Effect of heat treatment temperature on microstructure and mechanical properties of Mo–14Re alloy tubes

-

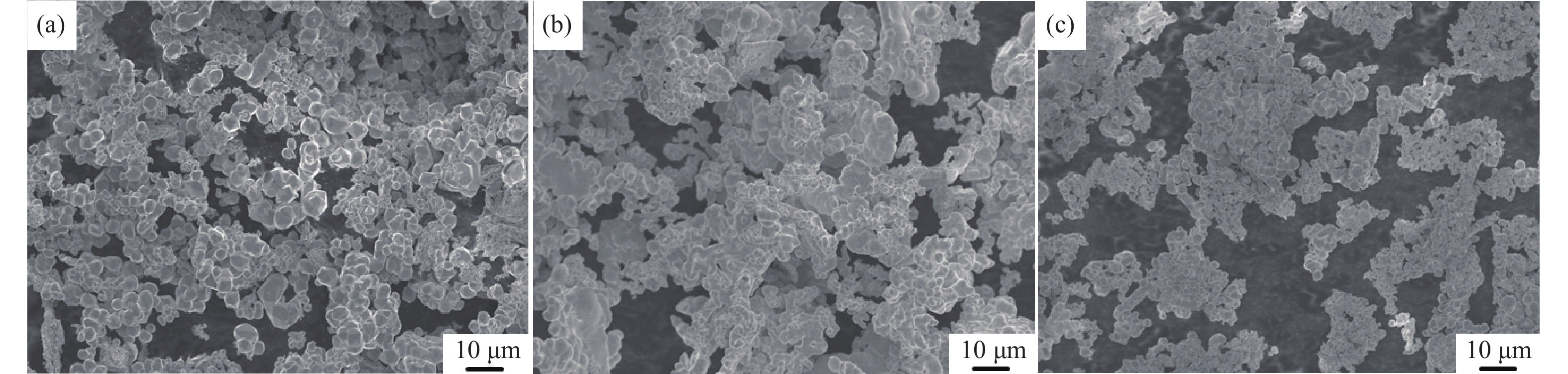

摘要: 研究了真空退火状态下不同热处理温度对Mo–14Re合金管材显微组织和室温力学性能的影响。结果表明:经轧制加工后的Mo–14Re合金管材晶粒组织沿轧制方向被拉长,呈明显的纤维组织,1100 ℃热处理后晶粒组织局部有宽化现象;随着热处理温度升高,1300 ℃热处理合金管材晶粒组织完成再结晶。热处理条件为1100 ℃、1 h的Mo–14Re合金管材表现出优异的强度与塑性组合,抗拉强度为710 MPa,延伸率为36.5%。断口分析发现,当退火温度在1100 ℃以下,Mo–14Re合金管材出现木纹状撕裂型断裂,表现出明显的塑性变形特征;当热处理温度提高到1300 ℃时,由于发生了再结晶,断口呈准解理断裂,塑性明显下降,变形主要以晶界滑移为主。综合分析表明,Mo–14Re合金轧制管材最佳热处理温度应该控制在1100~1300 ℃之间。

-

关键词:

- Mo–14Re合金管 /

- 微观组织 /

- 真空退火 /

- 力学性能 /

- 断口形貌

Abstract: The effects of heat treatment temperatures on the microstructure and mechanical properties of Mo–14Re alloy tubes after the vacuum annealing were studied in this paper. The results show that, the grains of Mo–14Re alloy tubes after rolling are elongated along the rolling direction, showing the obvious fiber structure, and the grains are locally widened after the heat treatment at 1100 ℃. With the increase of heat treatment temperature, the grains of Mo–14Re alloy tubes are completely recrystallized at 1300 ℃. The Mo–14Re alloy tubes show the excellent combination of strength and plasticity at 1100 ℃ for 1 h, the tensile strength is 710 MPa, and the elongation is 36.5%. In the fracture analysis, it is found that the Mo–14Re alloy tubes have the wood grain tearing fracture at the annealing temperature below 1100 ℃, showing the obvious plastic deformation characteristics. However, when the heat treatment temperature is increased to 1300 ℃, the fracture is quasi-cleavage due to the recrystallization, and the plastic deformation is mainly caused by grain boundary slip. Comprehensive analysis shows that the optimal heat treatment temperature of Mo–14Re alloy rolling tubes should be controlled between 1100 ℃ and 1300 ℃.-

Key words:

- Mo–14Re alloy tubes /

- microstructure /

- vacuum annealing /

- mechanical properties /

- fracture morphology

-

表 1 Mo–14Re管材轧制前后密度

Table 1. Density of the Mo–14Re pipes before and after rolling

材料状态 实测密度 / (g·cm−3) 相对密度 / % 烧结坯料 10.13 92.1 轧制管材 10.98 99.7 表 2 Murakamig腐蚀剂成分

Table 2. Component of Murakamig etchant

K3Fe(CN)6 KOH(或者NaOH) H2O 10 g 10 g 100 mL -

[1] Tan S B, Ye Y C, Ren J W, et al. Effect of alloying elements on low temperature plasticity of molybdenum. Rare Met Mater Eng, 1998, 27(Suppl 1): 145谭拴斌, 叶永才, 任吉文, 等. 合金元素对钼低温塑性的影响. 稀有金属材料与工程, 1998, 27(增刊 1): 145 [2] Liu R Z, An G, Yang Q L, et al. Microstructures and mechanical properties of Mo–Re–La alloy. Powder Metall Technol, 2018, 36(6): 429刘仁智, 安耿, 杨秦莉, 等. 钼–铼–镧合金微观组织及力学性能研究. 粉末冶金技术, 2018, 36(6): 429 [3] Leonhardt T, Carlen J C, Buck M, et al. Investigation of mechanical properties and microstructure of various molybdenum-rhenium alloys. AIP Conf Proc, 1999, 458: 685 [4] Bryskin B, Carlen J. Rhenium and molybdenum/tungsten based alloys: an overview of database// Proceedings of the 1998 127th Annual Meeting and Exhibition, Elyria, 1998: 11 [5] Tan Q, Manufacture and application of Mo–Re alloys. China Molybd Ind, 1998, 22(1): 26谭强. 钼–铼合金的制造及应用. 中国钼业, 1998, 22(1): 26 [6] Fabritsiev S A, Gosudarenkova V A, Potapova V A, et al. Effects of neutron irradiation on physical and mechanical properties of Mo–Re alloys. J Nucl Mater, 1992, 191-194: 426 [7] Busby J T, Leonard K J, Zinkle S J. Radiation-damage in molybdenum-rhenium alloys for space reactor applications. J Nucl Mater, 2007, 366(3): 388 doi: 10.1016/j.jnucmat.2007.03.028 [8] King J C, El-Genk M S. Submersion-subcritical safe space (S4) reactor. Nucl Eng Des, 2006, 236(17): 1759 doi: 10.1016/j.nucengdes.2005.12.010 [9] King J C, El-Genk M S. Solid-core, gas-cooled reactor for space and surface power // Space Technology and Applications International Forum-STAIF 2006. Albuquerque, 2006: 298 [10] El-Genk M S, Tournier J M P. Startup and load-following transients of a thermoelectric space reactor system with no single point failure // 3rd International Energy Conversion Engineering Conference. San Francisco, 2005: 459 [11] Hatton S A, El-Genk M S. How small can fast-spectrum space reactors get? // Space Technology and Applications International Forum-STAIF 2006. Albuquerque, 2006: 426 [12] Ashcroft J. Documentation of naval reactors papers and presentations for the space technology and international forum (STAIF) 2006 // Project Prometheus Reactor Module Final Report. Niskayuna, 2006 [13] Kambe M, Tsunoda H, Mishima K, et al. Rapid-L operator-free fast reactor concept without any control rods. Nucl Technol, 2003, 143(1): 11 doi: 10.13182/NT03-A3394 [14] Leichtfried G, Schneibel J H, Heilmaier M. Ductility and impact resistance of powder-metallurgical molybdenum-rhenium alloys. Metall Mater Trans A, 2006, 37(10): 2955 doi: 10.1007/s11661-006-0177-9 [15] Leonard K J, Busby J T, Zinkle S J. Microstructural and mechanical property changes with aging of Mo–41Re and Mo–47.5Re alloys. J Nucl Mater, 2007, 366(3): 369 doi: 10.1016/j.jnucmat.2007.03.027 [16] Burkhanov G S, Yusupov V S, Roschupkin V V, et al. Manufacturing features, structure, and properties of high-purity Mo–Re thin sheets. J Phys Conf Ser, 2021, 1758(1): 012006 doi: 10.1088/1742-6596/1758/1/012006 [17] Nemoto Y, Hasegawa A, Satou M, et al. Microstructural development and radiation hardening of neutron irradiated Mo–Re alloys. J Nucl Mater, 2004, 324(1): 62 doi: 10.1016/j.jnucmat.2003.09.007 [18] Mannheim R L, Garin J L. Structural identification of phases in Mo–Re alloys within the range from 5 to 95%Re. J Mater Process Technol, 2003, 143: 533 [19] Chen C, Wang M P, Guo M X, et al. Study on annealing behavior of Mo–43wt%Re alloy prepared by powder metallurgy. Trans Mater Heat Treat, 2007, 28(6): 54 doi: 10.3969/j.issn.1009-6264.2007.06.013陈畅, 汪明朴, 郭明星, 等. 粉冶金法制备Mo–43wt%Re合金退火行为的研究. 材料热处理学报, 2007, 28(6): 54 doi: 10.3969/j.issn.1009-6264.2007.06.013 [20] Tan S B, Zhang X M, Ren J W, et al. Structure and properties of molybdenum-rhenium alloys. Chin J Rare Met, 2004, 28(1): 127 doi: 10.3969/j.issn.0258-7076.2004.01.032谭栓斌, 张小明, 任吉文, 等. 钼铼合金带材的组织和性能. 稀有金属, 2004, 28(1): 127 doi: 10.3969/j.issn.0258-7076.2004.01.032 -

下载:

下载: