| [1] |

Mongkolchart W, Santiwong P, Chintavalakorn R, et al. Effect of surface treatment on physical and mechanical properties of nickel-titanium orthodontic archwires by fine particle shot peening method. Key Eng Mater, 2019, 801: 33 doi: 10.4028/www.scientific.net/KEM.801.33

|

| [2] |

Jiang Y, Chen J Z, Liu Y, et al. Progress of multi-layer ceramic capacitor (MLC). J Funct Mater Devices, 2003, 9(1): 100 doi: 10.3969/j.issn.1007-4252.2003.01.023蒋渝, 陈家钊, 刘颖, 等. 多层片式陶瓷电容器MLC研发进展. 功能材料与器件学报, 2003, 9(1): 100 doi: 10.3969/j.issn.1007-4252.2003.01.023

|

| [3] |

Sada T, Fujikawa N. Analysis of insulation resistance degradation in Ni-BaTiO3 multilayer ceramic capacitors under highly accelerated life test. Jpn J Appl Phys, 2017, 56(Suppl 10): 10PB04

|

| [4] |

Wang P, Xu H R, Zhu G S, et al. An efficient method to achieve MLCC miniaturization and ensure its reliability. J Mater Sci Mater Electron, 2017, 28(5): 4102 doi: 10.1007/s10854-016-6029-5

|

| [5] |

Qi H P, Cao H L, Huang Y D. Synthesis of flowerlike nickel particles and their microwave absorbing properties. J Cent South Univ, 2014, 21(8): 3007 doi: 10.1007/s11771-014-2269-9

|

| [6] |

Zaitsev A Y, Wilkinson D S, Weatherly G C, et al. The preparation of highly porous structures from filamentary nickel powders. J Power Sources, 2003, 123(2): 253 doi: 10.1016/S0378-7753(03)00534-2

|

| [7] |

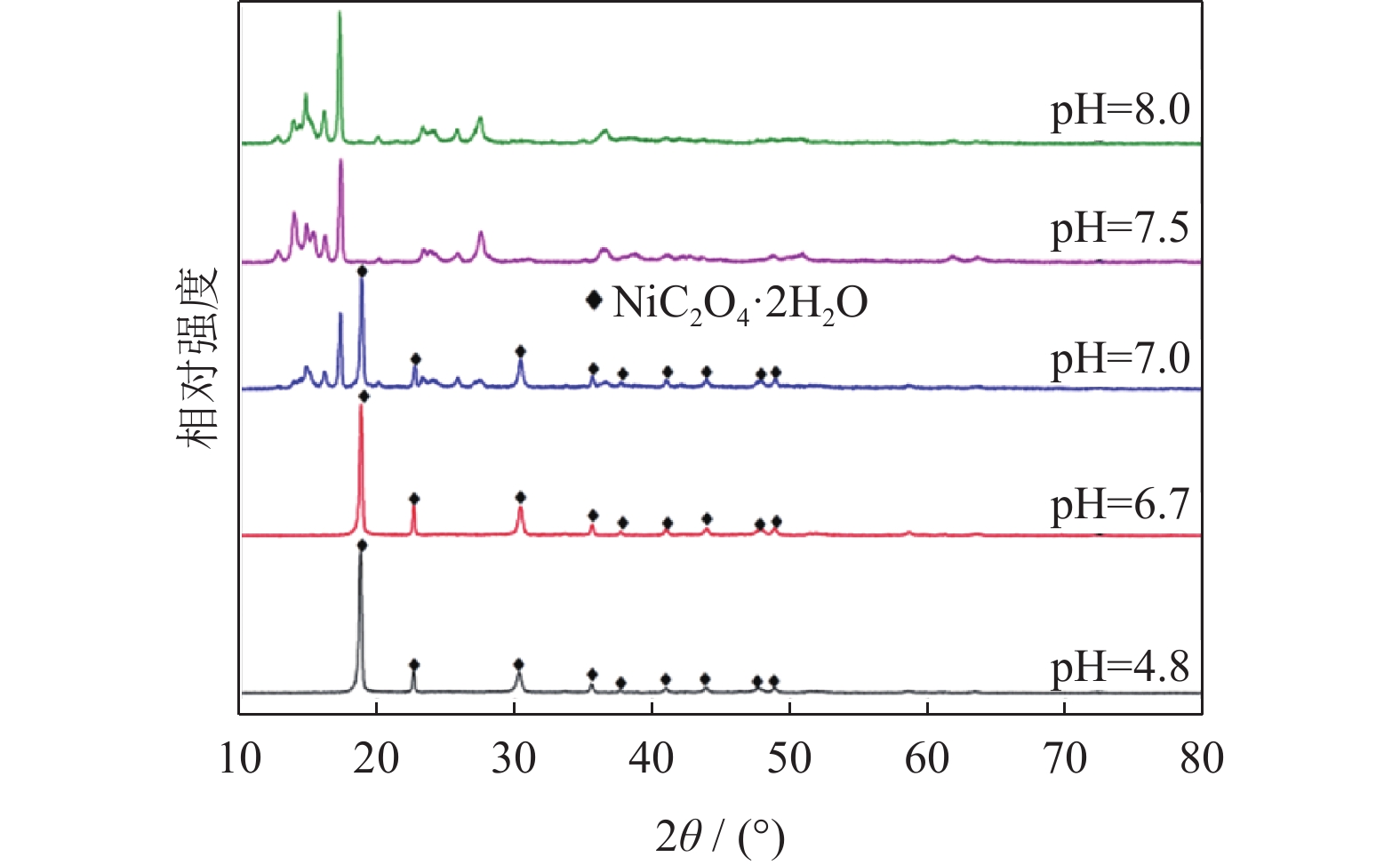

Tracey V A. Factors affecting the properties of nickel sintered structures for alkaline batteries. Ind Eng Chem Prod Res Dev, 1982, 21(4): 626 doi: 10.1021/i300008a023

|

| [8] |

Oh H J, Jo C H, Yoon C S, et al. Nickel oxalate dihydrate nanorods attached to reduced grapheneoxide sheets as a high-capacity anode for rechargeable lithium batteries. NPG Asia Mater, 2016, 8(5): e270 doi: 10.1038/am.2016.59

|

| [9] |

Jing L, Yang Q H, Zhang Z. Effects of additives on nickel electrowinning from sulfate system. Trans Nonferrous Met Soc China, 2010, 20(Suppl 1): 97

|

| [10] |

Meng L, Qu J K, Xie K Q, et al. Preparation of Ni from nickel laterite leaching solution by anion membrane electrolysis method. Chin J Nonferrous Met, 2015, 25(4): 1093 doi: 10.19476/j.ysxb.1004.0609.2015.04.034孟龙, 曲景奎, 谢克强, 等. 采用阴离子膜电解法从红土镍矿常压浸出液中制备金属镍. 中国有色金属学报, 2015, 25(4): 1093 doi: 10.19476/j.ysxb.1004.0609.2015.04.034

|

| [11] |

Panigrahi B B, Das K, Godkhindi M M. Dilatometry of ball milled nickel nano powder during non-isothermal sintering. Sci Sinter, 2007, 39(1): 25 doi: 10.2298/SOS0701025P

|

| [12] |

Baburaj E G, Hubert K T, Froes F H S. Preparation of Ni powder by mechanochemical process. J Alloys Compd, 1997, 257(1): 146

|

| [13] |

Zhou G L, Zhou H J, Yang Y W, et al. Method of removing iron and nickel carbonyl from synthesis gas. J Fuel Chem Technol, 2001, 29(Suppl): 241周广林, 周红军, 杨彦伟, 等. 从合成气脱羰基铁、羰基镍的方法. 燃料化学学报, 2001, 29(增刊): 241

|

| [14] |

Zhang S Y. Research on the Preparation of Ultrafine Nickel Powder by Chemical Vapor Deposition [Dissertation]. Changsha: Central South University, 2009张淑英. 化学气相沉积法制备超细镍粉的研究[学位论文]. 长沙: 中南大学, 2009

|

| [15] |

Si J J, Su X L. Preparation of ultrafine spherical nickle powder. Powder Metall Technol, 2021, 39(2): 177 doi: 10.19591/j.cnki.cn11-1974/tf.2019090003司佳佳, 苏晓磊. 超细球形镍粉的制备. 粉末冶金技术, 2021, 39(2): 177 doi: 10.19591/j.cnki.cn11-1974/tf.2019090003

|

| [16] |

Li L, Du J H, Gan G Y, et al. Study on preparation technology of nickel powder with liquid phase reduction method. Rare Met Mater Eng, 2015, 44(1): 36 doi: 10.1016/S1875-5372(15)30008-4

|

| [17] |

Yu Y, Ma H, Tian X X, et al. Synthesis and electromagnetic absorption properties of micro-nano nickel powders prepared with liquid phase reduction method. J Adv Dielect, 2016, 6(3): 1650025 doi: 10.1142/S2010135X16500259

|

| [18] |

Wu J H. Study on a New Method for Preparing Special Nickel Powder [Dissertation]. Changsha: Central South University, 2003邬建辉. 特种镍粉制备新方法研究[学位论文]. 长沙: 中南大学, 2003

|

| [19] |

Wu J H, Liu G, Tao S, et al. Preparation of fibrous nickel powder by precipitation transformation coupled with thermal decomposition. Trans Nonferrous Met Soc China, 2015, 25(8): 2653 doi: 10.1016/S1003-6326(15)63888-2

|

| [20] |

Yao Y L. Preparation of Ultrafine FeNi Alloy Powders by Thermal Decomposition Process and Their Microwave Absorbing Properties [Dissertation]. Changsha: Central South University, 2014姚永林. 超细FeNi合金粉热分解法制备及其吸波性能研究[学位论文]. 长沙: 中南大学, 2014

|

下载:

下载: