-

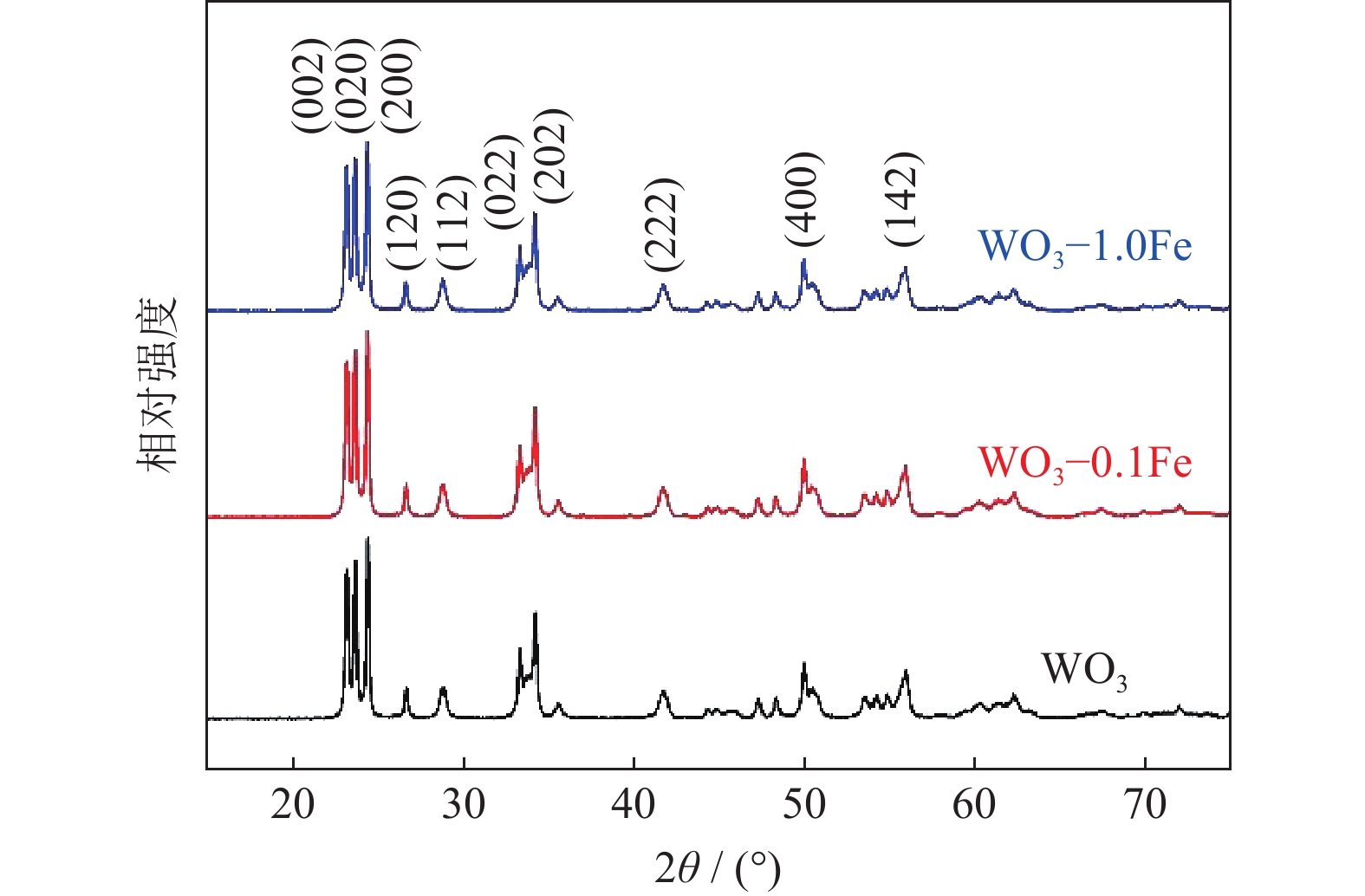

摘要: 采用液–固掺杂结合两步氢还原法分别制备未添加和添加质量分数0.1%和1.0%Fe的金属W粉,研究了微量Fe元素对WO3还原过程及产物结构特征的影响。结果表明:WO3前驱体粉体经掺杂和煅烧处理后,在其颗粒表层晶格中形成了含Fe固溶体;在氢气还原过程中,Fe的固溶能够降低WO2.9→WO2和WO2→W的还原温度,促进WO3中裂纹和空隙的产生,细化还原W粉尺寸;还原后Fe元素由偏聚在WO3颗粒表面迁移到W颗粒内部,其分布规律发生了明显转变。Abstract: Tungsten powders without and with Fe doping (0.1% and 1.0% in mass fraction) were prepared by liquid‒solid doping and two-step hydrogen reduction method, respectively. The influences of trace Fe on the reduction behaviors of WO3 powders and the microstructure characteristic of W powders were systematically studied. The results indicate that the Fe-containing solid solution is formed in the surface crystal lattice of WO3 particles after doping and calcination. In the process of hydrogen reduction, Fe solution can reduce the reaction temperatures of WO2.9→WO2 and WO2→W, promote the formation of micro-cracks and holes in the WO3, and refine the particle size of tungsten powders. After reduction, Fe migrates from the surface of WO3 particles to the interior of tungsten particles, and the Fe distribution changes obviously.

-

Key words:

- trace Fe /

- tungsten powders /

- hydrogen reduction /

- doping /

- ultrafine powders

-

图 3 WO3–1.0Fe粉末透射电镜表征结果:(a)低倍透射电镜形貌;(b)表层高分辨透射电镜形貌;(c)近表层高分辨透射电镜形貌;(d)高角环形暗场图像及能谱线扫描图谱

Figure 3. TEM analysis of WO3–1.0Fe powders: (a) low magnification TEM image; (b) high resolution TEM images at the outer area; (c) high resolution TEM images at the inner area; (d) HADDF image and EDS line scanning spectra

-

[1] Jiang X C. Application of ultrafine metal powder injection moulding on tungsten components in fusion devices. Powder Metall Technol, 2018, 36(4): 279蒋香草. 超细金属粉末注射成形在聚变装置钨零部件中的应用. 粉末冶金技术, 2018, 36(4): 279 [2] Xie Y J, Yang H C, Wang X B, et al. Study on the tungsten bulk materials prepared by selective laser melting. Powder Metall Technol, 2018, 36(2): 89谢琰军, 杨怀超, 王学兵, 等. 选择性激光熔化制备纯钨块体材料的研究. 粉末冶金技术, 2018, 36(2): 89 [3] Zhang B H, Niu S Y, Wang L. Preparation and study on microstructure and properties of special tungsten alloy electrode material. Powder Metall Technol, 2017, 35(4): 293张保红, 牛山延, 王玲. 特种钨合金电极材料制备工艺及组织性能研究. 粉末冶金技术, 2017, 35(4): 293 [4] Li B Y, Wu F, Zhang J, et al. Preparation of 90W–7Ni–3Fe heavy alloy sheet by tape-casting. Rare Met Mater Eng, 2019, 48(8): 2616李邦怿, 伍方, 张静, 等. 90W–7Ni–3Fe高比重合金薄板材的流延法制备. 稀有金属材料与工程, 2019, 48(8): 2616 [5] Zhou W P, Wang L, Qin Y N, et al. Preparation technology of large-sized tungsten heavy alloy. Rare Met Mater Eng, 2020, 49(11): 3957周武平, 王玲, 秦颖楠, 等. 大规格钨基高比重合金材料制备技术研究. 稀有金属材料与工程, 2020, 49(11): 3957 [6] Hamidi A G, Arabi H, Khaki J V. Sintering of a nano-crystalline tungsten heavy alloy powder. Int J Refract Met Hard Mater, 2019, 80: 204 doi: 10.1016/j.ijrmhm.2019.01.016 [7] Ye L, Han Y, Fan J L, et al. Fabrication of ultrafine-grain and great-performance W–Ni–Fe alloy with medium W content. J Alloys Compd, 2020, 846: 156237 doi: 10.1016/j.jallcom.2020.156237 [8] Deng N, Li J Q, Wang Y, et al. Microstructure and mechanical properties of liquid–phase sintered W@NiFe composite powders. Int J Refract Met Hard Mater, 2021, 95: 105447 doi: 10.1016/j.ijrmhm.2020.105447 [9] Fan J L, Gong X, Huang B Y, et al. Densification behavior of nanocrystalline W–Ni–Fe composite powders prepared by sol-spray drying and hydrogen reduction process. J Alloys Compd, 2010, 489: 188 doi: 10.1016/j.jallcom.2009.09.050 [10] Yin Q, Lai C, Chen S Q, et al. Investigations of the nickel promotional effect on the reduction and sintering of tungsten compounds. Int J Refract Met Hard Mater, 2019, 78: 296 doi: 10.1016/j.ijrmhm.2018.10.008 [11] Song H, Li Y G, Lou Z R, et al. Synthesis of Fe-doped WO3 nanostructures with high visible-light-driven photocatalytic activities. Appl Catal B, 2015, 166-167: 112 doi: 10.1016/j.apcatb.2014.11.020 [12] Sheng C M, Wang C, Wang H W, et al. Self-photodegradation of formaldehyde under visible-light by solid wood modified via nanostructured Fe-doped WO3 accompanied with superior dimensional stability. J Hazard Mater, 2017, 328: 127 doi: 10.1016/j.jhazmat.2017.01.018 [13] Huang Y, Cong L Y, Yu J, et al. The surface evolution of a catalyst jointly influenced by thermal spreading and solid-state reaction: A case study with an Fe2O3–MoO3 system. J Mol Catal A Chem, 2009, 302: 48 doi: 10.1016/j.molcata.2008.11.033 [14] Lai C, Wang J S, Zhou F, et al. Reduction, sintering and mechanical properties of rhenium-tungsten compounds. J Alloys Compd, 2018, 735: 2685 doi: 10.1016/j.jallcom.2017.11.064 [15] Kim D G, Min K H, Chang S Y, et al. Effect of pre-reduced Cu particles on hydrogen-reduction of W-oxide in WO3–CuO powder mixtures. Mater Sci Eng A, 2005, 399: 326 doi: 10.1016/j.msea.2005.04.010 [16] Cui Y T. Study on Fabrication, Property and Active Element’ s Behavior of Scandia Doped Dispenser Cathode [Dissertation]. Beijing: Beijing University of Technology, 2012崔云涛. 含钪扩散阴极的制备、性能及活性元素行为研究[学位论文]. 北京: 北京工业大学, 2012 -

下载:

下载: