-

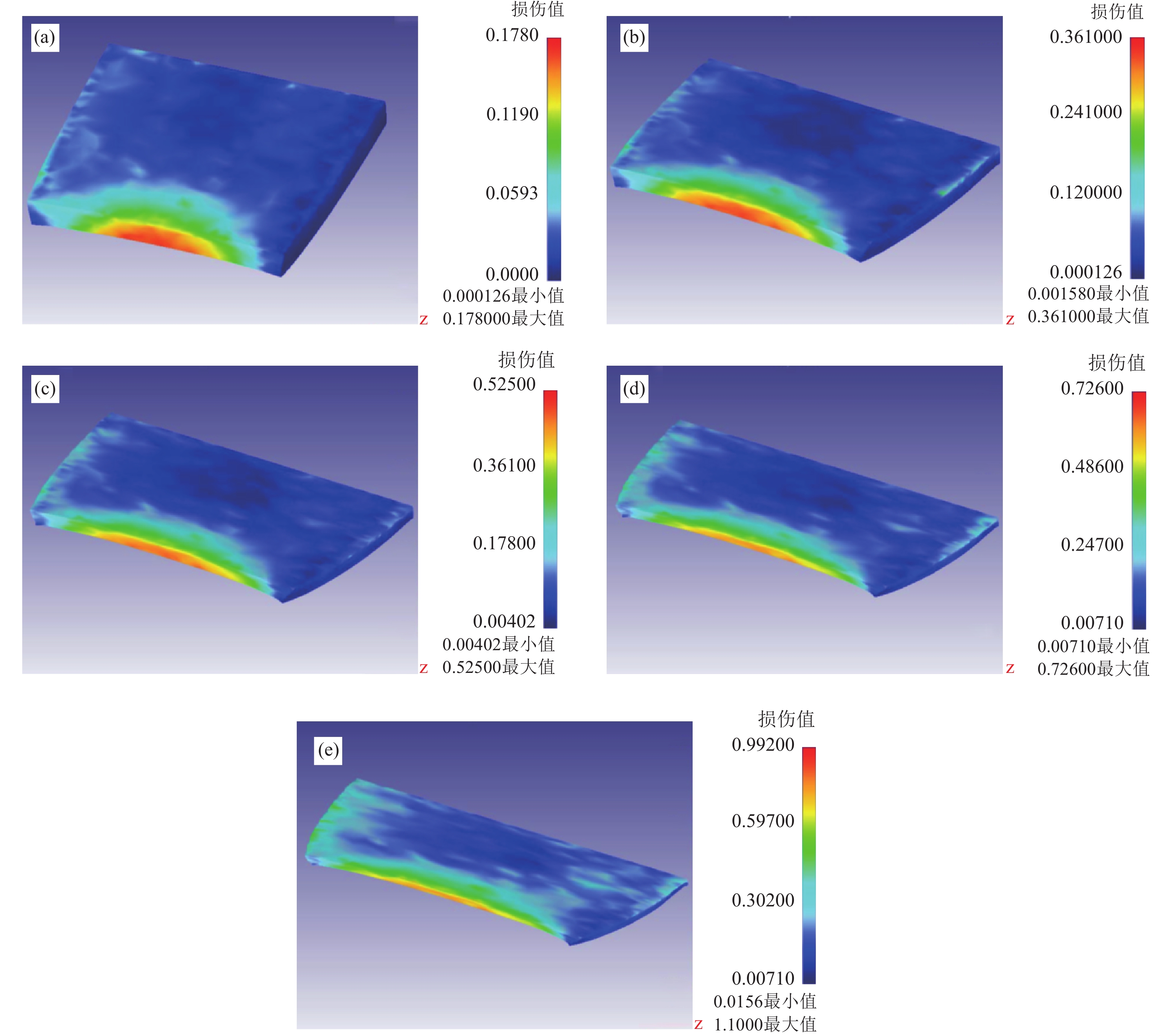

摘要: 钨是核聚变示范堆、散裂中子源及半导体领域中非常重要的一种难熔金属材料,通过对钨板进行轧制变形可以得到各项预期性能。本文通过DEFORM软件模拟大尺寸钨板坯料的轧制,分析轧制方式对损伤因子(损伤值)和应变的影响。结果发现,单向轧制的损伤严重区域主要分布在坯料侧面边缘处,易发生裂纹;交叉轧制对的损伤严重区域比较均匀地分布在坯料四周,由损伤累积产生韧性裂纹的倾向性小。交叉轧制板材在轧制方向的应变曲线在到达一次“最高值”后会下降到上一道次的横向应变,形成“最小值”,两次应变最大值的差值比单向轧制的小。Abstract: Tungsten is a very important refractory metal in the fields of nuclear fusion demonstration reactor, spallation neutron source, and semiconductor. The expected properties of tungsten plates can be obtained by rolling and deforming. The DEFORM software was used to simulate the rolling of tungsten plates in large size in this paper, and the influence of rolling mode on damage factor (damage value) and strain was analyzed. The results show that, the serious damage area for one-way rolling is mainly distributed at the side edge of the billets, which is easy to produce cracks; the serious damage area for cross rolling is uniformly distributed around the billets. The strain curves of cross rolling in the rolling direction may reach a “maximum value” and then descend to a “minimum value”, and the difference of strain between the two maximum value is smaller in cross rolling than that in one-way rolling.

-

Key words:

- tungsten plates /

- rolling /

- numerical simulation /

- large size billets

-

表 1 单向轧制各道次变形参数

Table 1. Deformation parameters of each pass for one-way rolling

道次 厚度 / mm 压下量 / mm 变形率 / % 1 23.5 8.5 26.6 2 17.5 6.0 25.5 3 13.0 4.5 25.7 4 9.5 3.5 26.9 5 7.0 2.5 25.9 表 2 交叉轧制各道次模拟参数

Table 2. Simulation parameters of each pass for the cross rolling

道次 厚度 / mm 加热温度 / ℃ 轧制方向 1 23.5 1600 横向 2 17.5 1550 换向 3 13.0 1500 换向 4 9.5 1450 换向 5 7.0 1400 换向 -

[1] Dubinko A, Terentyev D, Bakaeva A, et al. Evolution of plastic deformation in heavily deformed and recrystallized tungsten of ITER specification studied by TEM. Int J Refract Met Hard Mater, 2017, 66: 105 [2] Chao Y, Dmitry T, Thomas P, et al. Tensile properties of baseline and advanced tungsten grades for fusion applications. Int J Refract Met Hard Mater, 2018, 75: 153 doi: 10.1016/j.ijrmhm.2018.04.003 [3] Aldazabala J, García R C, Meizoso M A, et al. A comparison of the structure and mechanical properties of commercially pure tungsten rolled plates for the target of the European spallation source. Int J Refract Met Hard Mater, 2018, 70: 45 doi: 10.1016/j.ijrmhm.2017.09.006 [4] Krsjak V, Wei S H, Antusch S, et al. Mechanical properties of tungsten in the transition temperature range. J Nucl Mater, 2014, 450: 81 doi: 10.1016/j.jnucmat.2013.11.019 [5] Kohei T, Takeshi M, Akira H, et al. Recrystallization behavior of hot-rolled pure tungsten and its alloy plates during high-temperature annealing. Nucl Mater Energy, 2018, 15: 158 doi: 10.1016/j.nme.2018.04.004 [6] Liu W S, Long L P, Ma Y Z. Research and preparation methods for high-purity tungsten. Powder Metall Technol, 2012, 30(3): 223 doi: 10.19591/j.cnki.cn11-1974/tf.2012.03.012刘文胜, 龙路平, 马运柱. 高纯钨研究现状及制备工艺方法综述. 粉末冶金技术, 2012, 30(3): 223 doi: 10.19591/j.cnki.cn11-1974/tf.2012.03.012 [7] Li X C, Yi M Z, Luo C L, et al. Preparation of uniform fine size tungsten powder by boat-less continuous belt reduction furnace. Powder Metall Technol, 2008, 26(3): 163 doi: 10.19591/j.cnki.cn11-1974/tf.2008.03.001李新春, 易茂中, 罗崇玲, 等. 带式无舟皿连续还原炉制备粒度均匀的细颗粒钨粉. 粉末冶金技术, 2008, 26(3): 163 doi: 10.19591/j.cnki.cn11-1974/tf.2008.03.001 [8] Lin G A. Effect of morphology and particle size distribution of tungsten powder on compacting performance and green compact strength. Mater Sci Eng Powder Metall, 2009, 14(4): 260 doi: 10.3969/j.issn.1673-0224.2009.04.010林高安. 钨粉形貌与粒度分布对成形性和压坯强度的影响. 粉末冶金材料科学与工程, 2009, 14(4): 260 doi: 10.3969/j.issn.1673-0224.2009.04.010 [9] Shi J, Liu N, Liu A J, et al. Effect of pressing on microstructure and mechanical property of pure tungsten. Heat Treat, 2015, 30(4): 31石俊, 刘宁, 刘爱军, 等. 压制压力对纯钨显微组织和力学性能的影响. 热处理, 2015, 30(4): 31 [10] Li P, Hua R, Xue K M, et al. Research progress in tungsten and its alloys by plastic processing. Rare Met Mater Eng, 2016, 45(2): 529李萍, 华睿, 薛克敏, 等. 钨及其合金塑性加工的研究进展. 稀有金属材料与工程, 2016, 45(2): 529 [11] Huang P Y. Principle of Powder Metallurgy. Beijing: Metallurgical Industry Press, 2008黄培云. 粉末冶金原理. 北京: 冶金工业出版社, 2008 [12] Shen T L, Dai Y, Lee Y J. Microstructure and tensile properties of tungsten at elevated temperatures. J Nucl Mater, 2016, 468: 348 doi: 10.1016/j.jnucmat.2015.09.057 [13] Brady G B, James D P, Jonathan P L, et al. Mechanisms of deformation and ductility in tungsten—A review. Int J Refract Met Hard Mater, 2018, 75: 248 doi: 10.1016/j.ijrmhm.2018.04.021 [14] Chai R, Fang Z Z, Mark K, et al. Methods for improving ductility of tungsten—A review. Int J Refract Met Hard Mater, 2018, 75: 170 doi: 10.1016/j.ijrmhm.2018.04.012 [15] Zhang X X, Yan Q Z, Yang C T, et al. Recrystallization temperature of tungsten with different deformation degrees. Rare Met, 2016, 35(7): 566 doi: 10.1007/s12598-014-0315-2 [16] Liu N P, Dan X G, Zhang Y G, et al. Effects of the rolling pass on the microstructure and characteristics of hot rolled tungsten plates. Rare Met Lett, 2008, 27(8): 34刘宁平, 淡新国, 张永刚, 等. 轧制工艺对热轧钨板材组织和性能的影响. 稀有金属快报, 2008, 27(8): 34 [17] Lennon A M, Ramesh K T. The thermoviscoplastic response of polycrystalline tungsten in compression. Mater Sci Eng A, 2000, 276: 9 doi: 10.1016/S0921-5093(99)00517-1 [18] Wang J, Zhao G Q, Li M J. Establishment of processing map and analysis of microstructure on multi-crystalline tungsten plastic deformation process at elevated temperature. Mater Des, 2016, 103: 268 doi: 10.1016/j.matdes.2016.04.055 [19] Wang J, Zhao G Q, Chen L A, et al. A comparative study of constitutive models for powder metallurgy tungsten at elevated temperature. Mater Des, 2016, 90: 91 doi: 10.1016/j.matdes.2015.10.114 [20] Freudenthal A M. The Inelastic Behavior of Engineering Materials and Structures. New York: John Wiley and Sons, 1950 [21] Oyane M, Sato T, Okimoto K, et al. Criteria for ductile fracture and their applications. J Mech Working Technol, 1980, 4(1): 65 doi: 10.1016/0378-3804(80)90006-6 -

下载:

下载: