Thermal shock resistance of Al2O3 and Al2O3-13%TiO2 coatings deposited by supersonic atmospheric plasma spraying

-

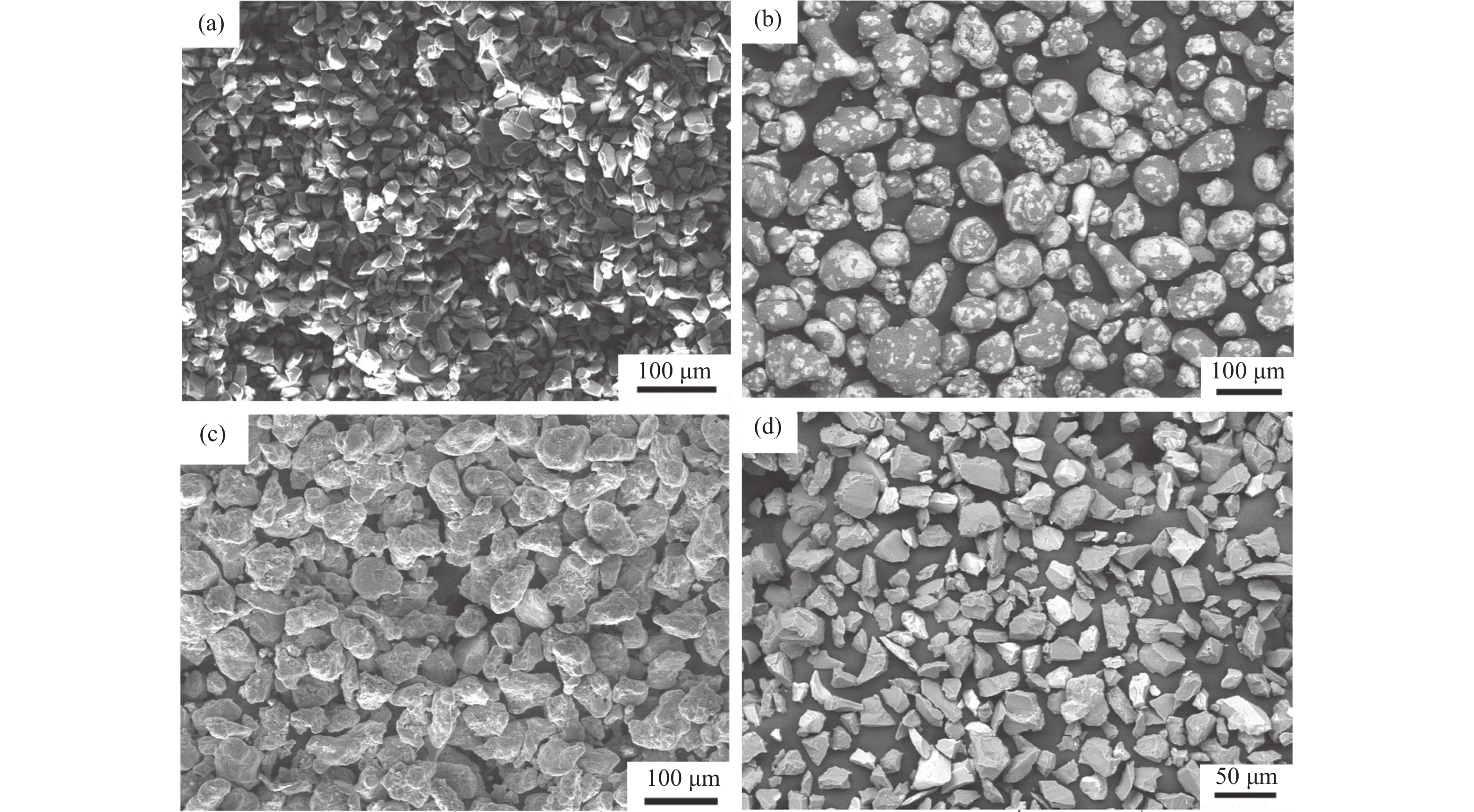

摘要: 采用超音速等离子喷涂工艺在不锈钢基体上制备了FeAl/Al2O3、FeCrAl/Al2O3、FeAl/Al2O3-13%TiO2、FeCrAl/Al2O3-13%TiO2四种涂层,通过扫描电镜表征微观结构,图像分析技术测量孔隙率,多峰法计算α-Al2O3质量分数,并测试了涂层的抗热震性能和结合强度。结果表明:超音速等离子喷涂制备的Al2O3涂层中α-Al2O3的质量分数约为40.3%~42.5%,涂层孔隙率约为3.47%~3.52%,制备的Al2O3-13%TiO2涂层中α-Al2O3的质量分数约为24.0%~29.7%,涂层孔隙率约为3.12%~3.31%。水淬热震实验(800 ℃/保温30 min)表明,FeCrAl/Al2O3涂层的抗热震性能最优,FeCrAl/Al2O3-13%TiO2涂层抗热震性能次之,FeAl/Al2O3涂层与FeAl/Al2O3-13%TiO2涂层抗热震性能最差。Abstract: The thermal shock resistance of FeAl/Al2O3, FeCrAl/Al2O3, FeAl/Al2O3-13%TiO2, and FeCrAl/Al2O3-13%TiO2 coatings deposited by supersonic atmospheric plasma spraying (SAPS) on the stainless steel matrix was investigated in this paper. The microstructure of the coatings was characterized by scanning electron microscope, the porosity was measured by image analysis, the mass fraction of α-Al2O3 was calculated by multi peak method, and the bonding strength was tested. The results show that, the mass fraction of α-Al2O3 in Al2O3 coating is 40.3%~42.5%, the porosity is 3.47%~3.52%; the mass fraction of α-Al2O3 in Al2O3-13%TiO2 coating is about 24.0%~29.7%, the porosity is 3.12%~3.31%. The results of water-quenching tests at 800 ℃ for 30 min show that, the FeCrAl/Al2O3 coating presents the highest thermal shock resistance, and the FeCrAl/Al2O3-13%TiO2 coating takes the second place. The FeAl/Al2O3 and FeAl/Al2O3-13%TiO2 coatings exhibite the same thermal shock resistance, which are the worst in four kinds of coatings.

-

Key words:

- supersonic atmospheric plasma spraying /

- hermal shock resistance /

- coatings /

- Al2O3 /

- FeAl /

- FeCrAl

-

表 1 涂层喷涂参数

Table 1. Spraying parameters for the coatings

涂层 电流 / A 电压 / V 氩气流量 / (L·min−1) 氢气流量 / (L·min−1) 喷涂距离 / mm 粒子温度 / ℃ 粒子速度 / (m·s−1) Al2O3 312 133 65.2 16.7 90 3250.70±2.18 399.72±1.11 FeAl 380 120 70.0 20.4 90 — — Al2O3-13%TiO2 366 131 65.0 15.4 90 3242.03±2.49 387.91±2.05 FeCrAl 380 130 65.0 12.4 100 — — 表 2 涂层喷涂参数

Table 2. Spraying parameters for the coatings

样品 衍射强度(计次) α-A12O3质量分数 / % (012) (104) (110) (113) (116) 纯α-A12O3 2443 3519 1460 3607 2912 — FeAl/Al2O3 878 1039 1262 956 946 42.5 FeCrAl/Al2O3 700 1231 1376 1014 456 40.3 FeAl/Al2O3-13%TiO2 695 548 670 456 505 24.0 FeCrAl/Al2O3-13%TiO2 787 704 810 671 648 29.7 -

[1] Halim Z A A, Ahmad N, Hanapi M F, et al. Rapid surface treatment of grey cast iron for reduction of friction and wear by alumina coating using gas tunnel plasma spray. Mater Chem Phys, 2020, 260: 124 [2] He M T, Meng H M, Wang Y C, et al. Research and development of advanced thermal barrier coating materials and preparation technology. Powder Metall Technol, 2019, 37(1): 62 doi: 10.19591/j.cnki.cn11-1974/tf.2019.01.011何明涛, 孟惠民, 王宇超, 等. 新型热障涂层材料及其制备技术的研究与发展. 粉末冶金技术, 2019, 37(1): 62 doi: 10.19591/j.cnki.cn11-1974/tf.2019.01.011 [3] Zeng Y, Lee S W, Ding C X. Plasma spray coatings in different nano size alumina. Mater Lett, 2002, 57: 495 doi: 10.1016/S0167-577X(02)00818-2 [4] Hu L, Zhang G K, Tang T. Research progress on formation mechanism and low temperature preparation technology of Al2O3 film on surface of FeAl/Al2O3 tritium permeation barrier. Mater Mech Eng, 2019, 43(6): 1胡立, 张桂凯, 唐涛. FeAl/Al2O3阻氚涂层表面Al2O3薄膜形成机制与低温制备技术的研究进展. 机械工程材料, 2019, 43(6): 1 [5] Lu X C, Yan D R, Yang Y, et al. Thermal behavior of nanostructured Al2O3-13%TiO2 ceramic coatings deposited by plasma spraying. Ordn Mater Sci Eng, 2011, 34(3): 9 doi: 10.3969/j.issn.1004-244X.2011.03.003路学成, 阎殿然, 杨勇, 等. 等离子喷涂纳米Al2O3-13%TiO2涂层热学特性研究. 兵器材料科学与工程, 2011, 34(3): 9 doi: 10.3969/j.issn.1004-244X.2011.03.003 [6] Yilmaz R, Kurt A O, Demir A, et al. Effects of TiO2 on the mechanical properties of the Al2O3-TiO2 plasma sprayed coating. J Eur Ceram Soc, 2007, 27: 1319 doi: 10.1016/j.jeurceramsoc.2006.04.099 [7] Wang C, Song R G. High temperature oxidation and thermal shock of plasma sprayed nano-Al2O3/TiO2 ceramic coating. Hot Working Technol, 2012, 41(14): 145 doi: 10.3969/j.issn.1001-3814.2012.14.041王超, 宋仁国. 离子喷涂纳米Al2O3/TiO2陶瓷复合涂层高温氧化和热震性能研究. 热加工工艺, 2012, 41(14): 145 doi: 10.3969/j.issn.1001-3814.2012.14.041 [8] Xu X J, He Y, Ma D L, et al. Study on the structure and thermal oxidization properties of plasma sprayed Al2O3-13TiO2 composite ceramic coatings. Surf Technol, 2010, 39(1): 15 doi: 10.3969/j.issn.1001-3660.2010.01.005徐心洁, 贺毅, 马东林, 等. 等离子喷涂Al2O3–13TiO2复合陶瓷涂层的组织及热氧化性能的研究. 表面技术, 2010, 39(1): 15 doi: 10.3969/j.issn.1001-3660.2010.01.005 [9] Bai Y, Zhao L, Qu Y M, et al. Particle in-flight behavior and its influence on the microstructure and properties of supersonic-atmospheric-plasma-sprayed nanostructured thermal barrier coatings. J Alloys Compd, 2015, 644: 873 doi: 10.1016/j.jallcom.2015.05.068 [10] Bai Y, Zhao L, Wang Y, et al. Fragmentation of in-flight particles and its influence on the microstructure and mechanical property of YSZ coating deposited by supersonic atmospheric plasma spraying. J Alloys Compd, 2015, 632: 794 doi: 10.1016/j.jallcom.2015.01.265 [11] Shaw L L. Thermal residual stresses in plates and coatings composed of multi-layered and functionally graded materials. Composites Part B, 1998, 29(3): 199 doi: 10.1016/S1359-8368(97)00029-2 [12] Yang Y Z, Liu Z G, Liu Z Y, et al. Interfacial phenomena in the plasma spraying Al2O3+13wt.% TiO2 ceramic coating. Thin Solid Films, 2001, 388(1-2): 208 doi: 10.1016/S0040-6090(01)00806-9 [13] Wang Y, Tian W, Yang Y, et al. Investigation of stress field and failure mode of plasma sprayed Al2O3-13%TiO2 coatings under thermal shock. Mater Sci Eng A, 2009, 516: 103 doi: 10.1016/j.msea.2009.03.041 [14] Irisawa T, Matsumoto H. Thermal shock resistance and adhesion strength of plasma-sprayed alumina coating on cast iron. Thin Solid Films, 2006, 509(1-2): 141 doi: 10.1016/j.tsf.2005.09.132 [15] Jordan E H, Gell M, Sohn Y H, et al. Fabrication and evaluation of plasma sprayed nanostructured alumina-titania coatings with superior properties. Mater Sci Eng A, 2001, 301(1): 80 doi: 10.1016/S0921-5093(00)01382-4 [16] Lu X C, Yan D R, Yang Y, et al. Phase evolution of plasma sprayed Al2O3-13%TiO2 coatings derived from nanocrystalline powders. Trans Nonferrous Met Soc China, 2013, 23(10): 2951 doi: 10.1016/S1003-6326(13)62819-8 [17] Sivakumar G, Dusane R O, Joshi S V. A novel approach to process phase pure α-A2O3 coatings by solution precursor plasma spraying. J Eur Ceram Soc, 2013, 33(13-14): 2823 doi: 10.1016/j.jeurceramsoc.2013.05.005 [18] Lang F, Yu Z, Gedevanishvili S, et al. Isothermal oxidation behavior of a sheet alloy of Fe-40at.%Al at temperatures between 1073 and 1473 K. Intermetallics, 2003, 11(7): 697 [19] Zhang Z G, Zhang X J, Pan T J, et al. Initial stage oxidation of Fe-Al and Fe-Cr-Al alloys at high temperature. Res Iron Steel, 2007, 35(3): 38 doi: 10.3969/j.issn.1001-1447.2007.03.011张志刚, 张学军, 潘太军, 等. FeAl和FeCrAl合金在高温下的初期氧化. 钢铁研究, 2007, 35(3): 38 doi: 10.3969/j.issn.1001-1447.2007.03.011 [20] Yang K, Chen J, Hao F, et al. Stress-induced phase transformation and amorphous-to-nanocrystalline transition in plasma-sprayed Al2O3 coating with relative low temperature heat treatment. Surf Coat Technol, 2014, 253: 277 doi: 10.1016/j.surfcoat.2014.05.056 -

下载:

下载: