-

摘要: 采用真空电弧炉熔炼法制备低密度Nb‒Ti‒Al合金铸锭,利用料浆烧结法在铸锭表面涂覆Si‒Cr‒Ti复合硅化物涂层,使用万能电子拉伸试验机对合金试样和涂层试样进行力学性能测试,研究硅化物涂层对试样力学性能的影响。结果表明,与合金试样相比,涂覆涂层后的低密度铌合金室温力学性能(抗拉强度、屈服强度及延伸率)显著下降。为进一步研究涂覆涂层合金力学性能下降的原因,采用扫描电子显微镜和能谱仪对合金试样和涂层试样进行显微组织观察、涂层/基体界面成分分析及C含量(质量分数)测定。结果表明,涂层试样力学性能下降的主要原因包括涂覆涂层后合金晶粒显著长大,合金中强化元素Al的向外扩散,脆性相Nb3Al的形成以及Si‒Cr‒Ti涂层对合金产生的“渗沉效应”。

-

关键词:

- 硅化物涂层 /

- Nb−Ti−Al合金 /

- 低密度铌合金 /

- 力学性能

Abstract: he low-density Nb‒Ti‒Al alloy ingots were prepared by vacuum arc furnace smelting method in this paper, the Si‒Cr‒Ti composite silicide coatings were deposited on the surface of Nb‒Ti‒Al alloys by the slurry sintering method, and the universal electronic tensile testing machine was used to study the effect of silicide coating on the mechanical properties of the uncoated and coated alloys. The results show that, the mechanical properties (tensile strength, yield strength, and elongation) at room temperature of the coated low-density niobium alloys are significantly reduced, comparing with the uncoated alloys. To investigate the reasons for the decrease in the mechanical properties of the uncoated alloys, the scanning electron microscope (SEM) and energy dispersive spectrometer (EDS) were used to observe the microstructure, analyze the composition of interface between coating and substrate, and test the C content (mass fraction) of the uncoated and coated alloys. In the results, the main reasons for the decrease in the mechanical properties of the coated niobium alloys are the significant growth of the alloy grains, the outward diffusion of the strengthening element Al, the formation of the brittle phase Nb3Al, and the “seepage effect” of the alloy due to the Si‒Cr‒Ti coating.-

Key words:

- silicide coatings /

- Nb−Ti−Al alloys /

- low-density niobium alloys /

- mechanical properties

-

图 2 合金试样及涂层试样金相显微形貌:(a)合金试样横向截面;(b)合金试样纵向截面;(c)合金试样纵向平面;(d)涂层试样横向截面;(e)涂层试样纵向截面;(f)涂层试样纵向平面

Figure 2. Metallographic microstructures of the alloy and coated samples: (a) transverse section of the alloy samples; (b) longitudinal section of the alloy samples; (c) longitudinal plane of the alloy samples; (d) transverse section of the coated samples; (e) longitudinal section of the coated samples; (f) longitudinal plane of the coated samples

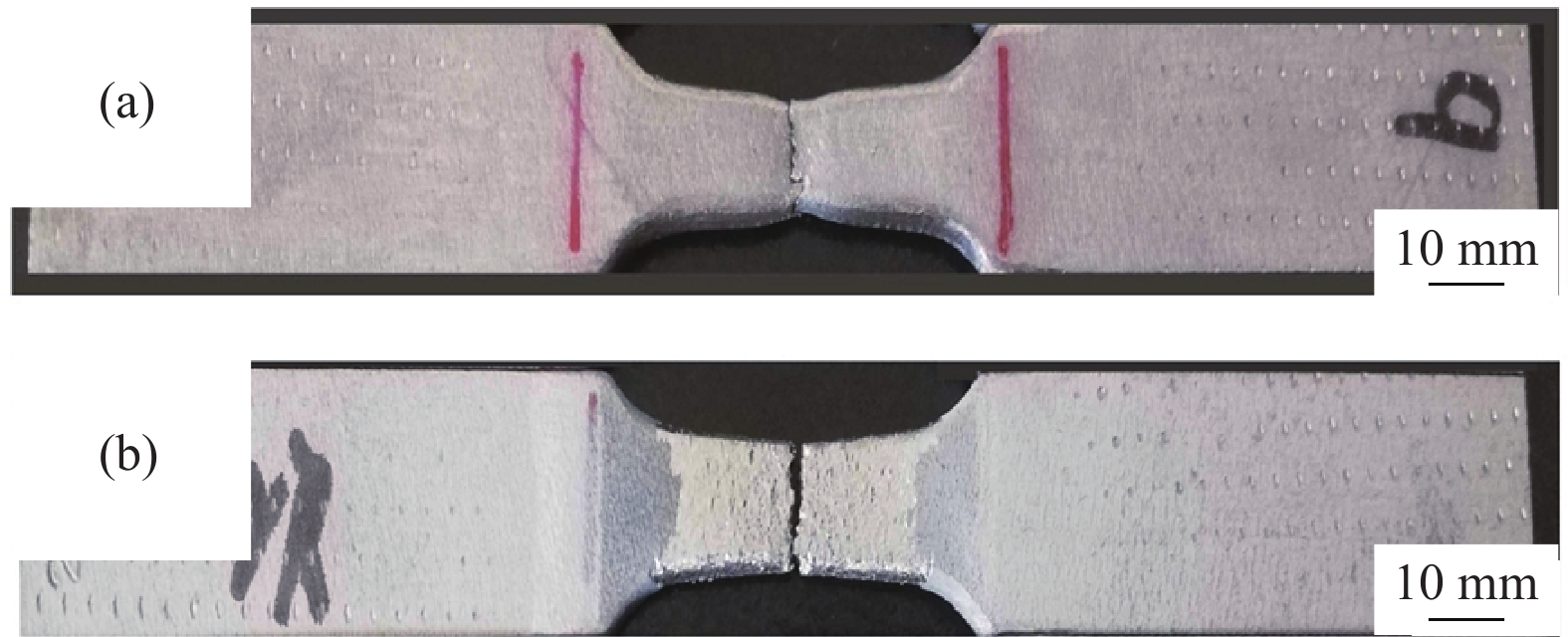

表 1 合金试样和涂层试样力学性能

Table 1. Mechanical properties of the alloy samples and the coated samples

试样编号 抗拉强度 / MPa 屈服强度 / MPa 延伸率 / % 合金试样-1# 780.3 750.5 23.6 合金试样-2# 775.9 746.1 24.4 合金试样-3# 770.4 740.4 26.0 涂层试样-1# 549.2 521.2 12.0 涂层试样-2# 558.0 527.6 11.2 涂层试样-3# 554.2 527.7 10.4 表 2 不同试样中C元素质量分数

Table 2. Mass fraction of C element in the different samples

×10‒6 合金试样 涂层试样 1 2 3 1 2 3 84 77 82 60 51 55 -

[1] Sikka V K, Loria E A. Characteristics of a multicomponent Nb‒Ti‒Al alloy via industrical-scale practice. Mater Sci Eng A, 1997, 239-240: 745 doi: 10.1016/S0921-5093(97)00662-X [2] Guo Q W, Wang Z X. Modern Metallurgy of Niobium and Tantalum. Beijing: Metallurgical Industry Press, 2009郭青蔚, 王肇信. 现代铌钽冶金. 北京: 冶金工业出版社, 2009 [3] Guo B H, Guo X P. Recent progress on room temperature fracture toughness of Nb‒Ti‒Cr‒Si based ultrahigh temperature alloy. Mater Rev, 2016, 30(17): 148郭宝会, 郭喜平. Nb‒Ti‒Cr‒Si基超高温合金的室温断裂韧性研究进展. 材料导报, 2016, 30(17): 148 [4] Cai Z Y, Xiao L R, Yu C X, et al. High temperature oxidation behavior of Nb‒Ti‒Al alloy and its silicide coating. Mater Sci Eng Powder Metall, 2013, 18(1): 94 doi: 10.3969/j.issn.1673-0224.2013.01.018蔡圳阳, 肖来荣, 余宸旭, 等. Nb‒Ti‒Al合金及其硅化物涂层的高温氧化行为. 粉末冶金材料科学与工程, 2013, 18(1): 94 doi: 10.3969/j.issn.1673-0224.2013.01.018 [5] Wang F, Zheng X, Bai R, et al. Microstructure and mechanical properties of low-density NbTiAlVZr alloy. Rare Met Mater Eng, 2011, 40(11): 1972王峰, 郑欣, 白润, 等. 低密度NbTiAlVZr合金的微观组织和力学性能. 稀有金属材料与工程, 2011, 40(11): 1972 [6] Wang Y Q, Liu Z G, Wang D X, et al. Several micro-alloy strengthening techniques in low-density Nb‒Ti‒Cr‒Al super alloys. Hunan Nonferrous Met, 2012, 28(6): 40 doi: 10.3969/j.issn.1003-5540.2012.06.012汪燕青, 刘兆刚, 王东新, 等. 几种Nb‒Ti‒Cr‒Al合金的微合金强化工艺. 湖南有色金属, 2012, 28(6): 40 doi: 10.3969/j.issn.1003-5540.2012.06.012 [7] Liu Z G, Wang Y Q, Liu C H, et al. Study on microstructure of as-cast Nb‒Ti‒Cr‒Al alloys. Hunan Nonferrous Met, 2012, 28(2): 47 doi: 10.3969/j.issn.1003-5540.2012.02.013刘兆刚, 汪燕青, 刘创红, 等. 铌钛铬铝合金的铸态微观组织分析研究. 湖南有色金属, 2012, 28(2): 47 doi: 10.3969/j.issn.1003-5540.2012.02.013 [8] Cai Z Y, Shen H T, Liu S N, et al. Review and prospect of refractory metal alloys and high temperature oxidation resistance coatings. Chin J Nonferrous Met, 2020, 30(9): 1991 doi: 10.11817/j.ysxb.1004.0609.2020-37623蔡圳阳, 沈鸿泰, 刘赛男, 等. 难熔金属合金及其高温抗氧化涂层研究现状与展望. 中国有色金属学报, 2020, 30(9): 1991 doi: 10.11817/j.ysxb.1004.0609.2020-37623 [9] Jia Z H. High-temperature oxidation-resistant coatings for columbium alloy and molybdenum alloy with slurry method. Powder Metall Technol, 2001, 19(2): 74 doi: 10.3321/j.issn:1001-3784.2001.02.003贾中华. 料浆法制备铌合金和钼合金高温抗氧化涂层. 粉末冶金技术, 2001, 19(2): 74 doi: 10.3321/j.issn:1001-3784.2001.02.003 [10] Zhao G, Zhou X J, Zhang J, et al. Preparation and antioxidation mechanism of Nb–Ti–Al based alloy protective coatings. Powder Metall Technol, 2017, 35(5): 347赵刚, 周小军, 张静, 等. Nb‒Ti‒Al基合金防护涂层制备及其抗氧化机理研究. 粉末冶金技术, 2017, 35(5): 347 [11] Yu C X, Xiao L R, Zhao L, et al. Dynamics of recrystallization and grain growth behavior of Nb‒Ti‒Al superalloy. Trans Mater Heat Treat, 2012, 33(Supple II): 40余宸旭, 肖来荣, 赵雷, 等. Nb‒Ti‒Al高温合金的再结晶动力学和晶粒长大行为. 材料热处理学报, 2012, 33(增刊II): 40 [12] Leonard K J, Mishurda J C, Vasudevan V K. Phase equilibria at 1100 ℃ in the Nb‒Ti‒A1 system. Mater Sci Eng A, 2002, 329-331: 282 doi: 10.1016/S0921-5093(01)01567-2 [13] Wei W Q, Wang H W, Zou C M, et al. Effects of Al contents on the microstructure of Nb‒Ti‒C alloys. Rare Met Mater Eng, 2011, 40(8): 1458魏文庆, 王宏伟, 邹鹑鸣, 等. Al含量对Nb‒Ti‒C合金组织的影响. 稀有金属材料与工程, 2011, 40(8): 1458 [14] Yin W H, Tang H P. Refractory Metal Materials and Engineering Applications. Beijing: Metallurgical Industry Press, 2012殷为宏, 汤慧萍. 难熔金属材料与工程应用. 北京: 冶金工业出版社, 2012 [15] Yu C X, Xiao L R, Zhao X J, et al. Microstructure and mechanical properties of Nb‒20Ti‒16Al alloy with carbon addition. Chin J Rare Met, 2017, 41(9): 980余宸旭, 肖来荣, 赵小军, 等. C元素的添加对Nb‒20Ti‒16Al合金组织和性能的影响. 稀有金属, 2017, 41(9): 980 [16] Xiao L R, Zhou X J, Wang Y F, et al. Formation and oxidation behavior of Ce-modified MoSi2‒NbSi2 coating on niobium alloy. Corros Sci, 2020, 173: 108751 doi: 10.1016/j.corsci.2020.108751 [17] Cai Z Y, Zhao X J, Zhang D X, et al. Microstructure and oxidation resistance of a YSZ modified silicide coating for Ta‒W alloy at 1800 ℃. Corros Sci, 2018, 143: 116 doi: 10.1016/j.corsci.2018.08.007 -

下载:

下载: