Effect of two-stage supersolidus liquid phase sintering on microstructure and properties of 15Cr high chromium cast iron

-

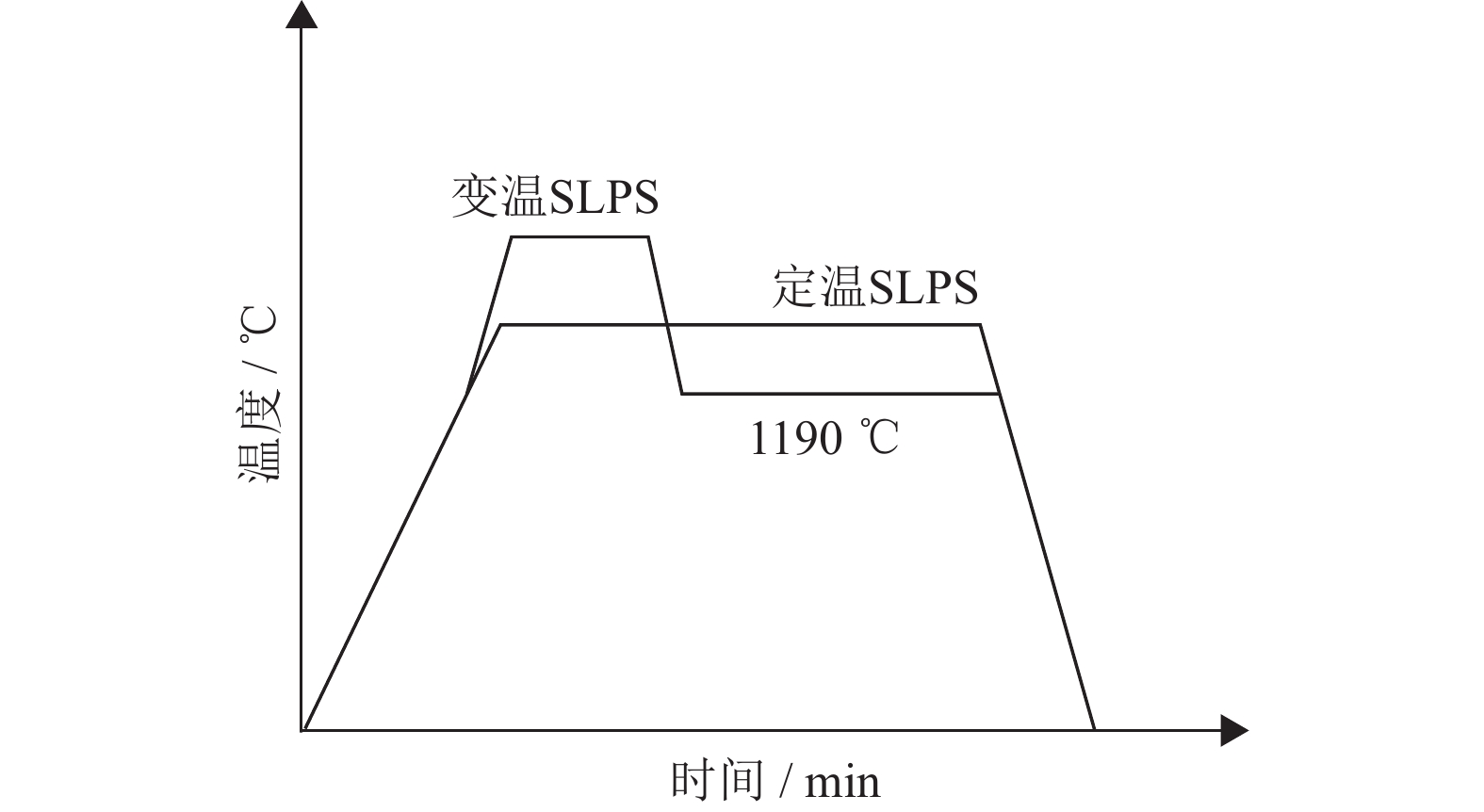

摘要: 为解决常规定温超固相线液相烧结出现的烧结温度窗口狭窄和产品力学性能对烧结温度波动敏感的问题,采用变温超固相线液相烧结工艺制备了粉末冶金高铬铸铁,研究了变温超固相线液相烧结的高温阶段工艺参数对15Cr系高铬铸铁显微组织和力学性能的影响,并与定温超固相线液相烧结制备的合金进行了对比。研究发现,变温超固相线液相烧结制备的合金由M7C3型碳化物、马氏体及少量奥氏体组成,通过高、低温两个阶段的烧结能够实现高效致密化和对显微组织的有效调控,制备出相对密度超过98.96%的高性能合金材料,烧结温度窗口相较于定温超固相线液相烧结扩展了15 ℃。在1225~1245 ℃、5~10 min的高温阶段窗口,随烧结温度升高与保温时间延长,合金显微组织逐渐粗化;当高温阶段烧结保温时间控制在10 min以内时,合金晶粒尺寸低于26.98 μm,组织粗化程度可接受。变温超固相线液相烧结高铬铸铁的硬度和冲击韧性优于定温超固相线液相烧结高铬铸铁,且冲击韧性在烧结窗口内保持稳定,平均值达12.10 J·cm−2。在1~3 J·cm−2冲击功下,变温超固相线液相烧结试样的抗冲击磨粒磨损性能优于定温超固相线液相烧结试样,随着冲击功提高,合金的抗冲击磨粒磨损性能提升从9.70%提高到19.83%。Abstract: To solve the problems in the one-stage supersolidus liquid phase sintering (SLPS) that the sintering temperature window is narrow and the mechanical properties of the products are very sensitive to the fluctuation of sintering temperature, the high chromium cast iron (HCCI) was prepared by the two-stage SLPS technique. The effects of process parameters in the high temperature stage (HTS) on the microstructure and mechanical properties of 15Cr high chromium cast iron prepared by the two-stage SLPS were studied, and the alloys prepared by the one-stage SLPS were compared. The results show that the alloys prepared by the two-stage SLPS are composed of M7C3-type carbides, martensite, and a small amount of austenite. Efficient densification and the effective control of microstructure can be achieved through the high and low temperature sintering, and the relative density of high performance alloy material is more than 98.96%. The sintering temperature window is 15 ℃ wider than that of one-stage SLPS. The microstructure of the alloys is gradually coarsened with the increase of the sintering temperature and the holding time during the high temperature stage from 1225 ℃ to 1245 ℃ for 5~10 min. However, when the holding time is controlled within 10 min during the high temperature stage, the grain size is less than 26.98 μm, and the coarsening degree is acceptable. The hardness and impact toughness of HCCI prepared by the two-stage SLPS are better than those prepared by the one-stage SLPS, and the impact toughness remains stable within the sintering window with the average value of 12.10 J·cm−2. Under the impact energy from 1 J·cm−2 to 3 J·cm−2, the impact abrasive wear resistance of the samples sintered by the two-stage SLPS is better than that of the samples sintered by the one-stage SLPS. With the increase of impact energy, the improvement of impact abrasive wear resistance of the alloys increases from 9.70% to 19.83%.

-

图 3 两种烧结方法所制备高铬铸铁X射线衍射图谱:(a)1210 ℃×90 min;(b)1225 ℃×10 min+1190 ℃×80 min;(c)1235 ℃×5 min+1190 ℃×85 min;(d)1235 ℃×15 min+1190 ℃×75 min;(e)1245 ℃×10 min+1190 ℃×80 min

Figure 3. XRD patterns of 15Cr HCCI prepared by the one-stage SLPS and the two-stage SLPS: (a) 1210 ℃×90 min; (b) 1225 ℃×10 min+1190 ℃×80 min; (c) 1235 ℃×5 min+1190 ℃×85 min; (d) 1235 ℃×15 min+1190 ℃×75 min; (e) 1245 ℃×10 min+1190 ℃×80 min

图 4 变温超固相线液相烧结15Cr高铬铸铁在高温阶段的显微组织演变:(a)1225 ℃×5 min+1190 ℃×85 min;(b)1225 ℃×15 min+1190 ℃×75 min;(c)1235 ℃×5 min+1190 ℃×85 min;(d)1235 ℃×15 min+1190 ℃×75 min;(e)1245 ℃×5 min+1190 ℃×85 min;(f)1245 ℃×15 min+1190 ℃×75 min

Figure 4. Microstructure evolution of 15Cr HCCI prepared by the two-stage SLPS in the high temperature stage (HTS): (a) 1225 ℃×5 min+1190 ℃×85 min; (b) 1225 ℃×15 min+1190 ℃×75 min; (c) 1235 ℃×5 min+1190 ℃×85 min; (d) 1235 ℃×15 min+1190 ℃×75 min; (e) 1245 ℃×5 min+1190 ℃×85 min; (f) 1245 ℃×15 min+1190 ℃×75 min

图 5 定温与变温超固相线液相烧结高铬铸铁显微组织:(a)1210 ℃×90 min;(b)1225 ℃×90 min;(c)1225 ℃×10 min+1190 ℃×80 min;(d)1240 ℃×90 min;(e)1245 ℃×10 min+1190 ℃×80 min

Figure 5. Microstructure of HCCI prepared by the one-stage SLPS and the two-stage SLPS: (a) 1210 ℃×90 min; (b) 1225 ℃×90 min; (c) 1225 ℃×10 min+1190 ℃×80 min; (d) 1240 ℃×90 min; (e) 1245 ℃×10 min+1190 ℃×80 min

表 1 15Cr系高铬铸铁原料粉末化学成分(质量分数)

Table 1. Chemical composition of the 15Cr HCCI

% Cr C Si Mn Fe 14.91 2.54 0.80 0.62 余量 -

[1] Tabrett C P, Sare I R, Ghomashchi M R. Microstructure-property relationships in high chromium white iron alloys. Int Mater Rev, 1996, 41(2): 59 doi: 10.1179/imr.1996.41.2.59 [2] Kallel M, Zouch F, Antar Z, et al. Hammer premature wear in mineral crushing process. Tribol Int, 2017, 115: 493 doi: 10.1016/j.triboint.2017.06.025 [3] Bedolla-Jacuinde A. Microstructure of vanadium-, niobium- and titanium-alloyed high-chromium white cast irons. Int J Cast Met Res, 2001, 13(6): 343 doi: 10.1080/13640461.2001.11819416 [4] Li X L, Xie W L, Zhou X J, et al. Influence of Ti, Nb, Mo on morphology and properties of high chromium carbides. Spec Cast Nonferrous Alloys, 2014, 34(8): 804李秀兰, 谢文玲, 周新军, 等. Ti、V、Nb、Mo对高铬铸铁碳化物形态与性能的影响. 特种铸造及有色合金, 2014, 34(8): 804 [5] Hou Y C, Wang Y, Pan Z Y, et al. Influence of rare earth nanoparticles and inoculants on performance and microstructure of high chromium cast iron. J Rare Earths, 2012, 30: 283 doi: 10.1016/S1002-0721(12)60038-6 [6] Yilmaz S O, Teker T. Effect of TiBAl inoculation and heat treatment on microstructure and mechanical properties of hypereutectic high chromium white cast iron. J Alloys Compd, 2016, 672: 324 doi: 10.1016/j.jallcom.2016.02.125 [7] Liu H H, Wang J, Shen B L, et al. Effects of deep cryogenic treatment on property of 3Cr13Mo1V1.5 high chromium cast iron. Mater Des, 2007, 28(3): 1059 [8] Qiu B, Xing S M, Dong Q, et al. Comparison of properties and impact abrasive wear performance of ZrO2−Al2O3/Fe composite prepared by pressure casting and infiltration casting process. Tribol Int, 2020, 142: 105979 doi: 10.1016/j.triboint.2019.105979 [9] Llewellyn R J, Yick S K, Dolman K F. Scouring erosion resistance of metallic materials used in slurry pump service. Wear, 2003, 256(6): 592 [10] Gu J H, Xiao P A, Song J Y, et al. Sintering of a hypoeutectic high chromium cast iron as well as its microstructure and properties. J Alloys Compd, 2018, 740: 485 doi: 10.1016/j.jallcom.2017.11.189 [11] Li Z T, Xiao P A, Gu J H, et al. Study on microstructure and mechanical properties of sintered Cr15 high chromium cast iron. Mater Sci Technol, 2020, 28(1): 7 doi: 10.11951/j.issn.1005-0299.20180208李忠涛, 肖平安, 顾景洪, 等. 烧结Cr15高铬铸铁组织与性能的研究. 材料科学与工艺, 2020, 28(1): 7 doi: 10.11951/j.issn.1005-0299.20180208 [12] German R M. Supersolidus liquid phase sintering of prealloyed powders. Met Powder Rep, 1998, 53(5): 36 [13] Chen N, Luo R, Xiong H W, et al. Dense M2 high speed steel containing core-shell MC carbonitrides using high-energy ball milled M2/VN composite powders. Mater Sci Eng A, 2020, 771: 138628 doi: 10.1016/j.msea.2019.138628 [14] Farayibi P K, Blüm M, Weber S. Densification of a high chromium cold work tool steel powder in different atmospheres by SLPS: Microstructure, heat treatment and micromechanical properties. Mater Sci Eng A, 2020, 777: 139053 doi: 10.1016/j.msea.2020.139053 [15] Dai Y X, Yang M, Song C J, et al. Solidification structure of C2.08Cr25.43Si1.19Mn0.43Fe70.87 powders fabricated by high pressure gas atomization. Mater Charact, 2010, 61(1): 116 [16] Xiao P A, Xiao L Q, Gu J H, et al. Study on sintering preparation and properties of 15Cr hypoeutectic high-chromium cast iron. J Hunan Univ Nat Sci, 2019, 46(12): 58肖平安, 肖璐琼, 顾景洪, 等. 15Cr系亚共晶高铬铸铁的烧结制备与性能研究. 湖南大学学报(自然科学版), 2019, 46(12): 58 [17] Lal A, Iacocca R G, German R M. Microstructural evolution during the supersolidus liquid phase sintering of nickel-based prealloyed powder mixtures. J Mater Sci, 2000, 35(18): 4507 doi: 10.1023/A:1004893618493 [18] Xiao L Q. Sintering Preparation and Properties of 15Cr Hypoeutectic High-Chromium Cast Iron [Dissertation]. Changsha: Hunan University, 2019肖璐琼. 15Cr系亚共晶高铬铸铁的烧结制备与性能研究[学位论文]. 长沙: 湖南大学, 2019 -

下载:

下载: