-

摘要: 钛及钛合金因具有密度低、强度高、耐腐蚀、生物相容性好等特点被广泛应用于军事、航空、医疗等领域。传统铸锻钛合金生产工艺复杂,成本高,严重限制了钛合金的应用,粉末冶金技术制备钛合金降低了生产成本,有利于钛合金的推广应用。本文从钛及钛合金粉末的制备与成形工艺方面介绍了粉末冶金钛及钛合金的研究现状,并阐述了其发展趋势。Abstract: Titanium and titanium alloys are widely used in military, aviation, and medical fields due to the low density, high strength, corrosion resistance, and good biocompatibility. The traditional production method of casting-forging titanium alloys is complicated and costly, which seriously limits the application of titanium alloys. Powder metallurgy technology can reduce the production cost of titanium alloys, which is expected to popularize the application of titanium alloys. The research status of titanium and titanium alloys by powder metallurgy was introduced in this paper from the aspects of powder preparation and forming process, and the development trend was described.

-

表 1 钛粉制备工艺

Table 1. Preparation technology of the titanium powders

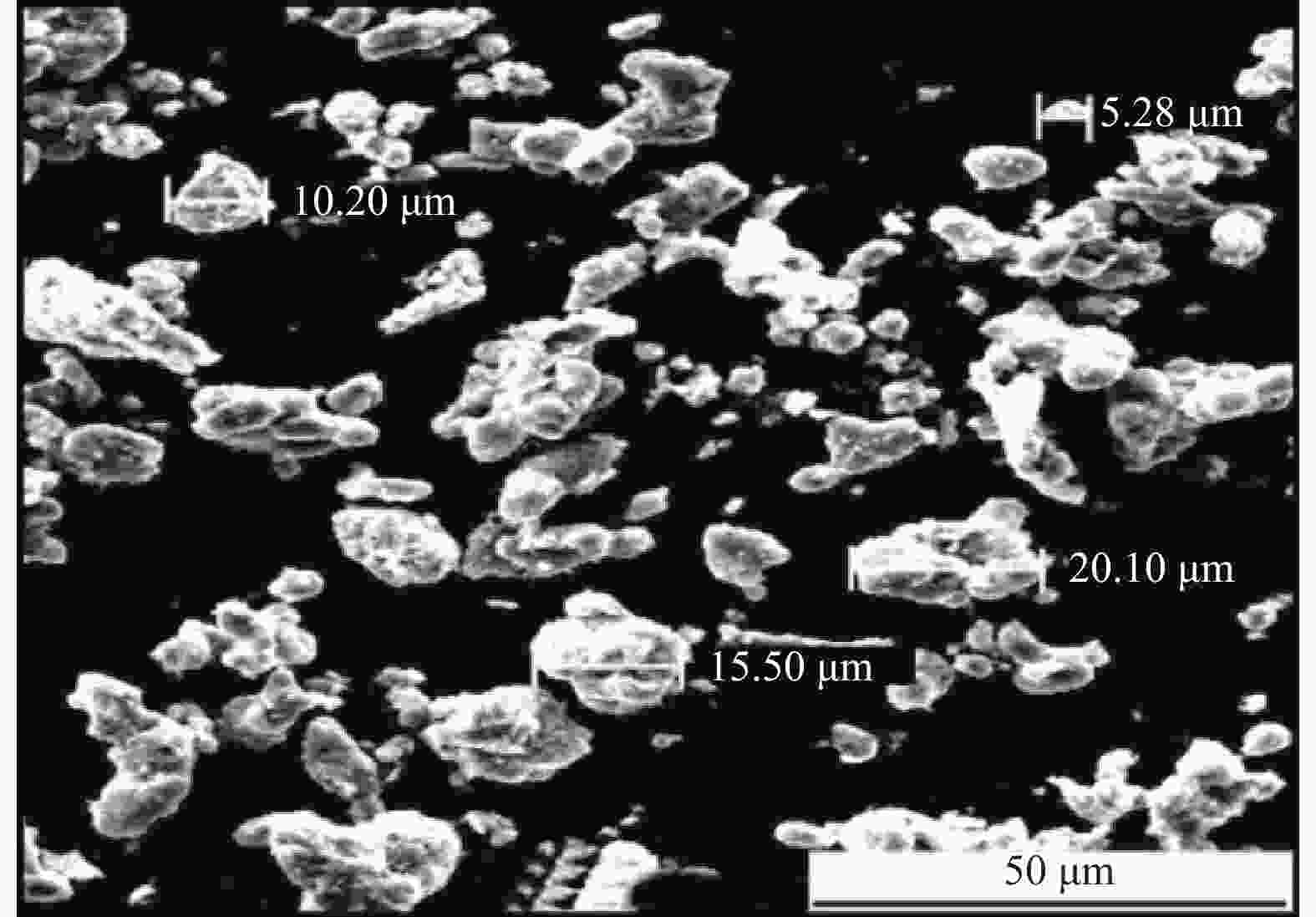

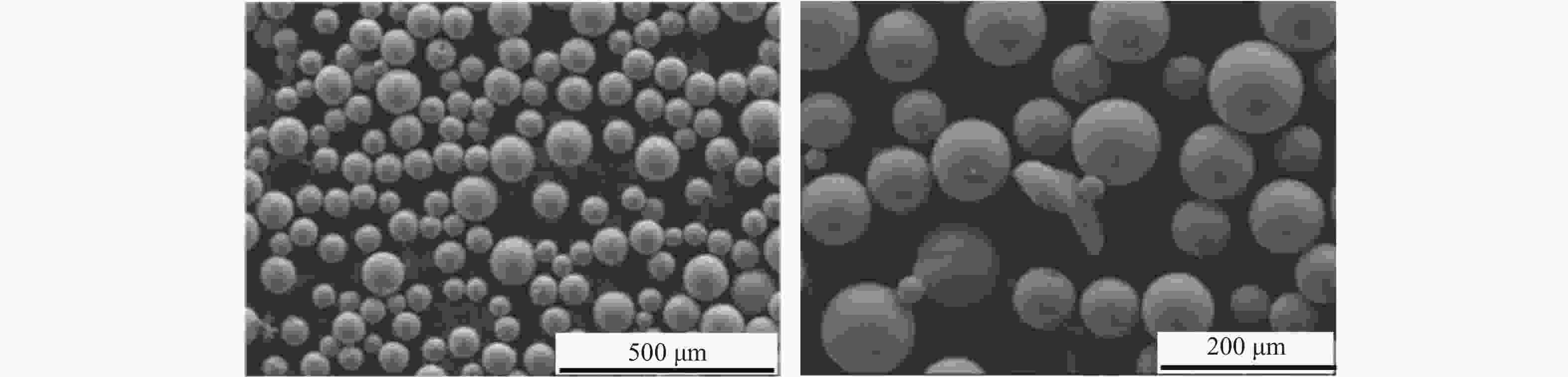

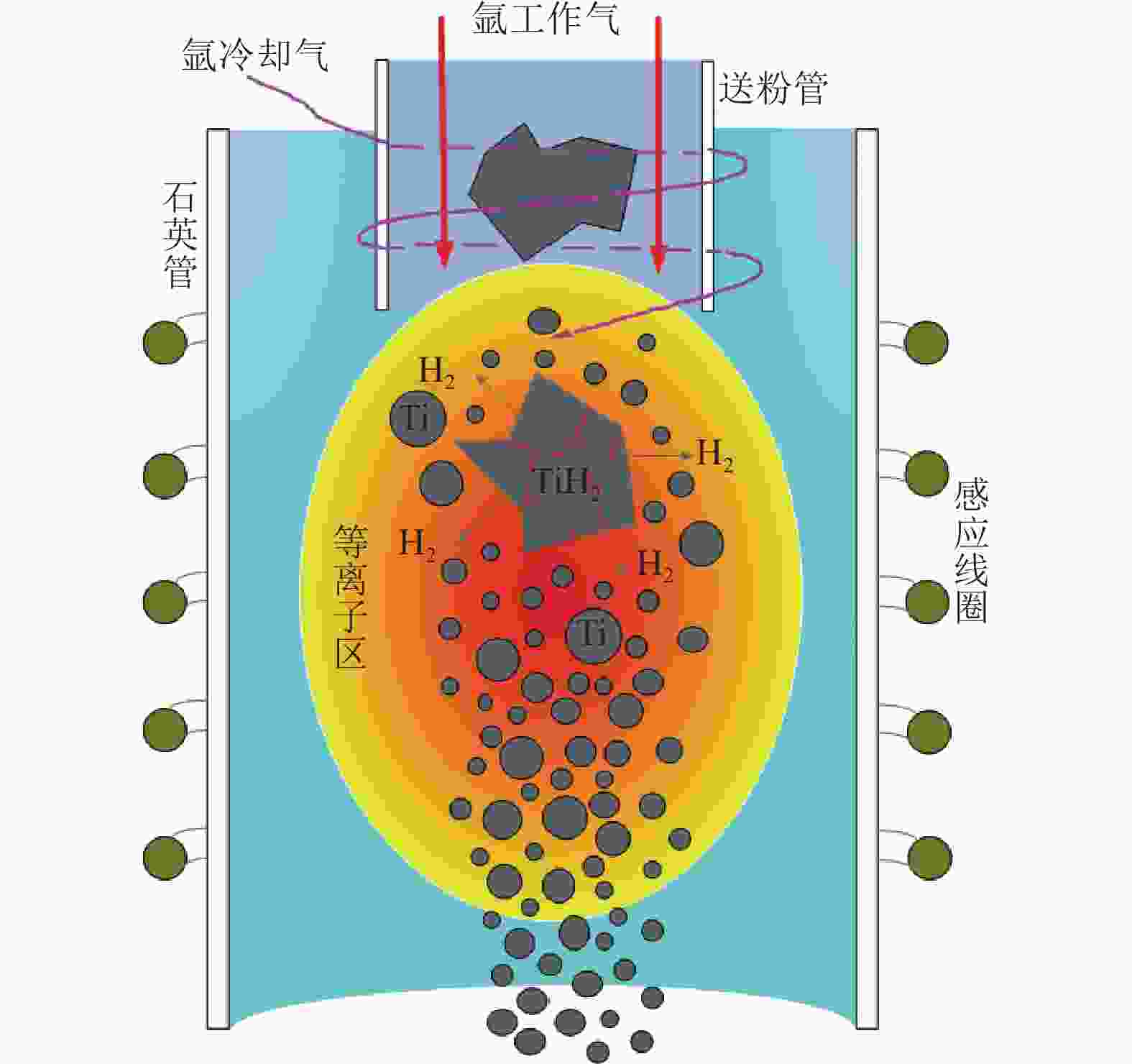

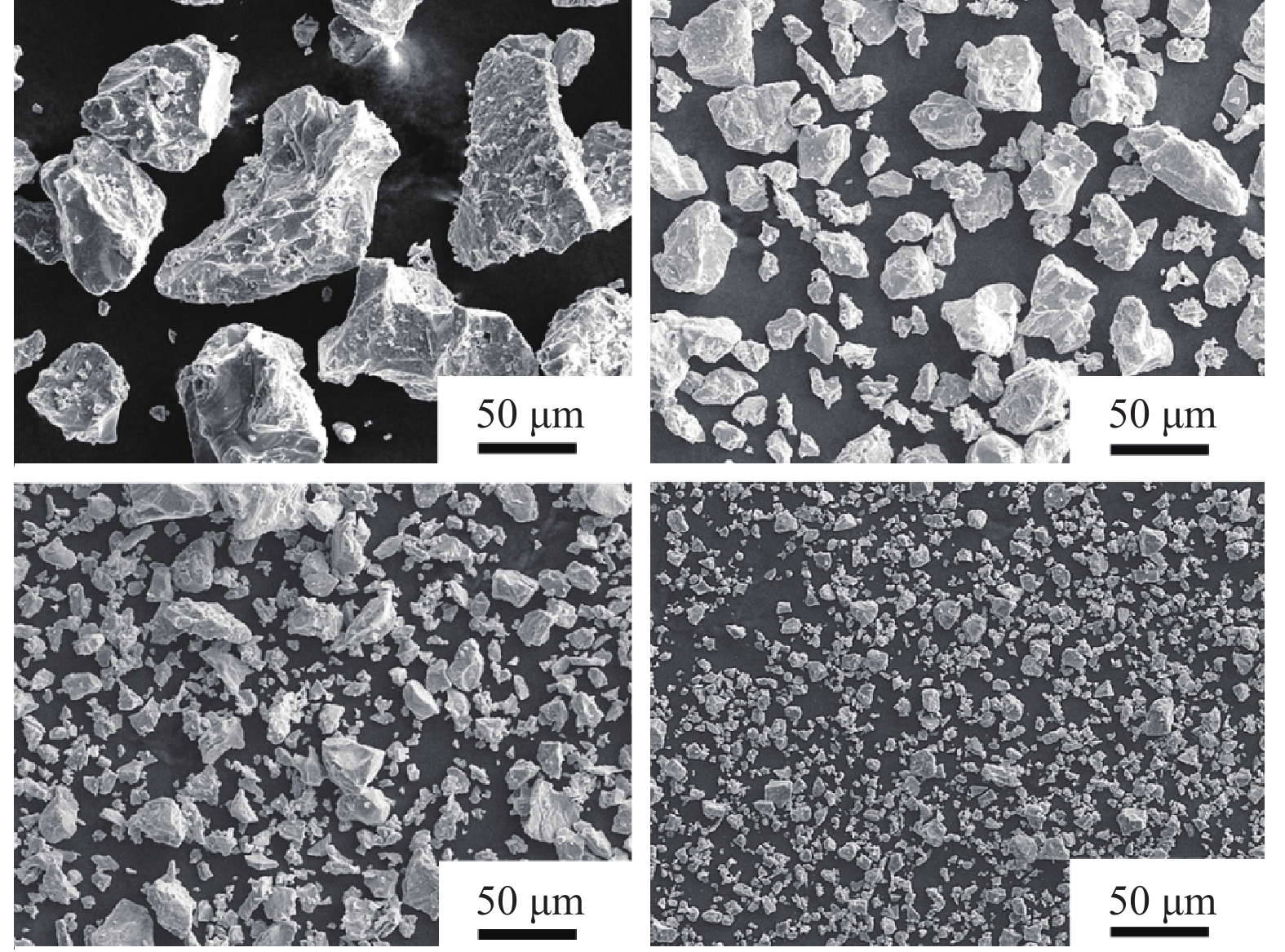

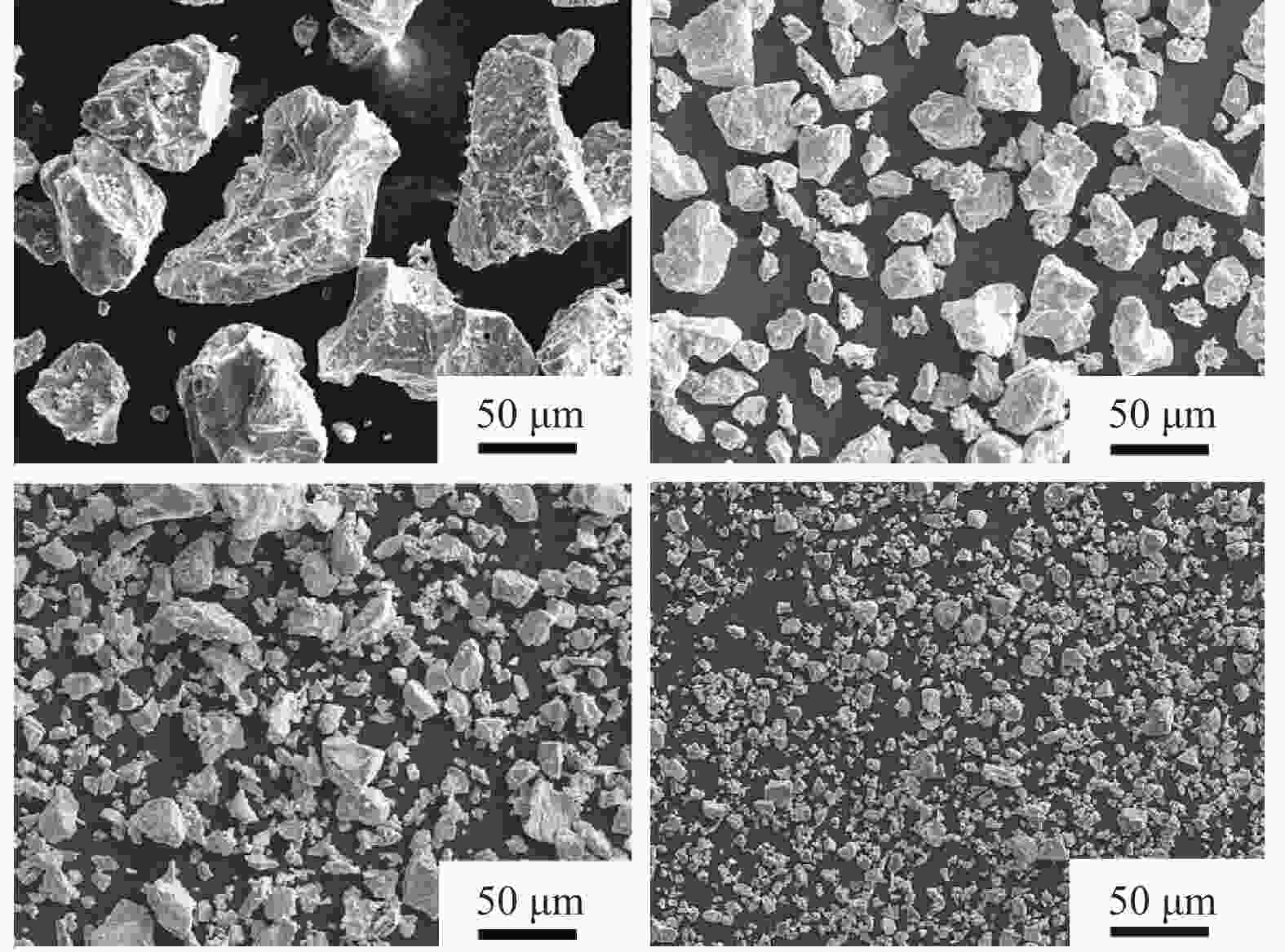

制粉方法 原料 粉末形貌 工艺及粉末特点 氢化脱氢法 电解钛或海绵钛 不规则形状 成本低,工艺简单,粉末粒度范围宽,O、N含量高 还原法 四氯化钛或二氧化钛 海绵形 O、N等杂质含量低,纯度高,流动性好,需要后续分离过程 雾化法 钛丝 球形 杂质含量低,球形度好,粒度大小均匀,粒度较粗 射频等离子体球化法 氢化钛颗粒 球形 纯度高,表面形貌好,内部空隙少,流动性好,生产技术较难 -

[1] Bolzoni L, Esteban P G, Ruiz-Navas E M, et al. Influence of powder characteristics on sintering behaviour and properties of PM Ti alloys produced from prealloyed powder and master alloy. Powder Metall, 2011, 54(4): 543 doi: 10.1179/003258910X12827272082623 [2] Wang H Y, Guo Z M, Lu B X, et al. Industrialized production technology of powder metallurgy (PM) titanium and titanium alloy. Prog Titanium Ind, 2017, 34(1): 1王海英, 郭志猛, 芦博欣, 等. 钛合金粉末冶金工业化生产技术. 钛工业进展, 2017, 34(1): 1 [3] Guo L, He W X, Zhou P, et al. Research status and development prospect of titanium and titanium alloy products in China. Hot Working Technol, 2020, 49(22): 22郭鲤, 何伟霞, 周鹏, 等. 我国钛及钛合金产品的研究现状及发展前景. 热加工工艺, 2020, 49(22): 22 [4] Wu Y J, Liang Y R. Progress in titanium powder and titanium powder metallurgy products. Prog Mater Sci Eng, 2011, 30(6): 44吴引江, 梁永仁. 钛粉末及其粉末冶金制品的发展现状. 中国材料进展, 2011, 30(6): 44 [5] Tan Z Q, Zhang Q, Guo X Y, et al. New development of powder metallurgy in automotive industry. J Cent South Univ, 2020, 27(6): 1611 doi: 10.1007/s11771-020-4394-y谭兆强, 张青, 郭学益, 等. 粉末冶金技术在汽车工业的新进展(英文). 中南大学学报(英文版), 2020, 27(6): 1611 doi: 10.1007/s11771-020-4394-y [6] Zhang C. Study on Preparation of Low Gap Atomic Titanium Alloy Based on Reaction Synthesis of HDH Titanium Powder [Dissertation]. Beijing: University of Science and Technology Beijing, 2019张策. 基于HDH钛粉反应合成制备低间隙原子钛合金技术研究[学位论文]. 北京: 北京科技大学, 2019 [7] Yang T Z. Progress of modern powder metallurgy materials and technology. China Met Bull, 2019(12): 10杨廷志. 现代粉末冶金材料与技术进展. 中国金属通报, 2019(12): 10 [8] Wang H Y, Yang F, Guo Z M, et al. Properties and microstructure of forged powder metallurgy Ti6Al4V alloy. Rare Met Mater Eng, 2020, 49(8): 2855王海英, 杨芳, 郭志猛, 等. 锻造粉末冶金Ti6Al4V合金的性能和组织研究. 稀有金属材料与工程, 2020, 49(8): 2855 [9] Han F L. New development in powder forging of automobile engine connecting rod. Mod Compon, 2008(7): 71韩凤麟. 粉末锻造汽车发动机连杆新进展. 现代零部件, 2008(7): 71 [10] Wu S, Wang F, Ma S B, et al. Experimental study of wear characteristics of powder forging die and mechanism analysis. J Hefei Univ Technol Nat Sci, 2016, 39(2): 156吴松, 王峰, 马少波, 等. 粉末热锻模具磨损特性的实验研究与机理分析. 合肥工业大学学报(自然科学版), 2016, 39(2): 156 [11] Li X. Preparation of Biomedical Titanium Alloy by Powder Metallurgy [Dissertation]. Harbin: Harbin Institute of Technology, 2019李霞. 粉末冶金制备生物医用钛合金[学位论文]. 哈尔滨: 哈尔滨工业大学, 2019 [12] Shi Y H, Zheng H. Preparing methods and application of spherical particles. China Powder Sci Technol, 2015, 21(4): 71施阳和, 郑华. 球形粉体的制备方法及应用. 中国粉体技术, 2015, 21(4): 71 [13] Yang X, Xi Z P, Liu Y, et al. Characterization of TiAl powders prepared by plasma rotating electrode processing. Rare Met Mater Eng, 2010, 39(12): 2251杨鑫, 奚正平, 刘咏, 等. 等离子旋转电极法制备钛铝粉末性能表征. 稀有金属材料与工程, 2010, 39(12): 2251 [14] Zhang Q L, Hao Z H, Li J, et al. Research progress on preparation of spherical metal powders by induction plasma spheroidization. Rare Met Mater Eng, 2020, 49(8): 2895张庆磊, 郝振华, 李静, 等. 感应等离子体球化法制备球形金属粉体的研究进展. 稀有金属材料与工程, 2020, 49(8): 2895 [15] Zeng G, Bai B L, Zhang P, et al. Research progress on producing spherical titanium powder. Prog Titanium Ind, 2015, 32(1): 7曾光, 白保良, 张鹏, 等. 球形钛粉制备技术的研究进展. 钛工业进展, 2015, 32(1): 7 [16] Li X, Gong Y, Liu S B, et al. Current development and prospects for titanium alloy powder metallurgy hot isostatic pressing technology. Foundry, 2020, 69(4): 335李欣, 龚燚, 刘时兵, 等. 钛合金粉末热等静压技术的发展现状及展望. 铸造, 2020, 69(4): 335 [17] Guo Z M, Zhang C, Wang H Y, et al. Preparation of low-cost and high-performance titanium alloys based on HDH titanium powder. Prog Titanium Ind, 2019, 36(5): 41郭志猛, 张策, 王海英, 等. 基于氢化脱氢钛粉制备低成本高性能钛合金. 钛工业进展, 2019, 36(5): 41 [18] Fang Z Z, Paramore J D, Sun P, et al. Powder metallurgy of titanium—past, present, and future. Int Mater Rev, 2018, 63(7): 407 doi: 10.1080/09506608.2017.1366003 [19] Chen G, Lu X, Zhang L, et al. Research progress in powder production and near-net-shape manufacturing of titanium and its alloys. Mater Sci Technol, 2020, 28(3): 98 doi: 10.11951/j.issn.1005-0299.20200041陈刚, 路新, 章林, 等. 钛及钛合金粉末制备与近净成形研究进展. 材料科学与工艺, 2020, 28(3): 98 doi: 10.11951/j.issn.1005-0299.20200041 [20] Hong Y, Qu T, Shen H S, et al. Titanium production through hydrogenation and dehydrogenation process. Rare Met, 2007, 31(3): 311洪艳, 曲涛, 沈化森, 等. 氢化脱氢法制备钛粉工艺研究. 稀有金属, 2007, 31(3): 311 [21] Weng Q G, Qiu Z L, Yuan T C, et al. Preparation process of ultrafine high purity Ti powders fabricated by electrolysis titanium using hydrogenation-dehydrogenation method. Mater Sci Eng Powder Metall, 2015, 20(2): 325翁启刚, 邱子力, 袁铁锤, 等. 电解钛氢化脱氢制备超细高纯钛粉工艺. 粉末冶金材料科学与工程, 2015, 20(2): 325 [22] Song J X, Xu B Q, Yang B, et al. Research of producing titanium by magnesiothermic reduction process. Light Met, 2009(12): 43宋建勋, 徐宝强, 杨斌, 等. 镁热还原法制取金属钛的实验研究. 轻金属, 2009(12): 43 [23] Fan S G, Dou Z H, Zhang T A, et al. Direct preparation of titanium powder by multistage deep reduction. Rare Met Mater Eng, 2020, 49(3): 1020范世钢, 豆志河, 张廷安, 等. 多级深度还原法直接制备钛粉. 稀有金属材料与工程, 2020, 49(3): 1020 [24] Wan H L, Xu B Q, Dai Y N, et al. Research progress on preparation of titanium powders by calciothermic reduction. J Funct Mater, 2012, 43(6): 700万贺利, 徐宝强, 戴永年, 等. 钙热还原法制备钛粉过程的研究. 功能材料, 2012, 43(6): 700 [25] Guo Z M, Lu B X, Yang F, et al. Advances in preparation of titanium alloy from powder metallurgy. Powder Metall Ind, 2020, 30(2): 1郭志猛, 芦博昕, 杨芳, 等. 粉末冶金钛合金制备技术研究进展. 粉末冶金工业, 2020, 30(2): 1 [26] Lu L L, Zhang S M, Xu J, et al. Review on advanced preparation technology of spherical titanium powders. Rare Met, 2017, 41(1): 94陆亮亮, 张少明, 徐骏, 等. 球形钛粉先进制备技术研究进展. 稀有金属, 2017, 41(1): 94 [27] Zheng M Y. Gas Atomization Technology Research of Titanium Alloy Powders for Additive Manufacturing [Dissertation]. Beijing: University of Science and Technology Beijing, 2019郑明月. 气雾化法制备增材制造用钛合金粉末研究[学位论文]. 北京: 北京科技大学, 2019 [28] Li B Q, Jin H C, Zhang Y C, et al. Research progress of preparation methods of spherical titanium powders for 3D printing. J Process Eng, 2017, 17(5): 911李保强, 金化成, 张延昌, 等. 3D打印用球形钛粉制备技术研究进展. 过程工程学报, 2017, 17(5): 911 [29] Liu C. Research on Plasma Atomization Preparation Equipment and Technology of Titanium Alloy Powder [Dissertation]. Shenyang: Shenyang University of Technology, 2019刘畅. 钛合金粉体等离子雾化制备设备及工艺研究[学位论文]. 沈阳: 沈阳工业大学, 2019 [30] Lu C, Xiao M Z, Qu Y B, et al. Research of parameters on the effect of CoCr alloys pherical powders produced by RF plasma. Powder Metall Ind, 2020, 30(6): 8路超, 肖梦智, 屈岳波, 等. 射频等离子球化制备球形钴铬合金粉末工艺研究. 粉末冶金工业, 2020, 30(6): 8 [31] Hu K, Zou L M, Mao X H, et al. Preparation of spherical titanium powder by RF plasma and its application in powder injection molding. Iron Steel Vanadium Titanium, 2020, 41(1): 36胡凯, 邹黎明, 毛新华, 等. 射频等离子体制备球形钛粉及其在粉末注射成形中的应用. 钢铁钒钛, 2020, 41(1): 36 [32] Gu Z T, Ye G Y, Jin Y P. Chemical compositions of spherical titanium powders prepared by RF induction plasma. High Power Laser Part Beams, 2012, 24(6): 1409 doi: 10.3788/HPLPB20122406.1409古忠涛, 叶高英, 金玉萍. 射频感应等离子体制备球形钛粉的成分分析. 强激光与粒子束, 2012, 24(6): 1409 doi: 10.3788/HPLPB20122406.1409 [33] Sheng Y W, Guo Z M, Hao J J, et al. Preparation of micro-spherical titanium powder by RF plasma. Rare Met Mater Eng, 2013, 42(6): 1291盛艳伟, 郭志猛, 郝俊杰, 等. 射频等离子体制备球形钛粉. 稀有金属材料与工程, 2013, 42(6): 1291 [34] Chen X W. Study on preparation process and mechanical properties of titanium alloy powder metallurgy. Metall Mater, 2020, 40(3): 1 doi: 10.3969/j.issn.1674-5183.2020.03.002陈学文. 钛合金粉末冶金制备工艺及力学性能研究. 冶金与材料, 2020, 40(3): 1 doi: 10.3969/j.issn.1674-5183.2020.03.002 [35] Chen F, Yan Z Q, Xu R J, et Al. Preparation and property characterization of Ti−Al−Fe−Mo valves for motorcycle engines. Rare Met Mater Eng, 2019, 48(10): 3297陈峰, 闫志巧, 许荣君, 等. 摩托车发动机用Ti−Al−Fe−Mo气门的制备及性能表征. 稀有金属材料与工程, 2019, 48(10): 3297 [36] Liu W B, Liang C, Chen W, et al. Determination of fluoride in praseodymium-neodymium alloy by ion selective electrode. Mater Res Appl, 2019, 13(3): 229刘文彬, 梁超, 陈伟, 等. 航空航天用粉末钛合金的热等静压工艺研究. 材料研究与应用, 2019, 13(3): 229 [37] Zhang Y. A titanium alloy powder preparation used for 3d printing technology research. World Nonferrous Met, 2017(9): 50张艳. 一种用于3D打印的钛合金粉末制备技术研究. 世界有色金属, 2017(9): 50 [38] Zhou W L, Li M H. Preparation of selective laser sintering 3D printed titanium alloy implants. J Harbin Med Univ, 2019, 53(6): 593周万琳, 李美华. 选择性激光烧结3D打印钛合金种植体的制备. 哈尔滨医科大学学报, 2019, 53(6): 593 [39] Guo L, Zhan H, You Y P, et al. Research progress on powder injection molding of titanium and titanium alloy. Mater Mech Eng, 2018, 42(6): 15郭鲤, 詹浩, 游玉萍, 等. 钛及钛合金粉末注射成形的研究进展. 机械工程材料, 2018, 42(6): 15 [40] Xiang Z Y, Xu R J, Liu B, et al. Preparation and mechanical property of powder metallurgy Ti−3Al−5Mo−4.5V (TC16) alloy. Mater Sci Eng Powder Metall, 2018, 23(5): 534向泽阳, 许荣君, 刘彬, 等. 粉末冶金Ti−3Al−5Mo−4.5V(TC16)合金的制备与力学性能. 粉末冶金材料科学与工程, 2018, 23(5): 534 [41] Zhang H R, Niu H Z, Zang M C, et al. Microstructures and mechanical behavior of a near α titanium alloy prepared by TiH2-based powder metallurgy. Mater Sci Eng A, 2020, 770: 138570 doi: 10.1016/j.msea.2019.138570 [42] Li S, Yang Y, Misra R, et al. Interfacial/intragranular reinforcement of titanium-matrix composites produced by a novel process involving core-shell structured powder. Carbon, 2020, 164: 378 doi: 10.1016/j.carbon.2020.04.010 [43] Froes F H, Senkov O N, Qazi J I. Hydrogen as a temporary alloying element in titanium alloys: thermohydrogen processing. Int Mater Rev, 2004, 49(3-4): 227 doi: 10.1179/095066004225010550 [44] Alexander M, Tian J H, Zhang S S, et al. Powder metallurgy technology and properties of Ti and Ti−6Al−4V alloy prepared using titanium hydride powder. J Nanjing Univ Aeronaut Astronaut, 2018, 50(1): 100Alexander M, 田金华, 张莎莎, 等. 氢化钛粉制备钛及Ti−6Al−4V钛合金粉末冶金工艺与性能研究. 南京航空航天大学学报, 2018, 50(1): 100 [45] American Society of Mechanical Engineers. ASTM B381-00 Specification for Titanium and Titanium Alloy Forgings. West Conshohocken: ASTM International, 2003 [46] General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China, Standardization Administration of China. GB25137-2010 Titanium and Titanium Alloy Forgings. Beijing: Standards Press of China, 2010中华人民共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会. GB25137-2010钛及钛合金锻件. 北京: 中国标准出版社, 2010 [47] Yu Y C. Research on Microstructure and Properties of Rapidly Solidified TiAl/Ti Based Alloy [Dissertation]. Ningxia: Ningxia University, 2019于永川. 快速凝固TiAl/Ti基合金的组织及性能研究[学位论文]. 宁夏: 宁夏大学, 2019 [48] Zhang Z Y, Yu H S, Wang S Q, et al. High strength ZK60 magnesium alloy produced by rapid solidification/powder metallurgy process. J Mater Eng, 2010(5): 72张振亚, 于化顺, 王少卿, 等. 快速凝固/粉末冶金法制备ZK60高强镁合金. 材料工程, 2010(5): 72 [49] Lou J. Study of Tensile Properties and Columnar Crystal Structure of Rapidly Solidified Titanium Alloy [Dissertation]. Shenyang: Shenyang University, 2012娄军. 快速凝固钛合金的组织与性能研究[学位论文]. 沈阳: 沈阳大学, 2012 [50] Li S, Kim Y, Nam T. Microstructure and superelastic behavior of rapidly solidified Ti−18Zr−12.5Nb−2Sn (at.%) alloy fibers. J Biomater Tissue Eng, 2018, 8(8): 1216 [51] Li S, Kim Y, Choi M, et al. Microstructure, mechanical and superelastic behaviors in Ni-free Ti−Zr−Nb−Sn shape memory alloy fibers prepared by rapid solidification processing. Mater Sci Eng A, 2020, 782: 139283 doi: 10.1016/j.msea.2020.139283 -

下载:

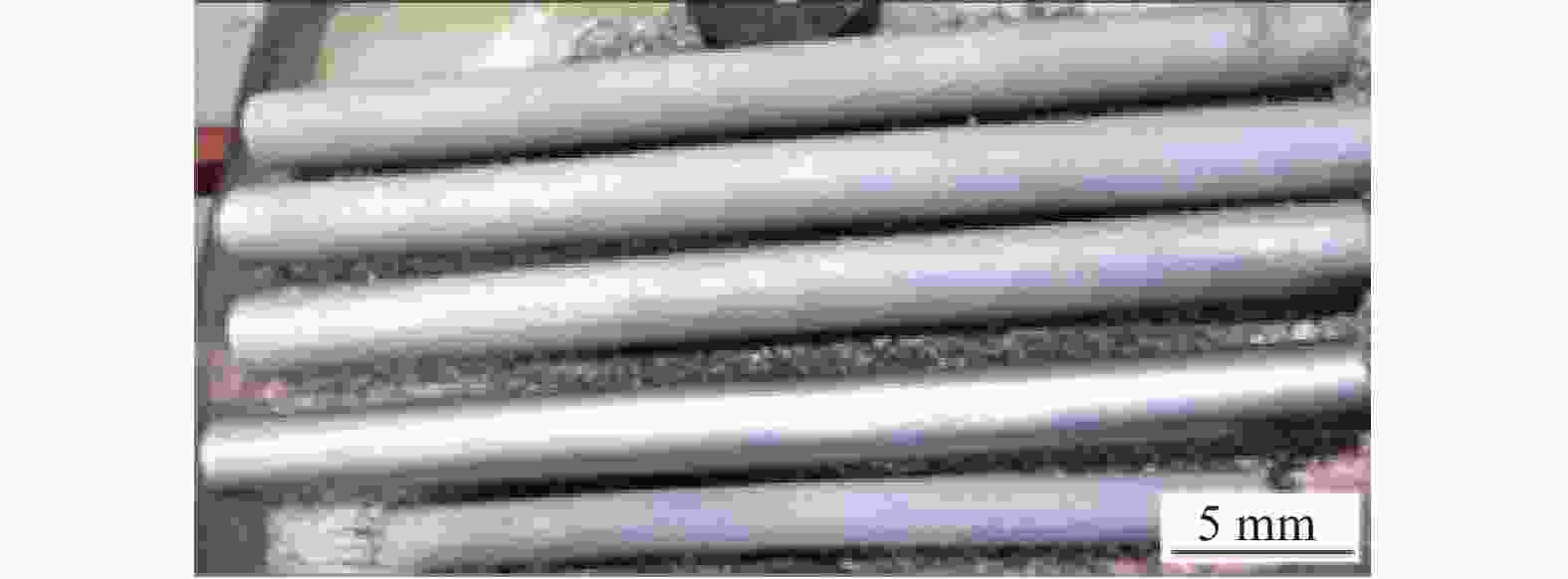

下载: