-

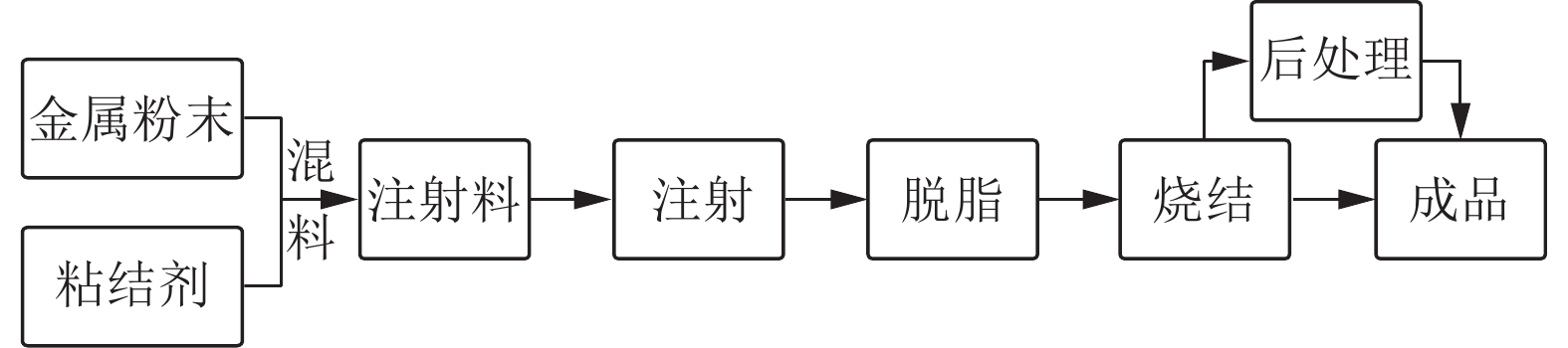

摘要: 金属粉末注射成形技术可以大批量、低成本地制造高性能异形精密零部件,是当前先进制造技术领域研究的热点之一。本文概述了金属粉末注射成形的工艺,包括粉末制备、粘结剂选取、混料、注射以及后续的脱脂、烧结,介绍了金属粉末注射成形的发展过程、现状及新工艺,深入分析了金属粉末注射成形数值模拟,在此基础上展望了金属粉末注射成形的发展趋势。Abstract: Metal powder injection molding (MIM) can be used to manufacture the high performance precision parts with the special shape in large quantities and low cost, which is regarded as one of the research hotspots in the field of the advanced manufacturing technology. The MIM technology was summarized in this paper, including the powder preparation, the binder selection, the mixing, the injection, and the subsequent debinding and sintering. The development, status, and new technology of MIM were introduced, the numerical simulation of MIM was deeply analyzed, and the development trend of MIM was prospected.

-

Key words:

- metal powder injection molding /

- powder metallurgy /

- numerical simulation /

- binder

-

表 1 金属粉末注射成形常用材料系列

Table 1. Common material series in MIM

材料系列 合金成分 低合金钢 Fe–2Ni,Fe–8Ni 不锈钢 304L,314L,316L,440A,440C,17-4PH 硬质合金 WC–6Co 重合金 W–Ni–Fe,W–Ni–Cu,W–Cu 工具钢 42CrMo4,M2 钛合金 TiAl,Ti–6Al–4V,TiMo 陶瓷 ZrO2,Si3N4,AlN,Al2O3,SiO2 新型合金 Fe–Al–Si,无Ni奥氏体不锈钢 表 2 金属粉末注射成形常用粘结剂体系及其优缺点

Table 2. Common binder systems and the characteristics of MIM

粘结剂体系 优点 缺点 热塑性体系 石蜡基粘结剂熔点低,流动性好,可填充复杂模腔;聚合物基粘结剂强度高,保形性好。 石蜡冷却时体积收缩大,注射时薄壁与厚壁的交界处应力较大;聚合物基粘结剂黏度高,混料难度大 热固性体系 脱脂时间短,可制备较大尺寸零件 注射坯强度低,脱脂不完全,注射料不能重复利用 凝胶水基体系 脱模简单,注射坯强度高,脱脂简单快速,

可生产大尺寸零件粘结剂中的水受热挥发影响注射料黏度,并且水对金属粉末有一定的氧化作用,凝胶化时间长,脱模困难 水溶性体系 绿色环保,不污染环境 注射坯易变形,不适合生产烧结密度高的产品 -

[1] Gao J X, Zhuo H Y, Gao Z P, et al. Situation and development tendency of MIM computer simulation technology. Cement Carb, 2006, 23(1): 47 doi: 10.3969/j.issn.1003-7292.2006.01.012高建祥, 卓海宇, 高泽平, 等. 金属粉末注射成形过程计算机模拟技术的现状及发展. 硬质合金, 2006, 23(1): 47 doi: 10.3969/j.issn.1003-7292.2006.01.012 [2] Wiech R E. Manufacture of Parts from Particulate Materials: US Patent, 5613183. 1997-3-18 [3] Wiech R E. Method and Means for Removing Binder from a Green Body: EP Patent, 0032404. 1981-7-22 [4] Rivers R D. Method of Injection Molding Powder Metal Parts: US Patent, 4113480. 1978-9-12 [5] Li Y P, Qu X H, Zheng Z S, et al. The present state in research and development trend in industrialization of PIM W–Cu composites. Powder Metall Technol, 2003, 21(2): 108 doi: 10.3321/j.issn:1001-3784.2003.02.008李云平, 曲选辉, 郑洲顺, 等. 注射成形W–Cu研究现状及产业化发展趋势. 粉末冶金技术, 2003, 21(2): 108 doi: 10.3321/j.issn:1001-3784.2003.02.008 [6] Hu G X, Zhang L X, Fan Y L, et al. Fabrication of high porous NiTi shape memory alloy by metal injection molding. J Mater Process Technol, 2008, 206(1-3): 395 doi: 10.1016/j.jmatprotec.2007.12.044 [7] Bose A, German R M. Potential of powder injection molding and hot isostatic pressing of nickel aluminide matrix composites. Ind Heat, 1988, 55(5): 38 [8] Kamal M R, Kenig S. The injection molding of thermoplastics part I: Theoretical model. Polym Eng Sci, 1972, 12(4): 294 doi: 10.1002/pen.760120408 [9] Kamal M R, Kenig S. The injection molding of thermoplastics part II: Experimental test of the model. Polym Eng Sci, 1972, 12(4): 302 doi: 10.1002/pen.760120409 [10] Hieber C A, Shen S F. Flow analysis of the non-isothermal two-dimensional filling process in injection molding. Isr J Technol, 1978, 16: 248 [11] Hieber C A, Shen S F. A finite-element/finite-difference simulation of the injection molding process. J Non-Newtonian Fluid Mech, 1980, 7: 1 doi: 10.1016/0377-0257(80)85012-9 [12] Lacey P M C. Development in the theory of particle mixing. J Appl Chem, 1954, 4(5): 257 [13] Liang S Q, Huang B Y. Rheology of Powder Injection Molding. Changsha: Central South University Press, 2000梁叔全, 黄伯云. 粉末注射成形流变学. 长沙: 中南大学出版社, 2000 [14] Yu N L, Sun S Q. Preparation of cobalt-chromium-molybdenum powders for metal injection molding. Hebei J Ind Sci Technol, 2021, 38(1): 1尉念伦, 孙世清. 金属注射成形用钴铬钼粉末的制备. 河北工业科技, 2021, 38(1): 1 [15] He Y Q, Chen Z H, Chen Z G, et al. Metal injection molding: principle and development. J Mater Sci Eng, 2013, 31(2): 317贺毅强, 陈志华, 陈志刚, 等. 金属粉末注射成形的原理与发展趋势. 材料科学与工程学报, 2013, 31(2): 317 [16] Hao X Y, Gai G S, Zou X, et al. Shape modification of HDH Ti powder and its mechanism analysis. Rare Met Mater Eng, 2009, 38(Suppl 3): 264郝向阳, 盖国胜, 邹欣, 等. 氢化脱氢钛粉末颗粒的整形及其机理研究. 稀有金属材料与工程, 2009, 38(增刊3): 264 [17] Mahmud N N, Azam F A A, Ramli M I, et al. Rheological properties of irregular-shaped titanium-hydroxyapatite bimodal powder composite moulded by powder injection moulding. J Mater Res Technol, 2021, 11: 2255 doi: 10.1016/j.jmrt.2021.02.016 [18] Guo S B, Qu X H. Research progress in binders used for metal injection molding. Powder Metall Technol, 2004, 22(3): 178 doi: 10.3321/j.issn:1001-3784.2004.03.012郭世柏, 曲选辉. 金属注射成形粘结剂的研究进展. 粉末冶金技术, 2004, 22(3): 178 doi: 10.3321/j.issn:1001-3784.2004.03.012 [19] Muller E, Horowitz D, Egozy A. Polyhydroxyalkanoate Molding Compositions: US Patent, 6071998. 2000-6-6 [20] Hens K F, Kupp D M, Alexander R A, et al. Method and Binder for Use in Powder Molding: US Patent, 5332537. 1994-7-26 [21] Hens S, Van Landuyt J, Bender H, et al. Chemical and structural analysis of etching residue layers in semiconductor devices with energy filtering transmission electron microscopy. Mater Sci Semicond Process, 2001, 4(1-3): 109 doi: 10.1016/S1369-8001(00)00147-5 [22] Zhao X J, Dang X A. Research status of metal powder injection molding technology and the mold. Mould Technol, 2008(5): 11 doi: 10.3969/j.issn.1001-4934.2008.05.004赵小娟, 党新安. 金属粉末注射成形技术及模具的研究现状. 模具技术, 2008(5): 11 doi: 10.3969/j.issn.1001-4934.2008.05.004 [23] Kwon T H, Hwang C J, Rhee R E. Numerical simulation of powder injection molding filling process for 3D complicated cavity geometries. Adv Powder Metall Part Mater, 1996, 5: 19 [24] Xiao P A, Hu Y Q, Liu J Z, et al. A Gradient Negative Pressure Thermal Degreasing Technology for Powder Injection Molding: China Patent, 1974080A. 2007-6-6肖平安, 胡业奇, 刘吉梓, 等. 一种粉末注射成形用梯度负压热脱脂技术: 中国专利, 1974080A. 2007-6-6 [25] Camargo A, Rodrigues D, Tschiptschin A P. Debinding kinetics of injection molding samples — The effects of the binder melt index flow. Key Eng Mater, 2001, 189-191: 604 doi: 10.4028/www.scientific.net/KEM.189-191.604 [26] Yang X M, Petcavich R J. Powder and Binder Systems for Use in Metal and Ceramic Powder Injection Molding: US Patent, 6008281. 1999-12-28 [27] Fan J L, Huang B Y, Qu X H, et al. Densification mechanism of liquid phase sintered tungsten heavy alloy during initial solid state sintering stage. Chin J Nonferrous Met, 1998, 8(Suppl 1): 36范景莲, 黄伯云, 曲选辉, 等. 液相烧结高比重合金早期固相烧结阶段的致密化机理. 中国有色金属学报, 1998, 8(增刊1): 36 [28] Dai Y, Wang L M. Partial Pressure Controlled Vacuum Degreasing and Sintering Integrated Furnace: China Patent, 2718480Y. 2005-8-17戴煜, 王利民. 分压控制式真空脱脂烧结一体炉: 中国专利, 2718480Y. 2005-8-17 [29] Yi J H, Shi W F. The technology of metal powder injection molding and its development. Miner Metall Eng, 2001, 21(2): 7易健宏, 史文芳. 金属粉末注射成形技术及其发展动态. 矿冶工程, 2001, 21(2): 7 [30] Chen L J, Li T, Li Y M, et al. Porous titanium implants fabricated by metal injection molding. Trans Nonferrous Met Soc China, 2009, 19(5): 1174 doi: 10.1016/S1003-6326(08)60424-0 [31] German R M. Powder Injection Molding. Princeton: Powder Industries Federation, 1997 [32] Zauner R. Micro powder injection moulding. Microelectron Eng, 2006, 83: 1442 doi: 10.1016/j.mee.2006.01.170 [33] Rota A C. New features in material issues for metallic micro components by MIM // World Conference on Powder Metallurgy & Particulate Materials. Orlando, 2002: 49 [34] Zeep B, Norajitra P, Piotter V. Net shaping of tungsten components by micro powder injection moulding. Fusion Eng Des, 2007, 82: 2660 doi: 10.1016/j.fusengdes.2007.07.013 [35] Piotter V, Zeep B, Norajitra P, et al. Development of a powder metallurgy process for tungsten components. Fusion Eng Des, 2008, 83: 1517 doi: 10.1016/j.fusengdes.2008.06.022 [36] Nishiyabu K. Micro metal powder injection molding [J/OL]. InTech (2012-03-15)[2020-12-07]. http://www.intechopen.com/books/some-critical-issues-for-injection-molding/micro-metal-powder-injection-molding [37] Ammosova L, Mnkknen K, Suvanto M. Precise fabrication of microtextured stainless steel surfaces using metal injection moulding. Precis Eng, 2020, 62: 89 doi: 10.1016/j.precisioneng.2019.11.012 [38] Piotter V, Gietzelt T, Merz L. Micro powder-injection moulding of metals and ceramics. Sadhana, 2003, 28: 299 doi: 10.1007/BF02717139 [39] Yin H Q, Jia C C, Qu X H. Status of micro powder injection molding. Powder Metall Technol, 2007, 25(5): 382尹海清, 贾成厂, 曲选辉. 粉末微注射成形技术现状. 粉末冶金技术, 2007, 25(5): 382 [40] Powder Injection Moulding International Group. WORLDPM2018 Congress: Global MIM markets show healthy growth. Powder Inject Mould Int, 2018, 12(4): 67 [41] Yang T Z. Progress of modern powder metallurgy materials and technology. China Met Bull, 2019(12): 10 doi: 10.3969/j.issn.1672-1667.2019.12.007杨廷志. 现代粉末冶金材料与技术进展. 中国金属通报, 2019(12): 10 doi: 10.3969/j.issn.1672-1667.2019.12.007 [42] Najima L A. Simulation of mold filling for powder injection molding processes. Adv Powder Metall, 1990, 3: 299 [43] Zhuo H Y, Gao J X, Qu X H. Research on mathematical mold of filling process of metal powder injection molding. New Technol New Process, 2007(6): 87 doi: 10.3969/j.issn.1003-5311.2007.06.034卓海宇, 高建祥, 曲选辉. 金属粉末注射成形充模过程数学模型研究. 新技术新工艺, 2007(6): 87 doi: 10.3969/j.issn.1003-5311.2007.06.034 [44] Samanta S K, Chattopadhyay H, Pustal B, et al. A numerical study of solidification in powder injection molding process. Int J Heat Mass Transfer, 2008, 51(3-4): 672 doi: 10.1016/j.ijheatmasstransfer.2007.04.033 [45] Wang Y H, Qu X H, He X B, et al. Numerical simulation of unique boundary layer effect during powder injection molding filling flow process. Mater Mech Eng, 2008, 32(2): 77 doi: 10.3969/j.issn.1000-3738.2008.02.023王玉会, 曲选辉, 何新波, 等. 粉末注射成形充模过程特有边界层效应的数值模拟. 机械工程材料, 2008, 32(2): 77 doi: 10.3969/j.issn.1000-3738.2008.02.023 [46] Wang Y H, Qu X H, He X B, et al. Two-fluid model during powder injection molding process. Mater Mech Eng, 2008, 32(5): 74 doi: 10.3969/j.issn.1000-3738.2008.05.022王玉会, 曲选辉, 何新波, 等. 粉末注射成型过程的双流体数学模型. 机械工程材料, 2008, 32(5): 74 doi: 10.3969/j.issn.1000-3738.2008.05.022 [47] Wang Y H, Qu X H, Zhang Y, et al. Boundary layer effect of powder injection molding filling flow process and mechanics analysis. Powder Metall Technol, 2008, 26(4): 254王玉会, 曲选辉, 张勇, 等. PIM充模过程的边界层效应及机理分析. 粉末冶金技术, 2008, 26(4): 254 [48] Aizawa T, Iwai T, Kihara J. Granular modeling of steel powder flow and compaction in injection molding // Proc Powder Injection Molding Symp92. New Jersey , 1992: 419 [49] Iwai T, Aizawa T, Kihara J. Numerical modeling for powder-binder compound flow in metal injection molding. Adv Powder Metall Part Mater, 1995, 49(3): 103 [50] Zheng Z S, Qu X H, Xu Q W, et al. Three-dimensional numerical simulation of two phase flow for powder injection molding and separation of powder and binder. Chin J Nonferrous Met, 2014, 24(1): 122郑洲顺, 曲选辉, 徐勤武, 等. 粉末注射成形两相流动三维数值模拟及粉末与粘结剂的分离. 中国有色金属学报, 2014, 24(1): 122 [51] Liu Y, Li Y M, Xiao Y F, et al. Research on particle contact model in powder injection molding. J Changsha Univ, 2010, 24(5): 30 doi: 10.3969/j.issn.1008-4681.2010.05.012刘煜, 李益民, 肖燕芳, 等. 粉末注射成型中颗粒接触模型的研究. 长沙大学学报, 2010, 24(5): 30 doi: 10.3969/j.issn.1008-4681.2010.05.012 [52] Li D P. Investigation on the Mold Filling Process in Powder Injection Molding Based on Granular Model [Dissertation]. Changsha: Central South University, 2013李大鹏. 基于颗粒模型的粉末注射成形充模流动过程研究[学位论文]. 长沙: 中南大学, 2013 [53] Zheng Z S, Qu X H, Han X L, et al. Computation and simulation of solidification on wall of cavity in powder injection molding filling process. Chin J Nonferrous Met, 2008, 18(3): 511 doi: 10.3321/j.issn:1004-0609.2008.03.022郑洲顺, 曲选辉, 韩旭里, 等. 粉末注射成形充模流动过程模壁凝固层增长的计算与模拟. 中国有色金属学报, 2008, 18(3): 511 doi: 10.3321/j.issn:1004-0609.2008.03.022 [54] Wu Y B, Zheng Z X. The optimal design of mold structure in powder injection molding based on the numerical simulation. Mach Des Manuf, 2009(12): 236 doi: 10.3969/j.issn.1001-3997.2009.12.097吴苑标, 郑振兴. 基于数值模拟的粉末注射成形模具结构优化设计. 机械设计与制造, 2009(12): 236 doi: 10.3969/j.issn.1001-3997.2009.12.097 [55] Liu F, Li W M. Numerical simulation research on the effect of gate patterns on powder volume fraction variation of MIM milling cutter. Mater Sci Eng Powder Metall, 2018, 23(3): 292 doi: 10.3969/j.issn.1673-0224.2018.03.009刘飞, 李文明. 数值模拟研究浇口方式对粉末注射成形铣刀粉体分布的影响. 粉末冶金材料科学与工程, 2018, 23(3): 292 doi: 10.3969/j.issn.1673-0224.2018.03.009 [56] Zheng Z X, Xia W, Zhou Z Y. Optimization of process parameters of powder injection molding based on numerical simulation. J South China Univ Technol Nat Sci, 2009, 37(2): 49郑振兴, 夏伟, 周照耀. 基于数值模拟的粉末注射成形工艺参数优化. 华南理工大学学报(自然科学版), 2009, 37(2): 49 -

下载:

下载: