Friction and wear properties of particle-reinforced iron-based composites under continuous high temperature braking

-

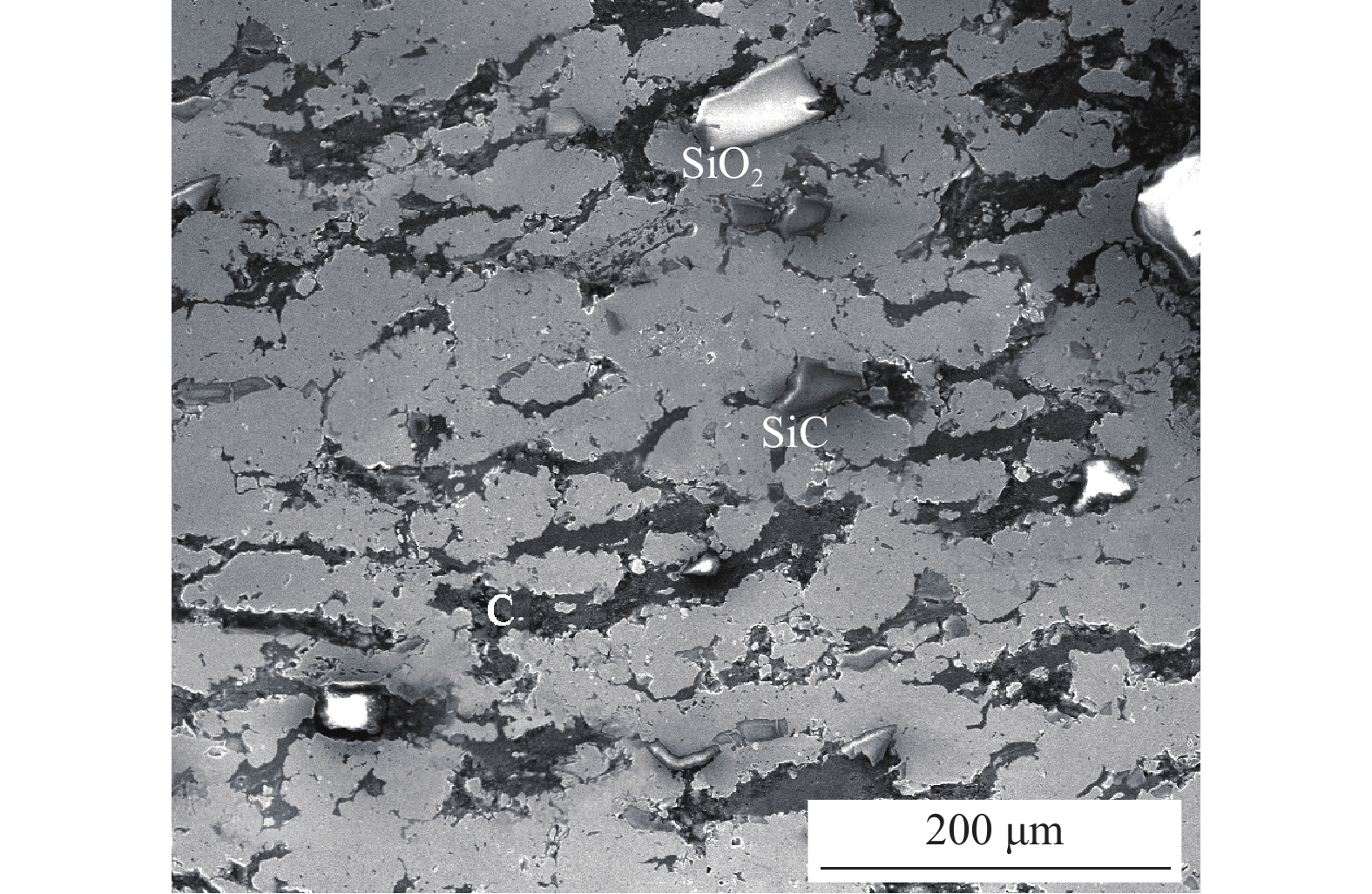

摘要: 采用粉末冶金烧结工艺制备了颗粒增强铁基复合材料,研究了颗粒增强铁基复合材料在连续高温制动条件下的摩擦磨损性能。通过扫描电子显微镜观察、能谱分析和热电偶测温等方法研究了摩擦系数、力矩、稳定系数和磨损率的变化规律,并分析相应磨损机理。结果表明:随接合次数增加,摩擦副温度显著提高,在表面形成多层结构的摩擦膜,可有效减少黏着倾向和犁沟效应,因此平均摩擦系数和平均力矩呈先上升后下降趋势,稳定系数下降。前期摩擦副接合以黏着磨损和磨粒磨损为主,磨损率较高;后期接合摩擦膜起到保护作用,以摩擦膜层间和边缘的疲劳磨损为主,磨损率较低。Abstract: The particle-reinforced iron-based composites were prepared by powder metallurgy in this paper, and the friction and wear properties of the iron-based composites were investigated under the continuous high-temperature braking conditions. The friction coefficient, torque, stability coefficient, and wear rate of the iron-based composites were studied by the scanning electron microscope, energy dispersive spectroscope, and thermocouple temperature measurement, and the corresponding wear mechanism was analyzed. The results show that, as the increase of joining time, the temperature of friction pairs increases significantly, and the formation of friction films with the multilayer structure on the surface can effectively reduce the adhesion tendency and the furrow effect. Accordingly, the average friction coefficient and average torque show the trend as rising first and then falling, and the stability coefficient decreases. The joining of friction pairs in the early stage is dominated by adhesive wear and abrasive wear with the relatively high wear rate; while in the later stage of joining, the friction films serve as the protective film, and the fatigue wear between the layers and edges of the friction films is mostly found in the process with the lower wear rate.

-

Key words:

- iron-based composites /

- continuous high temperature braking /

- friction /

- wear

-

表 1 实验用铁基粉末冶金材料化学成分(质量分数)

Table 1. Chemical compositions of the iron-based powder metallurgy materials in experimental

% Fe Cu Ni SiC SiO2 C 62 4 10 5 3 16 区域 Fe O C 其他 质量分数 / % 原子数分数 / % 质量分数 / % 原子数分数 / % 质量分数 / % 原子数分数 / % 质量分数 / % 原子数分数 / % A 53.32 26.91 30.29 53.36 6.28 14.73 10.11 5.00 B 56.56 28.80 33.80 60.07 3.22 7.62 6.42 3.51 C 6.12 1.44 11.11 9.11 81.34 88.79 1.43 0.66 D 41.14 26.10 20.89 46.26 2.00 5.89 35.97 21.75 -

[1] Qiu Q, Ji Z, Du J H, et al. Research progress of brake friction materials. Powder Metall Technol, 2019, 37(2): 153邱倩, 纪箴, 杜建华, 等. 制动摩擦材料研究进展. 粉末冶金技术, 2019, 37(2): 153 [2] Bao J S, Yin Y, Lu L J, et al. Tribological characterization on friction brake in continuous braking. Ind Lubr Tribol, 2018, 70(1): 172 doi: 10.1108/ILT-09-2016-0205 [3] Wang Z. Research on Control Strategy and Test Technology of Electromechanical Combined Braking for Electric Drive Tracked Vehicle [Dissertation]. Hangzhou: Zhejiang University, 2019王喆. 电传动履带车辆机电联合制动控制策略与试验技术研究[学位论文]. 杭州: 浙江大学, 2019 [4] Sun Y B. Wear rule research and life prediction of a certain tracked vehicle brake. Value Eng, 2013(6): 23孙玉豹. 某型履带车辆制动器磨损规律研究及寿命预测. 价值工程, 2013(6): 23 [5] Yevtushenko A A, Grzes P. Mutual influence of the velocity and temperature in the axisymmetric FE model of a disc brake. Int Commun Heat Mass Transfer, 2014, 57(10): 341 [6] Borawski A, Szpica D, Mieczkowski G, et al. Simulation study of the vehicle braking process with temperature dependent coefficient of friction between brake pad and disc. Heat Transfer Res, 2020, 52(2): 1 [7] Wang X F, Yin C L. Application situations of powder metallurgy friction materials and requests of raw materials. Powder Metall Ind, 2017, 27(3): 1王秀飞, 尹彩流. 粉末冶金摩擦材料的应用现状及对原材料的要求. 粉末冶金工业, 2017, 27(3): 1 [8] Zhou H B, Yao P P, Xiao Y L, et al. Topographical characteristics and wear mechanism of copper-based powder metallurgy friction materials reinforced by SiC particle. Chin J Nonferrous Met, 2014, 24(9): 2272周海滨, 姚萍屏, 肖叶龙, 等. SiC颗粒强化铜基粉末冶金摩擦材料的表面形貌特征及磨损机理. 中国有色金属学报, 2014, 24(9): 2272 [9] Du J H, Liu Y W, Li Y Y. Friction properties of Cu-based friction materials reinforced by nanometer materials. Opt Precis Eng, 2013, 21(10): 2581 doi: 10.3788/OPE.20132110.2581杜建华, 刘彦伟, 李园园. 纳米颗粒增强铜基摩擦材料的摩擦学性能. 光学精密工程, 2013, 21(10): 2581 doi: 10.3788/OPE.20132110.2581 [10] Xiao Y, Zhang Z, Yao P, et al. Mechanical and tribological behaviors of copper metal matrix composites for brake pads used in high-speed trains. Tribol Int, 2018, 119: 585 doi: 10.1016/j.triboint.2017.11.038 [11] Ram P T, Varma V K, Vedantam S. Effect of reinforcement type, size, and volume fraction on the tribological behavior of Fe matrix composites at high sliding speed conditions. Wear, 2014, 309(1-2): 247 doi: 10.1016/j.wear.2013.10.001 [12] Ma X, Luan C H, Fan S W, et al. Comparison of braking behaviors between iron- and copper-based powder metallurgy brake pads that used for C/C–SiC disc. Tribol Int, 2020, 154: 106686 [13] Zhang P, Zhang L, Fu K X, et al. Effects of different forms of Fe powder additives on the simulated braking performance of Cu-based friction materials for high-speed railway trains. Wear, 2018, 414-415: 317 doi: 10.1016/j.wear.2018.09.006 [14] Zhang P, Zhang L, Wu P, et al. Effect of carbon fiber on the braking performance of copper-based brake pad under continuous high-energy braking conditions. Wear, 2020, 458-459: 203408 doi: 10.1016/j.wear.2020.203408 [15] Venkatesh S, Murugapoopathiraja K. Scoping review of brake friction material for automotive. Mater Today Proc, 2019, 16: 927 doi: 10.1016/j.matpr.2019.05.178 [16] Peng T, Yan Q, Li G, et al. The braking behaviors of cu-based metallic brake pad for high-speed train under different initial braking speed. Tribol Lett, 2017, 65(4): 1 [17] Su L, Gao F, Han X, et al. Tribological behavior of copper-graphite powder third body on copper-based friction materials. Tribol Lett, 2015, 60(2): 30 doi: 10.1007/s11249-015-0605-3 [18] Yu X, Guo Z M, Yang J, et al. Effect of Fe content and friction components on properties of copper·based powder metallurgy friction material. Powder Metall Technol, 2014, 32(1): 43 doi: 10.3969/j.issn.1001-3784.2014.01.008于潇, 郭志猛, 杨剑, 等. Fe含量及摩擦组元对铜基粉末冶金摩擦材料性能的影响. 粉末冶金技术, 2014, 32(1): 43 doi: 10.3969/j.issn.1001-3784.2014.01.008 [19] Liu J X, Zhang C. Composition design overview of Cu-based powder metallurgy friction material. Powder Metall Ind, 2018, 28(6): 74刘建秀, 张驰. 铜基粉末冶金摩擦材料成分设计概述. 粉末冶金工业, 2018, 28(6): 74 [20] Peng T. Study on Brake Friction Behavior and Friction Stability of Brake Pad Material for High-speed Train [Dissertation]. Beijing: University of Science and Technology Beijing, 2019彭韬. 高铁刹车片材料制动摩擦行为及摩擦稳定性研究[学位论文]. 北京: 北京科技大学, 2019 [21] Peng T, Yan Q, Li G, et al. The influence of Cu/Fe ratio on the tribological behavior of brake friction materials. Tribol Lett, 2018, 66(1): 18 doi: 10.1007/s11249-017-0961-2 [22] Verma P C, Ciudin R, Bonfanti A, et al. Role of the friction layer in the high-temperature pin-on-disc study of a brake material. Wear, 2016, 346-347: 56 doi: 10.1016/j.wear.2015.11.004 [23] Lu H, Zhang J L, Liu L J, et al. The Effect of SiO2 particle size on Cu-based powder metallurgy friction materials. Powder Metall Technol, 2014, 32(3): 195卢宏, 张婧琳, 刘联军, 等. SiO2粒度对铜基粉末冶金摩擦材料性能影响. 粉末冶金技术, 2014, 32(3): 195 [24] Gong T, Yao P, Xiong X, et al. Microstructure and tribological behavior of interfaces in Cu-SiO2 and Cu-Cr metal matrix composites. J Alloys Compd, 2019, 786: 975 doi: 10.1016/j.jallcom.2019.01.255 [25] Si L, Liu C, Yan H, et al. The influences of high temperature on tribological properties of Cu-based friction materials with a friction phase of SiO2/SiC/Al2O3. AIP Adv, 2021, 11(2): 025335 doi: 10.1063/5.0040220 [26] Xiao X, Yin Y, Bao J S, et al. Review on the friction and wear of brake materials. Adv Mach Eng, 2016, 8(5): 1 [27] Su L, Gao F, Han X, et al. Effect of copper powder third body on tribological property of copper-based friction materials. Tribol Int, 2015, 90: 420 doi: 10.1016/j.triboint.2015.05.003 -

下载:

下载: