-

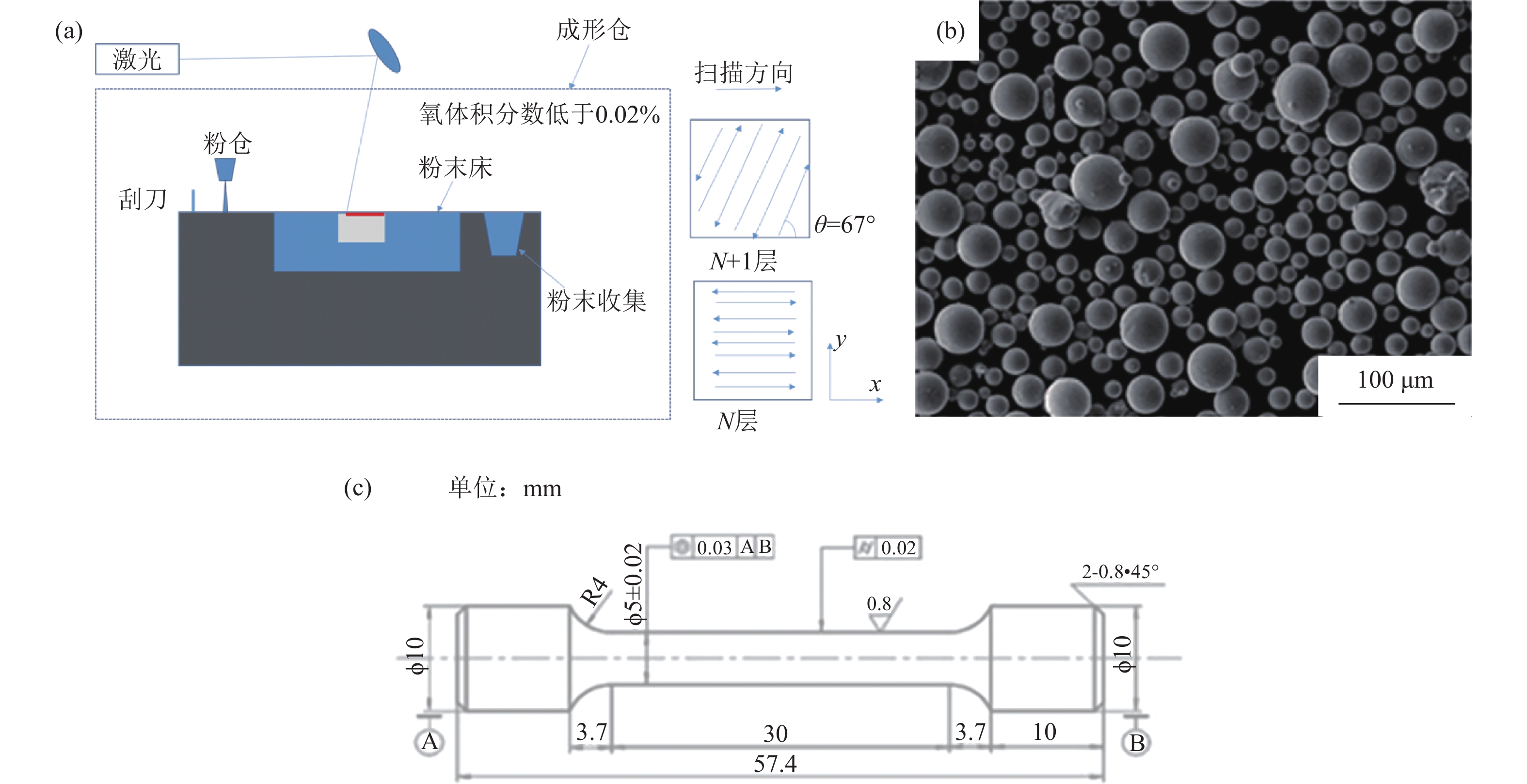

摘要: 孔洞、未熔粉、裂纹是在激光选区熔化制备试样过程中常见的缺陷,迄今为止,大量研究均集中在减少缺陷上,关于工艺参数对缺陷影响的研究较少。本文系统研究了工艺参数对激光选区熔化Ti6Al4V合金相对密度、表面粗糙度、力学性能的影响。结果表明,低激光功率、高扫描速度和高层厚将会引起不充分的粉末熔化以及球化效应。最佳工艺参数为激光功率200 W,扫描速度500 mm/s,层厚10 μm,扫描间距105 μm。在该参数下,试样的抗拉强度1077 MPa,屈服强度907 MPa。Abstract: The metallurgical defects, such as pores, unmelted powders, and cracks, always appear in the processed components prepared by selective laser melting (SLM). The numerous researches focus on minimizing the inherent defects, but there are few studies on the effect of process parameters on these defects. The influence of process parameters on the relative density, surface roughness, and tensile properties of the selective laser melted Ti6Al4V were studied in this paper. The results show that, the low laser power, high scanning speed, and high layer thickness cause the insufficient melting and the balling effects. In the case of Ti6Al4V, the optimized process parameters are considered as the laser power of 200 W, scanning speed of 500 mm/s, layer thickness 30 μm, and hatch distance of 105 μm, with which the processed sample presents the ultimate tensile strength as 1077 MPa and the yield strength as 907 MPa.

-

表 1 Ti6Al4V预合金粉末化学成分(质量分数)

Table 1. Nominal chemical composition of the Ti6Al4V alloy powders

% Al V O H N C Si Fe Ti 6.28 3.90 0.098 0.002 0.020 0.008 0.026 0.022 Bal. 表 2 优化激光功率实验参数

Table 2. Processing parameters for the laser power optimization.

试样编号 激光功率,

P / W扫描速度,

v / (mm·s‒1)扫描间距,

h / mm层厚,

t / mmA1 140 1100 0.105 0.03 A2 160 A3 180 A4 200 表 3 优化扫描速度实验参数

Table 3. Processing parameters for the laser scanning speed optimization.

试样编号 激光功率,

P / W扫描速度,

v / (mm·s‒1)扫描间距,

h / mm层厚,

t / mmB1 200 500 0.105 0.03 B2 800 B3 1100 B4 1400 B5 1700 表 4 优化层厚实验参数

Table 4. Processing parameters for the layer thickness optimization.

试样编号 激光功率,

P / W扫描速度,

v / (mm·s‒1)扫描间距,

h / mm层厚,

t / mmC1 200 500 0.105 0.03 C2 0.04 C3 0.05 C4 0.06 C5 0.07 -

[1] Edwards P, Ramulu M. Fatigue performance evaluation of selective laser melted Ti‒6A1‒4V. Mater Sci Eng A, 2014, 598: 327 doi: 10.1016/j.msea.2014.01.041 [2] Zhao Y, He Y H, Jiang Y, et al. Research on preparation of Ti6Al4V alloy using powder metallurgy. Powder Metall Technol, 2009, 27(2): 108赵瑶, 贺跃辉, 江垚, 等. 粉末冶金Ti6Al4V合金的研究. 粉末冶金技术, 2009, 27(2): 108 [3] Sterling A J, Torries B, Shamsaei N, et al. Fatigue behavior and failure mechanisms of direct laser deposited Ti‒6Al‒4V. Mater Sci Eng A, 2016, 655: 100 doi: 10.1016/j.msea.2015.12.026 [4] Miranda G, Araújo A, Bartolomeu F, et al. Design of Ti6Al4V‒HA composites produced by hot pressing for biomedical applications. Mater Des, 2016, 108: 488 doi: 10.1016/j.matdes.2016.07.023 [5] Azarniya A, Colera X G, Mirzaali M J, et al. Additive manufacturing of Ti–6Al–4V parts through laser metal deposition (LMD): Process, microstructure, and mechanical properties. J Alloys Compd, 2019, 804: 163 doi: 10.1016/j.jallcom.2019.04.255 [6] Liu Q, Wang Y, Zheng H, et al. Microstructure and mechanical properties of LMD-SLM hybrid forming Ti6Al4V alloy. Mater Sci Eng A, 2016, 660: 24 doi: 10.1016/j.msea.2016.02.069 [7] Wen Y, Zhang B, Narayan R L, et al. Laser powder bed fusion of compositionally graded CoCrMo-Inconel 718. Addit Manuf, 2021, 40: 101926 [8] Yu Z, Xu Z, Guo Y, et al. Study on properties of SLM-NiTi shape memory alloy under the same energy density. J Mater Res Technol, 2021, 13: 241 doi: 10.1016/j.jmrt.2021.04.058 [9] Ponnusamy P, Sharma B, Masood S H, et al. A study of tensile behavior of SLM processed 17-4 PH stainless steel. Mater Today Proc, 2021, 45(6): 4531 [10] Vastola G, Pei Q X, Zhang Y W. Predictive model for porosity in powder-bed fusion additive manufacturing at high beam energy regime. Addit Manuf, 2018, 22: 817 [11] Gu D D, Shen Y F. Balling phenomena in direct laser sintering of stainless steel powder: Metallurgical mechanisms and control methods. Mater Des, 2009, 30(8): 2903 doi: 10.1016/j.matdes.2009.01.013 [12] Murr L E, Quinones S A, Gaytan S M, et al. Microstructure and mechanical behavior of Ti‒6Al‒4V produced by rapid-layer manufacturing for biomedical applications. J Mech Behav Biomed Mater, 2009, 2(1): 20 doi: 10.1016/j.jmbbm.2008.05.004 [13] Krakhmalev P, Fredriksson G, Yadroitsava I, et al. Deformation behavior and microstructure of Ti‒6Al‒4V manufactured by SLM. Physics Procedia, 2016, 83: 778 doi: 10.1016/j.phpro.2016.08.080 [14] Yang Y, Li X, Khonsari M M, et al. On enhancing surface wear resistance via rotating grains during selective laser melting. Addit Manuf, 2020, 36: 101583 [15] Shi X S, Yan C, Feng W W, et al. Effect of high layer thickness on surface quality and defect behavior of Ti‒6Al‒4V fabricated by selective laser melting. Opt Laser Technol, 2020, 132: 106471 doi: 10.1016/j.optlastec.2020.106471 [16] Gong H J, Rafi K, Gu H F, et al. Analysis of defect generation in Ti–6Al–4V parts made using powder bed fusion additive manufacturing processes. Addit Manuf, 2014, 1-4: 87 [17] Prashanth K G, Scudino S, Maity T, et al. Is the energy density a reliable parameter for materials synthesis by selective laser melting? Mater Res Lett, 2017, 5(6): 386 [18] Cheng B, Shrestha S, Chou K. Stress and deformation evaluations of scanning strategy effect in selective laser melting. Addit Manuf, 2016, 12: 240 [19] Ni X Q, Kong D C, Wen Y, et al. Influence factors and improvement methods on the porosity of 3D printing metal materials. Powder Metall Technol, 2019, 37(3): 163倪晓晴, 孔德成, 温莹, 等. 3D打印金属材料中孔隙率的影响因素和改善方法. 粉末冶金技术, 2019, 37(3): 163 [20] Shen Y F, Gu D D, Pan Y F. Balling process in selective laser sintering 316 stainless steel powder. Key Eng Mater, 2006, 315-316: 357 doi: 10.4028/www.scientific.net/KEM.315-316.357 [21] Deckers J, Meyers S, Kruth J P, et al. Direct selective laser sintering/melting of high density alumina powder layers at elevated temperatures. Physics Procedia, 2014, 56: 117 doi: 10.1016/j.phpro.2014.08.154 [22] Yadroitsev I, Smurov I. Surface morphology in selective laser melting of metal powders. Physics Procedia, 2011, 12: 264 doi: 10.1016/j.phpro.2011.03.034 [23] Eberhard A, Michael K. Analysis and optimisation of vertical surface roughness in micro selective laser melting. Surf Topogr Metrol Prop, 2015, 3(3): 034007 doi: 10.1088/2051-672X/3/3/034007 [24] Spierings A B, Herres N, Levy G. Influence of the particle size distribution on surface quality and mechanical properties in AM steel parts. Rapid Prototyp J, 2011, 17(3): 195 doi: 10.1108/13552541111124770 [25] Chen Z E, Wu X H, Tomus D, et al. Surface roughness of selective laser melted Ti‒6Al‒4V alloy components. Addit Manuf, 2018, 21: 91 [26] Kang N, Coniglio N, Cao Y, et al. Intrinsic heat treatment induced graded surficial microstructure and tribological properties of selective laser melted titanium. J Tribol, 2021, 143(5): 1 [27] Aziz I A, Gabbitas B, Stanford M. Microstructure and tensile strength of rapid manufacturing parts. Adv Mater Res, 2014, 903: 114 doi: 10.4028/www.scientific.net/AMR.903.114 [28] Shi X Z, Ma S Y, Liu C M, et al. Selective laser melting-wire arc additive manufacturing hybrid fabrication of Ti‒6Al‒4V alloy: Microstructure and mechanical properties. Mater Sci Eng A, 2017, 684: 196 doi: 10.1016/j.msea.2016.12.065 [29] Bhardwaj A, Toshniwal K, Wahed M A, et al. Microstructural and SEM analysis on thin sheets of Ti6Al4V alloy subjected to biaxial and uniaxial tensile tests. Mater Today Proc, 2018, 5(2): 3729 doi: 10.1016/j.matpr.2017.11.625 -

下载:

下载: