Effect of jet milling processing on microstructure and mechanical properties of the sintered tungsten powders

-

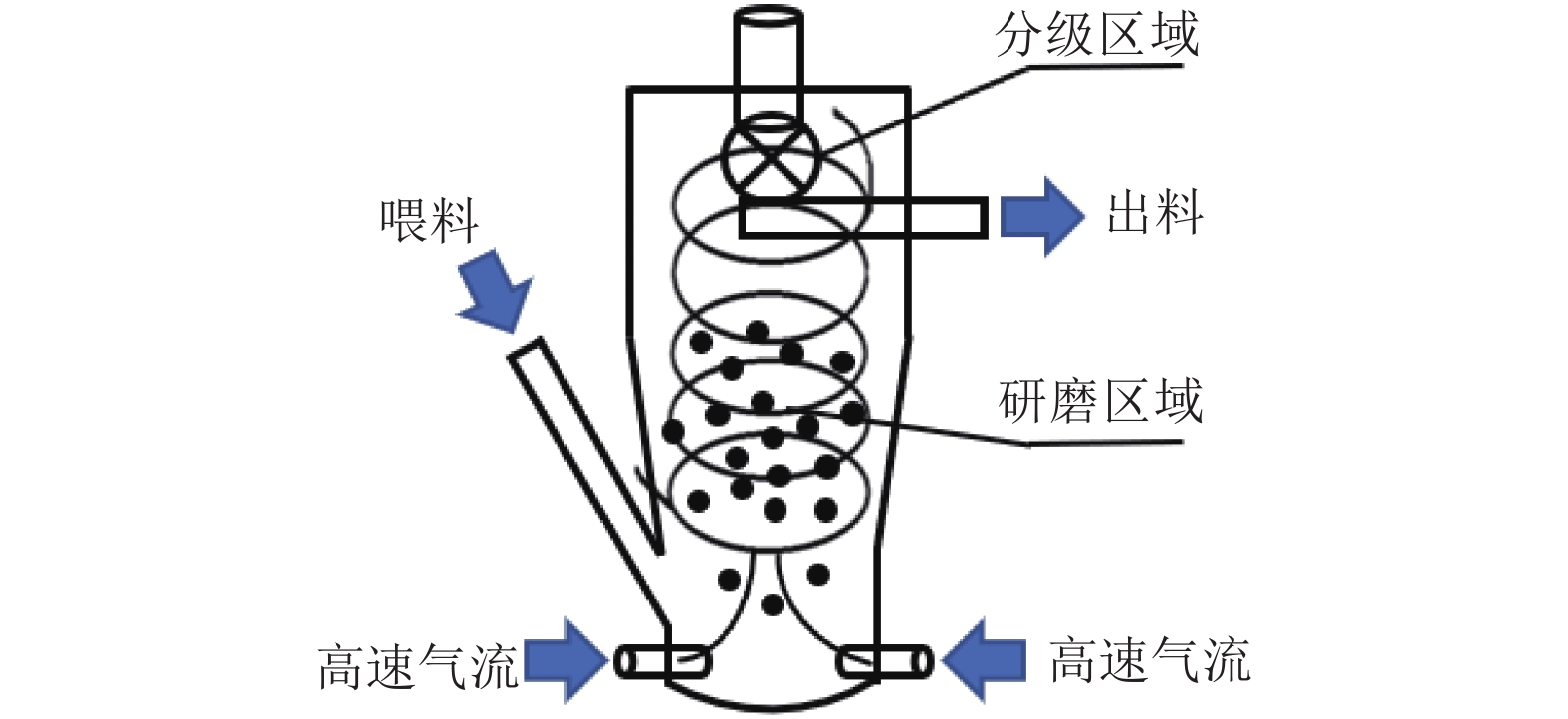

摘要: 采用气流磨分级技术对商业钨粉进行改性,研究气流磨处理和不同粒度搭配对钨粉粉末烧结体微观组织和力学性能的影响。结果表明,经气流磨分级处理后,粒度分布较窄的钨粉能实现良好的堆积均匀性,消除团聚体在烧结过程中形成的不规则粗孔,提升粉末烧结均匀性,提高烧结后期整体相对密度;烧结相对密度由90.7%提高至92.8%,抗弯强度由238.5 MPa提升至292.4 MPa。获得粒度分布窄、分散性好的钨粉可以消除烧结体中不规则粗孔,是提升烧结体力学性能的关键。Abstract: Commercial tungsten powders were modified by jet milling, the effects of jet milling treatment and particle size distribution on the microstructure and mechanical properties of the sintered tungsten body were studied. The results show that, the tungsten powders treated by jet milling in the narrower particle size distribution can achieve the better packing homogeneity, eliminate the irregular coarse pores formed during sintering, improve the sintering uniformity, and increase the relative density of the sintered body; the relative density of the sintered body increases from 90.7% to 92.8%, and the bending strength from 238.5 MPa to 292.4 MPa. The tungsten powders in the narrow particle size distribution with the good dispersibility can eliminate the irregular coarse pores in sintered body, which is the key factor to improve the mechanical properties of the sintered body.

-

Key words:

- jet milling /

- tungsten powders /

- sintering /

- pores /

- microstructure /

- mechanical properties

-

表 1 不同批次粉末的粒度分布参数

Table 1. Particle size distribution parameters of the different powders

批次 D10 / μm D50 / μm D90 / μm 比表面积 / (m2·kg−1) 原粉W0 5.95 12.57 23.03 187.2 气流磨W1 5.30 8.02 11.79 259.5 气流磨W2 5.49 8.91 15.72 231.6 气流磨W3 2.99 7.14 11.53 348.7 表 2 不同批次粉末的烧结后性能参数

Table 2. Properties parameters of the different sintered samples

批次 相对密度 / % 平均晶粒尺寸 / μm 抗弯强度 / MPa 原粉W0 90.7 10.5 238.5±21.3 气流磨W1 92.8 10.1 292.4±10.5 气流磨W2 92.6 10.3 263.1±14.6 气流磨W3 92.3 10.4 248.3±15.1 -

[1] Lassner E, Schubert W D. Tungsten: Properties, Chemistry, Technology of the Element, Alloys, and Chemical Compounds. New York: Kluwer Academic and Plenum Publishers, 1999 [2] Zhao M Y, Fan J L, Liu T, et al. Current situation and development trend of China tungsten processing industry. China Tungsten Ind, 2010, 25(2): 26 doi: 10.3969/j.issn.1009-0622.2010.02.007赵慕岳, 范景莲, 刘涛, 等. 中国钨加工业的现状与发展趋势. 中国钨业, 2010, 25(2): 26 doi: 10.3969/j.issn.1009-0622.2010.02.007 [3] Liu W S, Long L P, Ma Y Z. Research and preparation methods for high-purity tungsten. Powder Metall Technol, 2012, 30(3): 223 doi: 10.3969/j.issn.1001-3784.2012.03.012刘文胜, 龙路平, 马运柱. 高纯钨研究现状及制备工艺方法综述. 粉末冶金技术, 2012, 30(3): 223 doi: 10.3969/j.issn.1001-3784.2012.03.012 [4] Liao B B, Wei X Y. The application of tungsten and molybdenum materials in sapphire single crystal furnace. Cement Carb, 2018, 35(2): 134廖彬彬, 魏修宇. 钨钼材料在蓝宝石单晶炉中的应用. 硬质合金, 2018, 35(2): 134 [5] Liu W D. Research progress of preparation technology of tungsten sputtering targets for integrated circuits. China Tungsten Ind, 2020, 35(1): 36 doi: 10.3969/j.issn.1009-0622.2020.01.007刘文迪. 集成电路用钨溅射靶材制备技术的研究进展. 中国钨业, 2020, 35(1): 36 doi: 10.3969/j.issn.1009-0622.2020.01.007 [6] Chen J, Xiong N, Ge Q L, et al. Density uniformity of the tungsten crucible. China Tungsten Ind, 2017, 32(4): 35 doi: 10.3969/j.issn.1009-0622.2017.04.007陈锦, 熊宁, 葛启录, 等. 钨坩埚密度均匀性研究. 中国钨业, 2017, 32(4): 35 doi: 10.3969/j.issn.1009-0622.2017.04.007 [7] Li X Y, Zhang L, Dong Y H, et al. Pressureless two-step sintering of ultrafine-grained tungsten. Acta Mater, 2020, 186: 116 doi: 10.1016/j.actamat.2020.01.001 [8] Chen J, Xiong N, Ge Q L, et al. Manufacturing technology of tungsten crucibles. China Tungsten Ind, 2016, 31(1): 63 doi: 10.3969/j.issn.1009-0622.2016.01.012陈锦, 熊宁, 葛启录, 等. 钨坩埚的制备技术. 中国钨业, 2016, 31(1): 63 doi: 10.3969/j.issn.1009-0622.2016.01.012 [9] Lin F J T, De Jonghe L C, Rahaman M N. Microstructure refinement of sintered alumina by a two-step sintering technique. J Am Ceram Soc, 1997, 80(9): 2269 [10] Dynys F W, Halloran J W. Influence of aggregates on sintering. J Am Ceram Soc, 1984, 67(9): 596 doi: 10.1111/j.1151-2916.1984.tb19601.x [11] Evans A G. Considerations of inhomogeneity effects in sintering. J Am Ceram Soc, 1982, 65(10): 497 doi: 10.1111/j.1151-2916.1982.tb10340.x [12] Lange F F. Sinterability of agglomerated powders. J Am Ceram Soc, 1984, 67(2): 83 doi: 10.1111/j.1151-2916.1984.tb09620.x [13] Huang H, Qin M L, Qu X H, et al. Study on jet milling processing of tungsten powder. Rare Met Mater Eng, 2012, 41(12): 2210 doi: 10.3969/j.issn.1002-185X.2012.12.030黄化, 秦明礼, 曲选辉, 等. 气流磨处理钨粉的研究. 稀有金属材料与工程, 2012, 41(12): 2210 doi: 10.3969/j.issn.1002-185X.2012.12.030 [14] Berthiaux H, Chiron C, Dodds J. Modelling fine grinding in a fluidized bed opposed jet mill: Part Ⅱ: Continuous grinding. Powder Technol, 1999, 106(1-2): 88 doi: 10.1016/S0032-5910(99)00050-9 [15] Williamson G K, Hall W H. X-ray line broadening from filed aluminium and wolfram. Acta Metall, 1953, 1(1): 22 doi: 10.1016/0001-6160(53)90006-6 [16] Venkateswarlu K, Chandra Bose A, Rameshbabu N. X-ray peak broadening studies of nanocrystalline hydroxyapatite by Williamson–Hall analysis. Phys B, 2010, 405(20): 4256 doi: 10.1016/j.physb.2010.07.020 [17] Huang P Y. Theory of Power Metallurgy. 2nd Ed. Beijing: Metallurgical Industry Press, 2004黄培云. 粉末冶金原理. 2版. 北京: 冶金工业出版社, 2004 [18] Kingery W D, Francois B. The sintering of crystalline oxides, I. Interactions between grain boundaries and pores, [in] Sintering and Related Phenomena. New York: Gordon and Breach Science Publishers, 1967 -

下载:

下载: