-

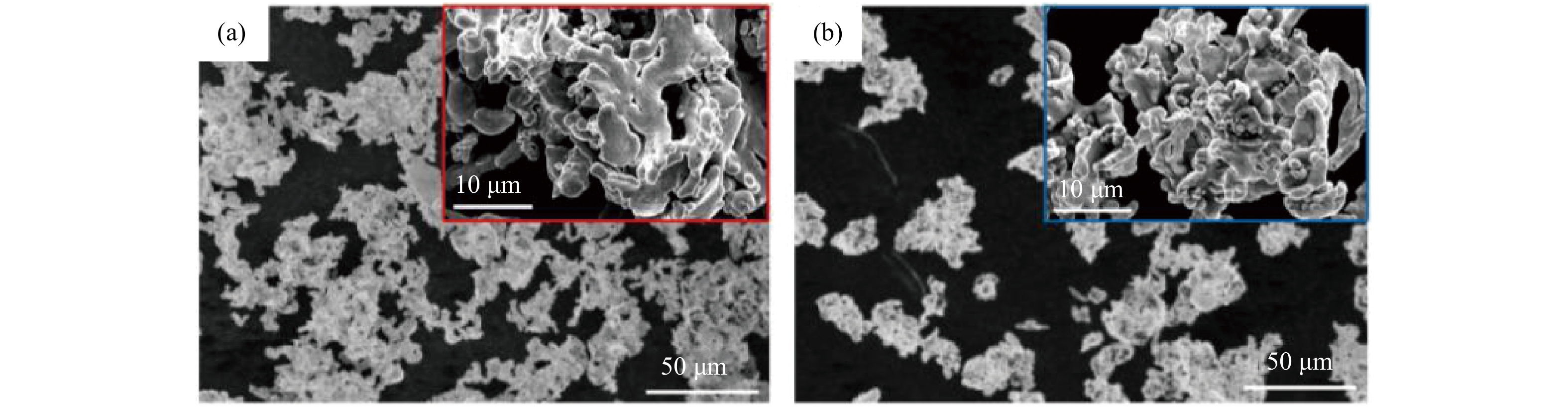

摘要: 采用气流分散处理得到两种不同粒度分布的Re粉,利用激光共聚焦显微镜、扫描电子显微镜、维氏硬度计、纳米压痕仪等设备研究粉末粒度和烧结温度对烧结Re坯显微组织及力学性能的影响。结果表明,气流分散处理后的Re粉团聚得到改善,粒度分布范围变窄,平均粒径由21.21 μm降至9.45 μm。随着温度升高,烧结坯的孔隙数量不断减少。粒度分散后的烧结Re坯显微组织更为均匀,在2320 ℃下的平均晶粒尺寸由10.8 μm降至9.9 μm。分散处理后的烧结坯体相对密度提高至98.6%,较未处理的提高了4%,显微硬度提高约12%。分散处理后的烧结坯体有更大的峰值硬度,硬度比未处理的高2~5 GPa。Abstract: Two kinds of rhenium powders with the different particle size distribution were prepared by jet dispersion treatment. The effects of the powder particle size and sintering temperature on the microstructure and mechanical properties of the sintered rhenium billet were studied by confocal laser scanning microscope, scanning electron microscope (SEM), Vickers hardness tester, and nano indentor. In the results, the agglomeration of rhenium powders is improved after the jet dispersion treatment, the particle size distribution of rhenium powders is narrowed, and the average particle size decreases from 21.21 μm to 9.45 μm. With the increase of sintering temperature, the number of pores in the sintered rhenium billet continues to decrease. The microstructure of the sintered rhenium billet after the dispersion treatment shows more uniform, and the average grain size at 2320 ℃ sintering temperature decreases from 10.8 μm to 9.9 μm. The relative density of the sintered rhenium billet after the dispersion treatment increases to 98.6%, which is 4% higher than untreated, and the microhardness increases by about 12%. The sintered rhenium billet after the dispersion treatment has the greater peak hardness, and the hardness is 2~5 GPa higher than that untreated.

-

Key words:

- rhenium powders /

- jet dispersion treatment /

- sintering /

- pores /

- microstructure /

- mechanical properties

-

图 6 分散处理前后粉末经2060 ℃烧结的Re坯电子背散射衍射分析和晶粒尺寸分布:(a)未处理Re坯电子背散射衍射分析;(b)分散处理后Re坯电子背散射衍射分析;(c)未处理Re坯晶粒尺寸分布;(d)分散处理后Re坯晶粒尺寸分布

Figure 6. EBSD analysis and the particle size distribution of the rhenium billets sintered at 2060 ℃ before and after the dispersion treatment: (a) EBSD analysis of the untreated rhenium billets; (b) EBSD analysis of the rhenium billets after the dispersion treatment; (c) the particle size distribution of the untreated rhenium billets; (d) the particle size distribution of the rhenium billets after the dispersion treatment

图 7 分散处理前后粉末经2320 ℃烧结的Re坯电子背散射衍射分析和晶粒尺寸分布:(a)未处理Re坯电子背散射衍射分析;(b)分散处理后Re坯电子背散射衍射分析;(c)未处理Re坯晶粒尺寸分布;(d)分散处理后Re坯晶粒尺寸分布

Figure 7. EBSD analysis and the particle size distribution of the rhenium billets sintered at 2320 ℃ before and after the dispersion treatment: (a) EBSD analysis of the untreated rhenium billets; (b) EBSD analysis of the rhenium billets after the dispersion treatment; (c) the particle size distribution of the untreated rhenium billets; (d) the particle size distribution of the rhenium billets after the dispersion treatment

-

[1] Cheng T Y, Xiong N, Peng K Y, et al. The application and preparation technology of rhenium and rhenium alloys. Rare Met Mater Eng, 2009, 38(2): 373 doi: 10.3321/j.issn:1002-185X.2009.02.042程挺宇, 熊宁, 彭楷元, 等. 铼及铼合金的应用现状及制造技术. 稀有金属材料与工程, 2009, 38(2): 373 doi: 10.3321/j.issn:1002-185X.2009.02.042 [2] Wittenauer J, Liddell K. Advances in the extraction, processing and application of refractory metals. JOM, 1991, 43: 6 [3] Carlen J C, Bryskin B D. Rhenium-a unique rare metal. Mater Manuf Processes, 1994, 9(6): 1087 doi: 10.1080/10426919408934977 [4] Wang H Z, Yang S L. Character, application and preparation method of rhenium. J Chin Rare Earth Soc, 2005, 23(Suppl 2): 189王海哲, 杨盛良. 铼的特性、应用及其制造技术. 中国稀土学报, 2005, 23(增刊 2): 189 [5] Bonnekoh C, Hoffmann A, Reiser J. The brittle-to-ductile transition in cold rolled tungsten: On the decrease of the brittle-to-ductile transition by 600 K to − 65 ℃. Int J Refract Met Hard Mater, 2018, 71: 181 doi: 10.1016/j.ijrmhm.2017.11.017 [6] Wu W P, Jiang P, Hua T S. Research progress of refractory metal rhenium and its alloy. Metall Funct Mater, 2015, 22(2): 48吴王平, 江鹏, 华同曙. 难熔金属铼及其合金的研究进展. 金属功能材料, 2015, 22(2): 48 [7] Wang Y, Wang C Y. Recent advances of rhenium separation and enrichment in China: Industrial processes and laboratory trials. Chin Chem Lett, 2018, 29: 345 doi: 10.1016/j.cclet.2018.01.001 [8] Bryskin B D, Danek F C. Powder processing and the fabrication of rhenium. JOM, 1991, 43: 24 [9] Zhang W Z. Progress of research on production and application of rhenium. China Molybdenum Ind, 2008, 32(4): 5 doi: 10.3969/j.issn.1006-2602.2008.04.002张文征. 铼的生产与应用研究进展. 中国钼业, 2008, 32(4): 5 doi: 10.3969/j.issn.1006-2602.2008.04.002 [10] Lin G A. Effect of morphology and particle size distribution of tungsten powder on compacting performance and green compact strength. Mater Sci Eng Powder Metall, 2009, 14(4): 260 doi: 10.3969/j.issn.1673-0224.2009.04.010林高安. 钨粉形貌与粒度分布对成形性和压坯强度的影响. 粉末冶金材料科学与工程, 2009, 14(4): 260 doi: 10.3969/j.issn.1673-0224.2009.04.010 [11] Tan P, Li Z F, Ge Y, et al. Effect of powder sizes on the mechanical properties of porous titanium sheets prepared by rolling and sintering process. Powder Metall Technol, 2020, 38(1): 30谈萍, 李增峰, 葛渊, 等. 钛粉粒度对轧制烧结多孔钛板力学性能的影响. 粉末冶金技术, 2020, 38(1): 30 [12] Wang G D, Xiong N, Liu G H, et al. Effect of powder characteristics on sintering densification of pure rhenium. Chin J Rare Met, 2019, 45(4): 507王广达, 熊宁, 刘国辉, 等. 粉末特性对纯铼烧结致密度的影响. 稀有金属, 2019, 45(4): 507 [13] Zhang K, Feng J N, Huang X L. Effects of Mo-powder grading and ratio on the rolling and punching properties of Mo-plate. China Tungsten Ind, 2015, 30(3): 52 doi: 10.3969/j.issn.1009-0622.2015.03.011张焜, 冯娟妮, 黄晓玲. 钼粉分级和配比对烧结钼板坯轧制性能的影响. 中国钨业, 2015, 30(3): 52 doi: 10.3969/j.issn.1009-0622.2015.03.011 [14] Wang Y H, Liu Q, Bo X W, et al. Research on sintering performance of high purity metal vanadium powder. Powder Metall Technol, 2019, 37(5): 339王焱辉, 刘奇, 薄新维, 等. 高纯金属钒粉烧结性能研究. 粉末冶金技术, 2019, 37(5): 339 [15] Huang H, Qin M L, Qu X H, et al. Study on jet milling processing of tungsten powder. Rare Met Mater Eng, 2012, 41(12): 2210 doi: 10.3969/j.issn.1002-185X.2012.12.030黄化, 秦明礼, 曲选辉, 等. 气流磨处理钨粉的研究. 稀有金属材料与工程, 2012, 41(12): 2210 doi: 10.3969/j.issn.1002-185X.2012.12.030 [16] Zhou L L, Bai M, Liu Z H, et al. The effect of sintering on the properties of ultrafine rhenium powders prepared by CVD method. Rare Met Mater Eng, 2011, 40(10): 1693 doi: 10.1016/S1875-5372(12)60001-0 -

下载:

下载: