Effects of HfC content on microstructure and mechanical properties of titanium zirconium molybdenum alloys

-

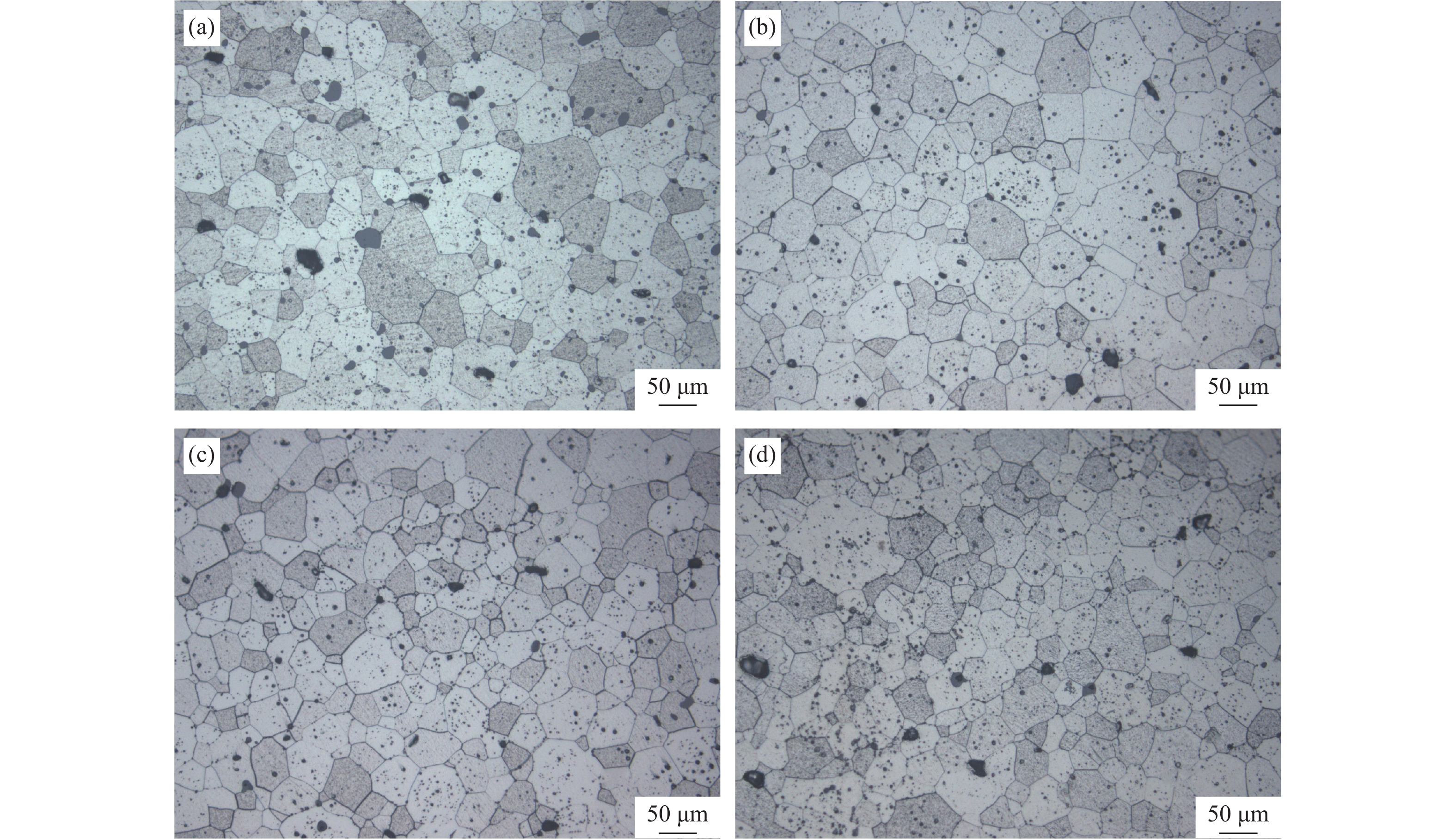

摘要: 在钼钛锆(titanium zirconium molybdenum alloy,TZM)合金粉末中分别添加质量分数为0、0.25%、0.50%、1.00%的HfC粉末颗粒,利用粉末冶金结合轧制变形的方法制备多元复合强化钼合金。通过金相组织观察、扫描电子显微镜形貌表征、能谱分析以及力学性能测试等手段,研究了HfC颗粒对TZM合金显微组织和力学性能的影响。结果表明,添加HfC颗粒可以抑制TZM合金晶粒在烧结过程中的长大,但添加量超过0.50%时,抑制效果减弱。当HfC颗粒质量分数为0.25%时,TZM合金的室温和高温抗拉强度最强,维氏硬度最高,塑性最优。Abstract: HfC particles with the mass fraction of 0, 0.25%, 0.50% and 1.00% were added into the titanium zirconium molybdenum (TZM) alloy powders, respectively. The composite reinforced molybdenum alloys were prepared by the powder metallurgy combined with the rolling deformation. The effects of the HfC particles on the microstructure and mechanical properties of the TZM alloys were studied by the metallographic analysis, the scanning electron microscopy, the energy spectrum analysis, and the mechanical properties tests. The results show that, the addition of HfC particles can inhibit the growth of TZM grains during the sintering process, however, when the mass fraction of HfC particles exceeds 0.50%, the inhibitory effect is weakened. When the mass fraction of HfC particles is 0.25%, the TZM alloys show the strongest tensile strength at room temperature and high temperature, the highest Vickers hardness, and the best plasticity.

-

表 1 TZM合金化学成分(质量分数)

Table 1. Chemical composition of the TZM alloys

% 试样编号 Mo HfC C Ti Zr 1 余量 0 0.03 0.50 0.1 2 余量 0.25 0.03 0.50 0.1 3 余量 0.50 0.03 0.50 0.1 4 余量 1.00 0.03 0.50 0.1 -

[1] Wu X G, Du X B. TZM alloy and its properties. China Molybdenum Ind, 2005, 29(5): 30 doi: 10.3969/j.issn.1006-2602.2005.05.007吴新光, 杜晓斌. TZM合金及其特性. 中国钼业, 2005, 29(5): 30 doi: 10.3969/j.issn.1006-2602.2005.05.007 [2] Cui C P, Cao R, Zhu X W. Effect of rare earth oxide on high temperature deformation resistance of molybdenum alloy. J Yibin Univ, 2020, 20(12): 24崔超鹏, 曹睿, 朱向炜. 稀土氧化物对钼合金高温变形抗力的影响. 宜宾学院学报, 2020, 20(12): 24 [3] Dong D, Wang C Y. Research progress on preparation technology of molybdenum alloy. Powder Metall Technol, 2017, 35(4): 304董帝, 王承阳. 钼合金制备工艺的研究进展. 粉末冶金技术, 2017, 35(4): 304 [4] Xu K D. Material Science and Engineering of Molybdenum. Beijing: Metallurgical Industry Press, 2014徐克玷. 钼的材料科学与工程. 北京: 冶金工业出版社, 2014 [5] Dong D, Huang H T, Xiong N, et al. Application of molybdenum and molybdenum alloys in nuclear reactors. China Molybdenum Ind, 2018, 42(4): 6董帝, 黄洪涛, 熊宁, 等. 钼及钼合金在核反应堆中的应用. 中国钼业, 2018, 42(4): 6 [6] Liu G, Zhang G J, Jiang F, et al. Microstructural design and property optimization of Mo alloys with high performance. Mater China, 2016, 35(3): 205刘刚, 张国君, 江峰, 等. 高性能钼合金的微观组织设计制备与性能优化. 中国材料进展, 2016, 35(3): 205 [7] Luo L M, Zhou Y F, Zhang Y X, et al. Current status and development trend of toughening technology of molybdenum-based materials. Chin J Nonferrous Met, 2019, 29(3): 525罗来马, 周宇芬, 章宇翔, 等. 钼基材料的强韧化技术研究现状和发展趋势. 中国有色金属学报, 2019, 29(3): 525 [8] Yang Z W, Lin J M, Zhang J F, et al. An effective approach for bonding of TZM and Nb–Zr system: Microstructure evolution, mechanical properties, and bonding mechanism. J Mater Sci Technol, 2021, 84: 16 doi: 10.1016/j.jmst.2020.09.054 [9] Fasoranti O, Ostrowski E T, Koel B E. Thermal stability of oxidized ultrathin Li films on TZM for plasma facing components. J Nuclear Mater, 2020, 543: 152587 [10] Yu Z T, Wang K S, Hu P, et al. Progress of low oxygen TZM molybdenum alloy. Mater Rev, 2015, 29(1): 92 doi: 10.11896/j.issn.1005-023X.2015.01.016于志涛, 王快社, 胡平, 等. 低氧TZM合金研究进展. 材料导报, 2015, 29(1): 92 doi: 10.11896/j.issn.1005-023X.2015.01.016 [11] Dong D, Liu G H, Xiong N, et al. A Method of Multi-Element Composite Reinforced Molybdenum Alloys and Its Preparation: China Patent, 201910857792.7. 2019-11-15.董帝, 刘国辉, 熊宁, 等. 一种多元复合强化钼合金及其制备方法: 中国专利, 201910857792.7. 2019-11-15. [12] Siller M, Lang D, Schatte J, et al. Interaction of precipitation, recovery and recrystallization in the Mo–Hf–C alloy MHC studied by multipass compression tests. Int J Refract Met Hard Mater, 2018, 73: 199 doi: 10.1016/j.ijrmhm.2018.02.014 [13] Li H, Hu P, Xing H R, et al. A survey of high temperature mechanical properties of molybdenum alloys. J Funct Mater, 2020, 51(10): 10044 doi: 10.3969/j.issn.1001-9731.2020.10.007李辉, 胡平, 邢海瑞, 等. 钼合金高温力学性能研究现状综述. 功能材料, 2020, 51(10): 10044 doi: 10.3969/j.issn.1001-9731.2020.10.007 [14] Wang C Y, Dong D, Teng Y K, et al. Effect of annealing on microstructure and mechanical properties of MHC molybdenum alloy sheet. Heat Treat Met, 2018, 43(7): 180王承阳, 董帝, 腾宇阔, 等. 退火工艺对MHC钼合金板材组织和力学性能的影响. 金属热处理, 2018, 43(7): 180 [15] Zhao H, Yang Q L, Fu J B, et al. Effect of carbon content on microstructure and mechanical properties of PM-MHC alloy rods. China Molybdenum Ind, 2020, 44(1): 45赵虎, 杨秦莉, 付静波, 等. C含量对PM-MHC合金棒组织及力学性能影响研究. 中国钼业, 2020, 44(1): 45 -

下载:

下载: