-

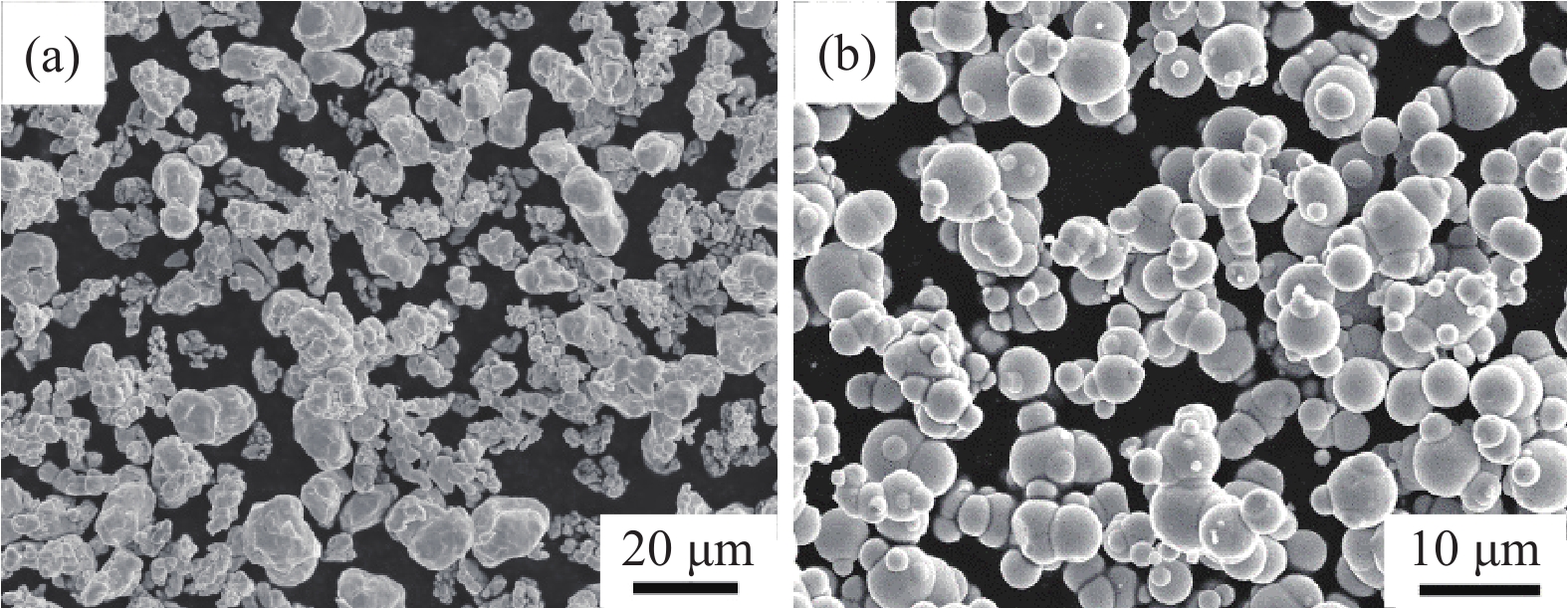

摘要: 分别以元素混合粉、机械合金化粉和水气联合雾化合金粉为原料,结合冷等静压成形、烧结及轧制工艺制备了Cu‒5%Fe合金(质量分数),对比了三种原料粉的铜铁合金粉末形貌、微观组织、力学性能及物理性能。结果表明,铁颗粒分布均匀,元素混合、机械合金化和水气联合雾化法粉末烧结体中铁颗粒平均尺寸分别为9.4 μm、1.2 μm、3.5 μm。水气联合雾化法合金样品综合性能最优,抗拉强度550 MPa,导电率59.5% IACS,磁饱和强度9.1 emu·g‒1。Abstract: Cu‒5%Fe alloys (mass fraction) were prepared by cold isostatic pressing, sintering, and rolling, using the elemental mixed powders, mechanical alloying powders, and water-gas combined atomized alloy powders as the raw materials. The powder morphology, microstructure, mechanical properties, and physical properties of the copper-iron alloys fabricated by the three kinds of raw materials were compared. The results show that, the iron particles are uniformly distributed, and the average size of the iron particles in the sintered body consisted of the powders by element mixing, mechanical alloying, and water-gas combined atomization are 9.4 μm, 1.2 μm, and 3.5 μm, respectively. The alloys with the water-gas combined atomization powders show the best overall performance as the tensile strength of 550 MPa, the electrical conductivity of 59.5% IACS, and the magnetic saturation strength of 9.1 emu·g‒1.

-

表 1 Cu‒5%Fe合金冷轧态性能参数对比

Table 1. Comparison of performance parameters of the cold rolled Cu‒5%Fe alloys

性能指标 烧结态铁相尺寸 /

μm抗拉强度 /

MPa延伸率 /

%弹性模量 /

GPa导电率 /

% IACS磁饱和强度 /

(emu·g‒1)矫顽力 /

Oe元素混合 9.4 489.2 0.8 125.9 38.6 27.4 56.3 机械合金化 1.2 509.6 3.2 83.4 43.2 14.8 10.5 水气联合雾化 3.5 550.1 1.8 111.2 59.5 9.1 168.0 -

[1] Lu X, Yao D, Chen Y, et al. Microstructure and hardness of Cu‒12%Fe composite at different drawing strains. J Zhejiang Univ Sci, 2014, 15: 149 doi: 10.1631/jzus.A1300164 [2] Funkenbusch P D, Courtney T H. Microstructural strengthening in cold worked in situ Cu‒14.8 Vol. % Fe composites. Scr Mater, 1981, 15(12): 1349 [3] Hu H, Li L, Xu L, et al. Research progress on preparation technology of Cu‒Fe alloy. Powder Metall Technol, 2019, 37(6): 468胡号, 李雷, 许磊, 等. Cu‒Fe合金制备技术研究进展. 粉末冶金技术, 2019, 37(6): 468 [4] He T Q, Wang L, Peng C X, et al. Fe‒Cu alloy phase separation process. Mater Eng, 2016, 44(2): 115 doi: 10.11868/j.issn.1001-4381.2016.02.018何统求, 王丽, 彭传校, 等. Fe‒Cu合金相分离过程. 材料工程, 2016, 44(2): 115 doi: 10.11868/j.issn.1001-4381.2016.02.018 [5] Nakagawa Y. Liquid immiscibility in copper-iron and copper-cobalt systems in the supercooled state. Acta Metall, 1958, 6(11): 704 doi: 10.1016/0001-6160(58)90061-0 [6] Wang W, Wu Y, Li L. Liquid-liquid phase separation of freely falling undercooled ternary Fe‒Cu‒Sn alloy. Sci Rep, 2015, 5: 16335 doi: 10.1038/srep16335 [7] Wang M, Zhang R, Xiao Z, et al. Microstructure and properties of Cu‒10wt%Fe alloy produced by double melt mixed casting and multi-stage thermomechanical treatment. J Alloys Compd, 2020, 820: 153323 doi: 10.1016/j.jallcom.2019.153323 [8] Wang M, Jiang Y, Li Z, et al. Microstructure evolution and deformation behaviour of Cu‒10wt%Fe alloy during cold rolling. Mater Sci Eng A, 2021, 801: 140379 doi: 10.1016/j.msea.2020.140379 [9] Zou J, Lu D, Fu Q, et al. Microstructure and properties of Cu–Fe deformation processed in-situ composite. Vacuum, 2019, 167: 54 doi: 10.1016/j.vacuum.2019.05.030 [10] Liu S, Jie J, Guo Z, et al. A comprehensive investigation on microstructure and magnetic properties of immiscible Cu‒Fe alloys with variation of Fe content. Mater Chem Phys, 2019, 238: 121909 doi: 10.1016/j.matchemphys.2019.121909 [11] Liu S, Jie J, Guo Z, et al. Solidification microstructure evolution and its corresponding mechanism of metastable immiscible Cu80Fe20 alloy with different cooling conditions. J Alloys Compd, 2018, 742: 99 doi: 10.1016/j.jallcom.2018.01.306 [12] Liu S, Jie J, Dong B, et al. Novel insight into evolution mechanism of second liquid-liquid phase separation in metastable immiscible Cu‒Fe alloy. Mater Des, 2018, 156: 71 doi: 10.1016/j.matdes.2018.06.044 [13] Benghalem A, Morris D. Microstructure and strength of wire-drawn Cu‒Ag filamentary composites. Acta Mater, 1997, 45(1): 397 doi: 10.1016/S1359-6454(96)00152-8 [14] Funkenbusch P, Courtney T. Reply to comments on “on the role of interphase barrier and substructural strengthening in deformation processed composite materials. Scr Metall Mater, 1990, 24: 1175 doi: 10.1016/0956-716X(90)90322-8 [15] Han K, Vasquez A, Xin Y, et al. Microstructure and tensile properties of nanostructured Cu‒25wt%Ag. Acta Mater, 2003, 51(3): 767 doi: 10.1016/S1359-6454(02)00468-8 [16] Abbas S F, Park K T, Kim T S, et al. Effect of composition and powder size on magnetic properties of rapidly solidified copper-iron alloys. J Alloys Compd, 2018, 741: 1188 doi: 10.1016/j.jallcom.2018.01.245 [17] Rowlands G. The variation of coercivity with particle size. J Phys D Appl Phys, 1976, 9: 1267 doi: 10.1088/0022-3727/9/8/013 [18] Dai X, Xie M, Zhou S, et al. Formation mechanism and improved properties of Cu95Fe5 homogeneous immiscible composite coating by the combination of mechanical alloying and laser cladding. J Alloys Compd, 2018, 740: 194 doi: 10.1016/j.jallcom.2018.01.007 -

下载:

下载: