-

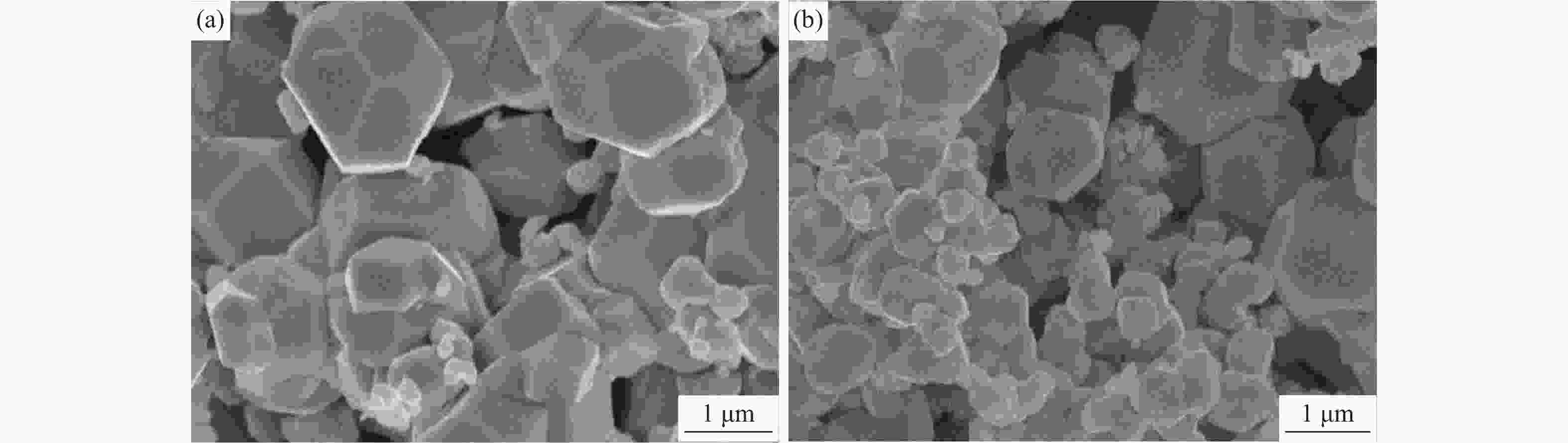

摘要: 大尺寸高相对密度钨管制品对于石英熔炼行业具有重要的应用价值,为了克服大尺寸钨管在制备过程中易出现压坯开裂和相对密度不高的问题,对不同粒度钨粉进行了掺混实验,研究了混合时间对压坯强度的影响。研究表明,对掺混钨粉进行气流破碎处理,可以有效地缩小粒度分布范围,提高颗粒均匀性。通过对压制压强和保压时间的研究,发现压制压强>230 MPa时,延长保压时间或提高压制压强并不会提高压坯强度。通过慢速升温烧结实验,发现钨管收缩率较大的温度集中在1600 ℃以下,延长中低温烧结时间可以较好的提高钨管的相对密度。Abstract: The tungsten tube products with the large size and high relative density have the important application in the quartz smelting industry. To overcome the problems of cracking and low relative density in the preparation process of the large size tungsten tube, the mixing experiments of tungsten powders with the different particle sizes were carried out, and the effect of mixing time on the compaction strength was studied. It is found that the particle size distribution can be effectively reduced and the particle uniformity can be improved by the further air crushing treatment for the mixed tungsten powders. When the pressing pressure is more than 230 MPa, the compaction strength will not be improved by prolonging the holding time or increasing the pressing pressure.The temperature for the tungsten tube with the higher shrinkage rate concentrates below 1600 ℃ in the sintering experiment by slow temperature rising. Therefore, the relative density of the tungsten tube can be improved by prolonging the sintering time at medium and low temperature.

-

Key words:

- tungsten tube /

- large size /

- sintering /

- relative density

-

表 1 掺混钨粉压坯强度

Table 1. Compact strength of the mixed tungsten powder

掺混比例 不同混料时间的压坯强度 / MPa 2 h 4 h 6 h A 1.67 1.74 1.70 95%A+5%B 1.94 2.16 2.37 90%A+10%B 1.86 2.16 2.35 80%A+20%B 1.56 1.62 2.29 70%A+30%B 1.71 1.96 2.52 表 2 钨粉预处理前后性能变化

Table 2. Performance change of the tungsten powders before and after pretreatment

试样 费氏粒度 / μm D10 / μm D50 / μm D90 / μm 压坯强度 / MPa 70%A+30%B 2.82 3.76 10.94 36.60 2.52 预处理后70%A+30%B 2.63 3.68 8.47 19.66 3.13 表 3 钨制品压制试验结果

Table 3. Pressing test results of the tungsten products

压制压强 / MPa 压坯密度 / (g·cm−3) 保压15 min 保压25 min 保压35 min 160 10.0 10.2 10.6 180 10.9 11.2 11.5 210 11.2 11.6 11.7 220 11.7 11.8 11.7 230 11.9 12.0 11.8 240 11.8 11.8 11.8 270 崩边 分层 开裂 表 4 烧结温度与钨管收缩性能

Table 4. Sintering temperature and shrinkage properties of the tungsten tubes

烧结温度 / ℃ 收缩率 / % 收缩占比 / % 1200 97.5 17 1400 93.1 30 1600 89.1 28 1800 87.5 11 2000 86.6 7 2100 86.3 2 2200 85.9 2 2280 85.6 2 表 5 大尺寸高相对密度钨管均匀性测试结果

Table 5. Uniformity test results of the tungsten tube with the large size and high relative density

试样 密度 /

(g·cm−3)硬度,HV30 平均晶粒度(截线法)/

μm1# 18.67 326 29.2 2# 18.70 336 31.3 3# 18.65 324 29.4 4# 18.69 327 26.7 -

[1] Chen J, Xiong N, Ge Q L, et al. Manufacturing technology of tungsten crucibles. China Tungsten Ind, 2016, 31(1): 63 doi: 10.3969/j.issn.1009-0622.2016.01.012陈锦, 熊宁, 葛启录, 等. 钨坩埚的制备技术. 中国钨业, 2016, 31(1): 63 doi: 10.3969/j.issn.1009-0622.2016.01.012 [2] Xie K D. Research progress in application and preparation technology of refractory metal tungsten and molybdenum tubes. Cement Carb, 2018, 35(3): 219谢康德. 难熔金属钨、钼管材的应用及其制备技术研究进展. 硬质合金, 2018, 35(3): 219 [3] Liu L X. Reflections on the high quality development of tungsten industry in China. China Tungsten Ind, 2019, 34(1): 10刘良先. 我国钨业高质量发展的思考. 中国钨业, 2019, 34(1): 10 [4] Zhao Z W, Sun F L, Yang J H, et al. Status and prospect for tungsten resource, technologies and industrial development in China. Chin J Nonferrous Met, 2019, 29(9): 1902赵中伟, 孙丰龙, 杨金洪, 等. 我国钨资源、技术和产业发展现状与展望. 中国有色金属学报, 2019, 29(9): 1902 [5] Tan S B, Guo R M, Liu J Z, et al. Metallurgy and processing technologies of tungsten alloys. China Tungsten Ind, 2007, 22(1): 51 doi: 10.3969/j.issn.1009-0622.2007.01.014谭栓斌, 郭让民, 刘建章, 等. 钨的冶金及其加工技术. 中国钨业, 2007, 22(1): 51 doi: 10.3969/j.issn.1009-0622.2007.01.014 [6] Zhou W P, Wang L, Qin Y N, et al. Preparation technology of large-sized tungsten heavy alloy. Rare Met Mater Eng, 2020, 49(11): 3957周武平, 王玲, 秦颖楠, 等. 大规格钨基高比重合金材料制备技术研究. 稀有金属材料与工程, 2020, 49(11): 3957 [7] Chen J, Xiong N, Ge Q L, et al. Density uniformity of the tungsten crucibles. China Tungsten Ind, 2017, 32(4): 35 doi: 10.3969/j.issn.1009-0622.2017.04.007陈锦, 熊宁, 葛启录, 等. 钨坩埚密度均匀性研究. 中国钨业, 2017, 32(4): 35 doi: 10.3969/j.issn.1009-0622.2017.04.007 [8] Luo B H, Zhang H M. Research on the effects of different tungsten oxide materials on tungsten powder properties. Cement Carb, 2006, 23(3): 139 doi: 10.3969/j.issn.1003-7292.2006.03.003罗斌辉, 张华明. 不同氧化钨原料对钨粉性能的影响研究. 硬质合金, 2006, 23(3): 139 doi: 10.3969/j.issn.1003-7292.2006.03.003 [9] Liu W S, Long L P, Ma Y Z. Research and preparation methods for high-purity tungsten. Powder Metall Technol, 2012, 30(3): 223 doi: 10.3969/j.issn.1001-3784.2012.03.012刘文胜, 龙路平, 马运柱. 高纯钨研究现状及制备工艺方法综述. 粉末冶金技术, 2012, 30(3): 223 doi: 10.3969/j.issn.1001-3784.2012.03.012 [10] Li X C, Yi M Z, Luo C L, et al. Preparation of uniform fine size tungsten powder by boat-less continuous belt reduction furnace. Powder Metall Technol, 2008, 26(3): 163李新春, 易茂中, 罗崇玲, 等. 带式无舟皿连续还原炉制备粒度均匀的细颗粒钨粉. 粉末冶金技术, 2008, 26(3): 163 [11] Lin G A. Effect of morphology and particle size distribution of tungsten powder on compacting performance and green compact strength. Mater Sci Eng Powder Metall, 2009, 14(4): 260 doi: 10.3969/j.issn.1673-0224.2009.04.010林高安. 钨粉形貌与粒度分布对成形性和压坯强度的影响. 粉末冶金材料科学与工程, 2009, 14(4): 260 doi: 10.3969/j.issn.1673-0224.2009.04.010 [12] Shi J, Liu N, Liu A J, et al. Effect of pressing on microstructure and mechanical property of pure tungsten. Heat Treat, 2015, 30(4): 31 doi: 10.3969/j.issn.1008-1690.2015.04.008石俊, 刘宁, 刘爱军, 等. 压制压力对纯钨显微组织和力学性能的影响. 热处理, 2015, 30(4): 31 doi: 10.3969/j.issn.1008-1690.2015.04.008 [13] Wang L Y, Li C B, Zhang Y Q. Application of jet grading technology in tungsten products. Thermal Spray Technol, 2019, 11(3): 70 doi: 10.3969/j.issn.1674-7127.2019.03.011王芦燕, 李曹兵, 张宇晴. 射流分级技术在钨制品中的应用. 热喷涂技术, 2019, 11(3): 70 doi: 10.3969/j.issn.1674-7127.2019.03.011 [14] Li P, Hua R, Xue K M, et al. Research progress in tungsten and its alloys by plastic processing. Rare Met Mater Eng, 2016, 45(2): 529李萍, 华睿, 薛克敏, 等. 钨及其合金塑性加工的研究进展. 稀有金属材料与工程, 2016, 45(2): 529 [15] Huang P Y. Principle of Powder Metallurgy. Beijing: Metallurgical Industry Press, 2008黄培云. 粉末冶金原理. 北京: 冶金工业出版社, 2008 [16] Li L P, Duan X J, Duan H Q, et al. Analysis on the causes of cracks in the bottom of tungsten crucibles. Rare Met Mater Eng, 2002, 31(Suppl 2): 64李来平, 段小建, 段海清, 等. 钨坩埚底部出现裂纹的原因分析. 稀有金属材料与工程, 2002, 31(增刊 2): 64 [17] Han F L. Basic Course of Powder Metallurgy. Guangzhou: South China University of Technology Press, 2005韩凤麟. 粉末冶金基础教程. 广州: 华南理工大学出版社, 2005 -

下载:

下载: