| [1] |

Chen J, Xiong N, Ge Q L, et al. Research on powder metallurgy process for preparing aluminum matrix boron carbide composites. Powder Metall Technol, 2019, 37(6): 461陈锦, 熊宁, 葛启录, 等. 粉末冶金法制备铝基碳化硼复合材料的研究进展. 粉末冶金技术, 2019, 37(6): 461

|

| [2] |

Li G R, Xu T, Wang H M, et al. Microstructure study of hot rolling nanosized in-situ Al2O3 particle reinforced A356 matrix composites. J Alloys Compd, 2021, 855: 157107 doi: 10.1016/j.jallcom.2020.157107

|

| [3] |

Chen M X, Li X P, Ji G, et al. Novel composite powders with uniform TiB2 nano-particle distribution for 3D printing. Appl Sci, 2017, 7: 250 doi: 10.3390/app7030250

|

| [4] |

Tang S S, Shao S Y, Liu H Y, et al. Microstructure and mechanical behaviors of 6061 Al matrix hybrid composites reinforced with SiC and stainless steel particles. Mater Sci Eng A, 2021, 804: 140732 doi: 10.1016/j.msea.2021.140732

|

| [5] |

Sun J. The Microstructure Control of in situ TiB2 Particle Reinforced Aluminum Composite [Dissertation]. Shanghai: Shanghai Jiao Tong University, 2015孙靖. 原位自生TiB2颗粒增强铝基复合材料组织控制[学位论文]. 上海: 上海交通大学, 2015

|

| [6] |

Yi J C, Zhang X W, Rao J H, et al. In-situ chemical reaction mechanism and non-equilibrium microstructural evolution of (TiB2+TiC)/AlSi10Mg composites prepared by SLM-CS processing. J Alloys Compd, 2021, 857: 157553 doi: 10.1016/j.jallcom.2020.157553

|

| [7] |

Ma S M, Wang Y Q, Wang X M. Microstructures and mechanical properties of an Al–Cu–Mg–Sc alloy reinforced with in-situ TiB2 particulates. Mater Sci Eng A, 2020, 788: 139603 doi: 10.1016/j.msea.2020.139603

|

| [8] |

Hu Z R, Chen F, Xu J L, et al. 3D printing graphene-aluminum nanocomposites. J Alloys Compd, 2018, 746: 269 doi: 10.1016/j.jallcom.2018.02.272

|

| [9] |

Geng K, Li S F, Yang Y F, et al. 3D printing of Al matrix composites through in situ impregnation of carbon nanotubes on Al powder. Carbon, 2020, 162: 465 doi: 10.1016/j.carbon.2020.02.087

|

| [10] |

Zhou S Y, Su Y, Wang H, et al. Selective laser melting additive manufacturing of 7xxx series Al–Zn–Mg–Cu alloy: Cracking elimination by co-incorporation of Si and TiB2. Addit Manuf, 2020, 36: 101458

|

| [11] |

Prathumwan R, Subannajui K. Fabrication of a ceramic/metal (Al2O3/Al) composite by 3D printing as an advanced refractory with enhanced electrical conductivity. RSC Adv, 2020, 10: 32301 doi: 10.1039/D0RA01515F

|

| [12] |

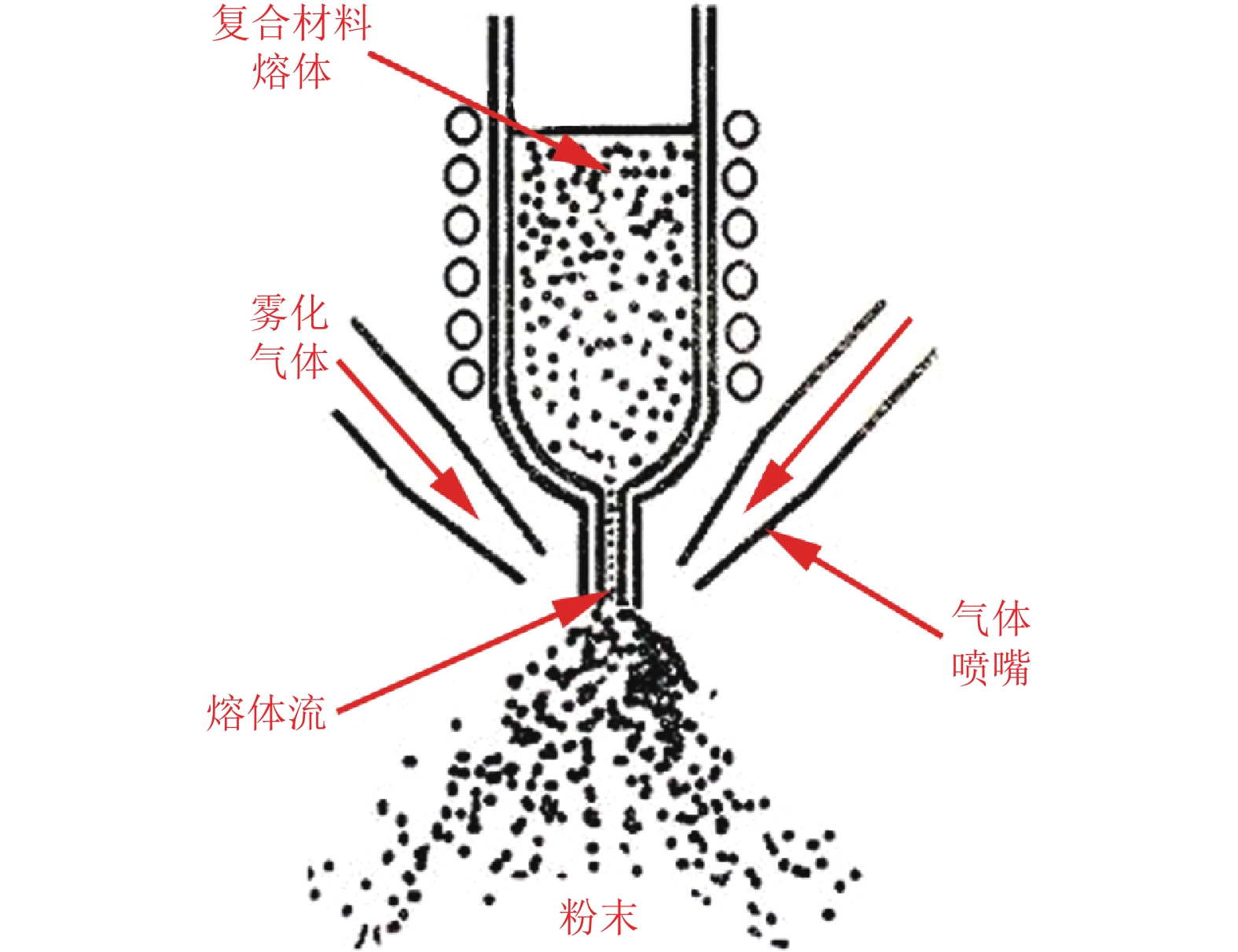

Zhao S Y, Wang L Q, Tan P, et al. Preparation and properties of spherical Ti–35.8Al–18.4Nb alloy powders by VIGA-CC method. Powder Metall Technol, 2020, 38(6): 443赵少阳, 王利卿, 谈萍, 等. VIGA-CC法制备球形Ti–35.8Al–18.4Nb合金粉末及其性能研究. 粉末冶金技术, 2020, 38(6): 443

|

| [13] |

Zhang L L. Al–Ti–B Manufacture, Grain Refinement of Al Alloys and Effect of Kinetic Behaviors of TiB2 Particles [Dissertation]. Shenyang: Institute of Metal Research, Chinese Academy of Sciences, 2017张丽丽. Al–Ti–B中间合金制备、Al合金细化及TiB2粒子动力学行为的影响[学位论文]. 沈阳: 中国科学院金属研究所, 2017

|

| [14] |

Wang Q L. Production of High Boron Al‒B Master Alloys and Investigation on Reaction Mechanism between KBF4 and Molten Aluminum [Dissertation]. Shenyang: Institute of Metal Research, Chinese Academy of Sciences, 2012王青亮. 高硼含量铝硼中间合金制备及KBF4与铝熔体反应机理研究[学位论文]. 沈阳: 中国科学院金属研究所, 2012

|

| [15] |

Shangguan D, Ahuja S, Stefanescu D M. An analytical model for the interaction between an insoluble particle and advancing solid/liquid interface. Metall Trans A, 1992, 23: 669 doi: 10.1007/BF02801184

|

| [16] |

Yu H S, Min G H, Zhao S X, et al. Study on particle pushing distance during solidification of particulate reinforced composites. Acta Metall Sinica, 1999, 35(7): 781 doi: 10.3321/j.issn:0412-1961.1999.07.026于化顺, 闵光辉, 赵生旭, 等. 复合材料凝固过程中颗粒推移距离及其影响因素. 金属学报, 1999, 35(7): 781 doi: 10.3321/j.issn:0412-1961.1999.07.026

|

| [17] |

Greer A L. Overview: Application of heterogeneous nucleation in grain-refining of metals. J Chem Phys, 2016, 145: 211704 doi: 10.1063/1.4968846

|

| [18] |

Jia Y W, Wang S C, Shu D. Grain size prediction and investigation of 7055 aluminum alloy inoculated by Al–5Ti–1B master alloy. J Alloys Compd, 2020, 821: 153504 doi: 10.1016/j.jallcom.2019.153504

|

| [19] |

Zhao L. Study of the Rapid Solidification of Ternary Immiscible Alloys [Dissertation]. Shenyang: Institute of Metal Research, Chinese Academy of Sciences, 2012赵雷. 三元难混溶合金的快速凝固过程研究[学位论文]. 沈阳: 中国科学院金属研究所, 2012

|

下载:

下载: