Effect of hot isostatic pressing sintering temperature on the properties of Mo–Na alloys

-

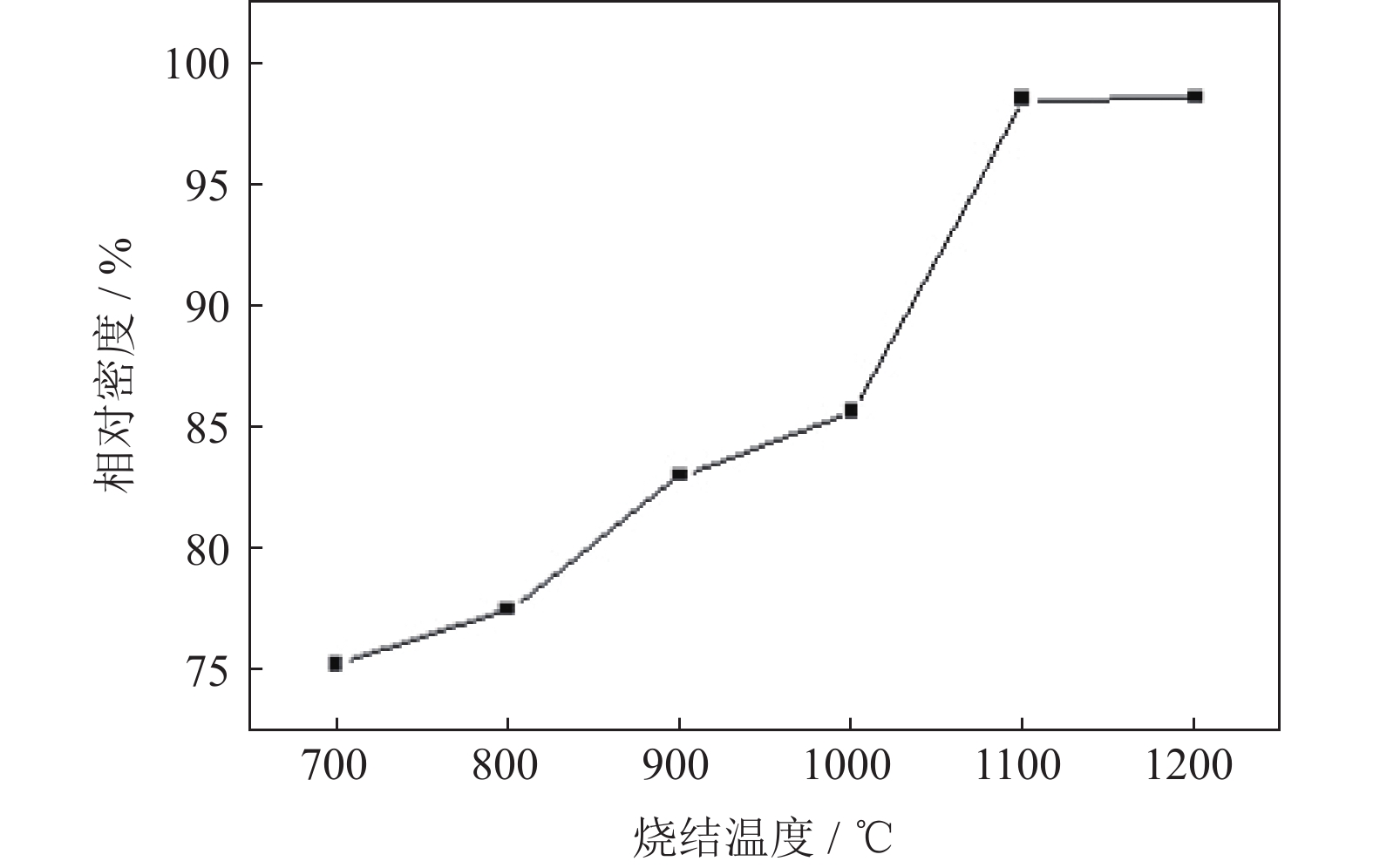

摘要: 采用热等静压烧结法制备Mo–Na合金,研究了热等静压烧结温度对Mo–Na合金显微组织、硬度、密度及Na质量分数的影响,分析了Mo–Na合金热等静压烧结的致密化过程。结果表明:采用热等静压烧结法制备的Mo–Na合金显微组织细小均匀,平均晶粒尺寸在10 μm以下。随着热等静压烧结温度的升高,相对密度及硬度随之升高,在1100 ℃时达到最大,分别为99.58%和HRA 54.50,热等静压过程中液相的形成对Mo–Na合金的致密化起到了重要作用。热等静压过程很好地避免了低熔点Na金属高温烧结过程中的挥发,在1100 ℃烧结后Na质量分数基本无变化。Abstract: Mo–Na alloys were prepared by the hot isostatic pressing (HIP) sintering. The effects of HIP sintering temperature on the microstructure, hardness, density, and Na mass fraction of the Mo–Na alloys were studied. The densification process of the Mo–Na alloys sintered by HIP was analyzed. The results show that, the microstructure of the Mo–Na alloys prepared by HIP sintering is ultrafine and uniform, the average grain size of the alloys is below 10 μm. With the increase of the HIP sintering temperature, the relative density and hardness increase and reach the maximum value at 1100 ℃, which is 99.58% and HRA 54.50, respectively. The liquid phase formation during HIP plays an important role in the densification of the Mo–Na alloys. The volatilization of the Na metals with the low melting point during the high temperature sintering is well avoided in the process of HIP, and the Na mass fraction is almost unchanged after sintering at 1100 ℃.

-

Key words:

- hot isostatic pressing /

- Mo–Na alloys /

- sintering temperature /

- densification

-

表 1 不同烧结工艺条件下Mo–Na合金化学成分(质量分数)

Table 1. Chemical composition of the Mo–Na alloys in different sintering conditions

% 状态 O C Fe Ni Mg Si Al K 粉末态 0.150 0.0022 0.0016 0.0010 0.0006 0.0010 0.0003 0.0032 700 ℃热等静压烧结 0.130 0.0024 0.0020 0.0008 0.0006 0.0011 0.0003 0.0030 800 ℃热等静压烧结 0.139 0.0026 0.0021 0.0008 0.0006 0.0010 0.0003 0.0028 900 ℃热等静压烧结 0.139 0.0022 0.0023 0.0010 0.0006 0.0011 0.0003 0.0030 1000 ℃热等静压烧结 0.139 0.0027 0.0020 0.0010 0.0006 0.0010 0.0003 0.0032 1100 ℃热等静压烧结 0.139 0.0024 0.0018 0.0010 0.0006 0.0011 0.0003 0.0028 1200 ℃热等静压烧结 0.139 0.0023 0.0018 0.0010 0.0006 0.0011 0.0003 0.0027 1100 ℃真空热压烧结 0.180 0.0021 0.0018 0.0010 0.0006 0.0010 0.0003 0.0028 -

[1] Liu X J, Wang L, Wang H Q, et al. New progress in CIGS thin film solar cells. Electron Process Technol, 2013, 34(5): 258刘晓剑, 王玲, 王宏芹, 等. CIGS薄膜太阳能电池研究新进展. 电子工艺技术, 2013, 34(5): 258 [2] Cheng S Q, Zhang K Z, Zhang Y X, et al. Effects of different Cs distribution in the film on the performance of CIGS thin film solar cells. Sol Energy Mater Sol Cells, 2021, 222: 110917 doi: 10.1016/j.solmat.2020.110917 [3] Blösch P, Nishiwakia S, Chirilă A, et al. Sodium-doped molybdenum back contacts for flexible Cu(In, Ga)Se2 solar cells. Thin Solid Films, 2013, 535: 214 doi: 10.1016/j.tsf.2012.10.080 [4] Peng S, Wang Y, Wang W. Most promising CIGS thin film solar cell. World Build Mater, 2010, 31(4): 1 doi: 10.3963/j.issn.1674-6066.2010.04.001彭寿, 王芸, 王伟. 最具发展前景的CIGS薄膜太阳能电池. 建材世界, 2010, 31(4): 1 doi: 10.3963/j.issn.1674-6066.2010.04.001 [5] Wang Z A. Studies and Preparation of Absorb Layer for CIGS Thin Film Solar Cells [Dissertation]. Shanghai: East China Normal University, 2010王正安. 铜铟镓硒薄膜太阳能电池CIGS吸收层的研究与制备[学位论文]. 上海: 华东师范大学, 2010 [6] Zhu Q, Chen L B, Wang N, et al. Preparation of Mo–Na targets by vacuum hot pressing technique. China Molybdenum Ind, 2015, 39(6): 55朱琦, 陈良斌, 王娜, 等. 真空热压烧结制备Mo–Na合金靶材的研究. 中国钼业, 2015, 39(6): 55 [7] Kim S C, Park H, Lee E W, et al. Role of Na in reaction pathways and kinetics of CuInSe2 formation from stacked binary precursors. Thin Solid Films, 2011, 519(21): 7250 doi: 10.1016/j.tsf.2010.12.222 [8] Rudmann D, Brémaud D, da Cunha A F, et al. Sodium incorporation strategies for CIGS growth at different temperatures. Thin Solid Films, 2005, 480-481: 55 doi: 10.1016/j.tsf.2004.11.071 [9] Shin Y M, Shin D H, Kim J H, et al. Effect of Na doping using Na2S on the structure and photovoltaic properties of CIGS solar cells. Curr Appl Phys, 2011, 11(Suppl 1): S59 [10] Wang B, Liu P, Li W, et al. Progress in research of CIGS thin film solar cells. Mater Rev, 2011, 25(10): 54王波, 刘平, 李伟, 等. 铜铟镓硒(CIGS)薄膜太阳能电池的研究进展. 材料导报, 2011, 25(10): 54 [11] Guan M X. Application of hot isostatic presses in power metallurgy. Tianjin Metall, 2001(5): 40 doi: 10.3969/j.issn.1006-110X.2001.05.014关明鑫. 热等静压在粉末冶金中的应用. 天津冶金, 2001(5): 40 doi: 10.3969/j.issn.1006-110X.2001.05.014 [12] Shen Q M, Yang J, Shan X Y, et al. Development and application of HIP technology. Rare Met Cement Carb, 2003, 31(2): 33 doi: 10.3969/j.issn.1004-0536.2003.02.010谌启明, 杨靖, 单先裕, 等. 热等静压技术的发展及应用. 稀有金属与硬质合金, 2003, 31(2): 33 doi: 10.3969/j.issn.1004-0536.2003.02.010 [13] Lin X H, Li L P, Li B, et al. Application of hot isostatic pressing in preparation of rare and refractory metal products. Powder Metall Ind, 2017, 27(3): 63林小辉, 李来平, 李斌, 等. 热等静压在稀有难熔金属产品制备中的应用. 粉末冶金工业, 2017, 27(3): 63 [14] Han F L. The PM HIP parts process and design guidelines. Powder Metall Technol, 2016, 34(1): 62 doi: 10.3969/j.issn.1001-3784.2016.01.012韩凤麟. 粉末冶金/热等静压(PM HIP)零件的生产工艺与设计准则. 粉末冶金技术, 2016, 34(1): 62 doi: 10.3969/j.issn.1001-3784.2016.01.012 [15] Williams B. Recent trends in hot isostatic pressing (HIP): processing and applications. Transl by Han F L. Powder Metall Technol, 2014, 32(6): 464Williams B. 近年来热等静压(HIP)处理与应用发展趋势. 韩凤麟, 译. 粉末冶金技术, 2014, 32(6): 464 [16] Wang X F, He W W, Zhu J L, et al. Microstructure and mechanical properties of Fe–Co–Ni based superalloy prepared by hot isostatic pressing. Powder Metall Technol, 2020, 38(5): 371王新锋, 贺卫卫, 朱纪磊, 等. 热等静压铁钴镍基高温合金的显微组织和力学性能. 粉末冶金技术, 2020, 38(5): 371 [17] Guo Z J, Lin Y, Wang W M, et al. Effect of HIP on physicomechanical properties of molybdenum. Ordnance Mater Sci Eng, 2002, 25(4): 22 doi: 10.3969/j.issn.1004-244X.2002.04.006郭志俊, 林勇, 王文明, 等. 热等静压工艺对金属钼力学性能的影响. 兵器材料科学与工程, 2002, 25(4): 22 doi: 10.3969/j.issn.1004-244X.2002.04.006 [18] Wang N, Zhu Q, Zeng Y, et al. Study on the phase transition of Mo–Na alloy during sintering process. China Molybdenum Ind, 2016, 40(3): 53王娜, 朱琦, 曾毅, 等. Mo–Na合金烧结过程中的物相演变. 中国钼业, 2016, 40(3): 53 -

下载:

下载: