Preparation and damping capacity of three-dimensional network Ti2AlC/Mg matrix composites

-

摘要: 采用前驱体法制备Ti2AlC多孔陶瓷预制体,通过辅助压力浸渗工艺制备出组织致密的三维网络相互贯通的Ti2AlC/Mg基复合材料。利用扫描电镜和X射线衍射仪分析复合材料的微观组织和物相组成,使用机械振动分析仪测试复合材料阻尼性能。结果表明,复合材料具有宏观上及微观上双尺度的三维网络结构。恒定温度条件下,复合材料在1 Hz和10 Hz测试条件下的最高损耗正切值分别为0.13和0.15,相比于基体AZ91D镁合金分别提高了约30%和67%,其阻尼表现增强。恒定应变条件下,在最高测试温度时,复合材料出现最大损耗正切值。两种测试条件下,复合材料存储模量均高于基体AZ91D镁合金。从内耗值-存储模量二者平衡的角度来看,复合材料不仅具有更宽的应用温度范围,也具有更好的阻尼-强度平衡性。

-

关键词:

- Ti2AlC/Mg基复合材料 /

- 前驱体法 /

- 三维网络结构 /

- 阻尼性能

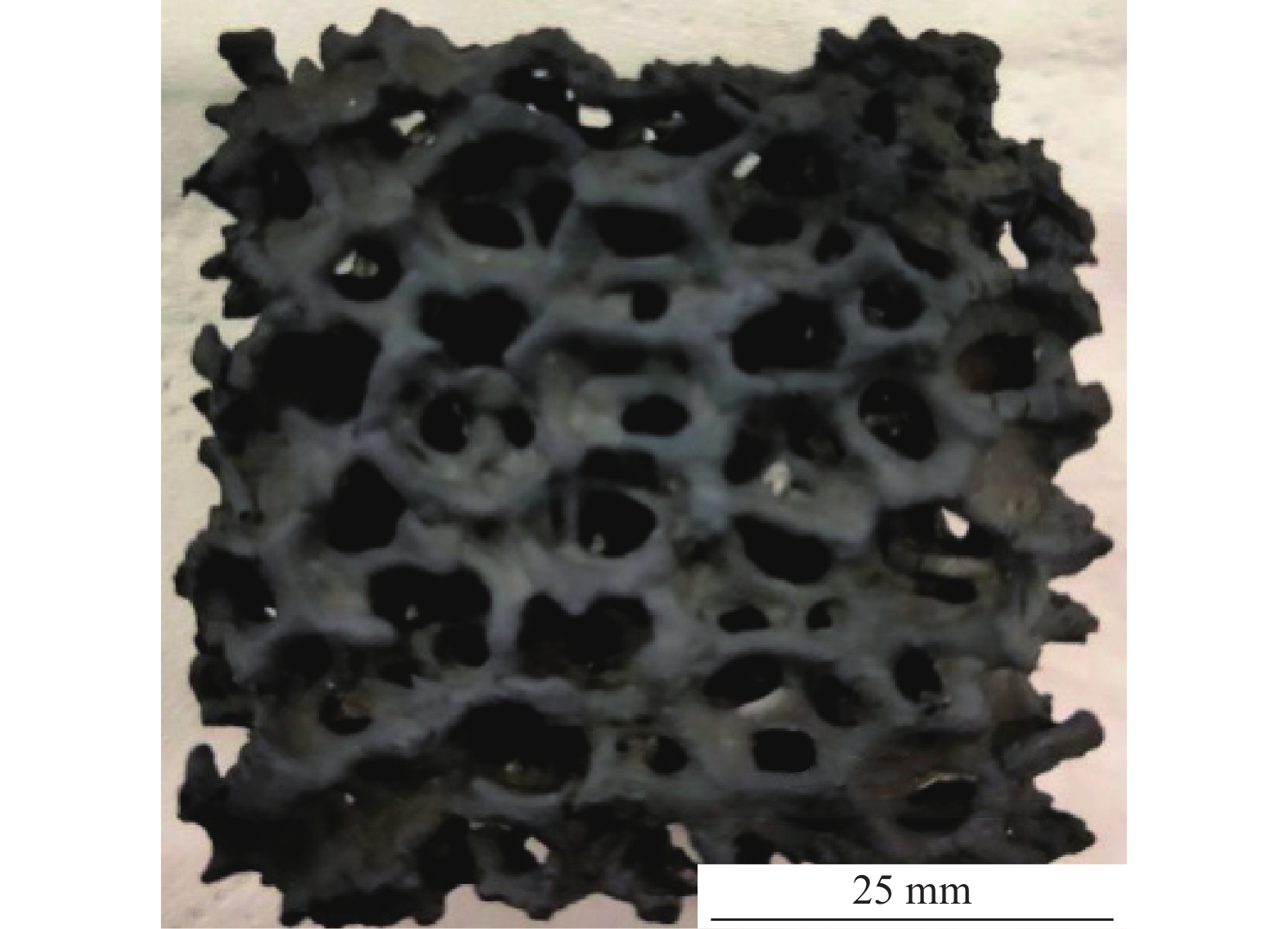

Abstract: The Ti2AlC porous ceramic preforms were prepared by precursor method in this paper, and the Ti2AlC/Mg matrix composites with the dense three-dimensional network structure were prepared by auxiliary pressure infiltration process. The microstructure and phase composition of the composites were investigated by scanning electron microscope (SEM) and X-ray diffractometer (XRD), and the damping performance of the composites was tested by vibration analyzer. The results show that, the composites have the two-scale three-dimensional network structure at the macro and micro levels. At the constant temperature, the maximum loss tangent values of the composites are 0.13 and 0.15 at 1 Hz and 10 Hz, respectively, increasing by about 30% and 67% compared with AZ91D, the damping performance is enhanced. Under the constant strain, the composites have the maximum loss tangent value at the highest test temperature. In the two test conditions, both of the storage modulus is higher than that of AZ91D. From the view of the balance between internal friction and storage modulus, the composites not only have the wider application temperature range, but also have the better damping-strength balance. -

表 1 原料粉末基本物性

Table 1. Physical properties of the raw material powders

材料 质量分数 / % 粒径 / μm 生产厂家 Ti2AlC 90% 2~75 北京福斯曼科技有限公司 Ti 99% 2~75 北京福斯曼科技有限公司 表 2 实验粉末的用量(质量分数)

Table 2. Dosage of the experimental powders

% Ti2AlC粉 Ti粉 碱性硅溶胶

(陶瓷粉末)羧甲基纤维素

(陶瓷粉末)聚丙烯酰胺

(陶瓷粉末)90.0 10.0 2.0 2.0 1.2 -

[1] Feng Y, Chen C, Peng C Q, et al. Research progress on magnesium matrix composites. Chin J Nonferrous Met, 2017, 27(12): 2385冯艳, 陈超, 彭超群, 等. 镁基复合材料的研究进展. 中国有色金属学报, 2017, 27(12): 2385 [2] Zhang S W. Research and application summary of damping magnesium alloys. Met World, 2019(4): 5张士卫. 阻尼镁合金的研究与应用综述. 金属世界, 2019(4): 5 [3] Amadori S, Catania G. An effective coating material solution and modeling technique for damping oriented design of thin walled mechanical components. Compos Struct, 2018, 191(5): 251 [4] Wan D Q, Hu Y L, Ye S T, et al. Effect of alloying elements on magnesium alloy damping capacities at room temperature. Int J Miner Metall Mater, 2019, 26(6): 760 doi: 10.1007/s12613-019-1789-6 [5] Wan D Q, Hu Y L, Ye S T, et al. Research status and prospects of high damping magnesium matrix materials. Funct Mater, 2018, 49(5): 5035万迪庆, 胡莹琳, 叶舒婷, 等. 镁基高阻尼材料加工工艺研究现状及展望. 功能材料, 2018, 49(5): 5035 [6] Xiao H Q, Chen Y J, Zhao H, et al. Research progress in magnesium matrix damping composites. Spec Cast Nonferrous Alloys, 2018, 38(4): 382肖华强, 陈禹伽, 赵辉, 等. 镁基阻尼复合材料的研究进展. 特种铸造及有色合金, 2018, 38(4): 382 [7] Li F G, Yu S R, Yuan M. Damping capacity of Mg2Si/AZ91D composites. Acta Mater Compos Sin, 2017, 34(9): 1997李凡国, 于思荣, 袁明. Mg2Si/AZ91D复合材料阻尼性能. 复合材料学报, 2017, 34(9): 1997 [8] Liu E Y, Yu S R, Zhao Y, et al. Microstructure and properties of fly ash cenosphere/AZ91D composites. Rare Met Mater Eng, 2017, 46(11): 3298刘恩洋, 于思荣, 赵严, 等. 漂珠/AZ91D复合材料微观组织与性能. 稀有金属材料与工程, 2017, 46(11): 3298 [9] Ruan A J, Ma L Q, Pan A X, et al. Study on mechanical property and damping capacity of SiC particle reinforced magnesium matrix composite produced by powder metallurgy. Light Alloy Fab Technol, 2012, 40(2): 50 doi: 10.3969/j.issn.1007-7235.2012.02.012阮爱杰, 马立群, 潘安霞, 等. 粉末冶金法SiCp/Mg基复合材料的力学性能和阻尼性能研究. 轻合金加工技术, 2012, 40(2): 50 doi: 10.3969/j.issn.1007-7235.2012.02.012 [10] Wang Y, Zhou J X, Xia J H, et al. Damping capacity of AlN particles reinforced magnesium−aluminum matrix composites by powder metallurgy. J Xi'an Technol Univ, 2018, 38(6): 620王勇, 周吉学, 夏金环, 等. 粉末冶金法AlN颗粒增强镁铝基复合材料的阻尼性能. 西安工业大学学报, 2018, 38(6): 620 [11] Yao Y T, Chen L Q, Wang W G. Damping capacities of (B4C+Ti) hybrid reinforced Mg and AZ91D composites processed by in situ reactive infiltration technique. Acta Metall Sinica, 2019, 55(1): 141姚彦桃, 陈礼清, 王文广. 原位反应浸渗法制备(B4C+Ti)混杂增强Mg及AZ91D复合材料及其阻尼性能. 金属学报, 2019, 55(1): 141 [12] Wu Y W, Wu K, Deng K K, et al. Damping capacities and tensile properties of magnesium matrix composites reinforced by graphite particles. Mater Sci Eng A, 2010, 527(26): 6816 doi: 10.1016/j.msea.2010.07.050 [13] Wu Y W, Wu K, Deng K K, et al. Damping capacities and microstructures of magnesium matrix composites reinforced by graphite particles. Mater Des, 2010, 31(10): 4862 doi: 10.1016/j.matdes.2010.05.033 [14] Wu Y W, Wu K, Deng K K, et al. Effect of extrusion temperature on microstructures and damping capacities of Grp/AZ91 composite. J Alloys Compd, 2010, 506: 688 doi: 10.1016/j.jallcom.2010.07.043 [15] Amini S, Barsoum M W. On the effect of texture on the mechanical and damping properties of nanocrystalline Mg-matrix composites reinforced with MAX phases. Mater Sci Eng A, 2010, 527(16): 3707 [16] Anasori B, Caspi E, Barsoum M W. Fabrication and mechanical properties of pressureless melt infiltrated magnesium alloy composites reinforced with TiC and Ti2AlC particles. Mater Sci Eng A, 2014, 618: 511 doi: 10.1016/j.msea.2014.09.039 [17] Mei D, Lamaka S V, Feiler C, et al. The effect of small-molecule bio-relevant organic components at low concentration on the corrosion of commercially pure Mg and Mg-0.8Ca alloy: An overall perspective. Corros Sci, 2019, 153: 258 [18] Shamma M, Caspi E, Anasori B, et al. In situ neutron diffraction evidence for fully reversible dislocation motion in highly textured polycrystalline Ti2AlC samples. Acta Mater, 2015, 98: 51 [19] Chen Y J. Preparation and Damping Capacities of Ti 2AlC/Mg Based Composites with Two-Scale Three-Dimensional Network [Dissertation]. Guiyang: Guizhou University, 2019陈禹伽. 双尺度三维网络Ti2AlC/Mg基复合材料制备及其阻尼性能研究[学位论文]. 贵阳: 贵州大学, 2019 [20] Ji S J. Study on Preparation of SiC-Based Ceramic Foam Filter Material by Organic Foam Dipping Method (PSD) and Foam Gel Method (FGC) [Dissertation]. Changsha: Central South University, 2013冀树军. 有机泡沫浸渍法(PSD)及发泡凝胶法(FGC)制备SiC基泡沫陶瓷过滤材料的研究[学位论文]. 长沙: 中南大学, 2013 -

下载:

下载: