Effect of CuSn15 content on the structure and properties of pressureless sintered FeCoCu matrix and diamond tools

-

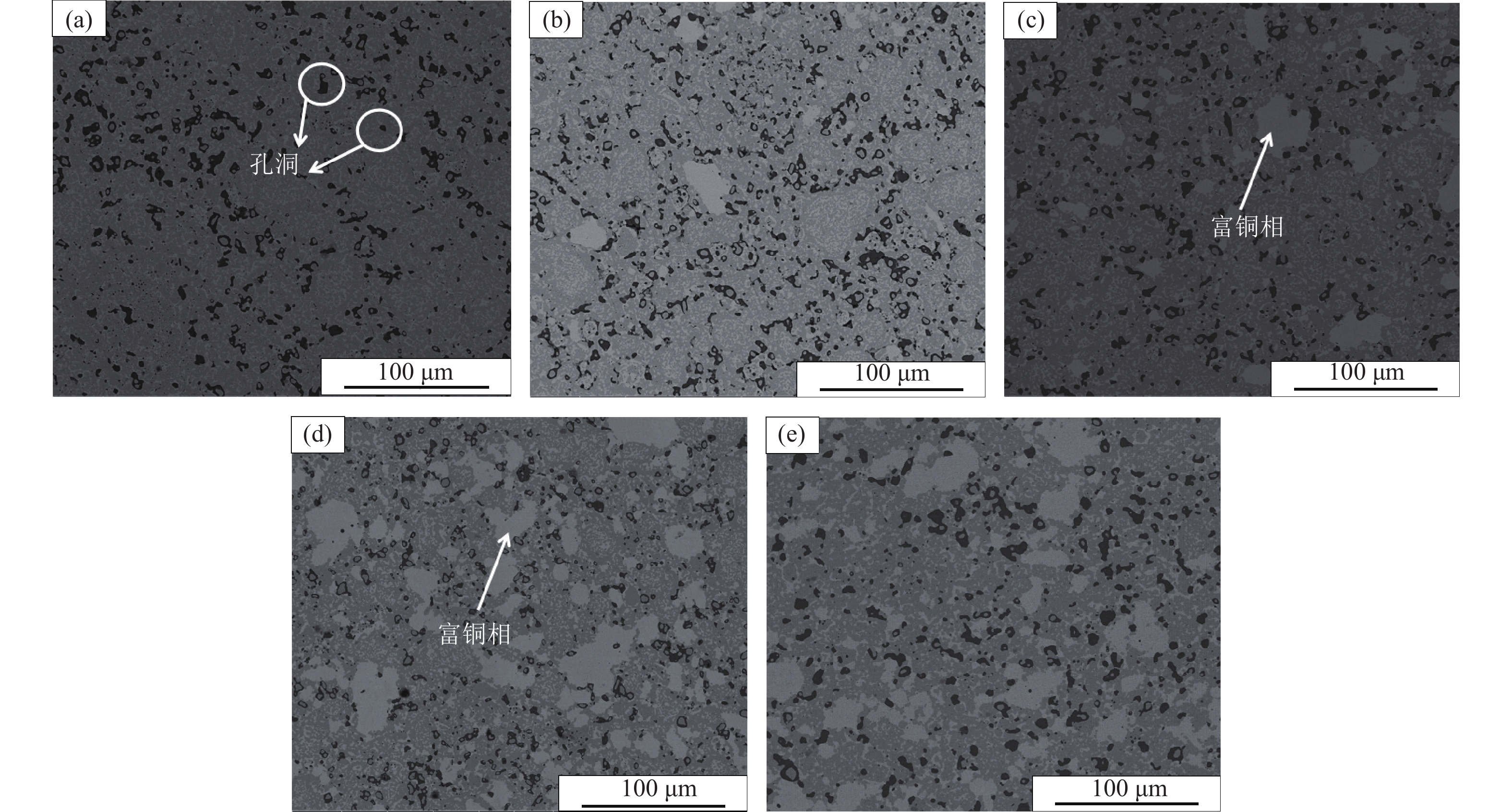

摘要: 以FeCoCu预合金粉作为金刚石工具的主要胎体材料,以CuSn15预合金粉为添加剂,通过无压烧结制备胎体和金刚石工具材料,研究了CuSn15含量对胎体和金刚石工具材料力学性能、金刚石把持力和显微组织的影响,分析了添加CuSn15后金刚石与胎体金属结合界面,探讨了界面之间化学键合、机械包镶以及胎体与金刚石颗粒支撑力三个方面的变化对金刚石把持力的影响。结果表明:随着CnSn15添加量的增多,FeCoCu胎体材料的相对密度、硬度、抗弯强度呈先增大再降低的趋势。添加质量分数8%CuSn15的FeCoCu胎体性能较好,此时胎体相对密度为97.5%,硬度为HRB 104.6,抗弯强度为1112.6 MPa。采用添加质量分数8%CuSn15的FeCoCu胎体制备金刚石工具时,其强度损失率较低,为21.7%,表明胎体对金刚石工具有较好把持力。Abstract: The matrix and diamond tool materials were prepared by pressureless sintering, using FeCoCu pre-alloyed powders as the main matrix materials and CuSn15 pre-alloyed powders as the additive. The effects of CuSn15 content on the mechanical properties, diamond holding power, and microstructure of the matrix and diamond tool materials were investigated. The bonding interface between the diamond and the matrix metal was analyzed after adding CuSn15, and the influence of chemical bonding, mechanical insertion, and the supporting force between the matrix and diamond particles on diamond holding power was discussed. The results show that with the increase of CnSn15, the relative density, hardness, and bending strength of the FeCoCu matrix increase first and then decrease. The mechanical properties of the FeCoCu matrix with the CuSn15 mass fraction of 8% are better, the relative density, hardness, and bending strength are 97.5%, HRB 104.6, and 1112.6 MPa respectively. The strength loss rate of the FeCoCu matrix with 8% CuSn15 is 21.7%, which indicates that the matrix has a good holding power for the diamond tools.

-

Key words:

- FeCoCu matrix /

- diamond tools /

- pressureless sintering /

- CuSn15 /

- diamond holding power

-

表 1 图1(c)中两种区域的能谱分析

Table 1. EDS analysis of two areas in Fig.1(c)

区域 质量分数 / % 物相 Fe Co Cu Sn 灰白色区 26.08 6.34 66.37 1.21 面心立方 Cu 深灰色区 64.70 18.70 16.28 0.06 体心立方 Fe 表 2 FeCoCu胎体材料的相对密度及线收缩率

Table 2. Relative density and linear shrinkage of the FeCoCu matrix materials

编号 胎体成分 相对密度 / % 线收缩率 / % 1 FeCoCu 92.6 6.32±0.05 2 95%FeCoCu+5%CuSn15 94.3 8.32±0.08 3 92%FeCoCu+8%CuSn15 97.5 10.13±0.16 4 89%FeCoCu+11%CuSn15 94.1 7.56±0.12 5 86%FeCoCu+14%CuSn15 89.2 4.43±0.16 表 3 添加不同质量分数CuSn15的胎体烧结体及其形成的金刚石工具材料的抗弯强度

Table 3. Bending strength of the sintered matrix and the diamond tool materials added by CuSn15 in the different mass fraction

编号 胎体成分 抗弯强度 / MPa 强度损失率 / % 胎体烧结体 金刚石工具材料 1 FeCoCu 872.3 546.8 37.3 2 95%FeCoCu+5%CuSn15 942.1 643.8 31.7 3 92%FeCoCu+8%CuSn15 1112.6 870.7 21.7 4 89%FeCoCu+11%CuSn15 983.6 692.5 29.6 5 86%FeCoCu+14%CuSn15 782.9 444.7 43.2 表 4 添加不同质量分数CuSn15金刚石工具材料中金刚石颗粒与胎体之间的间隙宽度

Table 4. Gap values between the diamond particles and the matrix in the diamond tool materials added by CuSn15 in the different mass fraction

编号 胎体成分 间隙宽度 / μm 平均间隙宽度 / μm 1 FeCoCu 3.84 4.13 4.32 4.24 4.13 2 95%FeCoCu+5%CuSn15 1.99 2.26 2.31 1.96 2.13 3 92%FeCoCu+8%CuSn15 1.11 0.98 1.23 0.87 1.05 4 89%FeCoCu+11%CuSn15 1.68 1.64 1.52 1.47 1.58 5 86%FeCoCu+14%CuSn15 4.16 3.96 4.32 3.82 4.07 -

[1] De Oliveira L J, Bobrovnitchii G S, Filgueira M. Processing and characterization of impregnated diamond cutting tools using a ferrous metal matrix. Int J Refract Met Hard Mater, 2007, 25(4): 328 doi: 10.1016/j.ijrmhm.2006.08.006 [2] Liu Y H, Wang L M, Zhang J H, et al. Preparation and characterization of low sintering temperature ultra-fine cobalt powder. Diamond Abras Eng, 2009(3): 51刘宇慧, 汪礼敏, 张景怀, 等. 一种具有较低烧结温度的超细钴粉的制备及表征. 金刚石与磨料磨具工程, 2009(3): 51 [3] De Paula Barbosa A, Bobrovnitchii G S, Skury A L D, et al. Structure, microstructure and mechanical properties of PM Fe–Cu–Co alloys. Mater Des, 2010, 31(1): 522 doi: 10.1016/j.matdes.2009.07.027 [4] De Oliveira H C P, Coelho A, Amaral P M, et al. Comparison between cobalt and niobium as a matrix component for diamond impregnated tools used for stone cutting. Key Eng Mater, 2013, 548(4): 98 [5] Cygan-Bączek E, Wyżga P, Cygan S, et al. Improvement in hardness and wear behaviour of iron-based Mn–Cu–Sn matrix for sintered diamond tools by dispersion strengthening. Materials, 2021, 14(7): 1774 doi: 10.3390/ma14071774 [6] Wang C, Zhang X F, Wang C F, et al. Currrnt research situation and development of Cu-based diamond tools made by powder metallurge. Powder Metall Technol, 2012, 30(2): 140王闯, 张效芬, 王长福, 等. 粉末冶金Cu基金刚石工具的研究现状及进展. 粉末冶金技术, 2012, 30(2): 140 [7] Xiao C J, Dou Z Q, Li J, et al. Study on the properties of diamond saw blades prepared by Cu-based pre-alloyed powders. Powder Metall Technol, 2018, 36(4): 287肖长江, 窦志强, 李娟, 等. 铜基预合金粉末制备金刚石锯片的性能研究. 粉末冶金技术, 2018, 36(4): 287 [8] Shekhar M, Yadav S K S. Diamond abrasive based cutting tool for processing of advanced engineering materials: a review. Mater Today, 2020, 22(4): 3126 [9] Yu Q, Ma J, Long W M, et al. Application of silicon brass pre-alloyed powder in diamond tools. Powder Metall Technol, 2020, 38(3): 206于奇, 马佳, 龙伟民, 等. 硅黄铜预合金粉末在金刚石工具中的应用. 粉末冶金技术, 2020, 38(3): 206 [10] Kozyrev E N, Kumykov V K, Kushhabiev A S, et al. Development of diamond–metal compositions for diamond tools. J Surf Invest, 2020, 14(3): 639 doi: 10.1134/S1027451020030076 [11] Kumar D, Dwarapudi S, Sista K S, et al. Iron powder-based metal matrix for diamond cutting tools: A revie. ISIJ Int, 2020, 14(3): 639 [12] Xie D L, Wan L, Song D D, et al. Pressureless sintering curve and sintering activation energy of Fe–Co–Cu pre-alloyed powders. Mater Des, 2015, 87(3): 482 [13] Xie Z G, Liu X Y, Qin H Q, et al. Sintering and mechanical properties of FeCoCu fetal boby applied for diamond tools. J Cent South Univ Sci Technol, 2010, 41(6): 2178谢志刚, 刘心宇, 秦海青, 等. 金刚石制品用FeCoCu胎体的烧结与力学性能研究. 中南大学学报(自然科学版), 2010, 41(6): 2178 [14] Wang C P, Liu X J, Ohnuma I. Phase equilibria in Fe–Cu–X (X: Co, Cr, Si, V) ternary systems. J Phase Equilib, 2002, 23(3): 236 doi: 10.1361/105497102770331712 [15] Liu X F, Luo J H, Wang X C. Surface quality, microstructure and mechanical properties of Cu–Sn alloy plate prepared by two-phase zone continuous casting. Trans Nonferrous Met Soc China, 2015, 25(6): 1901 doi: 10.1016/S1003-6326(15)63797-9 [16] Mechnik V A, Bondarenko N A, Kuzin N O, et al. The role of structure formation in forming the physicomechanical properties of composites of the diamond–(Fe–Cu–Ni–Sn) system. J Frict Wear, 2016, 37(4): 377 doi: 10.3103/S1068366616040139 -

下载:

下载: