, et al. Simulating liquids and solid-liquid interactions with lagrangian meshes. ACM Trans Graph, 2013, 32(2): 17 [17] Mohammadi A, Arabanian A S, Dalafi A. The impact of the spectral filter bandwidth on the spectral entanglement and indistinguishability of photon pairs of SPDC process. Int J Opt Photonics, 2018, 12(2): 119 doi: 10.29252/ijop.12.2.119 -

下载:

下载: