-

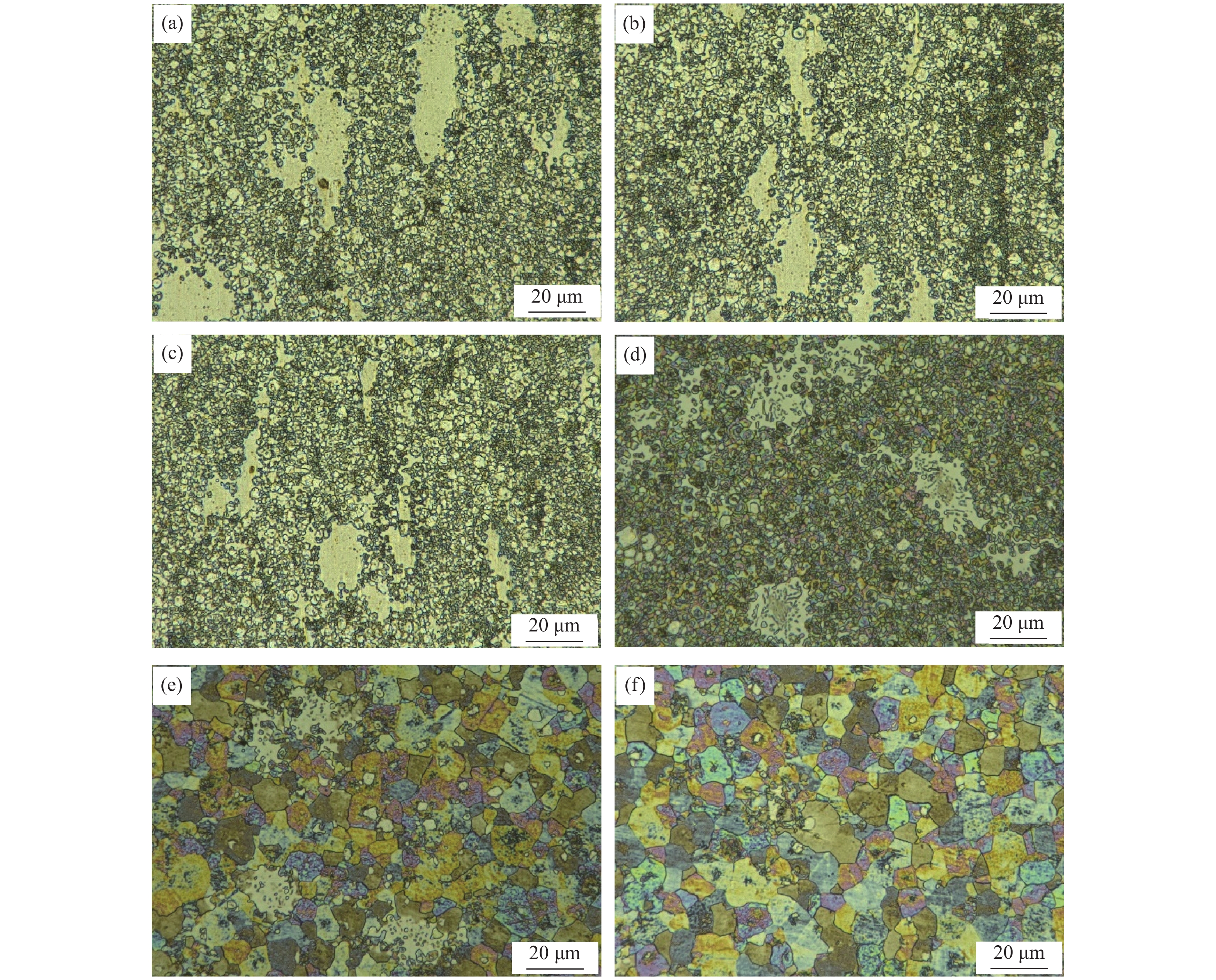

摘要: 在已有WTi10热压靶材制备工艺条件下,通过增加后续退火工艺,改善材料的组织结构,提高材料的纯度。采用基恩士体式显微镜、扫描电子显微镜和辉光放电质谱仪等设备观察和测量材料的显微组织、晶粒尺寸和纯度。结果表明,随着退火温度的升高,富钛β1(W, Ti)相逐渐减少,富钨β(W, Ti)相逐渐增多;当退火温度低于1200 ℃时,材料的主要组织为W相、富钨β(W, Ti)相和富钛β1(W, Ti)相;当退火温度达到1700 ℃时,富钛β1(W, Ti)相基本消失,形成平均晶粒尺寸为7.9 μm的均匀再结晶组织,其O质量分数仅为0.041%,而纯度达到99.995%以上。Abstract: To optimize the microstructure and purity of the WTi10 sputtering targets, the subsequent annealing process was treated without changing the initial hot pressing conditions. The microstructure, grain size, and purity of the samples were observed and measured by Keyence microscope, scanning electron microscope, and glow discharge mass spectrometer (GDMS). The results show that, with the increase of annealing temperature, the Ti-rich β1(W, Ti) phase gradually decreases, and the W-rich β(W, Ti) phase gradually increases. When the annealing temperature is lower than 1200 ℃, the materials consist of the W matrix with the W-rich β(W, Ti) phase and the Ti-rich β1(W, Ti) phase. A further increase in annealing temperature to 1700 ℃ results in a remarkable change in phase composition, leading to the disappearance of the Ti-rich β1(W, Ti) phase, which approaches a uniform recrystallized microstructure with an average grain size of 7.9 μm, meanwhile, the oxygen mass fraction of the samples is 0.041% and the purity is 99.995% above.

-

Key words:

- targets /

- annealing process /

- phase composition /

- grain size /

- purity

-

表 1 实验用热压烧结及退火工艺

Table 1. Hot pressing sintering and annealing process in the experiment

试样编号 烧结工艺 退火工艺 1# 升温500~800 ℃,保温30~120 min;

升温到900~1100 ℃,保温60~100 min;

升温到1300~1450 ℃,同时加压到20~50 MPa;

保温保压30~90 min,随炉冷却。无 2# 900 ℃、1 h 3# 1200 ℃、1 h 4# 1500 ℃、1 h 5# 1600 ℃、1 h 6# 1700 ℃、1 h 位置 元素原子数分数 / % W Ti 1 97.90 2.10 2 57.30 42.70 3 84.57 15.43 表 3 各工艺条件下试样气体杂质中元素质量分数

Table 3. Element mass fraction in the gas impurity of the samples treated by the different process

试样编号 气体杂质中元素质量分数 / % C H O N 1# 0.0061 0.00430 0.0739 0.0084 2# 0.0064 0.00360 0.0703 0.0089 3# 0.0042 0.00390 0.0634 0.0072 4# 0.0032 0.00140 0.0540 0.0030 5# 0.0026 0.00120 0.0510 0.0020 6# 0.0029 0.00056 0.0410 0.0014 表 4 1700 ℃退火条件下试样杂质中元素质量分数

Table 4. Element mass fraction in the impurity of the samples annealed at 1700 ℃

元素 质量分数 / ×10‒6 元素 质量分数 / ×10‒6 元素 质量分数 / ×10‒6 元素 质量分数 / ×10‒6 Li <0.010 Co 0.008 Cd <0.050 Er <0.0010 Be <0.001 Ni 0.220 In <0.050 Tm <0.0010 B <0.005 Cu 0.140 Sn 0.020 Yb <0.0050 F <0.050 Zn 0.050 Sb <0.010 Lu <0.0010 Na 0.020 Ga <0.010 Te <0.005 Hf <0.0050 Mg 0.390 Ge <0.010 I <0.001 Ta <1.000 Al 0.090 As 0.020 Cs <0.005 W 基体 Si 1.100 Se <0.010 Ba 0.070 Re <0.0500 P 0.170 Br <0.005 La <0.001 Os <0.0050 S 0.120 Rb <0.100 Ce <0.001 Ir <0.0010 Cl 1.300 Sr ≤9.200* Pr <0.001 Pt <0.0100 K 0.660 Y <5.000 Nd <0.001 Au <0.0500 Ca 0.030 Zr <0.100 Sm <0.001 Hg <0.1000 Sc <0.010 Nb <0.010 Eu <0.001 Tl <0.010 Ti 基体 Mo 0.220 Gd <0.001 Pb 0.0300 V 0.002 Ru <0.005 Tb <0.001 Bi <0.001 Cr 0.280 Rh <0.010 Dy <0.001 Th <0.0001 Mn 0.060 Pd <0.010 Ho <0.001 U <0.0001 Fe 1.900 Ag <0.010 — — — — 注:*可能存在干扰 -

[1] Dirks A G, Wolters R A M, Nellissen A J M. On the microstructure property relationship of W–Ti–(N) diffusion barriers. Thin Solid Films, 1990, 194(1): 201 [2] Ziani A, Kunkel B. Enhanced Sputter Target Manufacturing Method: US Patent, 20070017803A1. 2007-1-25 [3] Berger S. Elastic and plastic strains in Al/TiW/Si contacts during thermal cycles. Mater Sci Eng A, 2000, 288(2): 164 doi: 10.1016/S0921-5093(00)00863-7 [4] Hecker M, René H. Advanced Interconnects for ULSI Technology. New Jersey: Wiley Publishing, 2012 [5] Zhao Q S. Preparation of ulta-pure tungsten powder and tungsten material abroad. Rare Mater Cement Carb, 2003, 31(4): 56 [6] Sun Y, Xu Y F, Wang J, et al. A Metallization Coating Method for Through Hole of Thin Film Circuit: China Patent, 201710544398.9. 2017-12-1孙毅, 许延峰, 王进, 等. 一种薄膜电路通孔金属化镀膜方法: 中国专利, 201710544398.9. 2017-12-1 [7] Wei Y Y, Wu H, Jiang Z L, et al. Thin Film Circuit and Forming Method of Sputtering Metal Coating: China Patent, 201811640042.6. 2018-12-29魏永勇, 吴浩, 蒋昭丽, 等. 一种薄膜电路及其溅射金属涂层的形成方法: 中国专利, 201811640042.6. 2018-12-29 [8] Yan J. Fundamental Research on the Process and Appliacation of 3D RF Integrated Low-Loss TSV Interposer [Dissertation]. Xiamen: Xiamen University, 2018颜俊. 三维射频集成低损耗TSV转接板工艺及应用基础研究[学位论文]. 厦门: 厦门大学, 2018 [9] Wang Q X, Liang S H, Yang Y, et al. Effect of W powder size on the microstructure and mechanical properties of Ti–20wt%W alloy. Powder Metall Technol, 2010, 28(1): 26王庆相, 梁淑华, 杨怡, 等. W粉粒度对Ti–20%W合金组织和力学性能的影响. 粉末冶金技术, 2010, 28(1): 26 [10] Ma Y T, Liu J B, Huo R L, et al. Research on the preparation and performance of tungsten-aluminum transmission target for micro-computed tomography by magnetron sputtering. Acta Metall Sinica, 2015, 51(11): 1416马玉田, 刘俊标, 霍荣岭, 等. 基于磁控溅射法显微CTW–Al透射靶材的制备及其性能研究. 金属学报, 2015, 51(11): 1416 [11] Wickersham C E. Method of Producing Tungsten-Titanium Sputter Targets and Targets Produced Thereby: US Patent, 05234487. 1993-8-10 [12] Wickersham C E, Poole J E, Mueller J J. Particle contamination during sputter deposition of W–Ti films. J Vac Sci Technol A, 1992, 10(4): 1713 doi: 10.1116/1.577775 [13] Lo C F, Mcdonald P, Draper D, et al. Influence of tungsten sputtering target density on physical vapor deposition thin film properties. J Electron Mater, 2005, 34(12): 1468 doi: 10.1007/s11664-005-0152-z [14] Kecskes L J, Hall I W. Microstructure effects in hot-explosively-consolidated W–Ti alloys. J Mater Process Technol, 1999, 94: 247 doi: 10.1016/S0924-0136(99)00077-1 [15] Yang Y H, Wang Q D, Li B Q, et al. High temperature & high pressure preparation and phase characterization of WTi10 alloy. Rare Met Mater Eng, 2021, 50(2): 664杨益航, 王启东, 李保强, 等. WTi10合金的高温高压制备及相特征. 稀有金属材料与工程, 2021, 50(2): 664 -

下载:

下载: