Research progress on FeCrAl alloys used for nuclear fuel cladding prepared by powder metallurgy

-

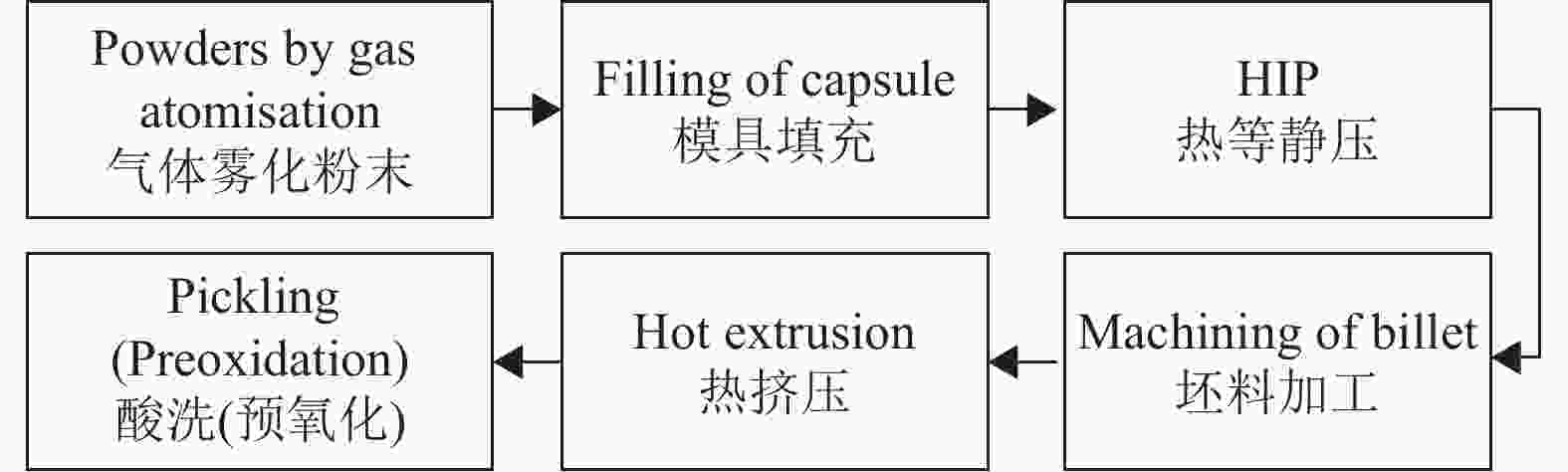

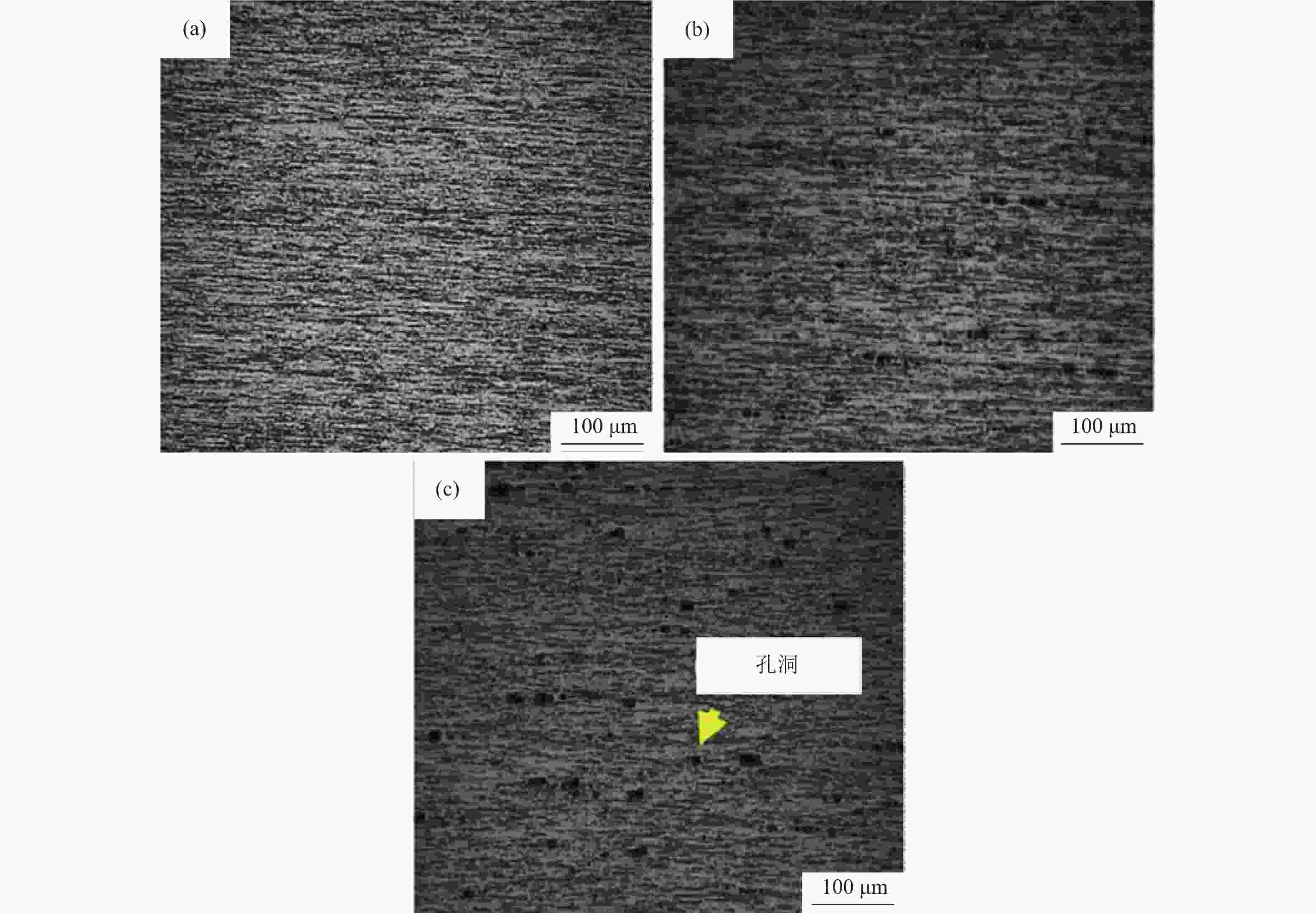

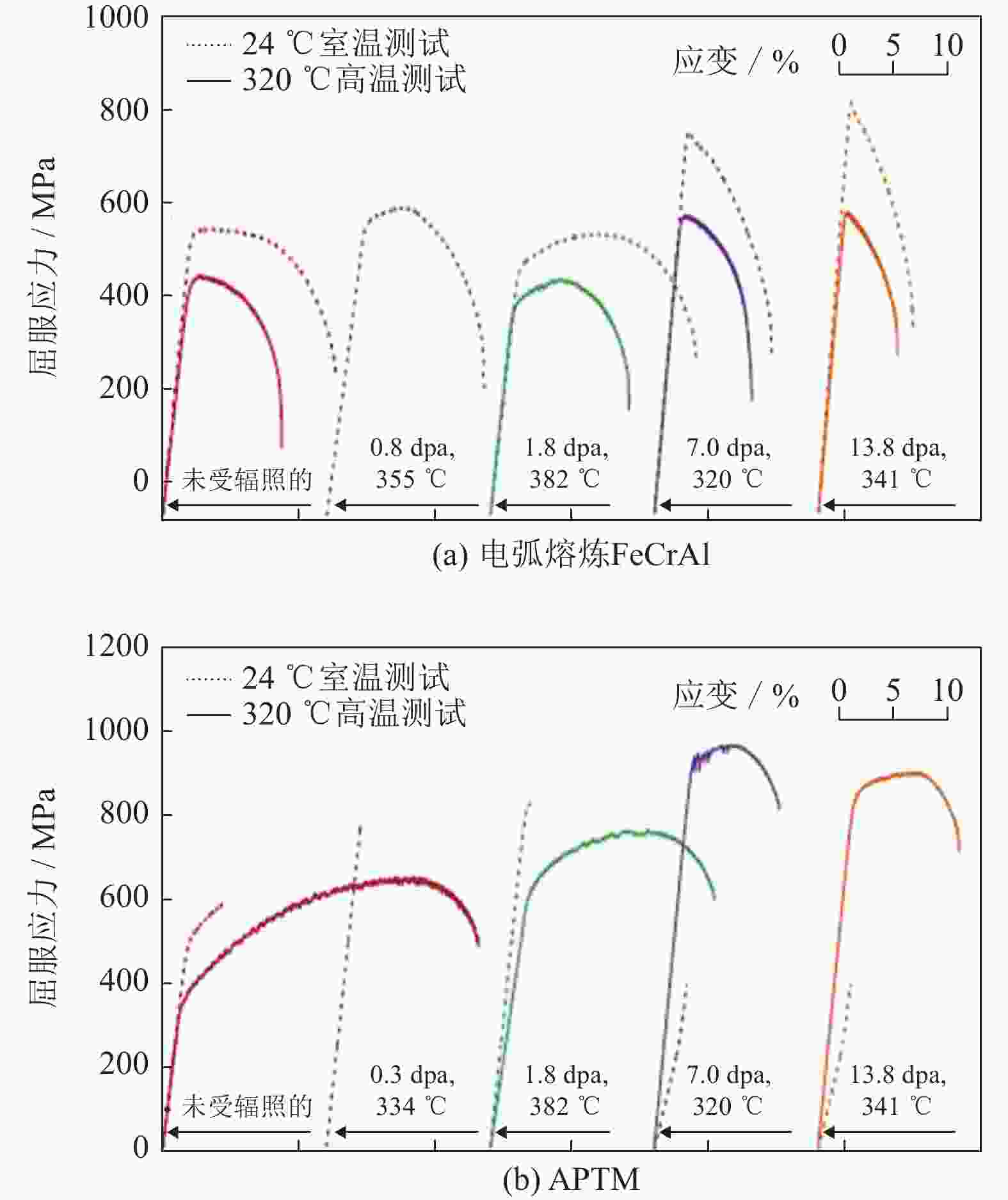

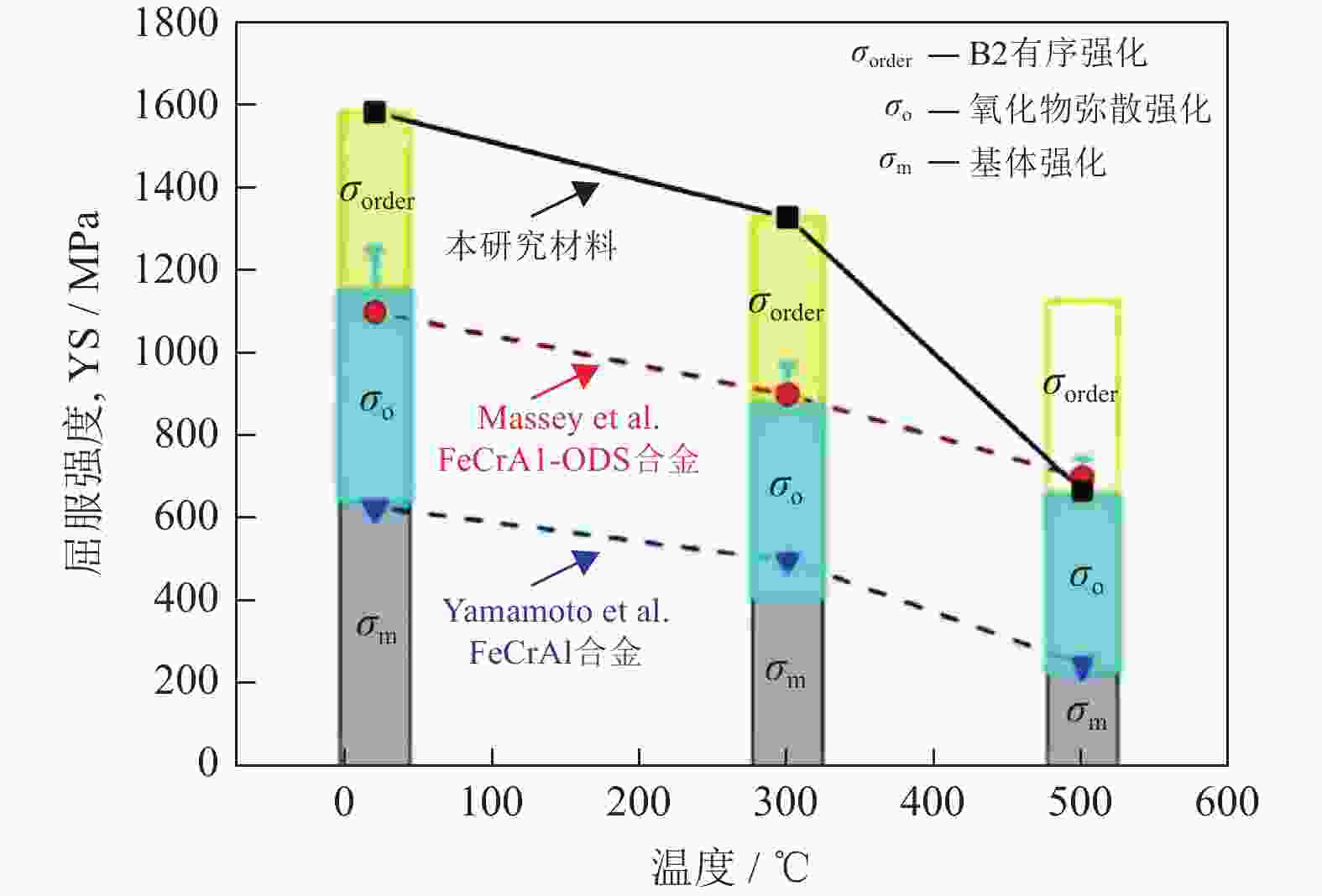

摘要: 燃料包壳是核反应堆安全运行的重要保障。福岛核事故后,国内外开展了大量新型事故容错燃料包壳的研发工作。由于具有抗高温氧化和高强度等优异的综合性能,FeCrAl合金已成为新一代事故容错燃料包壳的重要候选材料之一。经过多年积累,核燃料包壳FeCrAl合金的设计和制备研究已取得一定进展。利用粉末冶金方法制备性能更为优异的氧化物弥散强化FeCrAl合金前景广阔,受到国内外学者的广泛关注。本文综述了核燃料包壳FeCrAl合金的成分设计、熔炼制备和粉末冶金制备的研究现状,分析了不同方法制备合金的组织性能及存在的问题,对未来核燃料包壳FeCrAl合金的设计和制备进行了展望。Abstract: The fuel cladding plays an important role for the safe operation of the nuclear reactors. After the Fukushima nuclear accident, a large number of new types of the accident-tolerant fuel cladding have been developed. FeCrAl alloys have become one of the important candidate materials for the new generation of the accident-tolerant fuel cladding due to the excellent comprehensive properties, such as the high temperature oxidation resistance and the high strength. After years of research and development, some progress has been made in the design and preparation of FeCrAl alloys used for the nuclear fuel cladding. As one of the main research directions, the preparation of the oxide dispersion strengthened FeCrAl alloys with the better performance by powder metallurgy shows a broad prospect and has attracted the extensive attention from scholars at home and abroad. In this paper, the research status of the composition design, smelting, and powder metallurgy for the FeCrAl alloys used for the nuclear fuel cladding were reviewed. The microstructure, properties, and the existing problems of the FeCrAl alloys prepared by the different methods were analyzed. The future design and preparation of the FeCrAl alloys used for the nuclear fuel cladding were prospected.

-

Key words:

- nuclear fuel cladding /

- FeCrAl alloys /

- composition design /

- melting /

- powder metallurgy

-

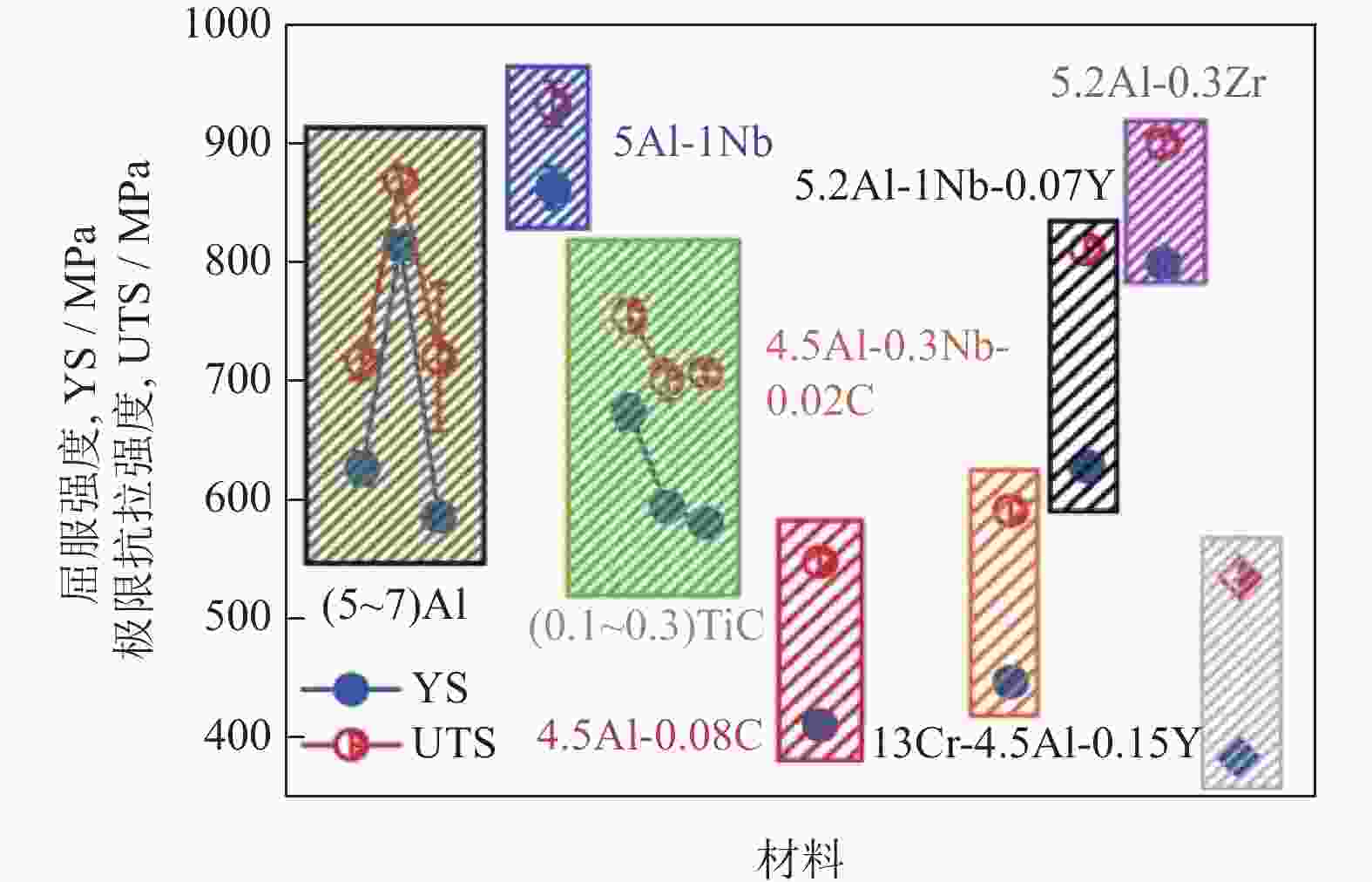

表 1 不同方法制备FeCrAl合金晶粒尺寸与拉伸性能

Table 1. Grain size and tensile properties of the FeCrAl alloy prepared by various methods

-

[1] Allison C M, Hohorst J K, Allison B S, et al. Preliminary assessment of the possible BWR core/vessel damage states for Fukushima Daiichi Station blackout scenarios using RELAP/SCDAPSIM. Sci Technol Nucl Install, 2012, 2012: 646327 [2] Yamamoto Y, Pint B A, Terrani K A, et al. Development and property evaluation of nuclear grade wrought FeCrAl fuel cladding for light water reactors. J Nucl Mater, 2015, 467: 703 doi: 10.1016/j.jnucmat.2015.10.019 [3] Gao S X, Li W J, Chen P, et al. Study on irradiation behavior of fuel rods with FeCrAl cladding. Nucl Power Eng, 2017, 38(5): 175高士鑫, 李文杰, 陈平, 等. FeCrAl包壳燃料棒辐照行为研究. 核动力工程, 2017, 38(5): 175 [4] Zhou J, Qiu S Y, Du P N, et al. Research progress in the FeCrAl alloys for accident tolerant fuel cladding. Mater Rev, 2017, 31(Suppl 2): 47周军, 邱绍宇, 杜沛南, 等. 耐事故燃料包壳用FeCrAl不锈钢的研究进展. 材料导报, 2017, 31(增刊2): 47 [5] Huang X, Li X Y, Fang X D, et al. Research progress in FeCrAl alloys for accident-tolerant fuel cladding. J Mater Eng, 2020, 48(3): 19 doi: 10.11868/j.issn.1001-4381.2018.001165黄希, 李小燕, 方晓东, 等. 容错事故燃料包壳用FeCrAl合金的研究进展. 材料工程, 2020, 48(3): 19 doi: 10.11868/j.issn.1001-4381.2018.001165 [6] Rebak R B, Terrani K A, Fawcett R M. FeCrAl alloys for accident tolerant Fuel cladding in light water reactors // ASME 2016 Pressure Vessels and Piping Conference. Vancouver, 2016: 1 [7] Rebak R B. Iron-chrome-aluminum alloy cladding for increasing safety in nuclear power plants. EPJ Nuclear Sci Technol, 2017, 3: 34 doi: 10.1051/epjn/2017029 [8] Terrani K A. Accident tolerant fuel cladding development: Promise, status, and challenges. J Nucl Mater, 2018, 501: 13 doi: 10.1016/j.jnucmat.2017.12.043 [9] Liu J K, Zhang X H, Yun D. A complete review and a prospect on the candidate materials for accident-tolerant fuel claddings. Mater Rev, 2018, 32(11): 1757 doi: 10.11896/j.issn.1005-023X.2018.11.001刘俊凯, 张新虎, 恽迪. 事故容错燃料包壳候选材料的研究现状及展望. 材料导报, 2018, 32(11): 1757 doi: 10.11896/j.issn.1005-023X.2018.11.001 [10] Field K G, Yamamoto Y, Pint B A, et al. Accident tolerant FeCrAl fuel cladding: current status towards commercialization // Proceedings of the 18th International Conference on Environmental Degradation of Materials in Nuclear Power Systems-Water Reactors. Portland, 2019: 1381 [11] Gussev M N, Field K G, Yamamoto Y. Design, properties, and weldability of advanced oxidation-resistant FeCrAl alloys. Mater Des, 2017, 129: 227 doi: 10.1016/j.matdes.2017.05.009 [12] Bai G H, Xue F, Zhang Y W, et al. Hot deformation behavior and processing maps of FeCrAl alloy for nuclear fuel cladding. Rare Met Mater Eng, 2020, 49(7): 2340柏广海, 薛飞, 张晏玮, 等. 燃料包壳用FeCrAl合金变形行为与热加工图研究. 稀有金属材料与工程, 2020, 49(7): 2340 [13] Han W T, Yabuuchi K, Kimura A, et al. Effect of Cr/Al contents on the 475 ℃ age-hardening in oxide dispersion strengthened ferritic steels. Nucl Mater Energy, 2016, 9: 610 doi: 10.1016/j.nme.2016.05.015 [14] Liu Z, Han Q, Guo Y L, et al. Development of interatomic potentials for Fe–Cr–Al alloy with the particle swarm optimization method. J Alloys Compd, 2019, 780: 881 doi: 10.1016/j.jallcom.2018.11.079 [15] Tu M H, Hu Y. Overview of the developpement course of FeCrAl alloys for the accident-tolerant fuel cladding // Progress Report on China Nuclear Science & Technology (Vol. 5). Weihai, 2017: 77涂蒙河, 胡勇. ATF用FeCrAl合金发展历程概述 // 中国核科学技术进展报告(第五卷). 威海, 2017: 77 [16] Ukai S, Fujiwara M. Perspective of ODS alloys application in nuclear environments. J Nucl Mater, 2002, 307: 749 [17] Ohtsuka S, Ukai S, Fujiwara M, et al. Nano-structure control in ODS martensitic steels by means of selecting titanium and oxygen contents. J Phys Chem Solids, 2005, 66(2-4): 571 doi: 10.1016/j.jpcs.2004.06.033 [18] Kimura A, Kasada R, Iwata N, et al. Development of Al added high-Cr ODS steels for fuel cladding of next generation nuclear systems. J Nucl Mater, 2011, 417(1-3): 176 doi: 10.1016/j.jnucmat.2010.12.300 [19] Dou P, Kimura A, Kasada R, et al. TEM and HRTEM study of oxide particles in an Al-alloyed high-Cr oxide dispersion strengthened steel with Zr addition. J Nucl Mater, 2014, 444(1-3): 441 doi: 10.1016/j.jnucmat.2013.10.028 [20] Dou P, Kimura A, Kasada R, et al. TEM and HRTEM study of oxide particles in an Al-alloyed high-Cr oxide dispersion strengthened ferritic steel with Hf addition. J Nucl Mater, 2017, 485: 189 doi: 10.1016/j.jnucmat.2016.12.001 [21] Field K G, Hu X X, Littrell K C, et al. Radiation tolerance of neutron-irradiated model Fe–Cr–Al alloys. J Nucl Mater, 2015, 465: 746 doi: 10.1016/j.jnucmat.2015.06.023 [22] Field K G, Briggs S A, Sridharan K, et al. Mechanical properties of neutron-irradiated model and commercial FeCrAl alloys. J Nucl Mater, 2017, 489: 118 doi: 10.1016/j.jnucmat.2017.03.038 [23] Briggs S A, Edmondson P D, Littrell K C, et al. A combined APT and SANS investigation of α′ phase precipitation in neutron-irradiated model FeCrAl alloys. Acta Mater, 2017, 129: 217 doi: 10.1016/j.actamat.2017.02.077 [24] Du P N, Zheng J Y, Wang H, et al. Effects of Nb content and annealing temperature on mechanical properties of FeCrAl alloy. Heat Treat Met, 2018, 43(12): 83杜沛南, 郑继云, 王辉, 等. Nb含量及退火温度对FeCrAl合金力学性能的影响. 金属热处理, 2018, 43(12): 83 [25] Su H Q. Study on Mechanics and High Temperature Oxidation of Fe–Cr–Al Cladding Materials by Al Element [Dissertation]. Harbin: Harbin Engineering University, 2019苏鸿全. Al元素对Fe–Cr–Al包壳材料力学及高温氧化规律研究[学位论文]. 哈尔滨: 哈尔滨工程大学, 2019 [26] Zhao L. The Mechanical Properties and Deformation Behavior of Micro-Pillars of Fe–13Cr–5Al–Mo Alloy [Dissertation]. Harbin: Harbin Institute of Technology, 2018赵琳. Fe–13Cr–5Al–Mo合金微柱力学性能与变形行为研究[学位论文]. 哈尔滨: 哈尔滨工业大学, 2018 [27] Dong H Q. Effect of Zr, Hf Addition on the Microstructure and Tensile Properties of FeCrAl-ODS Steels [Dissertation]. Tianjin: Tianjin University, 2017董红庆. Zr、Hf对Fe–Cr–Al系ODS钢显微组织和拉伸性能的影响[学位论文]. 天津: 天津大学, 2017 [28] Li B, Wu S X, Yan Y X, et al. Y–Fe phase and its effects on microstructure and properties in Fe–15Cr–4Al–Y alloys. J Chin Soc Rare Earths, 1997, 15(2): 139 doi: 10.3321/j.issn:1000-4343.1997.02.013李碚, 吴双霞, 颜玉新, 等. Fe–15Cr–4Al–Y合金中的Y–Fe相及其作用. 中国稀土学报, 1997, 15(2): 139 doi: 10.3321/j.issn:1000-4343.1997.02.013 [29] Sun Z Q, Bei H B, Yamamoto Y. Microstructural control of FeCrAl alloys using Mo and Nb additions. Mater Charact, 2017, 132: 126 doi: 10.1016/j.matchar.2017.08.008 [30] Unocic K A, Pint B A, Hoelzer D T. Advanced TEM characterization of oxide nanoparticles in ODS Fe–12Cr–5Al alloys. J Mater Sci, 2016, 51(20): 9190 doi: 10.1007/s10853-016-0111-5 [31] Dong H Q, Yu L M, Liu Y C, et al. Effect of hafnium addition on the microstructure and tensile properties of aluminum added high-Cr ODS steels. J Alloys Compd, 2017, 702: 538 doi: 10.1016/j.jallcom.2017.01.298 [32] García-Junceda A, Macía E, Garbiec D, et al. Effect of small variations in Zr content on the microstructure and properties of ferritic ODS steels consolidated by SPS. Metals, 2020, 10(3): 348 doi: 10.3390/met10030348 [33] He Y, Liu J H, Han Z B, et al. Effects of La on mechanical properties of fecral stainless steel under high temperature. Contin Cast, 2015, 40(4): 1何杨, 刘建华, 韩志彪, 等. 稀土镧对FeCrAl不锈钢高温力学性能的影响. 连铸, 2015, 40(4): 1 [34] Naumenko D, Le-Coze J, Wessel E, et al. Effect of trace amounts of carbon and nitrogen on the high temperature oxidation resistance of high purity FeCrAl alloys. Mater Trans, 2002, 43(2): 168 doi: 10.2320/matertrans.43.168 [35] Sun Z Q, Yamamoto Y, Chen X. Impact toughness of commercial and model FeCrAl alloys. Mater Sci Eng A, 2018, 734: 93 doi: 10.1016/j.msea.2018.07.074 [36] Sun Z Q, Edmondson P D, Yamamoto Y. Effects of Laves phase particles on recovery and recrystallization behaviors of Nb-containing FeCrAl alloys. Acta Mater, 2018, 144: 716 doi: 10.1016/j.actamat.2017.11.027 [37] Sun Z Q, Yamamoto Y. Processability evaluation of a Mo-containing FeCrAl alloy for seamless thin-wall tube fabrication. Mater Sci Eng A, 2017, 700: 554 doi: 10.1016/j.msea.2017.06.036 [38] Yamamoto Y, Sun Z Q, Pint B A, et al. Optimized Gen-II FeCrAl Cladding Production in Large Quantity for Campaign Testing. Oak Ridge: Oak Ridge National Laboratory, 2016 [39] Hou P Y, Zhang X F, Cannon R M. Impurity distribution in Al2O3 formed on an FeCrAl alloy. Scr Mater, 2004, 50(1): 45 doi: 10.1016/j.scriptamat.2003.09.044 [40] He Y. Fundamental Research on the Solidification Characteristics and High-Temperature Mechanical Properties of High-Al FeCrAl Stainless Steel [Dissertation]. Beijing: University of Science and Technology Beijing, 2019何杨. 高铝FeCrAl不锈钢凝固特性及高温力学性能基础研究[学位论文]. 北京: 北京科技大学, 2019 [41] Shi Z M, Han F S. The microstructure and mechanical properties of micro-scale Y2O3 strengthened 9Cr steel fabricated by vacuum casting. Mater Des, 2015, 66: 304 doi: 10.1016/j.matdes.2014.10.075 [42] Zhang Y, Guo W W, Yan Q Z. Composition, microstructure and mechanical homogeneity evaluation of the Y-bearing 9Cr F/M steel fabricated by VIM & casting technique. Mater Res Express, 2020, 7(3): 036518 doi: 10.1088/2053-1591/ab7c83 [43] Dryepondt S, Unocic K A, Hoelzer D T, et al. Development of ODS FeCrAl Alloys for Accident-Tolerant Fuel Cladding. Oak Ridge: Oak Ridge National Laboratory, 2015 [44] Ukai S, Nishida T, Okada H, et al. Development of oxide dispersion strengthened ferritic steels for FBR core application, (I) improvement of mechanical properties by recrystallization processing. J Nucl Sci Technol, 1997, 34(3): 256 doi: 10.1080/18811248.1997.9733658 [45] Dou P, Kimura A, Okuda T, et al. Effects of extrusion temperature on the nano-mesoscopic structure and mechanical properties of an Al-alloyed high-Cr ODS ferritic steel. J Nucl Mater, 2011, 417(1-3): 166 doi: 10.1016/j.jnucmat.2011.01.061 [46] Dou P, Sang W, Kimura A. Morphology, crystal and metal/oxide interface structures of nanoparticles in Fe–15Cr–2W–0.5Ti–7Al–0.4 Zr–0.5 Y2O3 ODS steel. J Nucl Mater, 2019, 523: 231 [47] Ukai S, Harada M, Okada H, et al. Alloying design of oxide dispersion strengthened ferritic steel for long life FBRs core materials. J Nucl Mater, 1993, 204: 65 doi: 10.1016/0022-3115(93)90200-I [48] Iwata N Y, Kimura A, Fujiwara M, et al. Effect of milling on morphological and microstructural properties of powder particles for High-Cr Oxide dispersion strengthened ferritic steels. J Nucl Mater, 2007, 367: 191 [49] Massey C P, Dryepondt S N, Edmondson P D, et al. Influence of mechanical alloying and extrusion conditions on the microstructure and tensile properties of Low-Cr ODS FeCrAl alloys. J Nucl Mater, 2018, 512: 227 doi: 10.1016/j.jnucmat.2018.10.017 [50] Xu H J. Research on Microstructure and Mechanical Property of 15Cr-ODS Ferritic Alloys [Dissertation]. Shenyang: Northeastern University, 2017徐海健. 15Cr-ODS铁素体合金微观结构及力学性能的研究[学位论文]. 沈阳: 东北大学, 2017 [51] Jönsson B, Berglund R, Magnusson J, et al. High temperature properties of a new powder metallurgical FeCrAl alloy. Mater Sci Forum, 2004, 461: 455 [52] Wen D H. Composition Optimization and High-Temperature Microstructural Stabilities of Stainless Steels for Nuclear Fuel Cladding Materials [Dissertation]. Dalian: Dalian University of Technology, 2019温冬辉. 核燃料包壳材料不锈钢的成分优化与高温组织稳定性研究[学位论文]. 大连: 大连理工大学, 2019 [53] Boegelein T, Dryepondt S N, Pandey A, et al. Mechanical response and deformation mechanisms of ferritic oxide dispersion strengthened steel structures produced by selective laser melting. Acta Mater, 2015, 87: 201 doi: 10.1016/j.actamat.2014.12.047 [54] Czyrska-Filemonowicz A, Dubiel B. Mechanically alloyed, ferritic oxide dispersion strengthened alloys: structure and properties. J Mater Process Technol, 1997, 64(1-3): 53 doi: 10.1016/S0924-0136(96)02553-8 [55] Li J, Wu S J, Ma P, et al. Microstructure evolution and mechanical properties of ODS FeCrAl alloys fabricated by an internal oxidation process. Mater Sci Eng A, 2019, 757: 42 doi: 10.1016/j.msea.2019.04.088 [56] Pimentel G, Chao J, Capdevila C. Recrystallization process in Fe–Cr–Al oxide dispersion-strengthened alloy: Microstructural evolution and recrystallization mechanism. JOM, 2014, 66(5): 780 doi: 10.1007/s11837-014-0916-0 [57] Miller M K, Hoelzer D T, Kenik E A, et al. Nanometer scale precipitation in ferritic MA/ODS alloy MA957. J Nucl Mater, 2004, 329-333: 338 doi: 10.1016/j.jnucmat.2004.04.085 [58] Chao J, Capdevila-Montes C, González-Carrasco J L. On the delamination of FeCrAl ODS alloys. Mater Sci Eng A, 2009, 515(1-2): 190 doi: 10.1016/j.msea.2009.03.017 [59] Quadakkers W J, Elschner A, Speier W, et al. Composition and growth mechanisms of alumina scales on FeCrAl-based alloys determined by SNMS. Appl Surf Sci, 1991, 52(4): 271 doi: 10.1016/0169-4332(91)90069-V [60] Czyrska-Filemonowicz A, Szot K, Wasilkowska A, et al. Microscopy (AFM, TEM, SEM) studies of oxide scale formation on FeCrAl based ODS alloys. Solid State Ionics, 1999, 117(1-2): 13 doi: 10.1016/S0167-2738(98)00243-4 [61] Czyrska-Filemonowicz A, Clemens D, Quadakkers W J. The effect of high temperature exposure on the structure and oxidation behaviour of mechanically alloyed ferritic ODS alloys. J Mater Process Technol, 1995, 53(1-2): 93 doi: 10.1016/0924-0136(95)01965-H [62] García-Rodríguez N, Campos M, Torralba J M, et al. Capability of mechanical alloying and SPS technique to develop nanostructured high Cr, Al alloyed ODS steels. Mater Sci Technol, 2014, 30(13): 1676 doi: 10.1179/1743284714Y.0000000595 [63] Shibata H, Ukai S, Oono N H, et al. Development of accident tolerant FeCrAl-ODS steels utilizing Ce-oxide particles dispersion. J Nucl Mater, 2018, 502: 228 doi: 10.1016/j.jnucmat.2018.02.020 [64] Shibata H, Ukai S, Oono N H, et al. Development of accident-tolerant FeCrAl steels containing Al2O3 particles by means of internal Al oxidation. Metall Mater Trans A, 2019, 50(4): 1816 doi: 10.1007/s11661-019-05122-2 [65] Zhang S H, Ukai S, Nishikawa T, et al. Development and characterization of γ/α transformable FeCrAl-ODS alloys by cobalt addition. J Alloys Compd, 2019, 797: 390 doi: 10.1016/j.jallcom.2019.05.024 [66] Nishikawa T, Zhang S H, Ukai S, et al. Development of α/γ transformable FeCrAl-ODS alloys by nickel addition. Mater Trans, 2019, 60(2): 355 doi: 10.2320/matertrans.M2018271 [67] Ding R F, Wang H, Jiang Y, et al. Effects of ZrC addition on the microstructure and mechanical properties of Fe–Cr–Al alloys fabricated by spark plasma sintering. J Alloys Compd, 2019, 805: 1025 doi: 10.1016/j.jallcom.2019.07.181 [68] Zhang S H, Ukai S, Aghamiri S M S, et al. Tensile properties of Co-added FeCrAl oxide dispersion strengthened alloy. J Alloys Compd, 2021, 852: 156956 doi: 10.1016/j.jallcom.2020.156956 [69] Naimi F, Niepce J-C, Ariane M, et al. Joining of oxide dispersion-strengthened steel using spark plasma sintering. Metals, 2020, 10(8): 1040 doi: 10.3390/met10081040 [70] Liu T, Shen H L, Zhang T W, et al. Effects of consolidation process on the microstructure and mechanical properties of ODS ferritic alloy. Mater Sci Forum, 2013, 747: 507 [71] Liu Z C, Wang G W, Xiao X Y, et al. Process optimization of selective laser melting nickel-based superalloy. Powder Metall Technol, 2021, 39(1): 81刘泽程, 王国伟, 肖祥友, 等. 选择性激光熔化镍基高温合金的工艺优化. 粉末冶金技术, 2021, 39(1): 81 [72] Ni X Q, Kong D C, Wen Y, et al. Influence factors and improvement methods on the porosity of 3D printing metal materials. Powder Metall Technol, 2019, 37(3): 163倪晓晴, 孔德成, 温莹, 等. 3D打印金属材料中孔隙率的影响因素和改善方法. 粉末冶金技术, 2019, 37(3): 163 [73] Walker J C, Berggreen K M, Jones A R, et al. Fabrication of Fe–Cr–Al oxide dispersion strengthened PM2000 alloy using selective laser melting. Adv Eng Mater, 2009, 11(7): 541 doi: 10.1002/adem.200800407 [74] Gao R, Zeng L F, Ding H L, et al. Characterization of oxide dispersion strengthened ferritic steel fabricated by electron beam selective melting. Mater Des, 2016, 89: 1171 doi: 10.1016/j.matdes.2015.10.073 [75] Maloy S A, Aydogan E, Anderoglu O, et al. Viability of Thin Wall Tube Forming of ATF FeCrAl. Los Alamos: Los Alamos National Laboratory, 2016 [76] Field K G, Snead M A, Yamamoto Y, et al. Handbook on the Material Properties of FeCrAl Alloys for Nuclear Power Production Applications. Oak Ridge: Oak Ridge National Laboratory, 2017 -

下载:

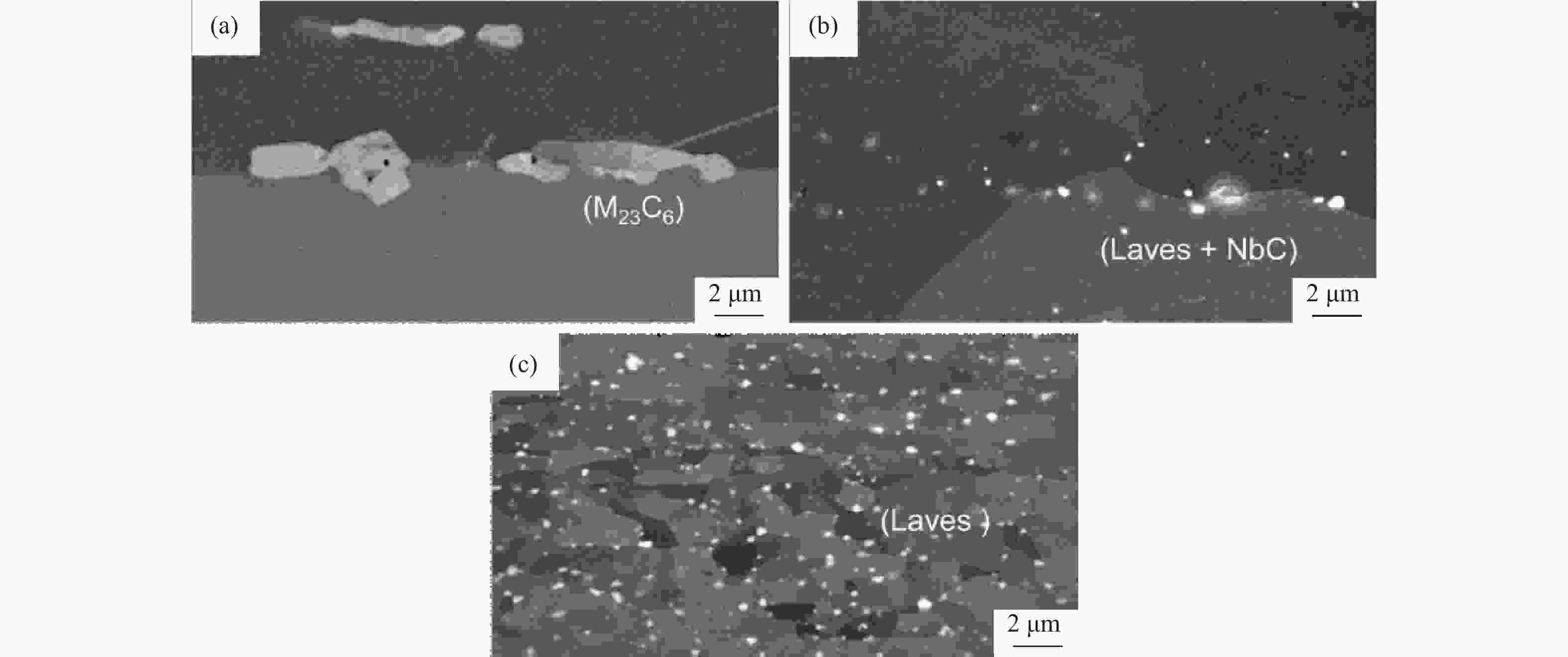

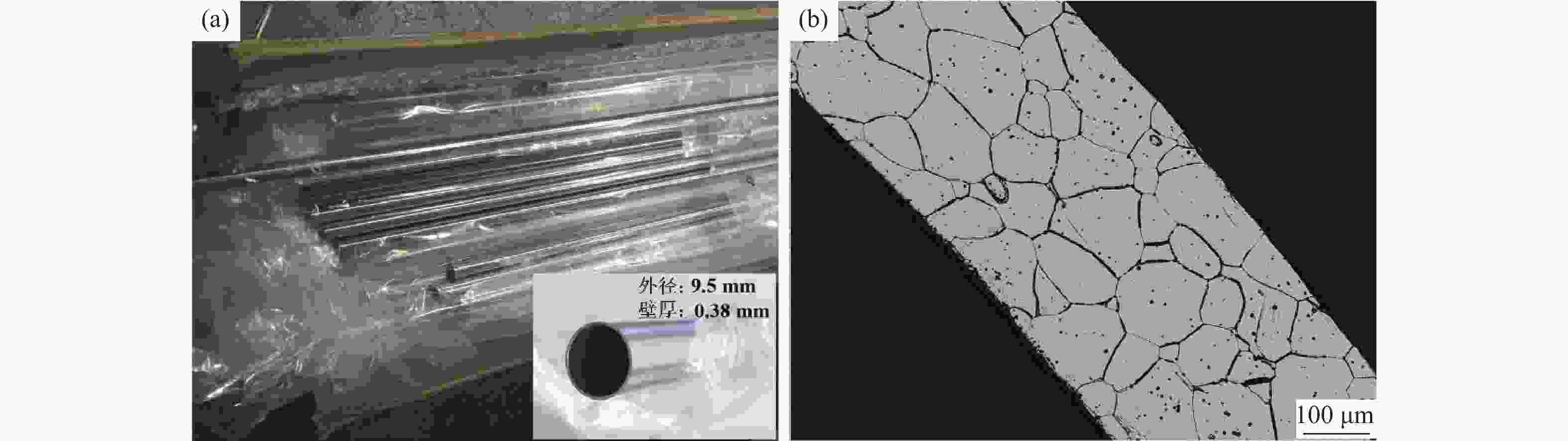

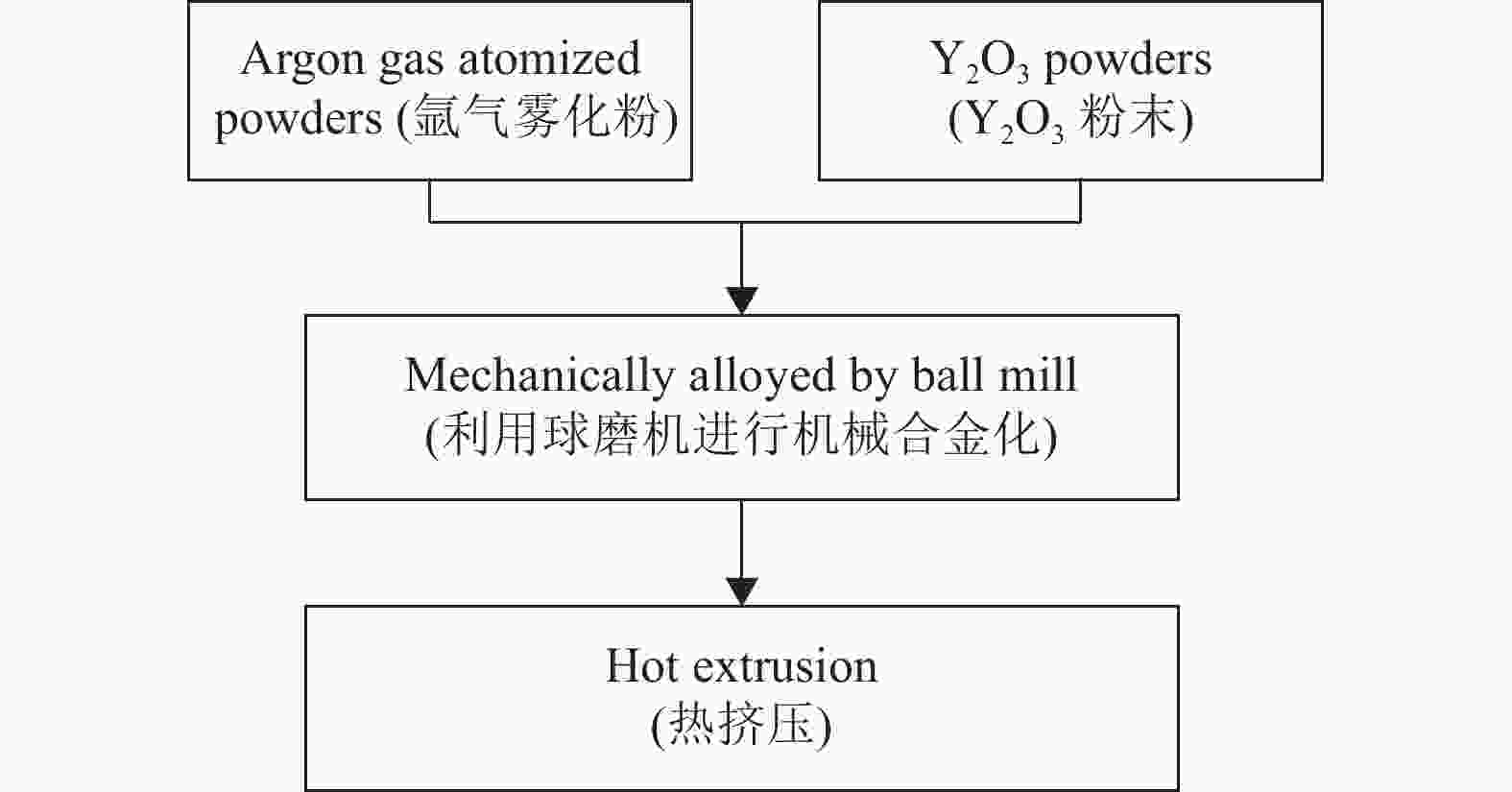

下载: