Damage mechanism of Fe-based powder metallurgy friction materials in high energy braking

-

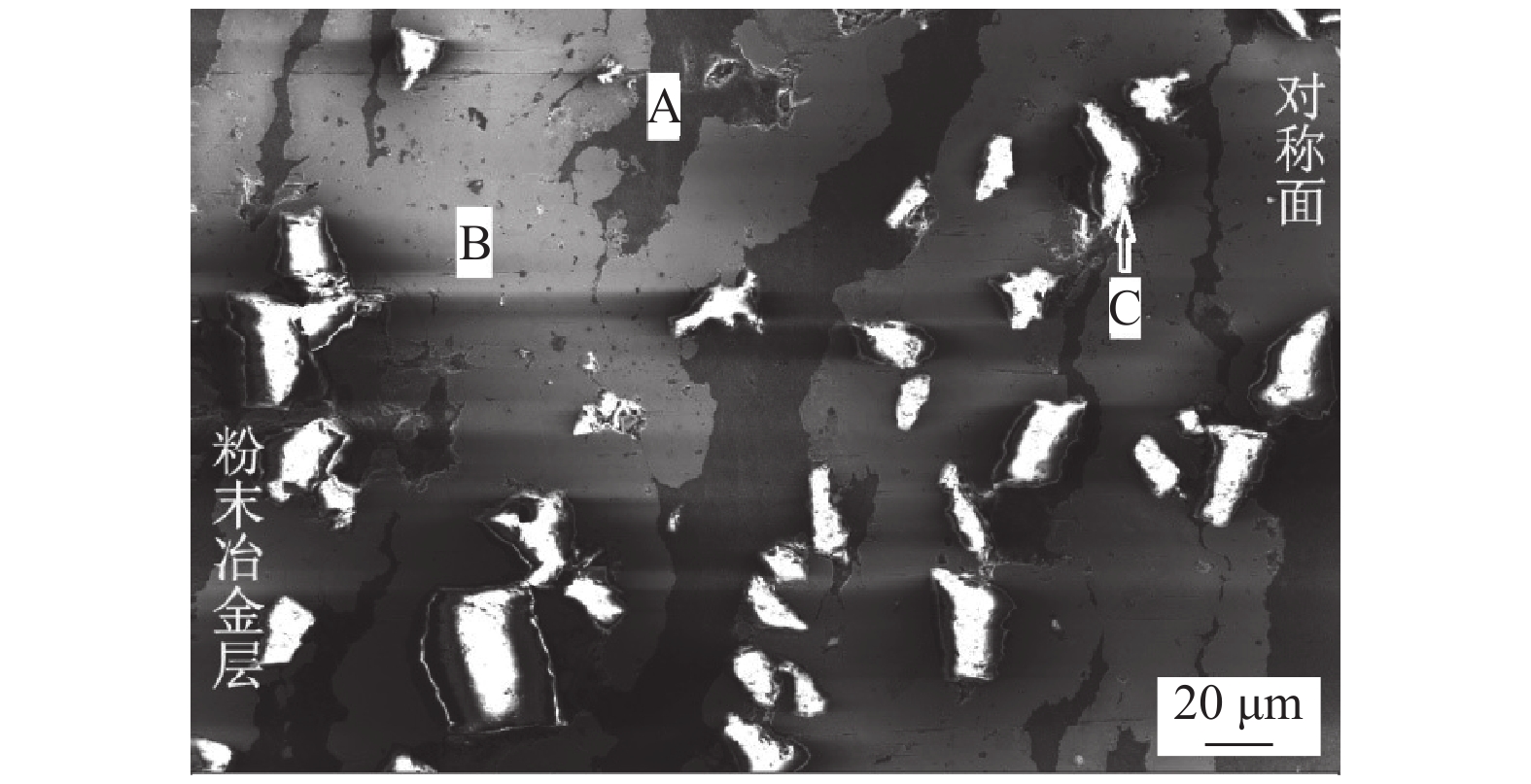

摘要: 采用粉末冶金压烧技术制备铁基粉末冶金摩擦材料,研究摩擦材料在转速7500 r·min−1、面压0.8 MPa、转动惯量0.045 kg·m2工况下的高能制动损伤机制。结果表明:铁基粉末冶金层损伤及失效主要表现为摩擦接触面内层石墨脱落和表面裂纹两方面。表面热裂纹的萌生主要分布在基体和石墨相的界面处以及边缘脱落锐角处。微裂纹的存在降低了主裂纹继续扩展的能量,阻碍主裂纹扩展,起到提高摩擦件性能稳定的作用。Abstract: Fe-based powder metallurgy friction materials were prepared by powder metallurgy pressure sintering technology, and the damage mechanism of the friction materials under the high energy braking conditions as the speed of 7500 r·min−1, the surface pressure of 0.8 MPa, and the inertia moment of 0.045 kg·m2 was studied. The results show that, the damage and failure of the Fe-based powder metallurgy layers are mainly graphite shedding and surface crack. The initiation of surface thermal cracks is mainly distributed at the interface between the matrix and graphite phase and at the sharp corners of the edge shedding. The existence of micro-cracks reduces the energy of the main crack propagation, hinders the main crack propagation, and plays a role in improving the performance stability of the friction parts.

-

表 1 摩擦层主要成分(质量分数)

Table 1. Main components of friction layer

% Al C SiO2 Fe 3~6 16~20 7~8 余量 表 2 摩擦副材料的物理性能与热物性参数

Table 2. Physical and thermophysical parameters of the friction pair materials

摩擦副材料 密度 /

(kg·cm−3)热传导系数 /

[W·(m·K)−1]比热 /

[J·(kg·℃)−1]热膨胀系数 /

(×10‒6 K‒1)弹性模量 /

GPa泊松比 对偶盘65Mn 7.8 51 460 10.6 206 0.3 制动盘铁基粉末冶金 6.5 10 410 12.0 120 0.3 表 3 制动工况

Table 3. Braking condition

初始温度 / ℃ 转速 / (r·min−1) 压力 / MPa 惯量 / (kg·m2) 环境温度 / ℃ 制动时间 / s 60 7500 0.8 0.045 25 1.95 -

[1] Fang X L, Zheng H J. Application and prospect of copper-based powder metallurgy friction materials. Powder Metall Technol, 2020, 38(4): 313 doi: 10.19591/j.cnki.cn11-1974/tf.2019040008方小亮, 郑合静. 铜基粉末冶金摩擦材料的应用及展望. 粉末冶金技术, 2020, 38(4): 313 doi: 10.19591/j.cnki.cn11-1974/tf.2019040008 [2] Peng T. Study on Brake Friction Behavior and Friction Stability of Brake Pad Materials for High-Speed Train [Dissertation]. Beijing: University of Science and Technology Beijing, 2019彭韬. 高铁刹车片材料制动摩擦行为及摩擦稳定性研究[学位论文]. 北京: 北京科技大学, 2019 [3] Tan M F, Huang S W, Liu X J, et al. A study on brake materials for the rotating wings of Z-8 helicopter. Powder Metall Technol, 1989, 7(3): 149 doi: 10.19591/j.cnki.cn11-1974/tf.1989.03.006谭明福, 黄尚文, 刘先交, 等. 直八型多用直升机旋翼刹车材料的研制. 粉末冶金技术, 1989, 7(3): 149 doi: 10.19591/j.cnki.cn11-1974/tf.1989.03.006 [4] Fedorchinko И М. Modern Friction Materials. Transl by Xu R Z. Beijing: Metallurgical Industry Press, 1983: 97费多尔钦科 И М. 现代摩擦材料. 徐润泽, 译. 北京: 冶金工业出社, 1983: 97 [5] Locker K D. Friction materials-An overview. Powder Metall, 1992, 35(4): 253 [6] Zhang L R, Li D S, Ye J L. Study on the materials selection of aircraft wheel brake assembles. J Mater Eng, 1996(5): 27张连荣, 李东生, 叶菊兰. 民航飞机刹车装置选材研究. 材料工程, 1996(5): 27 [7] Zhang Z L. Experimental Study on Effect of Sintering Process on Performance of Powder Metallurgy Brake Pad [Dissertation]. Beijing: China University of Geosciences, 2017张志龙. 烧结工艺对粉末冶金刹车片性能影响的试验研究[学位论文]. 北京: 中国地质大学, 2017 [8] Jia D J. Study on Friction and Wear Properties of Copper Matrix Powder Metallurgy Friction Materials [Dissertation]. Zhengzhou: Zhengzhou University of Light Industry, 2018贾德晋. 铜基粉末冶金摩擦材料基体摩擦磨损性能研究[学位论文]. 郑州: 郑州轻工业学院, 2018 [9] Xu J B, Cheng J G, Chen P Q, et al. Developments and applications of powder metallurgy friction pairs and their forming technology. Mod Manuf Technol Equip, 2019(6): 150 doi: 10.3969/j.issn.1673-5587.2019.06.072徐家兵, 程继贵, 陈鹏起, 等. 粉末冶金摩擦副材料及其成形技术. 现代制造技术与装备, 2019(6): 150 doi: 10.3969/j.issn.1673-5587.2019.06.072 [10] Liu J F. Study on the Effects of Bamboo Charcoal, Carbon Powder and Copper Powder on the Properties of Friction Materials [Dissertation]. Dalian: Dalian University of Technology, 2018刘建发. 竹炭、碳粉和铜粉对摩擦材料性能影响的研究[学位论文]. 大连: 大连理工大学, 2018 [11] Yue H F, Feng K Q, Li Y, et al. Effect of graphite content on Fe-based friction material prepared by in-situ carbothermic reduction and synthesis from vanadium and titanium iron concentrate. Trans Mater Heat Treat, 2015, 36(10): 16 doi: 10.13289/j.issn.1009-6264.2015.10.003岳慧芳, 冯可芹, 李莹, 等. 石墨对钒钛铁精矿原位制备铁基摩擦材料的影响. 材料热处理学报, 2015, 36(10): 16 doi: 10.13289/j.issn.1009-6264.2015.10.003 [12] Zhu Z G, Bai S, Wu J F, et al. Friction and wear behavior of resin/graphite composite under dry sliding. J Mater Sci Technol, 2015, 31(3): 325 [13] Wang M J. Application of powder metallurgy friction material on high speed train. Henan Sci Technol, 2018(2): 109王梦洁. 粉末冶金摩擦材料在高速列车上的应用. 河南科技, 2018(2): 109 [14] Han J J, Ning K Y, Han M, et al. The effect of rotation speed on the temperature and stress field of iron-based friction pairs. J Phys Conf Ser, 2020, 1637: 012039 doi: 10.1088/1742-6596/1637/1/012039 [15] Li Z Q. Research on Characteristics of Hot Spots and Initiation and Propagation Mechanisms of Cracks of Brake Discs Used for High Speed Trains [Dissertation]. Beijing: Beijing Jiaotong University, 2015李志强. 高速列车制动盘热斑特征及裂纹萌生扩展机制研究[学位论文]. 北京: 北京交通大学, 2015 -

下载:

下载: