Microstructure and mechanical properties of nanoscale xSiC/Mg‒5.5Zn‒0.1Y alloys by solid phase synthesis

-

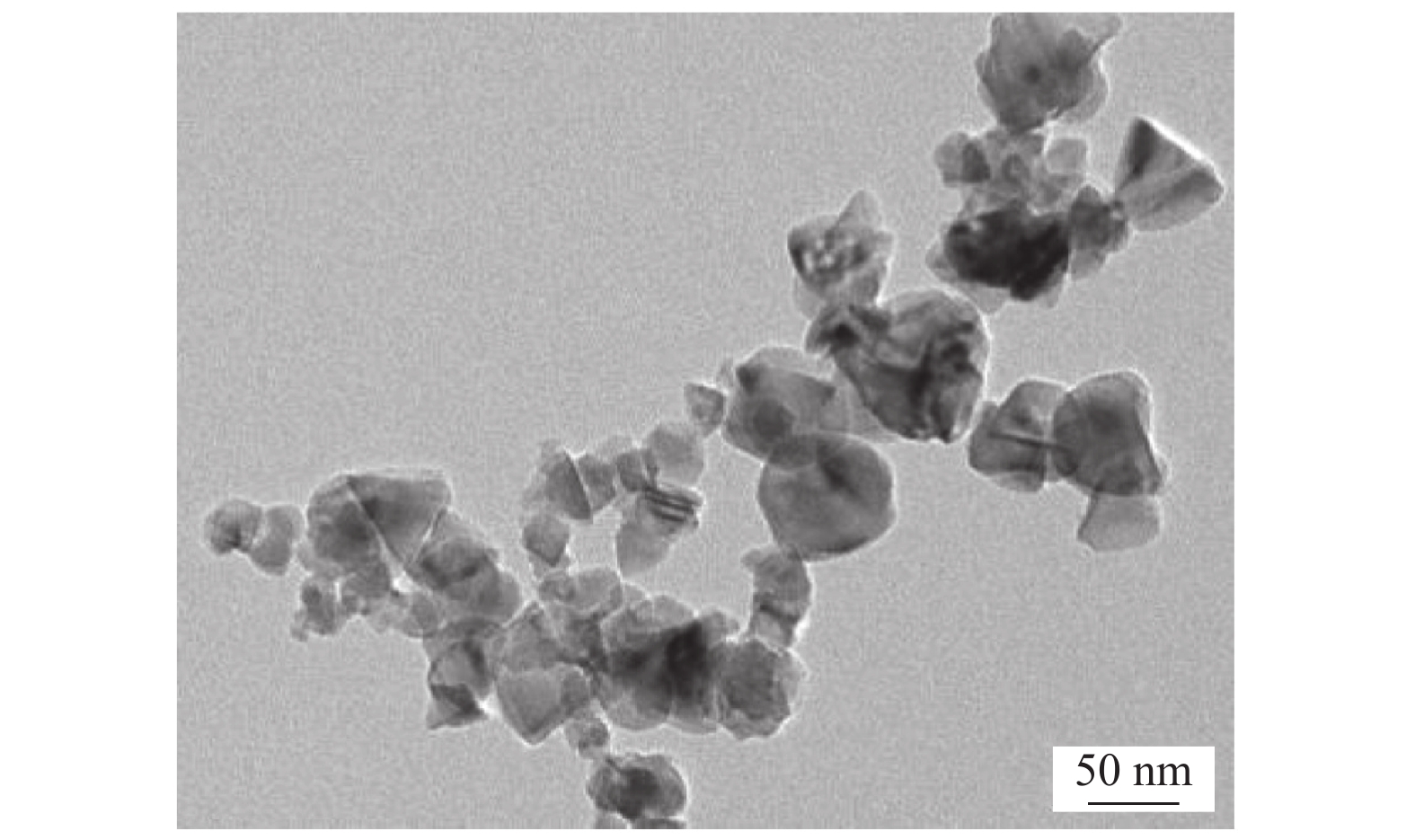

摘要: 通过固相合成的方法制备纳米级SiC颗粒增强Mg‒5.5Zn‒0.1Y合金,研究了SiC颗粒质量分数对Mg‒5.5Zn‒0.1Y合金组织及力学性能的影响。结果表明:随着SiC颗粒质量分数的提高,SiC颗粒分布状态变得更团聚,产生了明显的钉扎作用,具有显著细化晶粒的效果。SiC颗粒附近区域产生了大量位错,为添加质量分数2.0%SiC颗粒的Mg‒5.5Zn‒0.1Y合金再结晶形核提供有利条件,促进晶粒细化。提高SiC颗粒质量分数,合金硬度增大,加入质量分数2.0%SiC颗粒时,合金获得了最高硬度(HV 82)。提高SiC颗粒质量分数,降低了合金裂纹数量,SiC颗粒和Mg‒5.5Zn‒0.1Y合金发生界面脱粘现象,形成裂纹源并引起断裂。提高SiC颗粒质量分数能够使合金获得更高的强度与伸长率。Abstract: The Mg‒5.5Zn‒0.1Y alloys reinforced by the nanoscale SiC particles were prepared by solid phase synthesis, and the effect of SiC particle mass fraction on the microstructure and mechanical properties of Mg‒5.5Zn‒0.1Y alloys was investigated. The results show that, the distribution of SiC particles becomes more uniform with the increase of SiC particle mass fraction, which results in the significant napping and grain refinement. A large number of dislocations occur in the vicinity of SiC particles in the Mg‒5.5Zn‒0.1Y alloys doped by SiC particles in the mass fraction of 2.0%, which provide the favorable conditions for the recrystallization nucleation and promote the grain refinement. Increasing the SiC particle mass fraction can increase the hardness of alloys. When the SiC particle mass fraction is 2.0%, the Mg‒5.5Zn‒0.1Y alloys achieve the maximum hardness as HV 82. When the SiC particle mass fraction is increased, the number of cracks is reduced, the interface between the SiC particles and Mg‒5.5Zn‒0.1Y alloys is de-bonded, the crack source is formed, and the fracture is caused. The higher SiC particle mass fraction can make the alloys obtain the higher strength and elongation.

-

表 1 SiC颗粒物理性能

Table 1. Physical properties of the SiC particles

密度 / (g∙cm‒3) 熔点 / K 弹性模量 / GPa 热膨胀系数 / (106·K‒1) 导热系数 / (W∙m‒1∙K‒1) 纯度 / % 平均粒度 / μm 3.25 2650 420 4.5 100~200 99.5 50 表 2 添加不同质量分数SiC颗粒Mg‒5.5Zn‒0.1Y合金平均晶粒尺寸

Table 2. Average grain size of the Mg‒5.5Zn‒0.1Y alloys doped by SiC particles in different mass fraction

SiC颗粒质量分数 / % 0 0.5 1.0 2.0 平均粒径 / μm 35.6 28.6 26.5 21.4 表 3 添加不同质量分数SiC颗粒Mg‒5.5Zn‒0.1Y合金维氏硬度

Table 3. Vickers hardness of the Mg‒5.5Zn‒0.1Y alloys doped by SiC particles in different mass fraction

SiC颗粒质量分数 / % 0 0.5 1.0 2.0 硬度,HV 62.6 69.2 76.1 82.8 表 4 添加不同质量分数SiC颗粒Mg‒5.5Zn‒0.1Y合金强度及伸长率

Table 4. Strength and elongation of the Mg‒5.5Zn‒0.1Y alloys doped by SiC particles in different mass fraction

SiC颗粒质量分数 / % σb / MPa σ0.2 / MPa δ / % 0 246 166 3.84 0.5 263 182 6.52 1.0 281 196 7.25 2.0 294 208 8.33 -

[1] Shen S D, Chen D, Chen Z H, et al. Phase composition and interface of rapidly solidified/powder metallurgy AZ91/SiCp Mg-based composite material. Chin J Nonferrous Met, 2008, 18(7): 1185盛绍顶, 陈鼎, 陈振华, 等. 快速凝固/粉末冶金AZ91/SiCp镁基复合材料的相组成及界面. 中国有色金属学报, 2008, 18(7): 1185 [2] Ren F Y, Xu L, Li C Y, et al. Research progress in the preparation of particle-reinforced magnesium matrix composites by powder metallurgy. Powder Metall Technol, 2020, 38(1): 66 doi: 10.19591/j.cnki.cn11-1974/tf.2020.01.010任峰岩, 许磊, 历长云, 等. 粉末冶金法制备颗粒增强镁基复合材料的研究进展. 粉末冶金技术, 2020, 38(1): 66 doi: 10.19591/j.cnki.cn11-1974/tf.2020.01.010 [3] Guan F, Cheng J L. Property modification of ZK60 Al‒Mg alloy by Y-doping. Chin J Vac Sci Technol, 2020, 40(10): 978关锋, 程军丽. Y添加量对齿轮用真空感应熔炼ZK60合金组织及拉伸性能的影响. 真空科学与技术学报, 2020, 40(10): 978 [4] Peng P, Tang A T, She J, et al. Ultrafine grained magnesium alloys research: status quo and future directions. Mater Rep, 2019, 33(9): 1526 doi: 10.11896/cldb.18010063彭鹏, 汤爱涛, 佘加, 等. 超细晶镁合金的研究现状及展望. 材料导报, 2019, 33(9): 1526 doi: 10.11896/cldb.18010063 [5] Yu H H, Guo Z M, Luo J, et al. Effect of sintering temperature on the microstructure and properties of SiO2 particles strengthening AZ91 magnesium alloy. Powder Metall Technol, 2014, 32(5): 338于海华, 郭志猛, 罗骥, 等. 烧结温度对SiO2颗粒强化AZ91镁合金组织与性能的影响. 粉末冶金技术, 2014, 32(5): 338 [6] Sun X F, Wang C J, Deng K K, et al. Aging behavior of AZ91 matrix influenced by 5 μm SiCp: Investigation on the microstructure and mechanical properties. J Alloys Compd, 2017, 727(5): 1263 [7] Wu G H, Xiao H, Zhou H Z, et al. Anisotropy of warm-temperature tensile properties of extruded AZ31 magnesium alloy. Chin J Nonferrous Met, 2017, 27(1): 57吴国华, 肖寒, 周慧子, 等. 挤压态AZ31镁合金温热拉伸性能的各向异性. 中国有色金属学报, 2017, 27(1): 57 [8] Paramsothy M, Chan J, Kwok R, et al. Al2O3 nanoparticle addition to commercial magnesium alloys: multiple beneficial effects. Nanomaterials, 2012, 2(2): 147 doi: 10.3390/nano2020147 [9] Habibnejad-Korayem M, Mahmudi R, Poole W J. Work hardening behavior of Mg-based nano-composites strengthened by Al2O3 nano-particles. Mater Sci Eng A, 2013, 567(4): 89 [10] Wen L H, Ji Z S, Xu H Y, et al. Aging strengthening of Mg‒Nd‒Zn‒Zr magnesium alloy prepared by solid recycling process. Chin J Nonferrous Met, 2016, 26(7): 1408文丽华, 吉泽升, 许红雨, 等. 固相再生Mg‒Nd‒Zn‒Zr镁合金的时效强化. 中国有色金属学报, 2016, 26(7): 1408 [11] Wu S Y, Ji Z S, Hu M, et al. Microstructure and mechanical properties of AZ31B magnesium alloy prepared by solid state recycling. Rare Met Mater Eng, 2018, 47(3): 736 doi: 10.1016/S1875-5372(18)30101-2武淑艳, 吉泽升, 胡明, 等. 固相再生AZ31B镁合金的组织与力学性能. 稀有金属材料与工程, 2018, 47(3): 736 doi: 10.1016/S1875-5372(18)30101-2 [12] Wen L H, Ji Z S, Ning H Y, et al. Effect of extruding times on microstructure and mechanical properties of ZM6‒Ce magnesium alloy. Rare Met Mater Eng, 2015, 44(9): 2305文丽华, 吉泽升, 宁慧燕, 等. 固相合成道次对ZM6‒Ce镁合金组织和性能的影响. 稀有金属材料与工程, 2015, 44(9): 2305 -

下载:

下载: