-

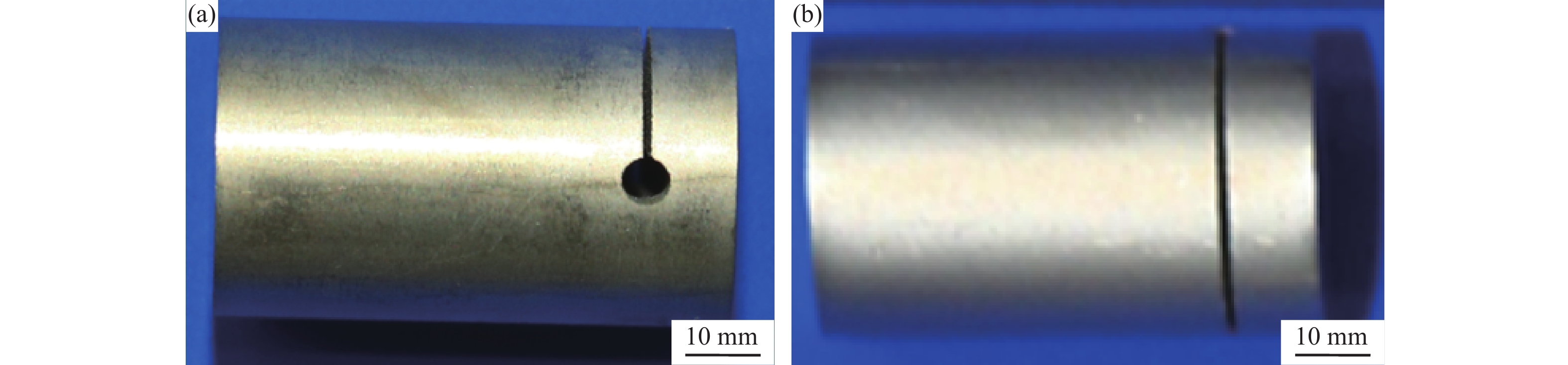

摘要: 采用非平衡磁控溅射工艺在Mo–La合金表面沉积FeCrAl涂层,研究所制备涂层的耐腐蚀性及涂层的腐蚀机理。结果表明:FeCrAl涂层样品在360 ℃、18.6 MPa、纯水的高压釜中腐蚀72 h,平均腐蚀速率为3.8 mg·dm‒2,低于同条件下锆合金以及未沉积涂层的钼镧合金的腐蚀速率,且涂层中的Al与外界环境介质中的氧发生反应,在涂层表面形成致密的Al2O3薄膜,在一定程度上减缓了涂层的腐蚀速度,有效保护了基体材料。FeCrAl涂层样品在1200 ℃、0.1 MPa的高温水蒸气环境下腐蚀8 h,Al2O3氧化膜厚度在4.0 μm左右,涂层维持保护效果,钼镧合金基体未暴露在腐蚀环境中;经淬火后,Al2O3氧化膜厚度减小至2.5 μm左右,涂层依旧维持结构完整性,没有出现贯穿性脱落,满足Mo–La合金表面耐腐蚀性的使用要求。Abstract: FeCrAl coatings were deposited on the surface of Mo–La alloys by the non-equilibrium magnetron sputtering process. The corrosion resistance and corrosion mechanism of the FeCrAl coatings were investigated. The results show that, the average corrosion rate of FeCrAl coatings is 3.8 mg·dm‒2 in the autoclave under 360 ℃, 18.6 MPa, and pure water corrosion condition for 72 h, which is lower than that of zirconium alloys and Mo–La alloys without coating. Al in the coating reacts with the oxygen in the environment medium, forming a dense Al2O3 film on the surface of the coatings, which slows down the corrosion rate of the coatings and effectively protects the substrate materials. The thickness of Al2O3 film is about 4 μm after the FeCrAl coatings are corroded for 8 h at 1200 ℃ and 0.1 MPa, the coatings maintain the protective effect, and the Mo–La alloy substrate is not exposed to the corrosion environment. After quenching, the thickness of Al2O3 film reduces to about 2.5 μm, the coatings keep the structural integrity, and there is no penetrating shedding in Mo–La alloy surface, which meets the requirement of corrosion resistance.

-

Key words:

- FeCrAl coatings /

- Mo–La alloys /

- nuclear reactor /

- magnetron sputtering /

- corrosion resistance

-

表 1 FeCrAl涂层沉积工艺参数

Table 1. Technical parameters of the FeCrAl coating deposition

靶材功率 / W 偏压 / V 转速 / (r·min‒1) 沉积时间 / h Al靶 不锈钢靶 Cr靶 1500 4000 2000 90 6 5 表 2 腐蚀实验参数

Table 2. Parameters of the corrosion tests for the molybdenum alloy canning materials

实验方法 温度 / ℃ 压力 / MPa 蒸汽流量 / (g·min‒1) 时间 / h 高压水腐蚀 360 18.6 — 72 高温水蒸汽腐蚀 1200 0.1 1.0 8 淬火 1200 0.1 1.0 8 -

[1] Ren Y G. The research and development of the self-brand nuclear fuel. Chin Nucl Power, 2018, 11(1): 46任永岗. 我国自主品牌核电燃料元件的研发. 中国核电, 2018, 11(1): 46 [2] Ji Q. Study on Preparation of FeCrAlY Coating and Corrosion Resistance at High Temperature and Pressure [Dissertation]. Xi'an: Xi'an University of Technology, 2019纪奇. FeCrAlY涂层的制备与高温高压抗腐蚀性能研究[学位论文]. 西安: 西安理工大学, 2019 [3] Cui C P, Gao Y M, Wei S Z, et al. The mechanical properties of the Mo‒0.5Ti and Mo‒0.1Zr alloys at room temperature and high temperature annealing. High Temp Mater Processes, 2017, 36(2): 167 [4] Hu P, Song R, Li X J, et al. Influence of concentrations of chloride ions on electrochemical corrosion behavior of titanium-zirconium-molybdenum alloy. J Alloys Compd, 2017, 708: 367 doi: 10.1016/j.jallcom.2017.03.025 [5] Deng J, Wang K S, Hu P, et al. Electrochemical behavior and microstructural characterization of lanthanum-doped titanium‒zirconium‒molybdenum alloy. J Alloys Compd, 2018, 763: 687 doi: 10.1016/j.jallcom.2018.05.338 [6] Bu C Y. Study on Properties of Molybdenum Wire Doped with Si, Al, K [Dissertation]. Xi'an: Xi'an University of Architecture and Technology, 2014卜春阳. 掺杂Si-Al-K高温钼合金丝材性能研究[学位论文]. 西安: 西安建筑科技大学, 2014 [7] Xia Y Q, Wang D C, Wang J S, et al. Study on high temperature molybdenum alloy doped with rare-earth element. China Molybdenum Ind, 2001, 25(4): 76(夏耀勤, 王鼎春, 王敬生, 等. 掺杂稀土元素的高温钼合金的研究. 中国钼业, 2001, 25(4): 76 [8] Endo M, Kimura K, Udagawa T, et al. Effects of doping molybdenum wire with rare-earth elements. High Temp High Press, 1990, 22(2): 129 [9] Yang Y C. The recent advanced application of rare earths in non-ferrous metal alloys. Rare Met Mater Eng, 1993, 22(4): 1杨遇春. 稀土在有色金属合金中应用的新进展. 稀有金属材料与工程, 1993, 22(4): 1 [10] An G, Sun J, Sun Y J, et al. Research on microstructure of electron beam welded joints of rare earth-molybdenum alloy. Mater Sci, 2019, 9(10): 947安耿, 孙军, 孙院军, 等. 稀土钼合金电子束焊接接头组织研究. 材料科学, 2019, 9(10): 947 [11] Hu X X, Terrani K A, Wirth B D, et al. Hydrogen permeation in FeCrAl alloys for LWR cladding application. J Nucl Mater, 2015, 461: 282 doi: 10.1016/j.jnucmat.2015.02.040 [12] Younker I, Fratoni M. Neutronic evaluation of coating and cladding materials for accident tolerant fuels. Prog Nucl Energy, 2016, 88: 10 doi: 10.1016/j.pnucene.2015.11.006 [13] Yang H Y, Chen Q S, Zhang R Q, et al. Effect of deposition temperature on microstructure and properties of FeCrAl coatings prepared by magnetron sputtering. Nucl Power Eng, 2020, 41(Suppl 1): 200杨红艳, 陈青松, 张瑞谦, 等. 沉积温度对磁控溅射制备FeCrAl涂层微观结构及性能的影响. 核动力工程, 2020, 41(增刊 1): 200 [14] Xie N P, Gu S Y, Zhang H A. Structure of molybdenum silicide coating prepared on molybdenum substrate by molten salt method. Mater Mech Eng, 2012, 36(1): 65谢能平, 古思勇, 张厚安. 采用熔盐法在钼基体上制备硅化钼涂层的结构. 机械工程材料, 2012, 36(1): 65 [15] Ma X C, Li J W, Wei S Z, et al. Research on the oxidation-resistant coating on the surface of molybdenum electrode in the glass kiln. Rare Met Cement Carb, 2014, 42(5): 51马小冲, 李继文, 魏世忠, 等. 玻璃窑炉用钼电极表面抗氧化涂层的研究. 稀有金属与硬质合金, 2014, 42(5): 51 [16] Tang D Z. Research on the Preparation and Properties of Coating on Molybdenum [Dissertation]. Changsha: Central South University, 2014汤德志. 钼合金表面涂层的制备及性能研究[学位论文]. 长沙: 中南大学, 2014 [17] Chen J, Li W, He D Y, et al. Surface microstructure and high-temperature erosion resistance of FeCrAl coating after high current pulsed electron beam treatment. Surf Technol, 2020, 49(5): 200陈军, 李伟, 贺冬云, 等. 强流脉冲电子束表面改性FeCrAl涂层的显微组织及耐高温腐蚀性能研究. 表面技术, 2020, 49(5): 200 [18] Zhang J L, Hu Y, Tu L M, et al. Corrosion behavior and oxide microstructure of Zr‒1Nb‒xGe alloys corroded in 360 ℃/18.6 MPa deionized water. Corros Sci, 2016, 102: 161 [19] Badini C, Laurella F. Oxidation of FeCrAl alloy: influence of temperature and atmosphere on scale growth rate and mechanism. Surf Coat Technol, 2001, 135(2-3): 291 doi: 10.1016/S0257-8972(00)00989-0 [20] Deng C P. Study on Formation Mechanism of Porosity and Cracks in Laser Welding of Magnesium Alloy Thin Plates [Dissertation]. Chongqing: Chongqing University, 2010邓彩萍. 镁合金薄板激光焊气孔及裂纹形成机理研究[学位论文]. 重庆: 重庆大学, 2010 -

下载:

下载: