-

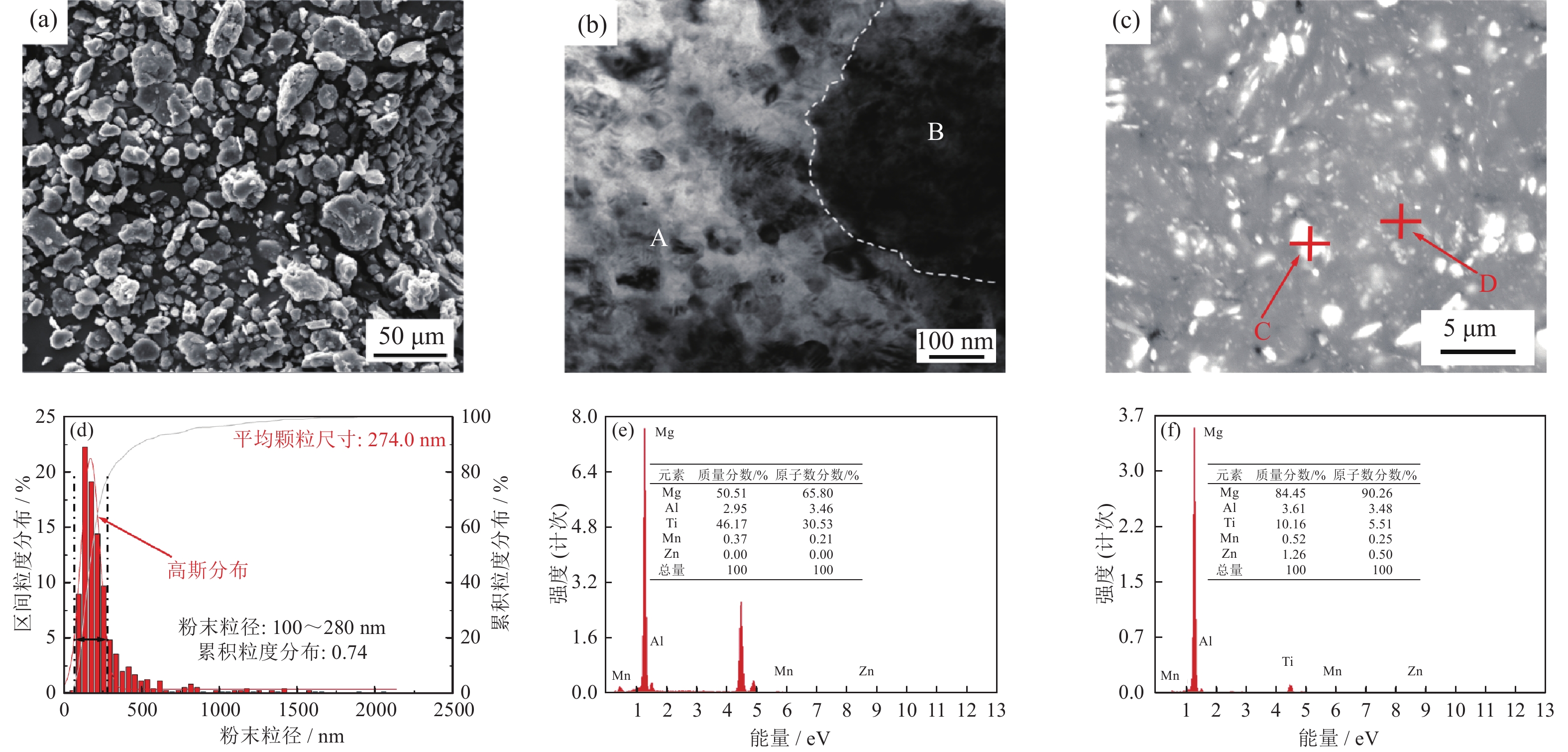

摘要: 通过机械球磨、真空热压和热挤压制备了AZ61Mg‒18%Ti(质量分数)复合材料,研究了复合材料的微观组织、室温力学性能和强化机制。结果表明,采用真空热压+热挤压制备的复合材料镁基体平均晶粒尺寸为180 nm,Ti颗粒及纳米级Ti3Al相弥散分布于镁基体中,Ti颗粒和Ti3Al相平均尺寸分别为265 nm和10 nm。超细晶AZ61Mg‒18%Ti复合材料具有优异的室温力学性能,其屈服强度、抗压强度和断裂应变分别达到606 MPa、698 MPa和12%。Abstract: The AZ61Mg‒18%Ti (mass fraction) composites were prepared by mechanical milling, vacuum hot pressing, and hot extrusion. The microstructure, room-temperature mechanical properties, and the corresponding strengthening mechanism were studied. The results show that, the average grain size of the magnesium matrix is about 180 nm, the Ti particles and the nano-sized Ti3Al phases are dispersive distribution in the magnesium matrix, and the average grain sizes of Ti particles and Ti3Al phases are 265 nm and 10 nm, respectively. The ultrafine-grained AZ61Mg‒18%Ti composites show the excellent room-temperature mechanical properties, the room-temperature yield strength, the compressive strength, and the fracture strain are 606 MPa, 698 MPa, and 12%, respectively.

-

图 1 复合材料微观组织、尺寸分布及能谱分析:(a)复合粉末扫描电镜显微形貌;(b)复合粉末透射电镜显微形貌;(c)Ti单质粒子扫描电镜显微形貌;(d)Ti颗粒尺寸分布;(e)C点能谱分析;(f)D点能谱分析

Figure 1. Microstructure, size distribution, and energy dispersive spectrometer (EDS) analysis of the composites: (a) scanning electron microscope (SEM) image of the composite powders; (b) transmission electron microscope (TEM) image of the composite powders; (c) SEM image of Ti particle; (d) particle size distribution of Ti; (e) EDS analysis of point C; (f) EDS analysis of point D

-

[1] Wan Y C, Tang B, Gao Y H, et al. Bulk nanocrystalline high-strength magnesium alloys prepared via rotary swaging. Acta Mater, 2020, 200: 274 doi: 10.1016/j.actamat.2020.09.024 [2] Chen L Y, Xu J Q, Choi H, et al. Processing and properties of magnesium containing a dense uniform dispersion of nanoparticles. Nature, 2015, 528(7583): 539 doi: 10.1038/nature16445 [3] Pan H C, Qin G W, Huang Y M, et al. Development of low-alloyed and rare-earth-free magnesium alloys having ultra-high strength. Acta Mater, 2018, 149: 350 doi: 10.1016/j.actamat.2018.03.002 [4] Goh C S, Wei J, Lee L C, et al. Properties and deformation behaviour of Mg‒Y2O3 nanocomposites. Acta Mater, 2007, 55(15): 5115 doi: 10.1016/j.actamat.2007.05.032 [5] Suh B C, Kim J H, Bae J H, et al. Effect of Sn addition on the microstructure and deformation behavior of Mg‒3Al alloy. Acta Mater, 2017, 124: 268 doi: 10.1016/j.actamat.2016.11.020 [6] Wu Z X, Ahmad R, Yin B, et al. Mechanistic origin and prediction of enhanced ductility in magnesium alloys. Science, 2018, 359(6374): 447 doi: 10.1126/science.aap8716 [7] Ren F Y, Xu L, Li C Y, et al. Research progress in the preparation of particle-reinforced magnesium matrix composites by powder metallurgy. Powder Metall Technol, 2020, 38(1): 66任峰岩, 许磊, 历长云, 等. 粉末冶金法制备颗粒增强镁基复合材料的研究进展. 粉末冶金技术, 2020, 38(1): 66 [8] Ding W J. Magnesium Alloy Science and Technology. Beijing: Science Press, 2007丁文江. 镁合金科学与技术. 北京: 科学出版社, 2007 [9] Wang Y, Choo H. Influence of texture on Hall-Petch relationships in an Mg alloy. Acta Mater, 2014, 81: 83 doi: 10.1016/j.actamat.2014.08.023 [10] Sun W T, Qiao X G, Zheng M Y, et al. Altered ageing behaviour of a nanostructured Mg‒8.2Gd‒3.8Y‒1.0Zn‒0.4Zr alloy processed by high pressure torsion. Acta Mater, 2018, 151: 260 [11] Yu H H, Li C Z, Xin Y C, et al. The mechanism for the high dependence of the Hall-Petch slope for twinning/slip on texture in Mg alloys. Acta Mater, 2017, 128: 313 doi: 10.1016/j.actamat.2017.02.044 [12] Wang X. Research on Mechanical Properties of Ultra-Fine Grain AZ31 Magnesium Alloy Prepared by Powder Metallurgy [Dissertation]. Harbin: Harbin Institute of Technology, 2013王辛. 粉末冶金超细晶AZ31镁合金材料制备与力学性能研究[学位论文]. 哈尔滨: 哈尔滨工业大学, 2013 [13] Yu H, Sun Y, Wan Z P, et al. Nanocrystalline Ti/AZ61 magnesium matrix composite: Evolution of microstructure and mechanical property during annealing treatment. J Alloys Compd, 2018, 741: 231 doi: 10.1016/j.jallcom.2018.01.136 [14] Sun X F, Wang C J, Deng K K, et al. High strength SiCp/AZ91 composite assisted by dynamic precipitated Mg17Al12 phase. J Alloys Compd, 2018, 732: 328 doi: 10.1016/j.jallcom.2017.10.164 [15] Homma T, Kunito N, Kamado S. Fabrication of extraordinary high-strength magnesium alloy by hot extrusion. Scr Mater, 2009, 61(6): 644 doi: 10.1016/j.scriptamat.2009.06.003 -

下载:

下载: