| [1] |

Liu L, Meng J, Liu J L, et al. Influence of Re on low-cycle fatigue behaviors of single crystal superalloys at intermediate temperature. J Mater Sci Technol, 2019, 35(9): 1917 doi: 10.1016/j.jmst.2019.05.026

|

| [2] |

Hou G C, Xie J, Yu J J, et al. Room temperature tensile behaviour of K640S Co-based superalloy. Mater Sci Technol, 2019, 35(5): 530 doi: 10.1080/02670836.2019.1572298

|

| [3] |

Tang L, Liang J J, Cui C Y, et al. Influence of Co content on the microstructures and mechanical properties of a Ni-Co base superalloy made by specific additive manufacturing process. Mater Sci Eng A, 2020, 786: 139438 doi: 10.1016/j.msea.2020.139438

|

| [4] |

Cox S C, Thornby J A, Gibbons G J, et al. 3D printing of porous hydroxyapatite scaffolds intended for use in bone tissue engineering applications. Mater Sci Eng C, 2015, 47(2): 237

|

| [5] |

Herzog D, Seyda V, Wycisk E, et al. Additive manufacturing of metals. Acta Mater, 2016, 117: 371 doi: 10.1016/j.actamat.2016.07.019

|

| [6] |

Panwisawas C, Tang Y T, Reed R C. Metal 3D printing as a disruptive technology for superalloys. Nat Commun, 2020, 11(1): 2327 doi: 10.1038/s41467-020-16188-7

|

| [7] |

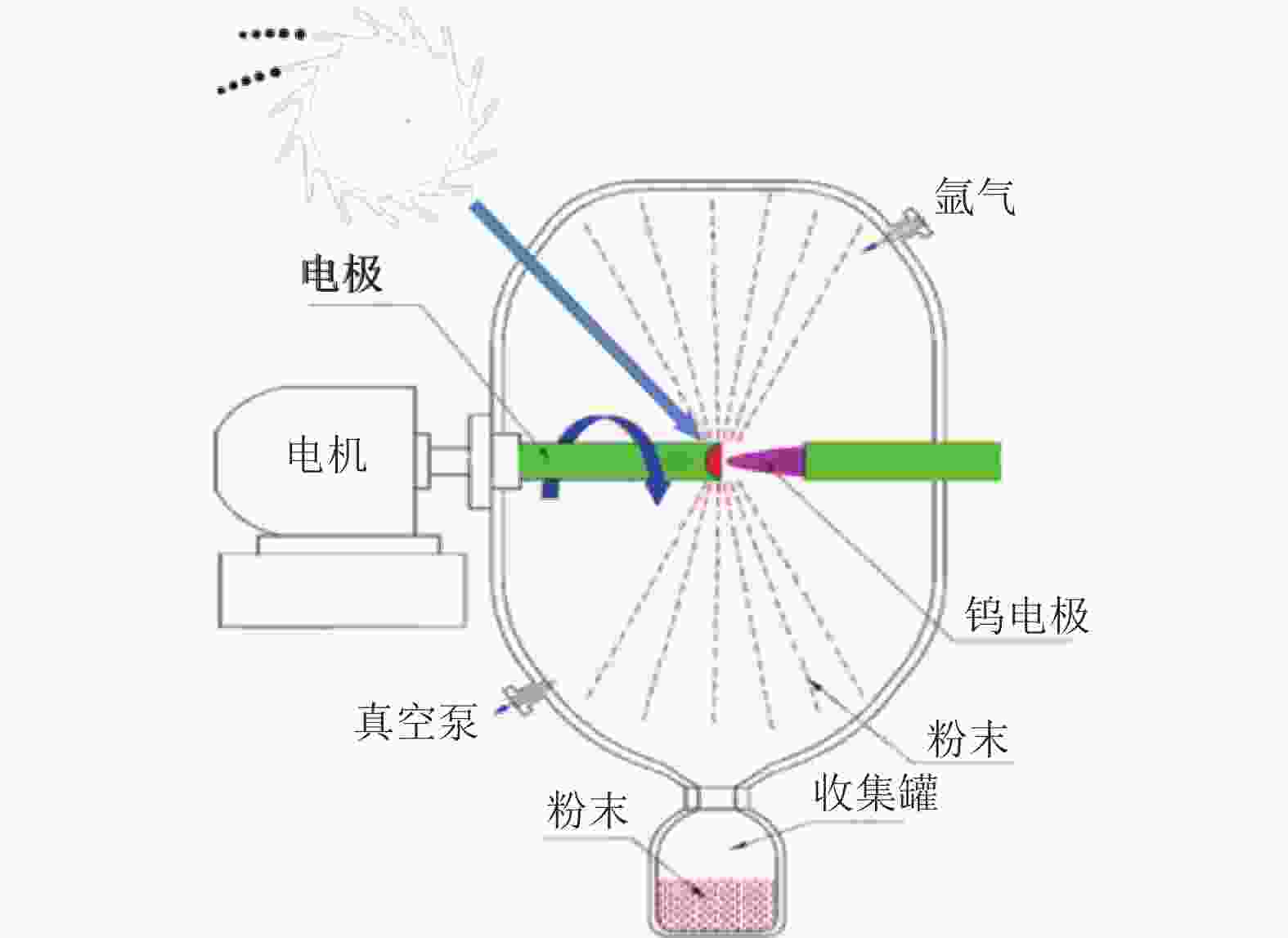

Lei N Z. Study on Process and Properties of Spherical Metal Powder Prepared by Plasma Rotating Electrode Process [Dissertation]. Xi'an: Xi'an University of Technology, 2019雷囡芝. 等离子旋转电极雾化法制备球形金属粉末的工艺及性能研究[学位论文]. 西安: 西安理工大学, 2019

|

| [8] |

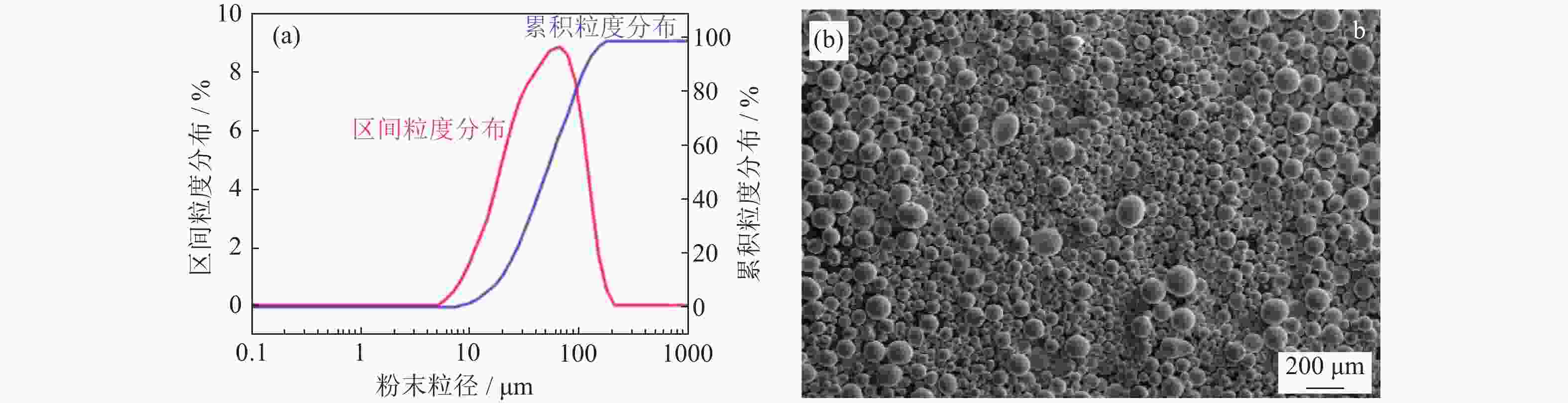

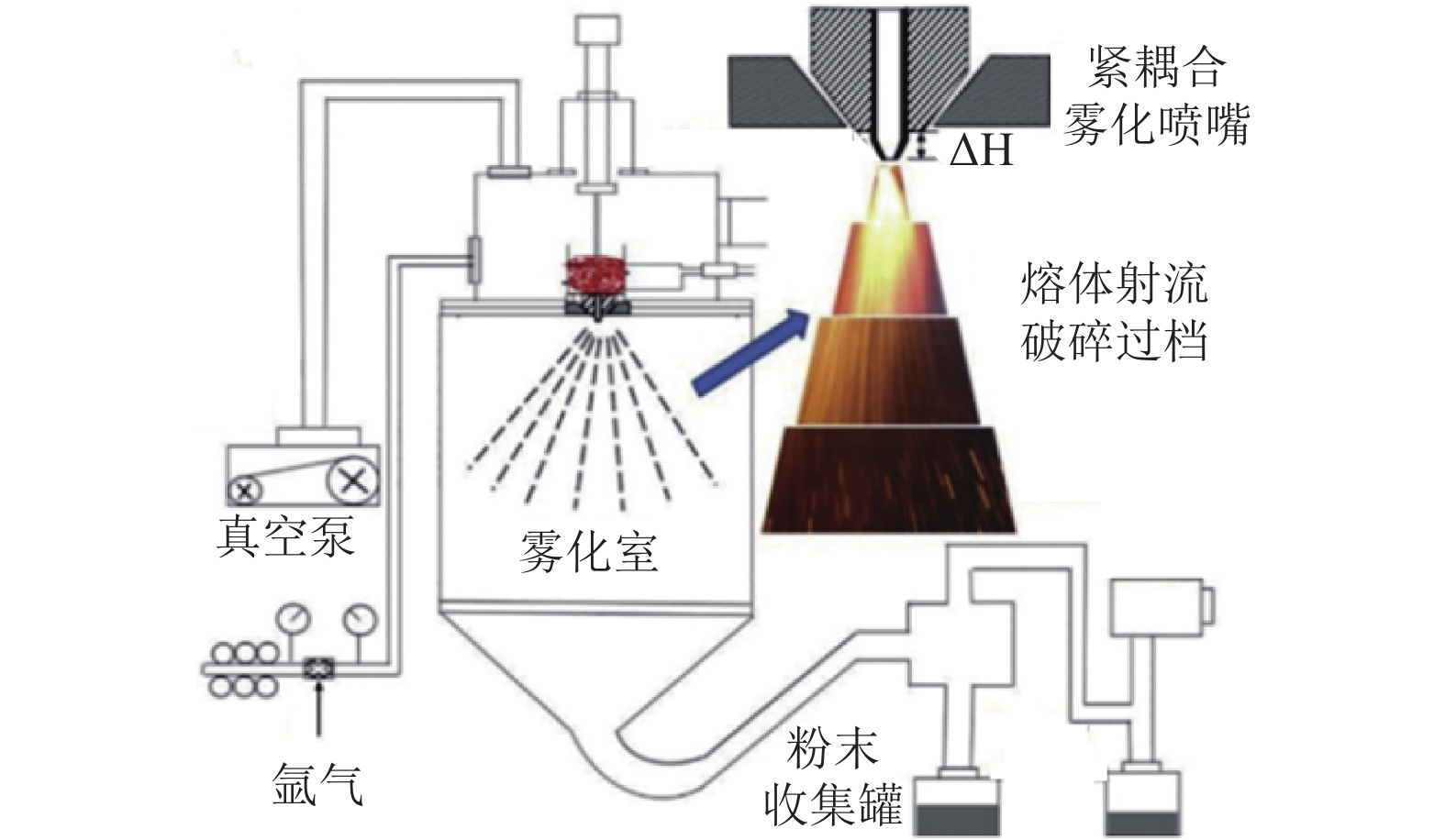

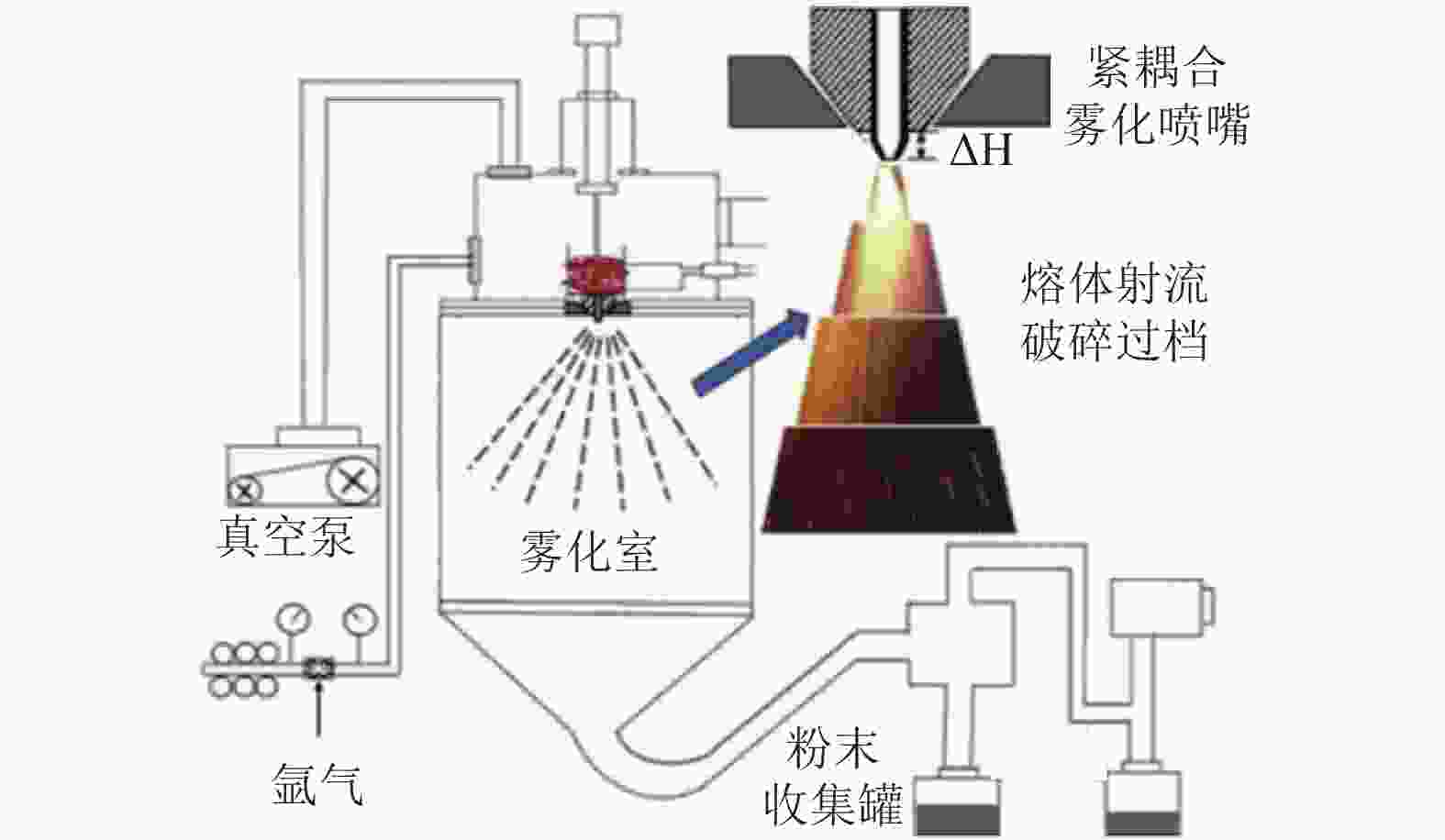

Wei M W, Chen S Y, Sun M, et al. Atomization simulation and preparation of 24CrNiMoY alloy steel powder using VIGA technology at high gas pressure. Powder Technol, 2020, 367: 724 doi: 10.1016/j.powtec.2020.04.030

|

| [9] |

Jia W M, Chen S Y, Wei M W. Characteristics and printability of K417G nickel-base alloy powder prepared by VIGA method. Powder Metall, 2019, 62(1): 30 doi: 10.1080/00325899.2018.1546921

|

| [10] |

Yang L B, Ren X N, Xia M, et al. Study on powder characteristics and effect factors of droplets size during electrode induction melting gas atomization. Rare Met Mater Eng, 2020, 49(6): 2017杨乐彪, 任晓娜, 夏敏, 等. 电极感应熔化气雾化粉末特性及液滴尺寸影响因素的研究. 稀有金属材料与工程, 2020, 49(6): 2017

|

| [11] |

Guo R P, Xu L, Zong B Y P, et al. Characterization of prealloyed Ti‒6Al‒4V powders from EIGA and PREP process and mechanical properties of HIPed powder compacts. Acta Metall Sinica, 2017, 30(8): 735 doi: 10.1007/s40195-017-0540-4

|

| [12] |

Jin Y, Liu P, Shi J G, et al. Effects of gas-atomized pressure on morphology and properties of TC4 powder prepared by electrode-induced gas atomization. Mater Sci Eng Powder Metall, 2018, 23(3): 312 doi: 10.3969/j.issn.1673-0224.2018.03.012金莹, 刘平, 史金光, 等. 雾化压力对电极感应熔炼气体雾化TC4粉末形貌与性能的影响. 粉末冶金材料科学与工程, 2018, 23(3): 312 doi: 10.3969/j.issn.1673-0224.2018.03.012

|

| [13] |

Chen G, Zhao S Y, Tan P, et al. A comparative study of Ti‒6Al‒4V powders for additive manufacturing by gas atomization, plasma rotating electrode process and plasma atomization. Powder Technol, 2018, 333: 38 doi: 10.1016/j.powtec.2018.04.013

|

| [14] |

Liu J, Xu N H, Yu J N. Preparation of TC4 alloy powder by plasma rotating electrode atomization. Ningxia Eng Technol, 2016, 15(4): 340 doi: 10.3969/j.issn.1671-7244.2016.04.011刘军, 许宁辉, 于建宁. 用等离子旋转电极雾化法制备TC4合金粉末的研究. 宁夏工程技术, 2016, 15(4): 340 doi: 10.3969/j.issn.1671-7244.2016.04.011

|

| [15] |

Wang H, Bai R M, Zhou X M, et al. Comparative analysis of Inconel718 powder prepared by PREP method and AA method. New Technol New Prod China, 2019(19): 1 doi: 10.3969/j.issn.1673-9957.2019.19.002王华, 白瑞敏, 周晓明, 等. PREP法和AA法制取Inconel718粉末对比分析. 中国新技术新产品, 2019(19): 1 doi: 10.3969/j.issn.1673-9957.2019.19.002

|

| [16] |

He J, Ma S Z, Zhang X G, et al. Research progress and prospects of metal powder preparation technology for additive manufacturing. Mech Eng Mater, 2020, 44(11): 46何杰, 马士洲, 张兴高, 等. 增材制造用金属粉末制备技术研究现状及展望. 机械工程材料, 2020, 44(11): 46

|

| [17] |

Anderson I E, Terpstra R L. Progress toward gas atomization processing with increased uniformity and control. Mater Sci Eng A, 2002, 326(1): 101 doi: 10.1016/S0921-5093(01)01427-7

|

| [18] |

Allimant A, Planche M P, Bailly Y, et al. Progress in gas atomization of liquid metals by means of a De Laval nozzle. Powder Technol, 2009, 190(1-2): 79 doi: 10.1016/j.powtec.2008.04.071

|

| [19] |

Strauss J T. Hotter gas increase atomization efficiency. Met Powder Rep, 1999, 54(11): 24 doi: 10.1016/S0026-0657(00)86269-4

|

| [20] |

Putimtsev B N. Effect of blast parameters on the mechanism of disintegration of a molten metal jet and on the properties of atomized powders. Powder Metall Met Ceram, 1972, 11(2): 85 doi: 10.1007/BF00814036

|

| [21] |

Ozbilen S, Unal A, Sheppard T. Influence of superheat on particle shape and size of gas atomised copper powders. Powder Metall, 1991, 34(1): 53 doi: 10.1179/pom.1991.34.1.53

|

| [22] |

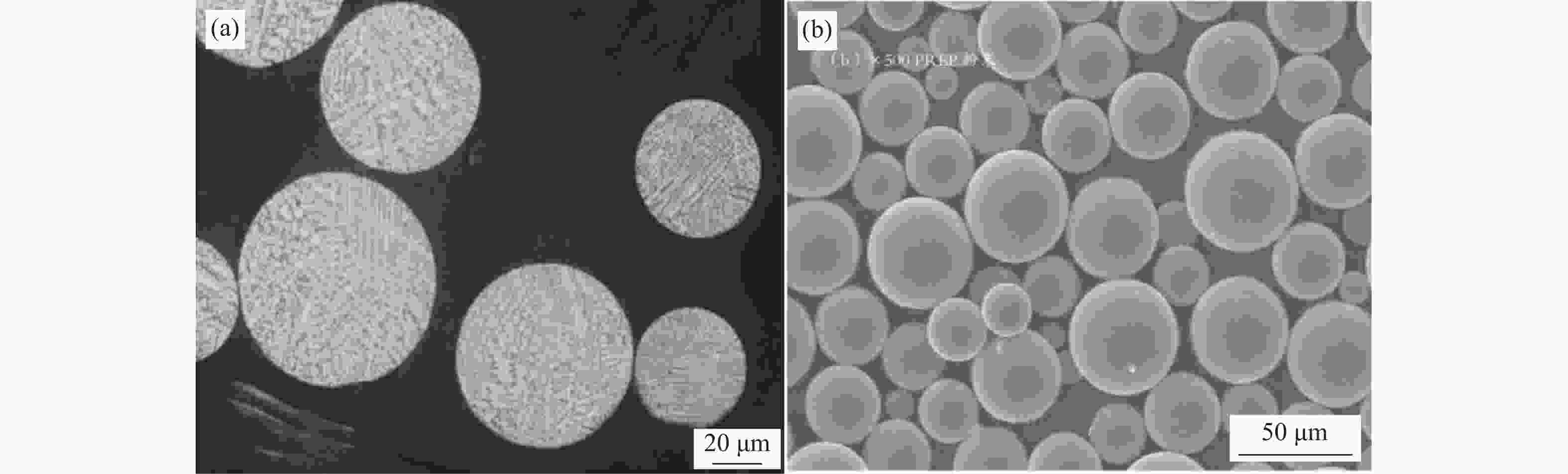

Basak C B, Krishnan M, Kumar R, et al. Characterization and process evaluation of Ni–Ti–Fe shape memory alloy macro-spheres directly fabricated via rotating electrode process. J Alloys Compd, 2014, 597(11): 15

|

| [23] |

Wosch E, Feldhaus S, Gammal T E. Rapid solidification of steel droplets in plasma rotating electrode process. ISIJ Int, 1995, 35(6): 764 doi: 10.2355/isijinternational.35.764

|

| [24] |

Liu S W, Duan W C, Dong B B. Effect of PREP process parameters on properties of AlSi10Mg aluminum alloy powder for 3D printing. Nonferrous Met Eng, 2019, 9(9): 45刘少伟, 段望春, 董兵斌. PREP工艺参数对3D打印用AlSi10Mg铝合金粉末性能的影响. 有色金属工程, 2019, 9(9): 45

|

| [25] |

Ma L, Jia Q G, Li Y Y, et al. Study on the matching between the diameter of the atomization chamber of the PREP equipment and the cooling crystallization of the powder droplets. China Plant Eng, 2019(17): 173 doi: 10.3969/j.issn.1671-0711.2019.17.095马乐, 贾庆功, 李扬扬, 等. PREP设备雾化室直径与粉末熔滴冷却结晶匹配研究. 中国设备工程, 2019(17): 173 doi: 10.3969/j.issn.1671-0711.2019.17.095

|

| [26] |

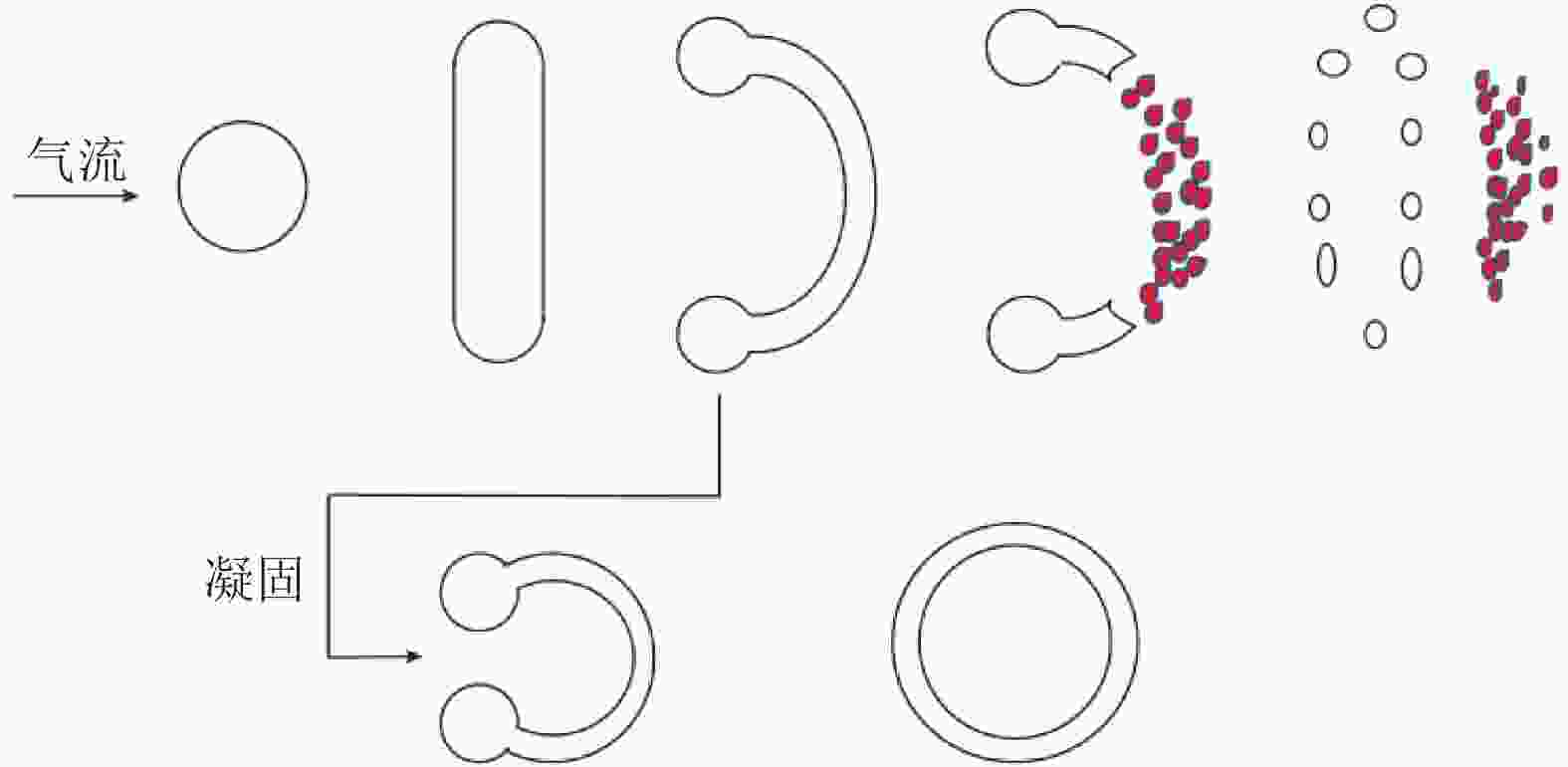

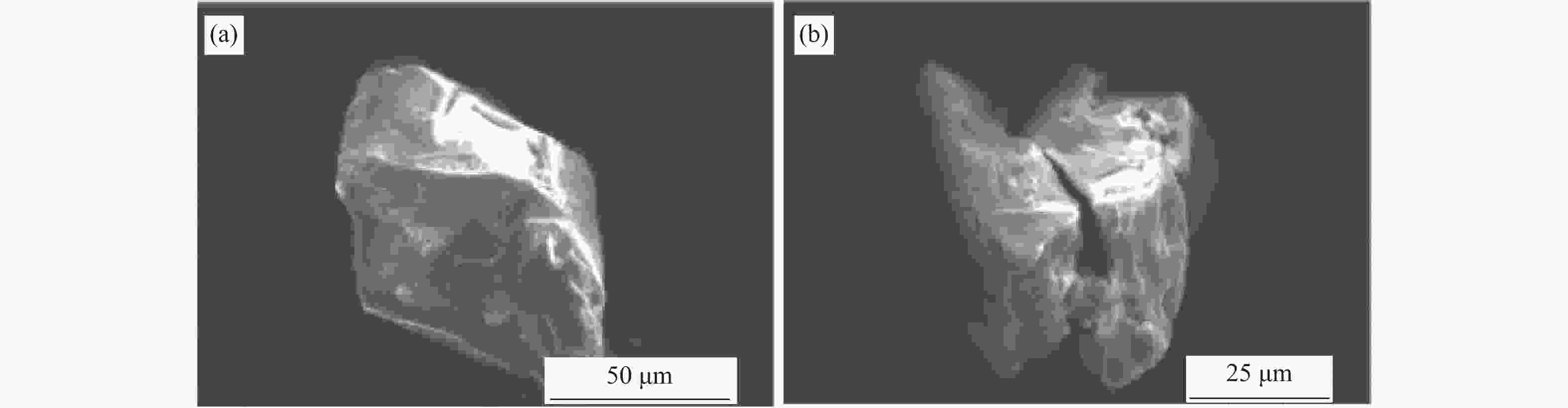

Zhang Y, Dong Y, Zhang Y W, et al. Investigation on abnormal particles in nickel-based superalloy powder by PERP. Powder Metall Ind, 2000, 10(6): 7 doi: 10.3969/j.issn.1006-6543.2000.06.001张莹, 董毅, 张义文, 等. 等离子旋转电极法所制取的镍基高温合金粉末中异常颗粒的研究. 粉末冶金工业, 2000, 10(6): 7 doi: 10.3969/j.issn.1006-6543.2000.06.001

|

| [27] |

Anderson I E, White E M H, Dehoff R. Feedstock powder processing research needs for additive manufacturing development. Curr Opin Solid State Mater Sci, 2018, 22(1): 8 doi: 10.1016/j.cossms.2018.01.002

|

| [28] |

Peng H L. Microstructure and Properties Analysis of Nickel-Based Superalloy Powders Prepared by Gas Atomization [Dissertation]. Guangzhou: South China University of Technology, 2016彭翰林. 镍基高温合金粉末组织结构分析及性能研究[学位论文]. 广州: 华南理工大学, 2016

|

| [29] |

Li X G, Liu C, Zhu Q. Research progress on gas atomization technology for preparation of feedstock powder used in metal additive manufacturing. Aeronaut Manuf Technol, 2019, 62(22): 22黎兴刚, 刘畅, 朱强. 面向金属增材制造的气体雾化制粉技术研究进展. 航空制造技术, 2019, 62(22): 22

|

| [30] |

Rabin B H, Smolik G R, Korth G E. Characterization of entrapped gases in rapidly solidified powders. Mater Sci Eng A, 1990, 124(1): 1 doi: 10.1016/0921-5093(90)90328-Z

|

| [31] |

Su P F, Liu Z M, Guo Y, et al. Microstructure and solidification defect of René104 nickel-base superalloy powder atomized by argon gas atomization. J Cent South Univ Sci Technol, 2018, 49(1): 64苏鹏飞, 刘祖铭, 郭旸, 等. 氩气雾化René104镍基高温合金粉末的显微组织和凝固缺陷. 中南大学学报(自然科学版), 2018, 49(1): 64)

|

| [32] |

Hann D B, Cherdantsev A V, Azzopardi B J. Study of bubbles entrapped into a gas-sheared liquid film. Int J Multiphase Flow, 2018, 108: 181 doi: 10.1016/j.ijmultiphaseflow.2018.07.001

|

| [33] |

Yuan H, Li Z, Xu W Y, et al. The study of argon atomized superalloy powders. Powder Metall Ind, 2010, 20(4): 1 doi: 10.3969/j.issn.1006-6543.2010.04.001袁华, 李周, 许文勇, 等. 氩气雾化制备高温合金粉末的研究. 粉末冶金工业, 2010, 20(4): 1 doi: 10.3969/j.issn.1006-6543.2010.04.001

|

| [34] |

Xu W Y, Li Z, Liu Y F, et al. Influence of temperature on the oxidation behaviors of the nickel-based superalloy powders. Powder Metall Technol, 2020, 38(3): 192许文勇, 李周, 刘玉峰, 等. 温度对镍基高温合金粉末氧化行为的影响. 粉末冶金技术, 2020, 38(3): 192

|

| [35] |

Zou J W, Wang W X. Development and application of P/M superalloy. J Aeronaut Mater, 2006(3): 244 doi: 10.3969/j.issn.1005-5053.2006.03.051邹金文, 汪武祥. 粉末高温合金研究进展与应用. 航空材料学报, 2006(3): 244 doi: 10.3969/j.issn.1005-5053.2006.03.051

|

| [36] |

Zhang Y W, Li K M. Removing non-metallic inclusion from superalloy powder during electrostatic separation process. Mater Sci Eng Powder Metall, 2016, 21(6): 885 doi: 10.3969/j.issn.1673-0224.2016.06.010张义文, 李科敏. 静电分离去除高温合金粉末中非金属夹杂物. 粉末冶金材料科学与工程, 2016, 21(6): 885 doi: 10.3969/j.issn.1673-0224.2016.06.010

|

下载:

下载: