Research progress on deposition mechanism of ceramic metallization by cold spraying

-

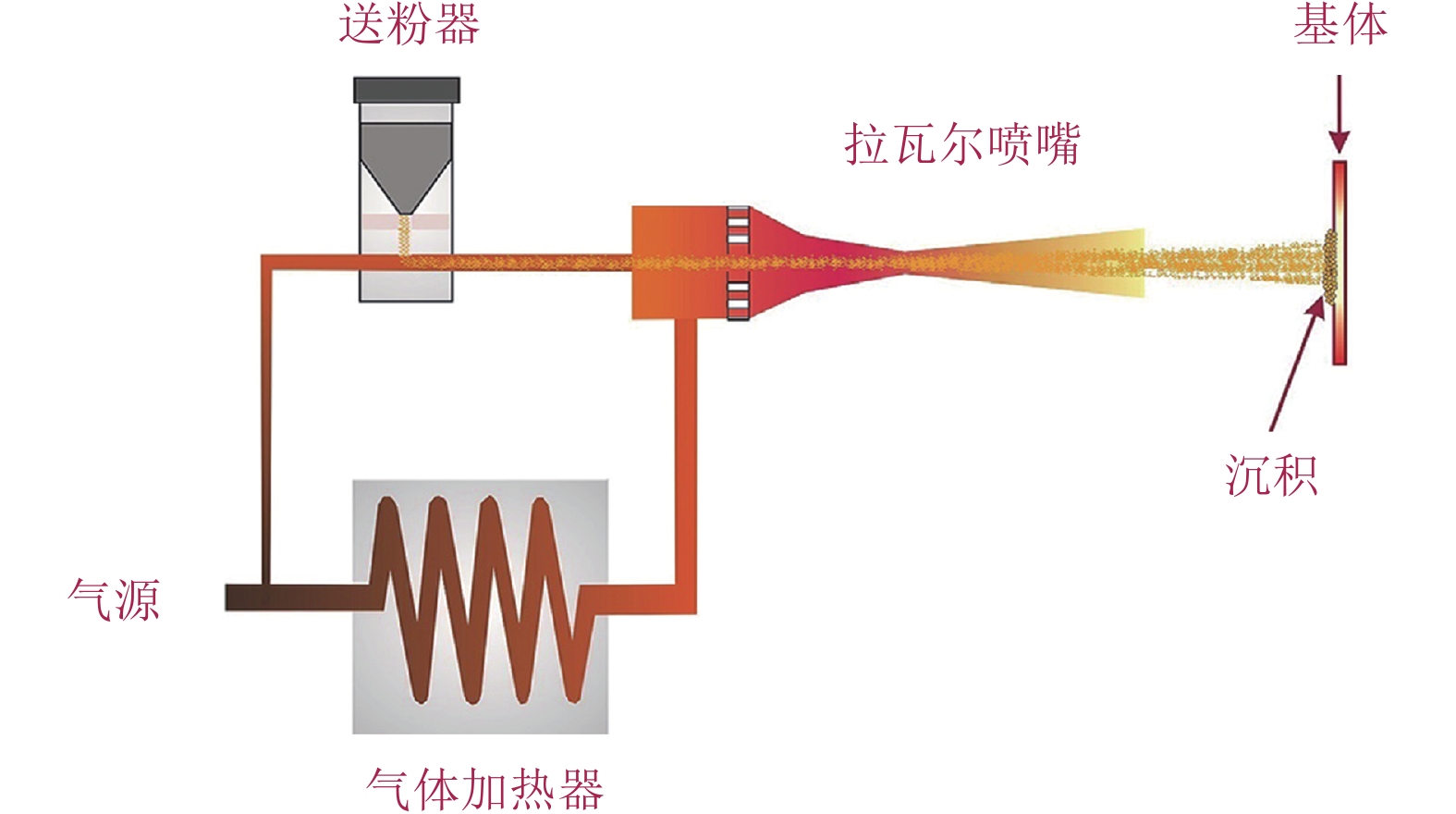

摘要: 陶瓷与金属由于在热膨胀系数上的差异,导致在热加工后结合强度较差。冷喷涂是一种新型绿色环保的表面涂层和增材制造技术,其优点是结合强度较高,对基体热影响小,残余应力为压应力,能够直接在陶瓷表面制备结合力较高的金属涂层,是一种潜在的陶瓷金属化技术。本文综述了国内外冷喷涂陶瓷金属化技术的研究进展和技术现状,着重介绍了冷喷涂陶瓷金属化涂层的组织结构特点和工艺优化方案,分析了金属陶瓷界面的两种结合现象和结合机理,并展望了冷喷涂陶瓷金属化技术的应用设想。Abstract: The difference in thermal expansion coefficient between ceramics and metals results in poor bonding strength after heat processing. Cold spraying (CS) is a new and green surface coating and additive manufacturing technology with the advantages as high bonding strength, little thermal impact on substrates, and residual compressive stress. The cold spraying is recognized as a potential ceramic metallization method because it can be employed to fabricate the metallic coatings on the ceramics directly with the relatively high bonding strength. The research progress and technical status of the cold spray ceramic metallization technology at home and abroad were reviewed in this article, the microstructure characteristics and process optimization were analyzed, the bonding phenomena and mechanisms of coatings were discussed, and the application potential and challenge of the cold spray ceramic metallization technology were summarized.

-

Key words:

- cold spray /

- ceramic /

- surface metallization /

- bonding mechanism

-

图 9 冷喷Al涂层与AlN单晶界面组织结构(a),Al晶粒选区电子衍射图(b),AlN基体选区电子衍射图(c),Al和AlN之间取向关系模拟衍射图(d)[62]

Figure 9. Interface microstructure of the cold sprayed Al film and AlN single-crystalline substrate (a), selected area electron diffraction (SAED) patterns taken near the interface of the Al crystallite (b), SAED patterns taken near the interface of the AlN substrate (c), orientation relationship between Al and AlN given as the simulated diffraction patterns (d)[62]

表 1 冷喷涂陶瓷金属化结合机理研究文献汇总

Table 1. Bonding mechanisms of the cold sprayed ceramic metallization coatings

作者 年份 粉末 基体 结合机理 结合强度 / MPa 文献 Imbriglio等 2019 Ti Al2O3 化学结合,机械结合 250.0 [67] Wüstefeld等 2017 Al AlN 异质外延,机械结合 42.0 [62] Qin等 2021 Al Al2O3 机械结合,化学结合 29.6 [68] Drehmann等 2018 Al SiC 机械结合 27.0 [71] Kromer等 2018 Al Al2O3 机械结合 20.0 [72] Kromer等 2018 Cu Al2O3 机械结合 19.0 [72] Drehmann等 2018 Al Si3N4 机械结合 18.0 [71] Kromer等 2018 Ti SiC 机械结合 17.0 [72] Drehmann等 2018 Al MgF2 机械结合 15.0 [71] Drehmann等 2014,2018 Al Al2O3 异质外延,机械结合 12.0 [69,71] Ko等 2016 Cu AlN 化学结合,机械结合 — [63] Ko等 2016 Al ZrO2 化学结合,机械结合 — [63] King等 2007~2008,2010 Al PZT — — [74‒76] Rafaja等 2009 Ti Al2O3 异质外延,机械结合 — [64] -

[1] Alkhimov A P, Kosarev V F, Papyrin A N. A method of “cold” gas-dynamic deposition. Sov Phys Dokl, 1990, 35: 1047 [2] Assadi H, Kreye H, Gärtner F, et al. Cold spraying — A materials perspective. Acta Mater, 2016, 116: 382 doi: 10.1016/j.actamat.2016.06.034 [3] Champagne V, Helfritch D. The unique abilities of cold spray deposition. Int Mater Rev, 2016, 61(7): 437 doi: 10.1080/09506608.2016.1194948 [4] Assadi H, Gärtner F, Stoltenhoff T, et al. Bonding mechanism in cold gas spraying. Acta Mater, 2003, 51(15): 4379 doi: 10.1016/S1359-6454(03)00274-X [5] Henao J, Bolelli G, Concustell A, et al. Deposition behavior of cold-sprayed metallic glass particles onto different substrates. Surf Coat Technol, 2018, 349: 13 doi: 10.1016/j.surfcoat.2018.05.047 [6] Henao J, Concustell A, Dosta S, et al. Deposition mechanisms of metallic glass particles by cold gas spraying. Acta Mater, 2017, 125: 327 doi: 10.1016/j.actamat.2016.12.007 [7] Sun C C, Zhou X L, Xie C. Effect of processing conditions on Al-based amorphous/nanocrystalline coating by cold-spraying. Surf Coat Technol, 2019, 362: 97 doi: 10.1016/j.surfcoat.2019.01.096 [8] Yoon S, Kim J, Bae G, et al. Formation of coating and tribological behavior of kinetic sprayed Fe-based bulk metallic glass. J Alloys Compd, 2011, 509(2): 347 doi: 10.1016/j.jallcom.2010.09.024 [9] Wang Q, Han P, Yin S, et al. Current research status on cold sprayed amorphous alloy coatings: A review. Coatings, 2021, 11(2): 206 doi: 10.3390/coatings11020206 [10] Guo X P, Chen J F, Yu H L, et al. A study on the microstructure and tribological behavior of cold-sprayed metal matrix composites reinforced by particulate quasicrystal. Surf Coat Technol, 2015, 268: 94 doi: 10.1016/j.surfcoat.2014.05.062 [11] Khun N W, Li R T, Loke K, et al. Effects of Al‒Cr‒Fe quasicrystal content on tribological properties of cold-sprayed titanium composite coatings. Tribol Trans, 2015, 58(4): 616 doi: 10.1080/10402004.2014.991860 [12] Ahn J E, Kim Y K, Yoon S H, et al. Tuning the microstructure and mechanical properties of cold sprayed equiatomic cocrfemnni high-entropy alloy coating layer. Met Mater Int, 2020, 27: 2406 [13] Xin W, Wang Y J, Wei S C, et al. Research progress of the preparation of high entropy alloy coatings by spraying. Chin J Eng, 2021, 43(2): 170辛蔚, 王玉江, 魏世丞, 等. 热喷涂制备高熵合金涂层的研究现状与展望. 工程科学学报, 2021, 43(2): 170 [14] Alhulaifi A S, Buck G A, Arbegast W J. Numerical and experimental investigation of cold spray gas dynamic effects for polymer coating. J Therm Spray Technol, 2012, 21(5): 852 doi: 10.1007/s11666-012-9743-4 [15] Khalkhali Z, Rothstein J P. Characterization of the cold spray deposition of a wide variety of polymeric powders. Surf Coat Technol, 2020, 383: 125251 doi: 10.1016/j.surfcoat.2019.125251 [16] Bush T B, Khalkhali Z, Champagne V, et al. Optimization of cold spray deposition of high-density polyethylene powders. J Therm Spray Technol, 2017, 26(7): 1548 doi: 10.1007/s11666-017-0627-5 [17] Xu Y, Hutchings I M. Cold spray deposition of thermoplastic powder. Surf Coat Technol, 2006, 201(6): 3044 doi: 10.1016/j.surfcoat.2006.06.016 [18] Ravi K, Ichikawa Y, Deplancke T, et al. Development of ultra-high molecular weight polyethylene (UHMWPE) coating by cold spray technique. J Therm Spray Technol, 2015, 24(6): 1015 doi: 10.1007/s11666-015-0276-5 [19] Ravi K, Ichikawa Y, Ogawa K, et al. Mechanistic study and characterization of cold-sprayed ultra-high molecular weight polyethylene-nano-ceramic composite coating. J Therm Spray Technol, 2015, 25(1-2): 160 [20] Ravi K, Deplancke T, Ogawa K, et al. Understanding deposition mechanism in cold sprayed ultra high molecular weight polyethylene coatings on metals by isolated particle deposition method. Addit Manuf, 2018, 21: 191 [21] Ravi K, Deplancke T, Lame O, et al. Influence of nanoceramic interlayer on polymer consolidation during cold-spray coating formation. J Mater Process Technol, 2019, 273: 116254 doi: 10.1016/j.jmatprotec.2019.116254 [22] Wesley L S, Ravi K, Bernard C, et al. Deposition mechanism analysis of cold-sprayed fluoropolymer coatings and its wettability evaluation. J Therm Spray Technol, 2020, 29(7): 1643 doi: 10.1007/s11666-020-01059-w [23] Tillmann W, Zajaczkowski J F. Investigation of low-pressure cold-gas dynamic spraying of polyamide-12 (PA12) on steel surfaces // IOP Conf Ser: Mater Sci Eng. Chongqin, 2019: 1 [24] Winnicki M, Gibas A, Baszczuk A, et al. Low pressure cold spraying of TiO2 on acrylonitrile butadiene styrene (ABS). Surf Coat Technol, 2021, 406: 126717 doi: 10.1016/j.surfcoat.2020.126717 [25] Liu Y, Wang Y Y, Suo X K, et al. Impact-induced bonding and boundary amorphization of TiN ceramic particles during room temperature vacuum cold spray deposition. Ceram Int, 2016, 42(1): 1640 doi: 10.1016/j.ceramint.2015.09.116 [26] Hasniyati M R, Zuhailawati H, Sivakumar R, et al. Optimization of multiple responses using overlaid contour plot and steepest methods analysis on hydroxyapatite coated magnesium via cold spray deposition. Surf Coat Technol, 2015, 280: 250 doi: 10.1016/j.surfcoat.2015.09.006 [27] Zhang Z C, Liu F L, Han E H, et al. Effects of Al2O3 on the microstructures and corrosion behavior of low-pressure cold gas sprayed Al 2024-Al2O3 composite coatings on AA 2024-T3 substrate. Surf Coat Technol, 2019, 370: 53 doi: 10.1016/j.surfcoat.2019.04.082 [28] Wang Q, Spencer K, Birbilis N, et al. The influence of ceramic particles on bond strength of cold spray composite coatings on AZ91 alloy substrate. Surf Coat Technol, 2010, 205(1): 50 doi: 10.1016/j.surfcoat.2010.06.008 [29] Shockley J M, Descartes S, Vo P, et al. The influence of Al2O3 particle morphology on the coating formation and dry sliding wear behavior of cold sprayed Al–Al2O3 composites. Surf Coat Technol, 2015, 270: 324 doi: 10.1016/j.surfcoat.2015.01.057 [30] Qiu X, Tariq N H, Qi L, et al. Influence of particulate morphology on microstructure and tribological properties of cold sprayed A380/Al2O3 composite coatings. J Mater Sci Technol, 2020, 44: 9 doi: 10.1016/j.jmst.2020.01.028 [31] Irissou E, Legoux J G, Arsenault B, et al. Investigation of Al‒Al2O3 cold spray coating formation and properties. J Therm Spray Technol, 2007, 16(5-6): 661 doi: 10.1007/s11666-007-9086-8 [32] Yu M, Li W Y, Chen H, et al. Effect of matrix/reinforcement combination on cold sprayed coating deposition behaviour. Surf Eng, 2014, 30(11): 796 doi: 10.1179/1743294414Y.0000000346 [33] Wang Y Y, Normand B, Suo X K, et al. Cold-sprayed AZ91D coating and SiC/AZ91D composite coatings. Coatings, 2018, 8(4): 122 doi: 10.3390/coatings8040122 [34] Wang Y Y, Normand B, Mary N, et al. Effects of ceramic particle size on microstructure and the corrosion behavior of cold sprayed SiCp/Al 5056 composite coatings. Surf Coat Technol, 2017, 315: 314 doi: 10.1016/j.surfcoat.2017.02.047 [35] Chen C Y, Xie Y C, Yan X C, et al. Tribological properties of Al/diamond composites produced by cold spray additive manufacturing. Addit Manuf, 2020, 36: 101434 [36] Winnicki M, Kozerski S, Małachowska A, et al. Optimization of ceramic content in nickel–alumina composite coatings obtained by low pressure cold spraying. Surf Coat Technol, 2021, 405: 126732 doi: 10.1016/j.surfcoat.2020.126732 [37] Wang L, Wang F, Li S, et al. Microstructure and application of alumina-supported Cu-based coating prepared by cold spray. Surf Coat Technol, 2019, 362: 113 doi: 10.1016/j.surfcoat.2019.01.089 [38] Lioma D, Sacks N, Botef I. Cold gas dynamic spraying of WC–Ni cemented carbide coatings. Int J Refract Met Hard Mater, 2015, 49: 365 doi: 10.1016/j.ijrmhm.2014.08.017 [39] Lima R S, Karthikeyan J, Kay C M, et al. Microstructural characteristics of cold-sprayed nanostructured WC‒Co coatings. Thin Solid Films, 2002, 416(1-2): 129 doi: 10.1016/S0040-6090(02)00631-4 [40] Gao P H, Li C J, Yang G J, et al. Influence of substrate hardness on deposition behavior of single porous WC‒12Co particle in cold spraying. Surf Coat Technol, 2008, 203(3-4): 384 doi: 10.1016/j.surfcoat.2008.09.016 [41] Ji G C, Chen X, Wang H T, et al. Deformation behaviors of cold-sprayed WC‒Co particles. J Therm Spray Technol, 2015, 24(6): 1100 doi: 10.1007/s11666-015-0252-0 [42] Couto M, Dosta S, Guilemany J M. Comparison of the mechanical and electrochemical properties of WC-17 and 12Co coatings onto Al7075-T6 obtained by high velocity oxy-fuel and cold gas spraying. Surf Coat Technol, 2015, 268: 180 doi: 10.1016/j.surfcoat.2014.04.034 [43] Huang Q, Qin J H, Yu M, et al. Cold spray deposition of non-metallic materials: Research progress and perspectives. Jiangxi Sci, 2020, 38(1): 7黄群, 秦加浩, 余敏, 等. 冷喷涂技术制备非金属材料涂层的研究进展. 江西科学, 2020, 38(1): 7 [44] Luo X T, Wei Y K, Wang Y, et al. Microstructure and mechanical property of Ti and Ti6Al4V prepared by an in-situ shot peening assisted cold spraying. Mater Des, 2015, 85: 527 doi: 10.1016/j.matdes.2015.07.015 [45] Wei Y K, Luo X T, Chu X, et al. Solid-state additive manufacturing high performance aluminum alloy 6061 enabled by an in-situ micro-forging assisted cold spray. Mater Sci Eng A, 2020, 776: 139024 doi: 10.1016/j.msea.2020.139024 [46] Wei Y K, Luo X T, Ge Y, et al. Deposition of fully dense Al-based coatings via in-situ micro-forging assisted cold spray for excellent corrosion protection of AZ31B magnesium alloy. J Alloys Compd, 2019, 806: 1116 doi: 10.1016/j.jallcom.2019.07.279 [47] Wei Y K, Li Y J, Zhang Y, et al. Corrosion resistant nickel coating with strong adhesion on AZ31B magnesium alloy prepared by an in-situ shot-peening-assisted cold spray. Corros Sci, 2018, 138: 105 doi: 10.1016/j.corsci.2018.04.018 [48] Li B, Yao J H, Zhang Q L, et al. Microstructure and tribological performance of tungsten carbide reinforced stainless steel composite coatings by supersonic laser deposition. Surf Coat Technol, 2015, 275: 58 doi: 10.1016/j.surfcoat.2015.05.040 [49] Luo F, Rocco L, Andrew C, et al. Characteristics of stellite 6 deposited by supersonic laser deposition under optimized parameters. J Iron Steel Res Int, 2013, 20(2): 52 doi: 10.1016/S1006-706X(13)60056-4 [50] Jiang Y L, Fang L, Yao J H. Deposition behavior at different substrate temperatures by using supersonic laser deposition. J Iron Steel Res Int, 2013, 20(10): 87 doi: 10.1016/S1006-706X(13)60182-X [51] Ozdemir O C, Schwartz P, Muftu S, et al. High rate deposition in cold spray. J Therm Spray Technol, 2021, 7: 1 [52] Groenewegen J R. Cold spray strategy for the air force [J/OL]. CSAT Workshop (2020-06-23) [2021-06-01]. https://www.coldsprayteam.com/csat-2020 [53] Xiao Y L. Dynamic metallization process accelerates repairment of aircraft parts. Powder Metall Technol, 2016, 34(1): 10萧玉麟. 动态金属化工艺加速修复飞机零件. 粉末冶金技术, 2016, 34(1): 10 [54] Schell J. Cold spray aerospace applications [J/OL]. CSAT Workshop (2016-06-22) [2021-06-01].https://www.coldsprayteam.com/csat-2016 [55] Hardikar K, Vlcek J, Bheemreddy V, et al. Assessing reliability of cold spray sputter targets in photovoltaic manufacturing. J Therm Spray Technol, 2017, 26(7): 1527 doi: 10.1007/s11666-017-0581-2 [56] Zou Y M, Wu J L, Zheng H Y. Tungsten metallization and alumina high temperature co-firing. Vac Electron, 2004, 4: 20 doi: 10.3969/j.issn.1002-8935.2004.04.007邹勇明, 吴金岭, 郑宏宇. 钨金属化与氧化铝陶瓷高温共烧. 真空电子技术, 2004, 4: 20 doi: 10.3969/j.issn.1002-8935.2004.04.007 [57] Zheng Z Q, Zhang Y, Yi F C, et al. Surface metallization of alumina ceramics: Effects of sintering time and substrate etching. Ceram Int, 2014, 40(8): 12709 doi: 10.1016/j.ceramint.2014.04.119 [58] Kiele P, Čvančara P, Langenmair M, et al. Thin film metallization stacks serve as reliable conductors on ceramic-based substrates for active implants. IEEE Trans Compon Packag Manuf Technol, 2020, 10(11): 1803 doi: 10.1109/TCPMT.2020.3026583 [59] Wang Y, Yang Z W, Zhang L X, et al. Low-temperature diffusion brazing of actively metallized Al2O3 ceramic tube and 5A05 aluminum alloy. Mater Des, 2015, 86: 328 doi: 10.1016/j.matdes.2015.07.112 [60] Wang L, Kang W T, Gao P Z, et al. Research progress of methods, mechanisms and influencing factors of ceramic metallization. J Ceram, 2019, 40(4): 411王玲, 康文涛, 高朋召, 等. 陶瓷金属化的方法、机理及影响因素的研究进展. 陶瓷学报, 2019, 40(4): 411 [61] Qin D C, Li B Z, Xiao Y L, et al. Research situation and development trend of ceramic metallization, Mater Rev, 2017, 31(30): 286秦典成, 李保忠, 肖永龙, 等. 陶瓷基板表面金属化研究现状与发展趋势. 材料导报, 2017, 31(30): 286 [62] Wüstefeld C, Rafaja D, Motylenko M, et al. Local heteroepitaxy as an adhesion mechanism in aluminium coatings cold gas sprayed on AlN substrates. Acta Mater, 2017, 128: 418 doi: 10.1016/j.actamat.2017.02.021 [63] Ko K H, Choi J O, Lee H. The interfacial restructuring to amorphous: A new adhesion mechanism of cold-sprayed coatings. Mater Lett, 2016, 175: 13 doi: 10.1016/j.matlet.2016.03.132 [64] Rafaja D, Schucknecht T, Klemm V, et al. Microstructural characterisation of titanium coatings deposited using cold gas spraying on Al2O3 substrates. Surf Coat Technol, 2009, 203(20-21): 3206 doi: 10.1016/j.surfcoat.2009.03.054 [65] Wu J W, Fang H Y, Yoon S, et al. The rebound phenomenon in kinetic spraying deposition. Scri Mater, 2006, 54(4): 665 doi: 10.1016/j.scriptamat.2005.10.028 [66] Klinkov S V, Kosarev V F, Rein M. Cold spray deposition: Significance of particle impact phenomena. Aerosp Sci Technol, 2005, 9(7): 582 doi: 10.1016/j.ast.2005.03.005 [67] Imbriglio S I, Hassani-Gangaraj M, Veysset D, et al. Adhesion strength of titanium particles to alumina substrates: A combined cold spray and LIPIT study. Surf Coat Technol, 2019, 361: 403 doi: 10.1016/j.surfcoat.2019.01.071 [68] Qin J H, Huang Q, Wang X, et al. Interfacial metal/ceramic bonding mechanism for metallization of ceramics via cold spraying. J Mater Process Technol, 2021, 288: 116845 doi: 10.1016/j.jmatprotec.2020.116845 [69] Drehmann R, Grund T, Lampke T, et al. Splat formation and adhesion mechanisms of cold gas-sprayed Al coatings on Al2O3 substrates. J Therm Spray Technol, 2013, 23(1-2): 68 [70] Drehmann R, Grund T, Lampke T, et al. Interface characterization and bonding mechanisms of cold gas-sprayed Al coatings on ceramic substrates. J Therm Spray Technol, 2014, 24(1-2): 92 [71] Drehmann R, Grund T, Lampke T, et al. Essential factors influencing the bonding strength of cold-sprayed aluminum coatings on ceramic substrates. J Therm Spray Technol, 2018, 27(3): 446 doi: 10.1007/s11666-018-0688-0 [72] Kromer R, Danlos Y, Costil S. Cold gas-sprayed deposition of metallic coatings onto ceramic substrates using laser surface texturing pre-treatment. J Therm Spray Technol, 2018, 27(5): 809 doi: 10.1007/s11666-018-0718-y [73] Imbriglio S I, Brodusch N, Aghasibeig M, et al. Influence of substrate characteristics on single Ti splat bonding to ceramic substrates by cold spray. J Therm Spray Technol, 2018, 27(6): 1011 doi: 10.1007/s11666-018-0743-x [74] King P C, Zahiri S H, Jahedi M, et al. Cold spray electroding of piezoelectric ceramic. Mater Forum, 2007, 31: 116 [75] King P C, Zahiri S H, Jahedi M, et al. Aluminium coating of lead zirconate titanate — a study of cold spray variables. Surf Coat Technol, 2010, 205(7): 2016 doi: 10.1016/j.surfcoat.2010.08.084 [76] King P C, Zahiri S H, Jahedi M. Focused ion beam micro-dissection of cold-sprayed particles. Acta Mater, 2008, 56(19): 5617 doi: 10.1016/j.actamat.2008.07.034 [77] Xiong Y M, Kang K, Bae G, et al. Dynamic amorphization and recrystallization of metals in kinetic spray process. Appl Phys Lett, 2008, 92(19): 194101 doi: 10.1063/1.2928218 [78] Xiong Y M, Xiong X, Yoon S, et al. Dependence of bonding mechanisms of cold sprayed coatings on strain-rate-induced non-equilibrium phase transformation. J Therm Spray Technol, 2011, 20(4): 860 doi: 10.1007/s11666-011-9634-0 [79] Kosarev V F, Klinkov S V, Melamed B M, et al. Cold spraying for power electronics: Deposition of thick topologically patterned copper layers on ceramics // International Conference on the Methods of Aerophysical Research. Novosibirsk, 2018: 030047-1 -

下载:

下载: