-

摘要: 利用不同原料粉末制备钨坩埚样品,并于高温环境下进行应用模拟实验。结果表明,射流分级预处理有助于提升钨坩埚组织均匀性及整体性能;以费氏粒度3.0~3.5 μm的钨粉为原料,经射流分级、压制、烧结等工艺,可制得密度较高(18.770 g·cm−3)、维氏硬度较高(HV0.3 372.15)的钨制品;将该钨坩埚置于高温环境下进行模拟应用验证,其密度及微观形貌较为稳定,变化较小。Abstract: The tungsten crucible samples were prepared by using the different tungsten powders, and the application simulation experiment was carried out in high temperature environment. The results show that, the jet grading pretreatment technology is an efficient process to improve the qualities of the tungsten crucible. The tungsten products with high density (18.770 g·cm−3) and high Vickers hardness (HV0.3 372.15) are prepared by jet grading, pressing, and sintering, using the tungsten powders with the Feller size of 3.0~3.5 μm as the raw materials. Meanwhile, the simulation application of tungsten crucibles is verified in the high temperature environment, which shows that the density and microstructure are stable.

-

Key words:

- tungsten crucible /

- pretreatment /

- preparation technology /

- high temperature application

-

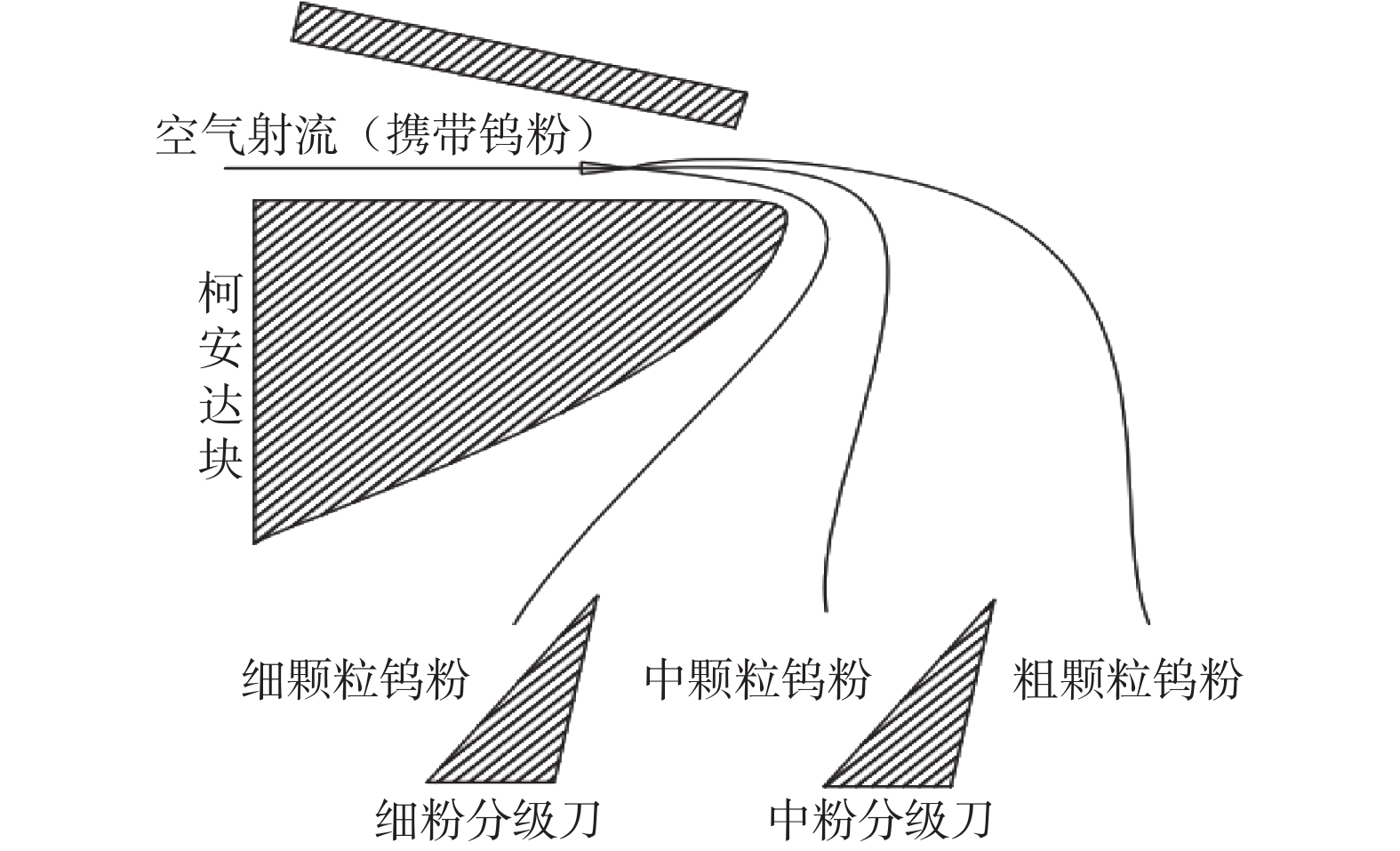

图 1 粉体射流分级原理示意图[15]

Figure 1. Schematic diagram of the jet grading

图 4 高温模拟应用前后钨坩埚的显微组织形貌:(a)样品1高温模拟应用前;(b)样品1高温模拟应用后;(c)样品2高温模拟应用前;(d)样品2高温模拟应用后;(e)样品3高温模拟应用前;(f)样品3高温模拟应用后;(g)样品4高温模拟应用前;(h)样品4高温模拟应用后

Figure 4. Microstructure of the different tungsten crucibles before and after the high temperature simulation: (a) sample 1 before the high temperature simulation; (b) sample 1 after the high temperature simulation; (c) sample 2 before the high temperature simulation; (d) sample 2 after the high temperature simulation; (e) sample 3 before the high temperature simulation; (f) sample 3 after the high temperature simulation; (g) sample 4 before the high temperature simulation; (h) sample 4 after the high temperature simulation

表 1 不同粉末制得的钨制品物理性能

Table 1. Physical properties of tungsten products using different powders

原料粉末 密度 / (g·cm−3) 维氏硬度,HV0.3 样品1 18.247 309.09 样品2 18.145 315.92 样品3 18.770 372.15 样品4 18.637 347.18 表 2 不同样品高温模拟应用前后密度变化

Table 2. Density and dimensions of the different samples before and after the high temperature simulation

样品编号 密度 / (g·cm−3) 高温模拟应用前 高温模拟应用后 样品1 18.247 18.319 样品2 18.145 18.262 样品3 18.770 18.763 样品4 18.637 18.639 -

[1] Zhao M Y, Fan J L, Liu T, et al. Current situation and development trend of China tungsten processing industry. China Tungsten Ind, 2010, 25(2): 26 doi: 10.3969/j.issn.1009-0622.2010.02.007赵慕岳, 范景莲, 刘涛, 等. 中国钨加工业的现状与发展趋势. 中国钨业, 2010, 25(2): 26 doi: 10.3969/j.issn.1009-0622.2010.02.007 [2] Hu S Q, Xiao S T. Research and development of deep processing tungsten products. China Tungsten Ind, 1999, 14(Suppl 1): 207胡仕清, 肖松涛. 钨深加工制品的研制与开发. 中国钨业, 1999, 14(增刊 1): 207 [3] Zhang B H, Niu S T, Wang L. Preparation and study on microstructure and properties of special tungsten alloy electrode material. Powder Metall Technol, 2017, 35(4): 293张保红, 牛山廷, 王玲. 特种钨合金电极材料制备工艺及组织性能研究. 粉末冶金技术, 2017, 35(4): 293 [4] Zhao Z W, Sun F L, Yang J H, et al. Status and prospect of tungsten resources, technologies and industrial development in China. Chin J Nonferrous Met, 2019, 29(9): 1902赵中伟, 孙丰龙, 杨金洪, 等. 我国钨资源、技术和产业发展现状与展望. 中国有色金属学报, 2019, 29(9): 1902 [5] Yu Z Q. Current situation analysis and suggestions of tungsten industry in China. Land Resour Inf, 2020(10): 55 doi: 10.3969/j.issn.1674-3709.2020.10.010余泽全. 中国钨行业现状分析及建议. 国土资源情报, 2020(10): 55 doi: 10.3969/j.issn.1674-3709.2020.10.010 [6] Chen J, Xiong N, Ge Q L, et al. Manufacturing technology of tungsten crucibles. China Tungsten Ind, 2016, 31(1): 63 doi: 10.3969/j.issn.1009-0622.2016.01.012陈锦, 熊宁, 葛启录, 等. 钨坩埚的制备技术. 中国钨业, 2016, 31(1): 63 doi: 10.3969/j.issn.1009-0622.2016.01.012 [7] Lei K. Discussion on the sustainable development model of tungsten products machinery processing industry in China. Sci Technol Innovation Herald, 2015(19): 244 doi: 10.3969/j.issn.1674-098X.2015.19.173雷凯. 我国钨制品机械加工业的可持续发展模式探讨. 科技创新导报, 2015(19): 244 doi: 10.3969/j.issn.1674-098X.2015.19.173 [8] Li L P, Duan X J, Duan H Q, et al. The analysis of cracks at the bottom of tungsten crucible. Rare Met Mater Eng, 2002, 31(Suppl): 64李来平, 段小建, 段海清, 等. 钨坩埚底部出现裂纹的原因分析. 稀有金属材料与工程, 2002, 31(增刊): 64 [9] Chen J H, Li K L, Wang Y F, et al. The effect of hot isostatic pressing on thermal conductivity of additively manufactured pure tungsten. Int J Refract Met Hard Mater, 2020, 87: 105135 doi: 10.1016/j.ijrmhm.2019.105135 [10] Dong Y H, Zhou X L, Hua X Z. Effect of porosity on thermal performance of Mo–Cu composite. Hot Working Technol, 2008, 37(16): 1 doi: 10.3969/j.issn.1001-3814.2008.16.001董应虎, 周贤良, 华小珍. 孔隙率对Mo/Cu复合材料热物理性能的影响. 热加工工艺, 2008, 37(16): 1 doi: 10.3969/j.issn.1001-3814.2008.16.001 [11] Chen J, Xiong N, Ge Q L, et al. Density uniformity of the tungsten crucible. China Tungsten Ind, 2017, 32(4): 35 doi: 10.3969/j.issn.1009-0622.2017.04.007陈锦, 熊宁, 葛启录, 等. 钨坩埚密度均匀性研究. 中国钨业, 2017, 32(4): 35 doi: 10.3969/j.issn.1009-0622.2017.04.007 [12] Chen Z G, Yan B Y, Feng Z L. Characteristics and technology analysis of tungsten series products produced by chemical vapor deposition. Rare Met Cement Carb, 2013, 41(6): 17陈志刚, 颜彬游, 冯振雷. 化学气相沉积法制备钨系列产品特点及工艺分析. 稀有金属与硬质合金, 2013, 41(6): 17 [13] Min X B, Wang Y M, Xia G M, et al. Preparation and applications of a new heterotypical refractory metal part. Powder Metall Technol, 2010, 28(4): 297闵小兵, 王跃明, 夏光明, 等. 一种新型难熔金属异型件的制备技术及其应用. 粉末冶金技术, 2010, 28(4): 297 [14] Zhang Y Y, Zhou W P, Wang T J, et al. Study on agglomeration and elimination methods of fine tungsten powder. Powder Metall Ind, 2018, 28(5): 11张莹莹, 周武平, 王铁军, 等. 细颗粒钨粉团聚和消除方法的研究. 粉末冶金工业, 2018, 28(5): 11 [15] Wang L Y, Li C B, Zhang Y Q, et al. Application of jet grading technology in tungsten products. Thermal Spray Technol, 2019, 11(3): 70 doi: 10.3969/j.issn.1674-7127.2019.03.011王芦燕, 李曹兵, 张宇晴, 等. 射流分级技术在钨制品中的应用. 热喷涂技术, 2019, 11(3): 70 doi: 10.3969/j.issn.1674-7127.2019.03.011 -

下载:

下载: