-

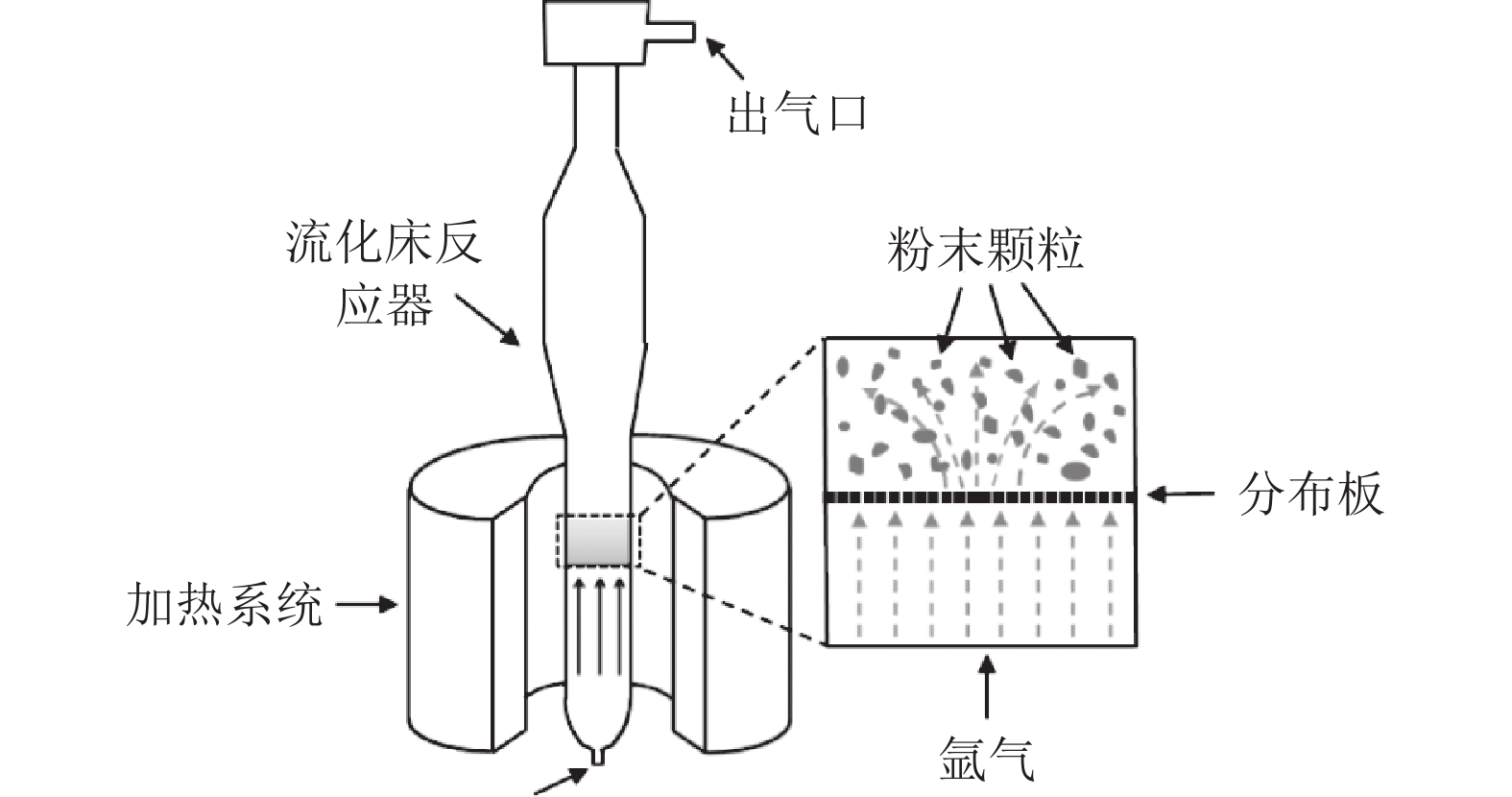

摘要: 采用氢化脱氢(hydrogenation-dehydrogenation,HDH)工艺制备不规则形状Nb521合金粉末,结合流化技术将氢化脱氢粉末进行改性处理,改善粉末球形度及流动性,所制流化Nb521合金粉末基本满足3D打印的工艺要求。通过X射线衍射(X-ray diffraction,XRD)分析、扫描电子显微镜(scanning electron microscope,SEM)观察、粒度分析、化学分析等手段,对粉末形貌、粒度分布、间隙元素含量、球形率以及流动性等特性进行表征。结果表明,经流化处理后,不规则形状的氢化脱氢Nb521合金粉末粒度分布变窄,球形率和流动性均得到显著提高,杂质元素含量得到有效控制,3D打印过程中的铺粉效果良好。Abstract: The irregular-shaped hydrogenation-dehydrogenation (HDH) Nb521 alloy powders were modified by fluidization to improve the sphericity and flowability in this study. The fluidized Nb521 powders basically met the requirements of 3D printing. The powder morphology, particle size distribution, interstitial element content, sphericity, and flowability were characterized and analyzed by X-ray diffraction (XRD), scanning electron microscope (SEM), particle size analysis, and chemical analysis. The results show that, the particle size distribution of the irregular-shaped HDH Nb521 alloy powders becomes narrow after the fluidization, the sphericity and flowability are significantly improved, while the impurity level is effectively controlled. The spreading performance of the fluidized Nb521 powders during 3D printing exhibits quite well.

-

Key words:

- Nb521 alloys /

- 3D printing /

- hydrogenation dehydrogenation /

- powder modification /

- flowability

-

表 1 氢化脱氢原料粉末和不同温度流化处理粉末粒度

Table 1. Particle size of the HDH raw powders and the powders after fluidizing at different temperatures

类别 流化温度 / ℃ D10 / μm D50 / μm D90 / μm 氢化脱氢原料粉末 — 9.1 29.6 68.1 流化粉末 450 14.9 35.5 69.2 500 20.9 40.0 72.6 600 23.0 41.9 73.7 表 2 氢化脱氢原料粉末和流化粉末间隙元素质量分数

Table 2. Interstitial element mass fraction of the HDH raw powders and fluidized powders

% 类别 O H N C 氢化脱氢原料粉末 0.26 0.009 0.021 0.012 流化粉末 0.22 0.008 0.021 0.012 -

[1] Xia M X, Zheng X, Li Z K, et al. Study on forging process of large sized niobium tungsten alloy bars. Hot Working Technol, 2011, 40(17): 112 doi: 10.3969/j.issn.1001-3814.2011.17.036夏明星, 郑欣, 李中奎, 等. 大规格铌钨合金棒材锻造工艺研究. 热加工工艺, 2011, 40(17): 112 doi: 10.3969/j.issn.1001-3814.2011.17.036 [2] Fu J, Zheng X, Li Z K, et al. Study on high-temperature strengthening of Nb-based alloy. Chin J Rare Met, 2008, 30(5): 548 doi: 10.3969/j.issn.0258-7076.2008.05.002付洁, 郑欣, 李中奎, 等. 铌基合金高温强化的研究. 稀有金属, 2008, 30(5): 548 doi: 10.3969/j.issn.0258-7076.2008.05.002 [3] Mireles O, Rodriguez O, Gao Y P, et al. Additive manufacture of refractory alloy C103 for propulsion applications // AIAA Propulsion and Energy 2020 Forum. Reston, 2020: 1 [4] Liu B K. Electron Beam Selective Melting of Nb521 Alloy and its Microstructure and Mechanical Properties [Dissertation]. Harbin: Harbin Institute of Technology, 2019刘宝鹍. Nb521合金电子束选区熔化及组织结构与力学性能[学位论文]. 哈尔滨: 哈尔滨工业大学, 2019 [5] Cheng Y. Research on Preparation of Fine Particles Low-Oxygen Niobium Powders by Electron Beam Smelting Niobium with Hydrogenation-Dehydrogenation Processing [Dissertation]. Zhengzhou: Zhengzhou University, 2018程阳. 电子束熔炼铌氢化脱氢制备细颗粒低氧铌粉的研究[学位论文]. 郑州: 郑州大学, 2018 [6] Li M H, Wu Y, Yao X N. Effect of electron-beam melting process on composition and mechanical property of Nb‒W alloy. J Ningxia Univ Nat Sci, 2012, 33(2): 179李麦海, 武宇, 姚修楠. 电子束熔炼工艺对Nb‒W合金成分及力学性能的影响. 宁夏大学学报(自然科学版), 2012, 33(2): 179 [7] Prasad N E, Wanhill R J H. Aerospace Materials and Material Technologies. Singapore: Springer Singapore, 2017 [8] Terrazas C A, Mireles J, Gaytan S M, et al. Fabrication and characterization of high-purity niobium using electron beam melting additive manufacturing technology. Int J Adv Manuf Technol, 2016, 84(5-8): 1115 [9] Neikov O D, Naboychenko S S, Yefimov N A. Handbook of Non-Ferrous Metal Powders. 2nd Ed. Oxford: Elsevier, 2019 [10] Guo Y, Jia L, Kong B, et al. Microstructure of rapidly solidified Nb-based pre-alloyed powders for additive manufacturing. Appl Surf Sci, 2017, 409: 367 doi: 10.1016/j.apsusc.2017.02.221 [11] Li A, Liu S F, Wang B J, et al. Research progress on preparation of metal powder for 3D printing. J Iron Steel Res, 2018, 30(6): 419李安, 刘世锋, 王伯健, 等. 3D打印用金属粉末制备技术研究进展. 钢铁研究学报, 2018, 30(6): 419 [12] Ding W W, Chen G, Qin M L, et al. Low-cost Ti powders for additive manufacturing treated by fluidized bed. Powder Technol, 2019, 350: 117 doi: 10.1016/j.powtec.2019.03.042 [13] Qin M L, Chen G, Ding W W, et al. A Preparation Method of Low-Cost Ti Powders for 3D Printing Modified by Fluidization: China Patent, 109382511. 2019-2-26秦明礼, 陈刚, 丁旺旺, 等. 一种3D打印用低成本钛粉的流化整形制备方法: 中国专利, 109382511. 2019-2-26 [14] Sankar M, Baligidad R G, Satyanarayana D V V, et al. Effect of internal oxidation on the microstructure and mechanical properties of C-103 alloy. Mater Sci Eng A, 2013, 574: 104 doi: 10.1016/j.msea.2013.02.057 [15] Dholea A, Bhattacharyaa A, Gupta R K, et al. The role of the metal-oxide Interface’ s terminating layer on the selective cold cracking of a commercial Niobium−Hafnium−Titanium (C-103) alloy. J Alloys Compd, 2020, 856(9): 157427 [16] Li X, Zeng K L, He P J, et al. Effect of tightly coupled gas atomization parameters on the properties of metal powders used for 3D printing. Powder Metall Technol, 2021, 39(2): 172李响, 曾克里, 何鹏江, 等. 紧耦合气雾化参数对3D打印用金属粉末性能的影响. 粉末冶金技术, 2021, 39(2): 172 [17] Yang K, Tang H P, Wang J, et al. Preparation and characterization of spherical tantalum powder by radio frequency plasma. Powder Metall Technol, 2020, 38(2): 138杨坤, 汤慧萍, 王建, 等. 射频等离子体制备球形钽粉及其性能表征. 粉末冶金技术, 2020, 38(2): 138 -

下载:

下载: