-

摘要: TiAl基合金具有优异的高温性能,是一种极具竞争力的新型轻质高温结构材料,在汽车、军工、航空航天等领域具有广阔的发展潜力和应用前景。然而,TiAl基合金室温脆性较大,成形困难,是阻碍其发展与应用的主要瓶颈之一。增材制造基于“离散+堆积”的成形思想,以激光、电子束、电弧等作为高能热源,通过熔化丝材或者粉末,逐层堆积实现零件的近净成形,是TiAl基合金最前沿、最具潜力的成形技术。本文主要概述了激光增材制造、电子束选区熔化、电弧增材制造TiAl基合金的研究进展,并展望了增材制造TiAl基合金的研究方向。Abstract: TiAl-based alloys have the excellent high-temperature properties as a highly competitive new lightweight high-temperature structural material, showing the broad development prospect and application potential in the automotive, military, aerospace, and other fields. However, because of the nature and inherent brittleness, the TiAl-based alloys are difficult to form, which inhibits the further development and the practical application. The additive manufacturing based on the forming idea of "discrete + accumulation" represents the most advanced and potential forming technology for the TiAl-based alloys, which uses the laser, electron beam, and arc as the high energy heat source to melt wires or powders and then stack them layer by layer. The research progress of TiAl-based alloys prepared by laser additive manufacturing, electron beam selective melting, and wire and arc additive manufacturing was summarized in this paper, and the future research direction of the TiAl-based alloys fabricated by additive manufacturing was prospected.

-

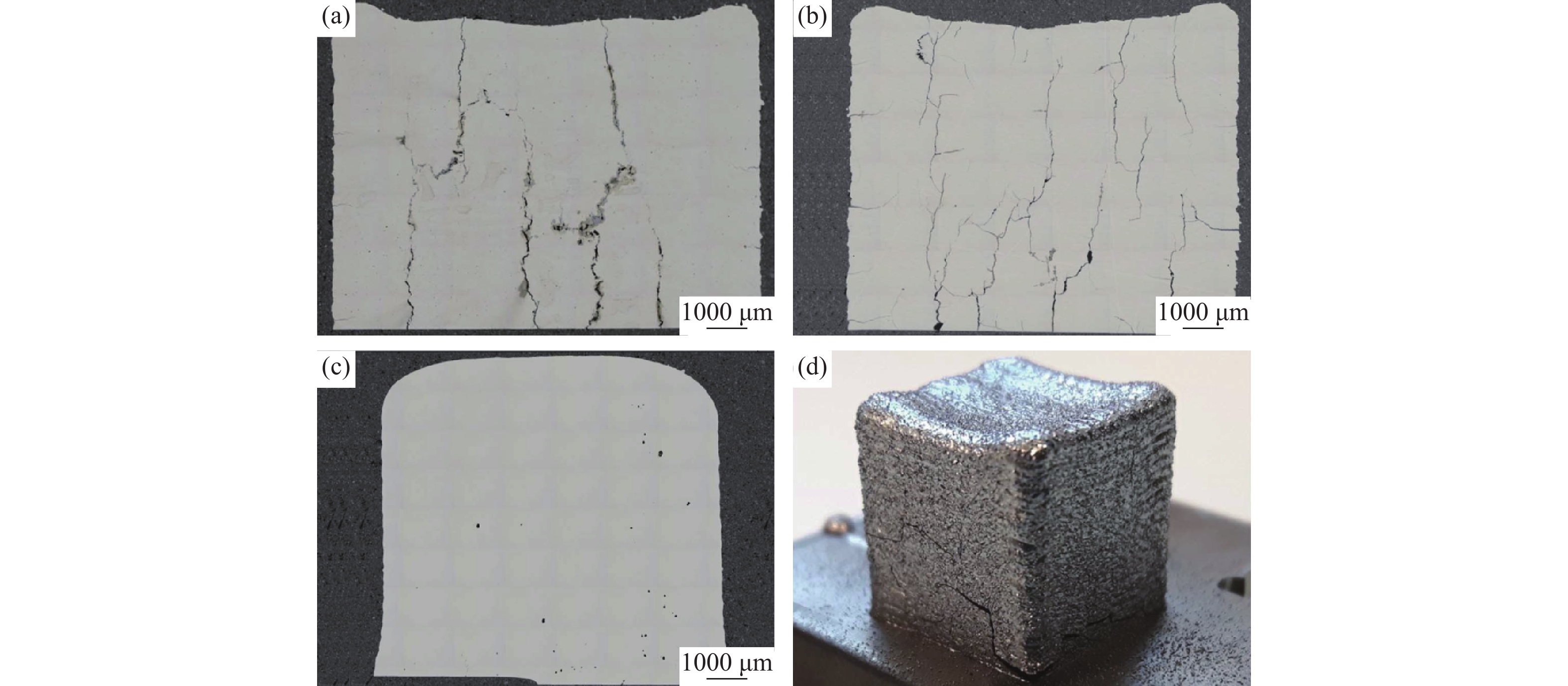

图 1 激光熔化沉积成形TiAl基合金中的裂纹[10]:(a)散焦+3.81 mm,功率200 W;(b)散焦‒3.81 mm,功率200 W;(c)散焦+3.81 mm,功率300 W;(d)散焦‒3.81 mm,功率300 W

Figure 1. Cracks in the TiAl-based alloys formed by LMD[10]: (a) defocused to +3.81 mm at 200 W; (b) defocused to ‒3.81 mm at 200 W; (c) defocused to +3.81 mm at 300 W; (d) defocused to ‒3.81 mm at 300 W

表 1 电子束选区熔化与传统工艺制备TiAl合金拉伸性能的对比

Table 1. Tensile properties comparison of the TiAl alloys prepared by SEBM and traditional process

文献 材料 工艺过程 屈服强度 / MPa 抗拉强度 / MPa 延伸率 / % [27] Ti‒48Al‒2Cr‒2Nb 电子束选区熔化 — 503 — [27] Ti‒48Al‒2Cr‒2Nb 电子束选区熔化+热等静压+退火(1260 ℃/2 h) 382 474 1.30 [27] Ti‒48Al‒2Cr‒2Nb 电子束选区熔化+热等静压+退火(1360 ℃/2 h) 373 429 0.80 [29] Ti‒47Al‒2Cr‒2Nb 电子束选区熔化 — 556~684 0.31~0.70 [30] Ti‒47Al‒2Cr‒2Nb 电子束选区熔化 462~523 462~568 0.27~0.98 [31] Ti‒48Al‒2Cr‒2Nb 电子束选区熔化+热等静压 370~90 430~450 1.00~1.20 [31] Ti‒48Al‒2Cr‒2Nb 电子束选区熔化+退火(1320 ℃/2 h) 350~370 460~480 1.00~1.20 [32] Ti‒48Al‒2Cr‒2Nb 铸造 312±10 570±20 0.48±0.05 [33] Ti‒48Al‒2Cr‒2Nb 铸造 — 510 0.4 [34] Ti‒48Al‒2Cr‒2Nb‒1B 锻造(1380 ℃/1 h)+空冷 440±15 557±15 1.30±0.10 -

[1] Kesler M S, Goyel S, Ebrahimi F, et al. Effect of microstructural parameters on the mechanical behavior of TiAlNb(Cr, Mo) alloys with γ+σ microstructure at ambient temperature. J Alloys Compd, 2017, 695: 2672 doi: 10.1016/j.jallcom.2016.11.181 [2] Zhou H T, Kong F T, Wang X P, et al. High strength in high Nb containing TiAl alloy sheet with fine duplex microstructure produced by hot pack rolling. J Alloys Compd, 2017, 695: 3495 doi: 10.1016/j.jallcom.2016.12.005 [3] Palomares-García A J, Pérez-Prado M T, Molina-Aldareguia J M. Effect of lamellar orientation on the strength and operating deformation mechanisms of fully lamellar TiAl alloys determined by micropillar compression. Acta Mater, 2017, 123: 102 doi: 10.1016/j.actamat.2016.10.034 [4] Xu W C, Jin X Z, Huang K, et al. Improvement of microstructure, mechanical properties and hot workability of a TiAl‒Nb‒Mo alloy through hot extrusion. Mater Sci Eng A, 2017, 705: 200 doi: 10.1016/j.msea.2017.08.082 [5] Ding J, Lin J P, Zhang M H, et al. High-temperature torsion induced gradient microstructures in high Nb‒TiAl alloy. Mater Lett, 2017, 209: 193 doi: 10.1016/j.matlet.2017.07.124 [6] Shi W T, Wang P, Liu Y D, et al. Crack initiation mechanism and experiment study of process optimization of TiAl alloy formed by selective laser melting. Chin J Rare Met, 2019, 43(4): 349石文天, 王朋, 刘玉德, 等. 选区激光熔化TiAl合金裂纹产生机制及工艺优化试验研究. 稀有金属, 2019, 43(4): 349 [7] Sun X, Yang H C, Shao W S, et al. Study on integrated fabrication of cathode-heater assembly by 3D printing. Powder Metall Technol, 2020, 38(4): 300孙信, 杨怀超, 邵文生, 等. 3D打印一体化制备阴极热子组件研究. 粉末冶金技术, 2020, 38(4): 300 [8] Zhang G X, Liu S F Yang X, et al. Research progress on preparation of biological implant materials by additive manufacturing. Powder Metall Technol, 2019, 37(4): 312张光曦, 刘世锋, 杨鑫, 等. 增材制造技术制备生物植入材料的研究进展. 粉末冶金技术, 2019, 37(4): 312 [9] Debroy T, Wei H L, Zuback J S, et al. Additive manufacturing of metallic components — process, structure and properties. Prog Mater Sci, 2018, 92: 112 doi: 10.1016/j.pmatsci.2017.10.001 [10] Sharman A R C, Hughes J I, Ridgway K. Characterisation of titanium aluminide components manufactured by laser metal deposition. Intermetallics, 2018, 93: 89 doi: 10.1016/j.intermet.2017.11.013 [11] Shi X Z, Ma S Y, Liu C M, et al. Parameter optimization for Ti‒47Al‒2Cr‒2Nb in selective laser melting based on geometric characteristics of single scan tracks. Opt Laser Technol, 2017, 90: 71 doi: 10.1016/j.optlastec.2016.11.002 [12] Weisheit A, Mordike B L, Smarsly W, et al. Laser surface remelting and laser surface gas alloying of an intermetallic TiAl alloy. Laser Eng, 2000, 10(1): 63 [13] Yang Y, Dang M Z, Li W, et al. Study on cracking mechanism and inhibiting process of TiAl alloys fabricated by selective laser melting. J Mech Eng, 2020, 56(3): 181 doi: 10.3901/JME.2020.03.181杨益, 党明珠, 李伟, 等. 激光选区熔化钛铝合金裂纹形成机理及抑制研究. 机械工程学报, 2020, 56(3): 181 doi: 10.3901/JME.2020.03.181 [14] Gussone J, Hagedorn Y C, Gherekhloo H, et al. Microstructure of γ-titanium aluminide processes by selective laser melting at elevated temperatures. Intermetallics, 2015, 66: 133 doi: 10.1016/j.intermet.2015.07.005 [15] Liu Z Q, Xu G J, Ma R X, et al. Properties of TiAl alloy prepared by additive manufacturing with laser coaxial powder feeding. Chin J Lasers, 2019, 46(3): 146刘占起, 徐国建, 马瑞鑫, 等. 激光同轴送粉增材制造TiAl合金的性能. 中国激光, 2019, 46(3): 146 [16] Liu Z Q, Wang W B, Ma R X, et al. Microstructure and properties of γ-TiAl alloy fabricated by laser melting deposition. Rare Met Mater Eng, 2020, 49(6): 1925刘占起, 王文博, 马瑞鑫, 等. 激光熔化沉积制造γ-TiAl合金的组织与性能. 稀有金属材料与工程, 2020, 49(6): 1925 [17] Liu Z Q, Ma R X, Wang W B, et al. Effect of substrate material on the microstructure, texture, phase and microhardness of a Ti‒48Al‒2Cr‒2Nb alloy processed by laser melting deposition. Rare Met Mater Eng, 2020, 49(7): 2262刘占起, 马瑞鑫, 王文博, 等. 基板材料对激光熔化沉积制造Ti‒48Al‒2Cr‒2Nb合金组织、织构、相和显微硬度的影响. 稀有金属材料与工程, 2020, 49(7): 2262 [18] Liu Z Q, Ma R X, Xu G J, et al. Effects of annealing on microstructure and mechanical properties of γ-TiAl alloy fabricated via laser melting deposition. Trans Nonferrous Met Soc China, 2020, 30(4): 917 doi: 10.1016/S1003-6326(20)65265-7 [19] Zhang J S, Cheng X, Zhang S Q, et al. Oxidation performance of Ti‒48Al‒2Nb‒2Cr intermetallic compounds prepared by laser additive manufacturing. Chin J Lasers, 2018, 45(4): 146张俊生, 程序, 张述泉, 等. 激光增材制造Ti‒48Al‒2Nb‒2Cr金属间化合物氧化性能. 中国激光, 2018, 45(4): 146 [20] Li W, Liu J, Wen S F, et al. Crystal orientation, crystallographic texture and phase evolution in the Ti‒45Al‒2Cr‒5Nb alloy processed by selective laser melting. Mater Charact, 2016, 113: 125 doi: 10.1016/j.matchar.2016.01.012 [21] Li W, Liu J, Zhou Y, et al. Effect of laser scanning speed on a Ti‒45Al‒2Cr‒5Nb alloy processed by selective laser melting: microstructure, phase and mechanical properties. J Alloys Compd, 2016, 688: 626 doi: 10.1016/j.jallcom.2016.07.206 [22] Li W, Liu J, Zhou Y, et al. Effect of substrate preheating on the texture, phase and nanohardness of a Ti‒45Al‒2Cr‒5Nb alloy processed by selective laser melting. Scr Mater, 2016, 118: 13 doi: 10.1016/j.scriptamat.2016.02.022 [23] Franzén S F. Titanium Aluminide Manufactured by Electron Beam Melting [Dissertation]. Gothenburg: Chalmers University of Technology, 2010 [24] Milberg J, Sigl M. Electron beam sintering of metal powder. Prod Eng, 2008, 2(2): 117 doi: 10.1007/s11740-008-0088-2 [25] Schwerdtfeger J, Körner C. Selective electron beam melting of Ti‒48Al‒2Cr‒2Nb: Microstructure and aluminium loss. Intermetallics, 2014, 49: 29 doi: 10.1016/j.intermet.2014.01.004 [26] Murr L E, Gaytan S M, Ceylan A, et al. Characterization of titanium aluminide alloy components fabricated by additive manufacturing using electron beam melting. Acta Mater, 2010, 58(5): 1887 doi: 10.1016/j.actamat.2009.11.032 [27] Chen W, Yang Y, Liu L L, et al. Microstructure control and tensile properties of EBM γ-TiAl. Aeronaut Manuf Technol, 2017(Suppl 1): 37陈玮, 杨洋, 刘亮亮, 等. 电子束增材制造γ-TiAl显微组织调控与拉仲性能研究. 航空制造技术, 2017(增刊1): 37 [28] Yue H Y, Chen Y Y, Wang X P, et al. Effect of beam current on microstructure, phase, grain characteristic and mechanical properties of Ti‒47Al‒2Cr‒2Nb alloy fabricated by selective electron beam melting. J Alloys Compd, 2018, 750: 617 doi: 10.1016/j.jallcom.2018.03.343 [29] Chen Y Y, Yue H Y, Wang X P. Microstructure, texture and tensile property as a function of scanning speed of Ti‒47Al‒2Cr‒2Nb alloy fabricated by selective electron beam melting. Mater Sci Eng A, 2018, 713: 195 doi: 10.1016/j.msea.2017.12.020 [30] Yue H Y, Chen Y Y, Wang X P, et al. Microstructure, texture and tensile properties of Ti‒47Al‒2Cr‒2Nb alloy produced by selective electron beam melting. J Alloys Compd, 2018, 766: 450 doi: 10.1016/j.jallcom.2018.07.025 [31] Biamino S, Penna A, Ackelid U, et al. Electron beam melting of Ti‒48Al‒2Cr‒2Nb alloy: Microstructure and mechanical properties investigation. Intermetallics, 2011, 19(6): 776 doi: 10.1016/j.intermet.2010.11.017 [32] Han J C, Xiao S L, Tian J, et al. Microstructure characterization and tensile properties of a Ni-containing TiAl-based alloy with heat treatment. Rare Met, 2016, 35(1): 26 doi: 10.1007/s12598-015-0626-y [33] Bao C L, Xie H S, Zhao J, et al. Effects of HIP on microstructure and mechanical properties of cast Ti‒48Al‒2Cr‒2Nb alloy. Foundry, 2017, 66(1): 64 doi: 10.3969/j.issn.1001-4977.2017.01.014包春玲, 谢华生, 赵军, 等. 热等静压处理对铸造Ti‒48Al‒2Cr‒2Nb合金组织和力学性能的影响. 铸造, 2017, 66(1): 64 doi: 10.3969/j.issn.1001-4977.2017.01.014 [34] Hu D, Godfrey A, Blenkinsop P A, et al. Processing-property-microstructure relationships in TiAl-based alloys. Metall Mater Trans A, 1998, 29(13): 919 doi: 10.1007/s11661-998-1000-6 [35] Sun S J. TiAl alloy turbine blade produced by additive manufacturing method applied to aircraft engine. Powder Metall Ind, 2015, 25(1): 65孙世杰. 增材制造方法生产的TiAl合金零件将被应用于飞机发动机涡轮叶片. 粉末冶金工业, 2015, 25(1): 65 [36] Ma Y, Cuiuri D, Hoye N, et al. The effect of location on the microstructure and mechanical properties of titanium aluminides produced by additive layer manufacturing using in-situ alloying and gas tungsten arc welding. Mater Sci Eng A, 2015, 631: 230 doi: 10.1016/j.msea.2015.02.051 [37] Ma Y, Cuiuri D, Li H J, et al. The effect of postproduction heat treatment on γ-TiAl alloys produced by the GTAW-based additive manufacturing process. Mater Sci Eng A, 2016, 657: 86 doi: 10.1016/j.msea.2016.01.060 [38] Ma Y, Cuiuri D, Hoye N, et al. Effects of wire feed conditions on in situ alloying and additive layer manufacturing of titanium aluminides using gas tungsten arc welding. J Mater Res, 2014, 29(17): 2066 doi: 10.1557/jmr.2014.203 [39] Wang J, Pan Z X, Wei L L, et al. Introduction of ternary alloying element in wire arc additive manufacturing of titanium aluminide intermetallic. Addit Manuf, 2019, 27: 236 -

下载:

下载: