| [1] |

Huang P Y. Theory of Powder Metallurgy. 2nd Ed. Beijing: Metallurgical Industry Press, 2004黄培云. 粉末冶金原理. 2版. 北京: 冶金工业出版社, 2004

|

| [2] |

Peng J G, Li D K, Chen D, et al. Comparison the characteristics of the finite element analysis software by the application in iron-based powder metallurgy industry. Powder Metall Technol, 2016, 34(6): 461 doi: 10.3969/j.issn.1001-3784.2016.06.012彭景光, 李德凯, 陈迪, 等. 有限元分析在铁基粉末冶金中的应用比较. 粉末冶金技术, 2016, 34(6): 461 doi: 10.3969/j.issn.1001-3784.2016.06.012

|

| [3] |

Qu X H. Comments of Editor-in-Chief. Powder Metall Technol, 2021, 39(1): 3曲选辉. 主编寄语. 粉末冶金技术, 2021, 39(1): 3

|

| [4] |

Jiang Y. Computer Simulation of Powder Metallurgy Process [Dissertation]. Lanzhou: Lanzhou University of Technology, 2019蒋煜. 粉末冶金过程的计算机仿真[学位论文]. 兰州: 兰州理工大学, 2019

|

| [5] |

Ma C Y. Numerical Simulation of Electromagnetic Field in Vacuum Induction Melting [Dissertation]. Shenyang: Northeastern University, 2013马长勇. 真空感应熔炼电磁场的数值模拟[学位论文]. 沈阳: 东北大学, 2013

|

| [6] |

Ouyang H W, Wang Q, Liu Z M. Numerical study on abrupt change of flow field in close-coupled gas atomization. Mater Sci Eng Powder Metall, 2010, 15(2): 96 doi: 10.3969/j.issn.1673-0224.2010.02.002欧阳鸿武, 王琼, 刘卓民. 紧耦合气雾化流场结构突变过程的数值模拟. 粉末冶金材料科学与工程, 2010, 15(2): 96 doi: 10.3969/j.issn.1673-0224.2010.02.002

|

| [7] |

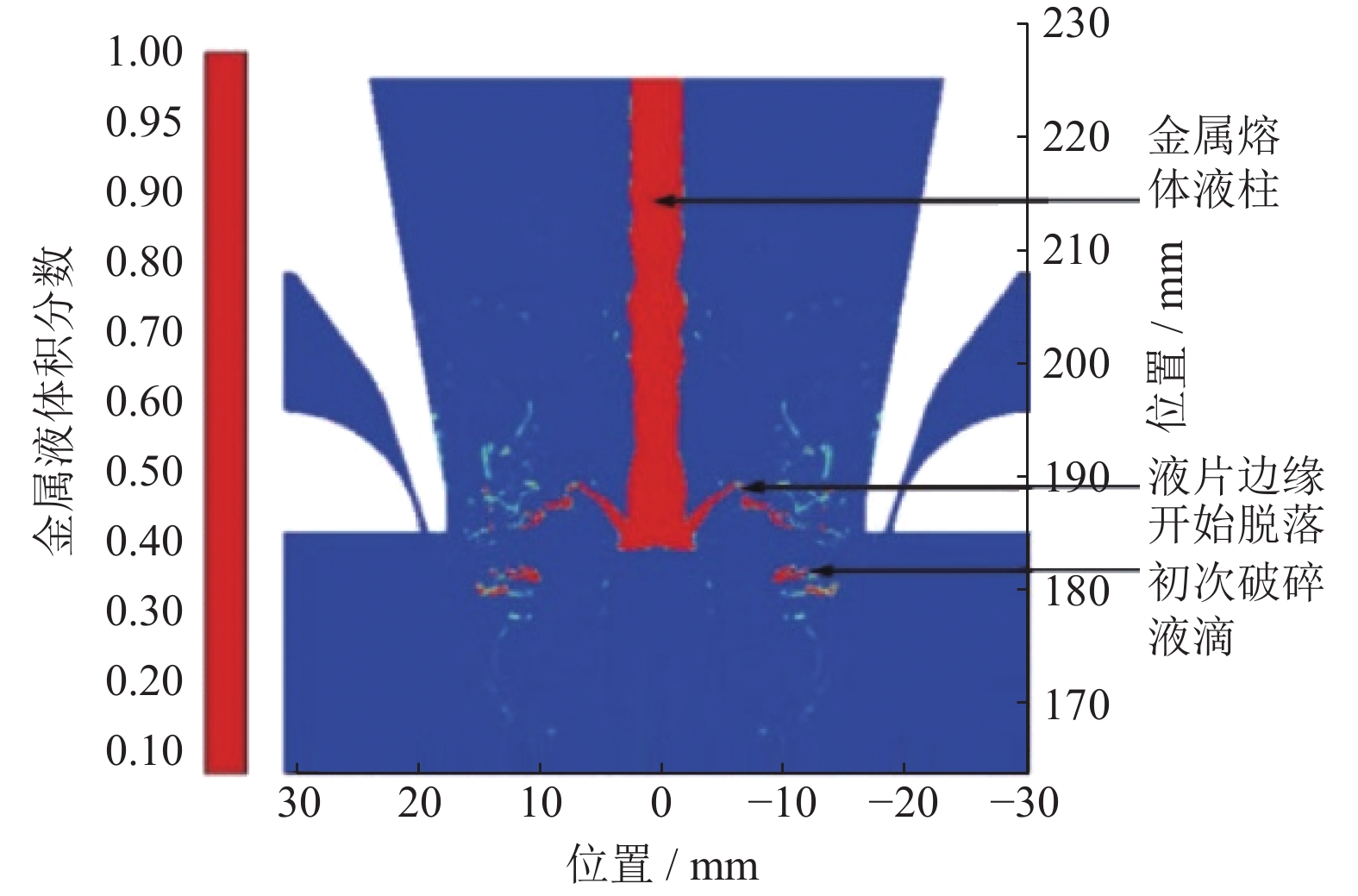

Xia M, Wang P, Zhang X H, et al. Computational fluid dynamic investigation of the primary and secondary atomization of the free-fall atomizer in electrode induction melting gas atomization process. Acta Phys Sin, 2018, 67(17): 41夏敏, 汪鹏, 张晓虎, 等. 电极感应熔化气雾化制粉技术中非限制式喷嘴雾化过程模拟. 物理学报, 2018, 67(17): 41

|

| [8] |

Zhou R, Zhang L H, He B Y, et al. Numerical simulation of residual stress field in green power metallurgy compacts by modified Drucker-Prager Cap model. Trans Nonferrous Met Soc China, 2013, 23(8): 2374 doi: 10.1016/S1003-6326(13)62744-2

|

| [9] |

Deng Z H, Yin H Q, Li W Q, et al. Design of Cu-based powder alloys used for low speed and heavy bearing with inverse design methodology. Powder Metall Technol, 2020, 38(2): 83邓正华, 尹海清, 李万全, 等. 基于逆向设计思想的低速重载轴承用铜基粉末合金的设计. 粉末冶金技术, 2020, 38(2): 83

|

| [10] |

Lee D J, Jung J M, Latypov M I, et al. Three-dimensional real structure-based finite element analysis of mechanical behavior for porous titanium manufactured by a space holder method. Comput Mater Sci, 2015, 100: 2 doi: 10.1016/j.commatsci.2014.10.020

|

| [11] |

Yang D L, Duan B H, Wang D Z. Numerical simulation and experimental investigation on multi-directional forging of pure molybdenum. Powder Metall Technol, 2021, 39(3): 216杨栋林, 段柏华, 王德志. 纯钼的多向锻造数值模拟及实验研究. 粉末冶金技术, 2021, 39(3): 216

|

| [12] |

Yang Z W, Guo S S, Sun K L. An application for forging of connecting rod based on DEFORM–3D. Mod Manuf Eng, 2010, 4(8): 93 doi: 10.3969/j.issn.1671-3133.2010.08.024杨兆伟, 郭顺生, 孙康岭. DEFORM–3D仿真软件在连杆锻造过程中的应用. 现代制造工程, 2010, 4(8): 93 doi: 10.3969/j.issn.1671-3133.2010.08.024

|

| [13] |

You M M, Pan S Y, Shen X P, et al. Current progress and prospect of numerical simulation in powder compaction. Powder Metall Ind, 2017, 27(4): 49尤萌萌, 潘诗琰, 申小平, 等. 粉末压制过程数值模拟的研究现状及展望. 粉末冶金工业, 2017, 27(4): 49

|

| [14] |

Mao H J, Shen X Y. Numerical simulation of powder metallurgy components strengthened by surface rolling. Hot Working Technol, 2020, 39(11): 110毛华杰, 沈小燕. 粉末冶金件表面滚压塑性变形强化过程的数值模拟. 热加工工艺, 2020, 39(11): 110

|

| [15] |

Zhang J. Study on the Compact Density and Sintering Deformation of Carbide Inserts [Dissertation]. Changsha: Central South University, 2014张京. 硬质合金刀片压坯密度分布与烧结变形的研究[学位论文]. 长沙: 中南大学, 2014

|

| [16] |

Lang L H, Wang G, Bu G L, et al. Study of numerical simulation and mechanical properties of hot isostatic pressed titanium alloy powder. Powder Metall Ind, 2015, 25(3): 1郎利辉, 王刚, 布国亮, 等. 钛合金粉末热等静压数值模拟及性能研究. 粉末冶金工业, 2015, 25(3): 1

|

| [17] |

Yu S, Lang L H, Wang G, et al. Research on numerical simulation of 2A12 aluminum alloy manufactured by hot isostatic pressing. Powder Metall Ind, 2016, 26(2): 17喻思, 郎利辉, 王刚, 等. 热等静压成形2A12铝合金粉末的数值模拟研究. 粉末冶金工业, 2016, 26(2): 17

|

| [18] |

Song Y, Li Y Y, Zhou Z Y, et al. Improved model and 3D simulation of densification process for iron powder. Trans Nonferrous Met Soc China, 2010, 20(8): 1470 doi: 10.1016/S1003-6326(09)60323-X

|

| [19] |

Tan S L, Zhang X M, Zhao Z P, et al. System simulation of multi-physical field coupling in electric current-assisted sintering. Powder Metall Technol, 2020, 38(6): 414谭树林, 张晓敏, 赵志鹏, 等. 电流辅助烧结过程的多物理场耦合体系模拟. 粉末冶金技术, 2020, 38(6): 414

|

| [20] |

Wang D, Yang Y. Functional characteristics of large-scalediscrete element software EDEM. Perspect Sci Technol Achiev, 2009, 4(3): 75 doi: 10.3969/j.issn.1005-5096.2009.03.034王东, 杨溢. 大型离散元软件EDEM的功能特点. 科技成果纵横, 2009, 4(3): 75 doi: 10.3969/j.issn.1005-5096.2009.03.034

|

| [21] |

Zhang H, Zhang Y Z. Brief introduction of particle mechanics simulation software EDEM. CAD/CAM Manuf Inform, 2008, 4(12): 48张辉, 张永震. 颗粒力学仿真软件EDEM简要介绍. CAD/CAM与制造业信息化, 2008, 4(12): 48

|

| [22] |

Zhao Y B, Ma L, Liu Bo, et al. Analysis on vibration packing density of pure iron powders based on discrete element method. Powder Metall Technol, 2020, 38(6): 429赵艳波, 马麟, 刘波, 等. 基于离散元法的纯铁粉振动填充密度分析. 粉末冶金技术, 2020, 38(6): 429

|

| [23] |

Liu Y L, Zeng Y. Mechanical behavior analysis on the compression molding process of NdFeB by different molding technology. Powder Metall Technol, 2020, 38(4): 262刘义伦, 曾洋. 不同成型工艺下钕铁硼模压成型过程的力学行为分析. 粉末冶金技术, 2020, 38(4): 262

|

下载:

下载: