Effect of long term ageing on γ' phase in spray formed FGH100L superalloy settled by different solution treatment

-

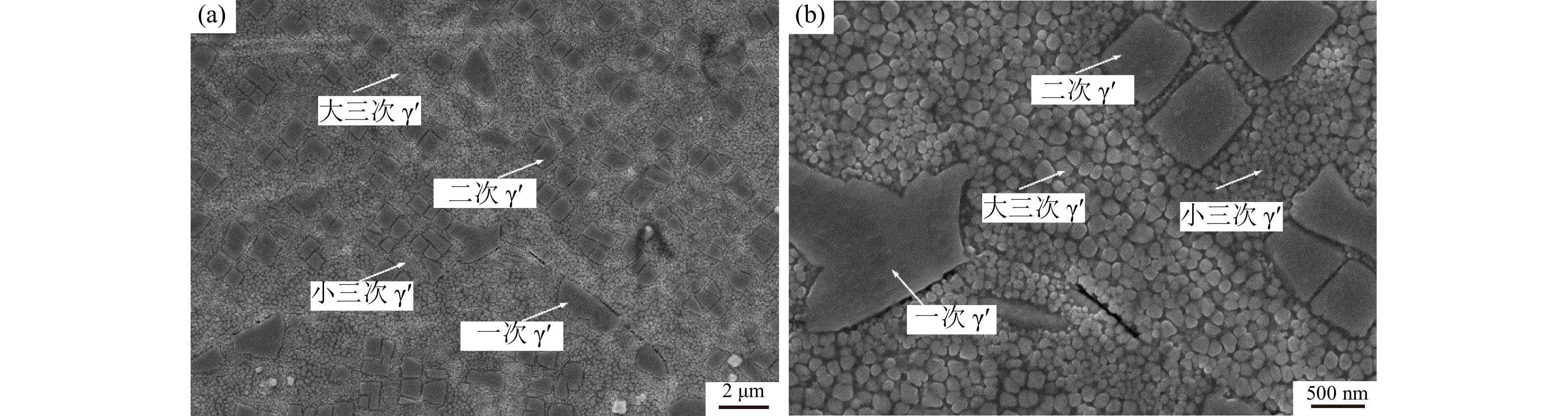

摘要: 对喷射成形镍基高温合金FGH100L分别进行亚固溶和过固溶热处理,采用扫描电镜研究了长期时效对合金中γ′相尺寸和形貌的影响。结果表明:亚固溶热处理合金中有四种尺寸的γ′相,在长期时效过程中,一次、二次和大三次γ'相尺寸均有明显增长,小三次γ'相尺寸略有减小,四种γ'相长大规律均不符合Lifshitz,Slyozov和Wagner(LWS)粗化模型。一次γ'相、二次γ'相和大三次γ'相出现相似的分裂现象,二次γ'相在时效500 h后出现不稳定生长现象,合金中无拓扑密排(TCP)相析出。过固溶热处理合金中有三种尺寸的γ′相,在长期时效过程中,一次γ'相尺寸略有增长,二次γ'相和三次γ'相尺寸并没有明显变化,三种γ'相长大规律均不符合LSW粗化模型。一次γ'相和三次γ'相形貌基本不变,二次γ'相处于正在分裂状态,没有完全分裂,合金中无TCP相析出。过固溶热处理合金的γ'相尺寸和形貌变化比亚固溶热处理合金小,前者组织稳定性更高。Abstract: The effects of long term ageing on the size and morphology of γ' precipitations in the spray formed nickel-based superalloy FGH100L after subsolvs and supersolvs heat treatment (HT) were studied by scanning electron microscope (SEM). The results show that there are four kinds of γ' phases in the alloys after the subsolvs HT, and during the long term ageing, the sizes of primary, secondary, and large tertiary γ' phases increase while the size of small tertiary γ' phase decreases. None of these γ' phases grow in accordance with the coarsening kinetics as the Lifshitz, Slyozov, and Wagner (LWS) theory during the long term ageing. Apart from the small tertiary γ' phase, other three kinds of γ' phases began splitting in a similar way, and the secondary γ' phase shows the unstable protrusion after ageing for 500 h. No topological close packed (TCP) phase is found in the subsolvs HTed alloys. There are three kinds of γ' phases in the alloys after the supersolvs HT, and during the long term ageing, the primary γ' phase grows up slightly while the secondary and tertiary γ' phases show no obvious change. None of these γ' phases grow in accordance with the coarsening kinetics as LWS theory during the long term ageing. The morphology of primary and tertiary γ' phases changes little, and the secondary γ' phase is splitting at the early stage. No TCP phase is found in the supersolvs HTed alloys. The size and morphology variations of γ' phases in the supersolvs HTed alloys are smaller than those in the subsolvs HTed alloys, indicating that the former has the better microstructure stability.

-

Key words:

- nickel-based superalloys /

- long-term ageing /

- γ' phase /

- spray forming /

- solution treatment

-

表 1 经760 ℃时效处理后Sub-SHT合金中γ'相粗化速率与拟合优度

Table 1. Coarsening rate and fit goodness of the γ' precipitates in the Sub-SHT alloys after the long-term ageing at 760 ℃

γ'相种类 粗化速率 / (μm3·h−1) 拟合优度,R2 一次γ' 4.5400×10−2 0.767 二次γ' 4.0390×10−4 0.880 大三次γ' 2.8460×10−5 0.850 小三次γ' −0.5286 ×10−9 0.346 表 2 经760 ℃时效处理后Super-SHT合金中γ'相粗化速率与拟合优度

Table 2. Coarsening rate and fit goodness of the γ' precipitates in the Super-SHT alloys after the long-term ageing at 760 ℃

γ'相种类 粗化速率 / (μm3·h−1) 拟合优度,R2 一次γ' 1.038×10−4 0.384 二次γ' 2.985×10−6 −0.280 三次γ' 0.156 0.184 -

[1] Gabb T P, Gayda J, Telesman J. NASA/TM-2003-212086 Realistic Subscale Evaluations of the Mechanical Properties of Advanced Disk Superalloys. Cleveland: Glenn Research Center, 2003 [2] Butzer G, Bowen K. Spray forming aerospace alloys. Adv Mater Proc, 1998, 153(3): 21 [3] Ge C C, Hao Z B, Yuan C, et al. Progress of research on preparation of spray formed new type 3rd generation PM superalloy // Proceedings of the 13th Annual Meeting of China Superalloys. Beijing, 2015: 407葛昌纯, 郝志博, 袁超, 等. 新型第三代粉末高温合金的喷射成型制备研究进展 // 第十三届中国高温合金年会论文集. 北京, 2015: 407 [4] Zhang H J, Du W H, Xin D M. Research on the microstructures and mechanical properties of high speed steel M2 produced by spray forming and traditional melting. Powder Metall Technol, 2019, 37(2): 124张海军, 杜文华, 辛栋梅. 喷射成形与传统熔炼高速钢M2的组织与力学性能研究. 粉末冶金技术, 2019, 37(2): 124 [5] Jia C L, Ge C C, Yan Q Z. Innovative technologies for powder metallurgy-based disk superalloys: Progress and proposal. Chin Phys B, 2016, 25(2): 026103 doi: 10.1088/1674-1056/25/2/026103 [6] Wu H X, Ge C C, Yan Q Z, et al. Plastic deformation behavior of spray formed superalloy FGH100. Mater Sci Eng A, 2017, 699: 156 doi: 10.1016/j.msea.2017.02.063 [7] Tian T, Ge C C, Li X G, et al. Influences of a hot-working process on the microstructural evolution and creep performance of a spray-formed nickel-based superalloy. Metals, 2020, 10(4): 454 doi: 10.3390/met10040454 [8] Tian T, Hao Z B, Jia C L, et al. Microstructure and properties of a new third generation powder metallurgy superalloy FGH100L. Acta Metall Sinica, 2019, 55(10): 1260 doi: 10.11900/0412.1961.2018.00500田甜, 郝志博, 贾崇林, 等. 新型第三代粉末高温合金FGH100L的显微组织与力学性能. 金属学报, 2019, 55(10): 1260 doi: 10.11900/0412.1961.2018.00500 [9] Jia C L, Zhang F L, Wei K, et al. Effective solution treatment can result in improved creep performance of superalloys. J Alloys Compd, 2019, 770: 166 doi: 10.1016/j.jallcom.2018.08.089 [10] Jia C L, Ge C C, Yan Q Z. Microstructure evolution and mechanical properties of disk superalloy under multiplex heat treatment. Mater Sci Eng A, 2016, 659: 287 doi: 10.1016/j.msea.2016.02.038 [11] Jia C L, Li Y, Zhang F L, et al. The creep behavior of a disk superalloy under different stress conditions. Met Powder Rep, 2018, 73(2): 94 doi: 10.1016/j.mprp.2018.02.002 [12] Tian T, Hao Z B, Li X G, et al. Influence of ageing treatment on microstructure and properties of a novel spray formed powder metallurgy superalloy FGH100L. J Alloys Compd, 2020, 830: 154699 doi: 10.1016/j.jallcom.2020.154699 [13] Liu C K, Zhou J Y, Wei Z W, et al. Evolution and quantitative characterization of γ' phase in FGH97 powder metallurgy superalloy during high-temperature heat exposure. Mater Mech Eng, 2018, 42(5): 9 doi: 10.11973/jxgccl201805002刘昌奎, 周静怡, 魏振伟, 等. 高温热暴露时FGH97粉末高温合金中γ'相的演变及其定量表征. 机械工程材料, 2018, 42(5): 9 doi: 10.11973/jxgccl201805002 [14] Wu K, Liu G Q, Hu B F, et al. Effect of solution cooling rate and post treatment on γ' precipitation and microhardness of a novel nickel-based P/M superalloy FGH98I. Rare Met Mater Eng, 2012, 41(7): 1267 doi: 10.3969/j.issn.1002-185X.2012.07.031吴凯, 刘国权, 胡本芙, 等. 固溶冷却速度和后处理对新型FGH98I镍基粉末高温合金γ'相析出和显微硬度的影响. 稀有金属材料与工程, 2012, 41(7): 1267 doi: 10.3969/j.issn.1002-185X.2012.07.031 [15] Zhang Y W, Han S B, Zhang G X, et al. Effect of long-term ageing on microstructure stability and mechanical property in FGH4097 PM super alloy. J Iron Steel Res, 2011, 23(Suppl 2): 494张义文, 韩寿波, 张国星, 等. 长时效后FGH4097合金的组织稳定性与力学性能. 钢铁研究学报, 2011, 23(增刊2): 494 [16] Jia J, Tao Y, Zhang Y W, et al. Microstructures and mechanical properties of as-HIP PM superalloy FGH98 // Proceedings of the 10~(th) China-Russia Symposium on Advanced Materials and Technologies. Beijing, 2009: 153 [17] Christofidou K A, Hardy M C, Li H, et al. On the effect of Nb on the microstructure and properties of next generation polycrystalline powder metallurgy Ni-based superalloys. Metall Mater Trans A, 2018, 49(9): 3896 doi: 10.1007/s11661-018-4682-4 [18] Smith T M, Bonacuse P, Sosa J, et al. A quantifiable and automated volume fraction characterization technique for secondary and tertiary γ' precipitates in Ni-based superalloys. Mater Charact, 2018, 140: 86 doi: 10.1016/j.matchar.2018.03.051 [19] Garg T P, Gayda J, Telesman J. The effects of heat treatment and microstructure variations on disk superalloy properties at high temperature // Superalloys 2008. Pennsylvania, 2008: 121 [20] Hu B F, Liu G Q, Wu K, et al. Morphological instability of γ' phase in nickel-based powder metallurgy superalloys. Acta Metall Sinica, 2012, 48(3): 257 doi: 10.3724/SP.J.1037.2011.00731胡本芙, 刘国权, 吴凯, 等. 镍基粉末冶金高温合金中γ'相形态不稳定性研究. 金属学报, 2012, 48(3): 257 doi: 10.3724/SP.J.1037.2011.00731 [21] Yoo Y S. Morphological instability of spherical γ' precipitates in a nickel base superalloy. Scr Mater, 2005, 53(1): 81 doi: 10.1016/j.scriptamat.2005.03.022 [22] Wang T T, Ge C C, Jia C L, et al. Fabrication and microstucture of spray formed powder metallurgy superalloy FGH4095M. Acta Phys Sinica, 2015, 64(10): 181王天天, 葛昌纯, 贾崇林, 等. 喷射成形粉末高温合金FGH4095M的制备及组织特征. 物理学报, 2015, 64(10): 181 [23] Baldan A. Review progress in Ostwald ripening theories and their applications to the γ'-precipitates in nickel-base superalloys: Part II Nickel-base superalloys. J Mater Sci, 2002, 37(12): 2379 doi: 10.1023/A:1015408116016 [24] Ardell A J, Nicholson R B, Eshelby J D. On the modulated structure of aged Ni−Al alloys. Acta Mater, 1966, 14(10): 1295 doi: 10.1016/0001-6160(66)90247-1 [25] Mullins W W, Sekerka R F. Morphological stability of a particle growing by diffusion or heat flow. J Appl Phys, 1963, 34(2): 323 doi: 10.1063/1.1702607 [26] Tiley J, Viswanathan G B, Srinivasan R, et al. Coarsening kinetics of γ' precipitates in the commercial nickel base superalloy René 88 DT. Acta Mater, 2009, 57(8): 2538 doi: 10.1016/j.actamat.2009.02.010 [27] Zhang L, Tian S G. Effect of long-term ageing on γ' phase and lattice constant of FGH95 P/M Ni-based superalloy. Powder Metall Technol, 2019, 37(3): 191张磊, 田素贵. 长期时效对FGH95镍基粉末高温合金γ'相及晶格常数的影响. 粉末冶金技术, 2019, 37(3): 191 [28] Kang F W, Sun J F, Zhang G Q, et al. Growth kinetics of γ' phase of spray formed ni-base superalloy during short-term ageing. Rare Met Mater Eng, 2007(7): 1205 doi: 10.3321/j.issn:1002-185X.2007.07.017康福伟, 孙剑飞, 张国庆, 等. 喷射成形镍基高温合金短期时效γ'相长大动力学. 稀有金属材料与工程, 2007(7): 1205 doi: 10.3321/j.issn:1002-185X.2007.07.017 [29] Cha P, Yeon D, Chung S. Phase-field study for the splitting mechanism of coherent misfitting precipitates in anisotropic elastic media. Scr Mater, 2005, 52(12): 1241 doi: 10.1016/j.scriptamat.2005.02.026 -

下载:

下载: