| [1] |

Xiong Z, Jiang W, Shi Y, et al. Evaluation of high-temperature strength of Mo/PSZ composites by modified small punch tests. Mater Trans, 2005, 46(3): 631 doi: 10.2320/matertrans.46.631

|

| [2] |

Guo Y L, Tang L, Zhang J Y. Sintering, microstructure, and electrical conductivity of zirconia-molybdenum cermet. J Mater Eng Perform, 2015, 24(8): 3180 doi: 10.1007/s11665-015-1562-6

|

| [3] |

Zhang D D, Nie F, Wei S Z, et al. Influence of process control agent on the refinement of Al2O3/Mo composite powder. Powder Metall Technol, 2011, 29(6): 403张丹丹, 倪锋, 魏世忠, 等. 过程控制剂对Al2O3/Mo复合粉末细化的影响. 粉末冶金技术, 2011, 29(6): 403

|

| [4] |

Kats M, Byl’kova Z I, Bogin N, et al. Thermal conductivity of lamellar metal/cermet composite materials based on ZrO2-Mo and Mo. Poroshk Metall, 1985, 266(2): 61

|

| [5] |

Wang Q, Guo C, Liu Y X. Research on metal-ceramic die material used for robot cover. Powder Metall Technol, 2020, 38(3): 357 doi: 10.19591/j.cnki.cn11-1974/tf.2019120012王强, 郭超, 刘永兴. 机器人覆盖件用金属陶瓷模具材料的研究. 粉末冶金技术, 2020, 38(3): 357 doi: 10.19591/j.cnki.cn11-1974/tf.2019120012

|

| [6] |

Martinelli J R, Sene F F. Electrical resistivity of ceramic-metal composite materials: application in crucibles for induction furnaces. Ceram Int, 2000, 26(3): 325 doi: 10.1016/S0272-8842(99)00059-0

|

| [7] |

Mclachlan D S, Blaszkiewicz M. Electric resistivity of composites. J Am Ceram Soc, 1990, 73(8): 2187 doi: 10.1111/j.1151-2916.1990.tb07576.x

|

| [8] |

Tchmutin I, Ponomarenko A, Krinichnaya E, et al. Electrical properties of composites based on conjugated polymers and conductive fillers. Carbon, 2003, 41: 1391 doi: 10.1016/S0008-6223(03)00067-8

|

| [9] |

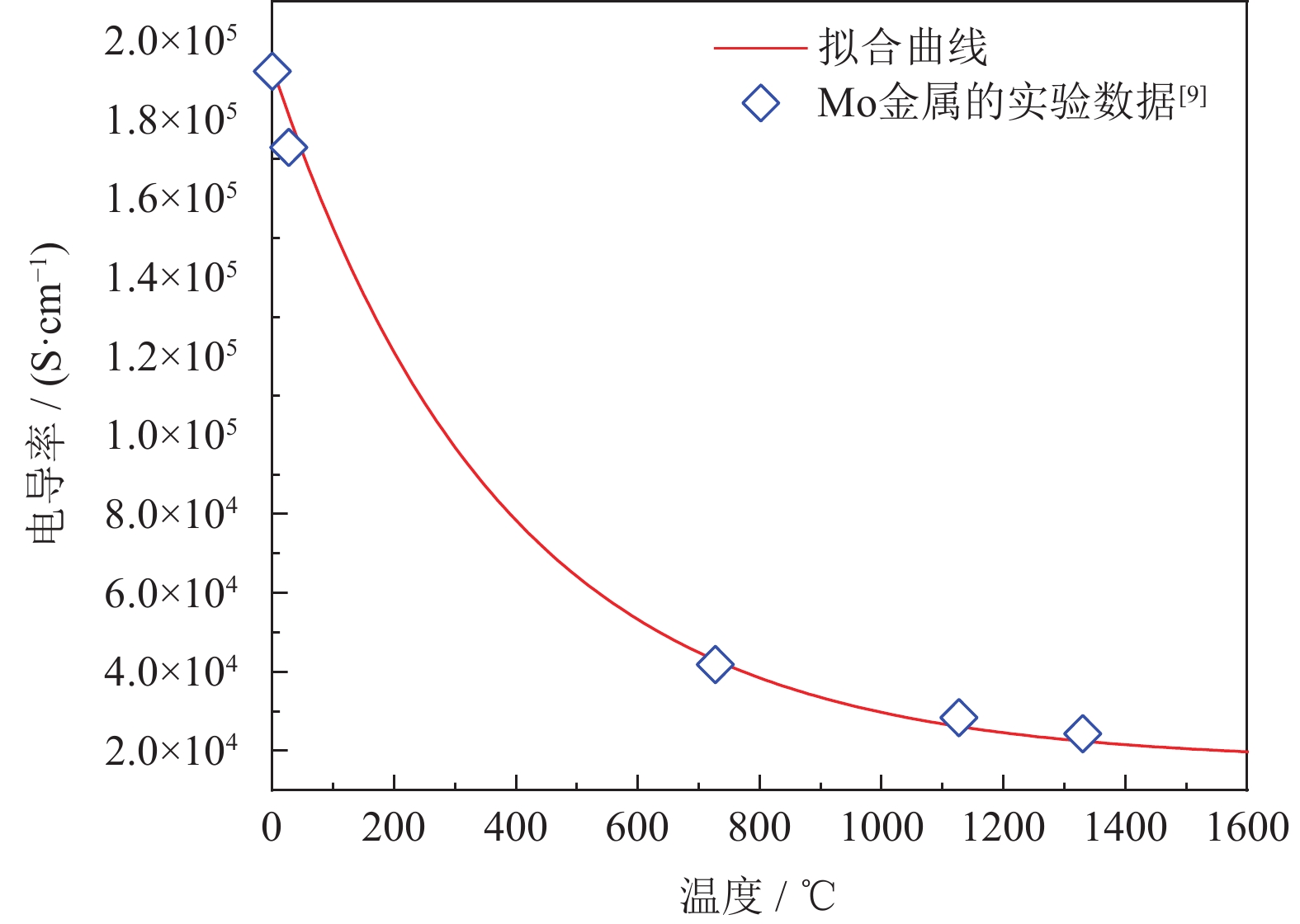

Wang L S. Special Ceramic. Changsha: Central South University Press, 1994王零森. 特种陶瓷. 长沙: 中南工业大学出版社, 1994

|

| [10] |

Muccillo E N S, Kleitz M. Impedance spectroscopy of Mg-partially stabilized zirconia and cubic phase decomposition. J Eur Ceram Soc, 1996, 16(4): 453 doi: 10.1016/0955-2219(95)00125-5

|

| [11] |

Peters D W, Feinstein L, Peltzer C. On the high-temperature electrical conductivity of alumina. J Chem Phy, 1965, 42(7): 2345 doi: 10.1063/1.1696298

|

| [12] |

Seemann H E. The thermal and electrical conductivity of fused quartz as a function of temperature. Phys Rev, 1928, 31(1): 119 doi: 10.1103/PhysRev.31.119

|

| [13] |

Ishibashi H, Tobimatsu H, Hayashi K, et al. Characterization of Mo-SiO2 functionally graded materials. Metall Mater Trans A, 2000, 31(1): 299 doi: 10.1007/s11661-000-0074-6

|

| [14] |

Egorov F F. Electrical conductivity of ZrN-Al2O3, Mo-Al2O3, and ZrN-Mo composite powders. Sov Powder Metall Met Ceram, 1980, 19(10): 705 doi: 10.1007/BF00793421

|

| [15] |

Zhao H. Research and development on the sintering techniques of molybdenum and molybdenum alloys. Powder Metall Technol, 2019, 37(5): 382 doi: 10.19591/j.cnki.cn11-1974/tf.2019.05.010赵虎. 钼及钼合金烧结技术研究及发展. 粉末冶金技术, 2019, 37(5): 382 doi: 10.19591/j.cnki.cn11-1974/tf.2019.05.010

|

| [16] |

Mizusaki J, Tsuchiya S, Waragi K, et al. Simple mathematical model for the electrical conductivity of highly porous ceramics. J Am Ceram Soc, 1996, 79(1): 109 doi: 10.1111/j.1151-2916.1996.tb07887.x

|

下载:

下载: