-

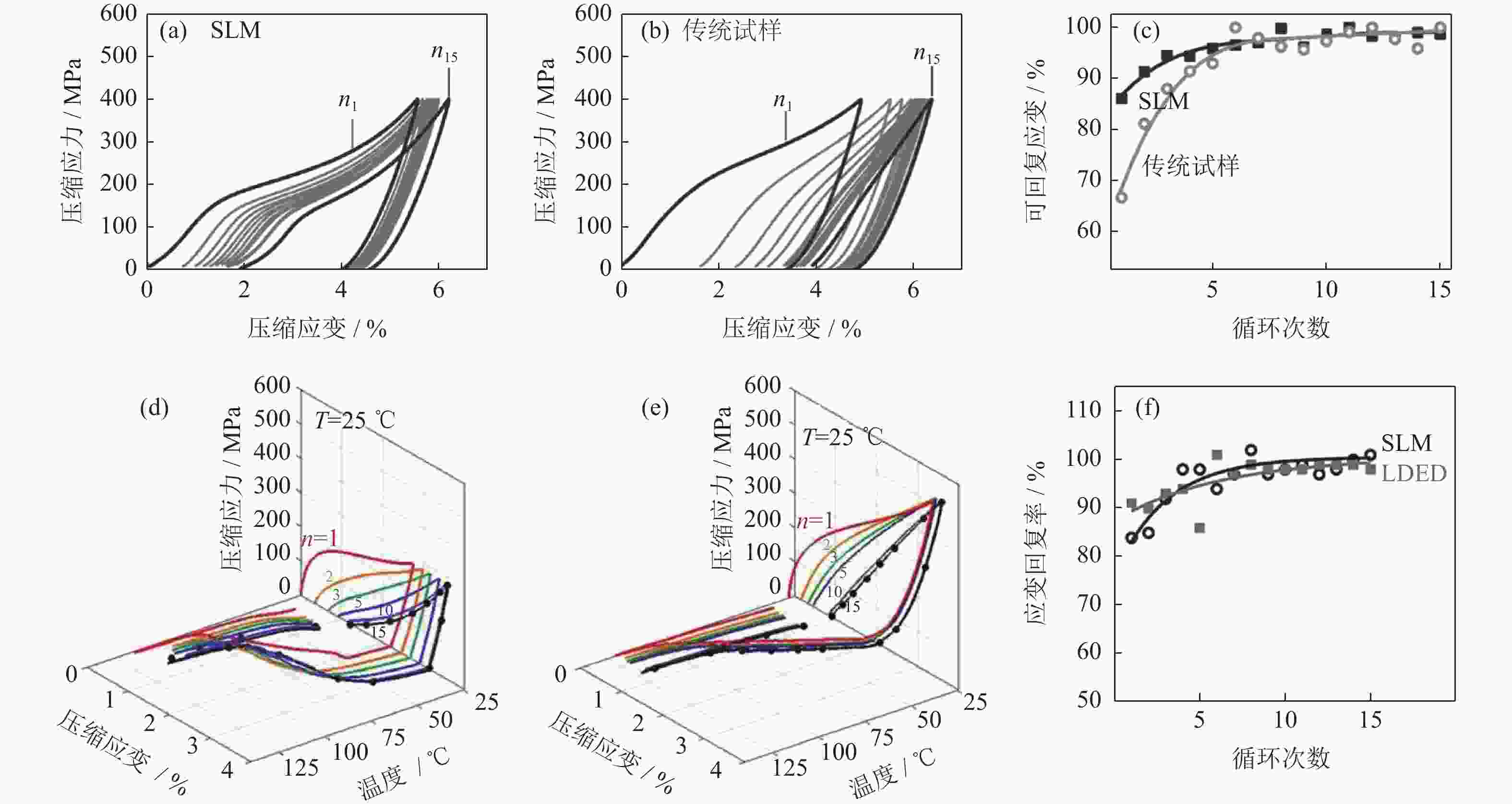

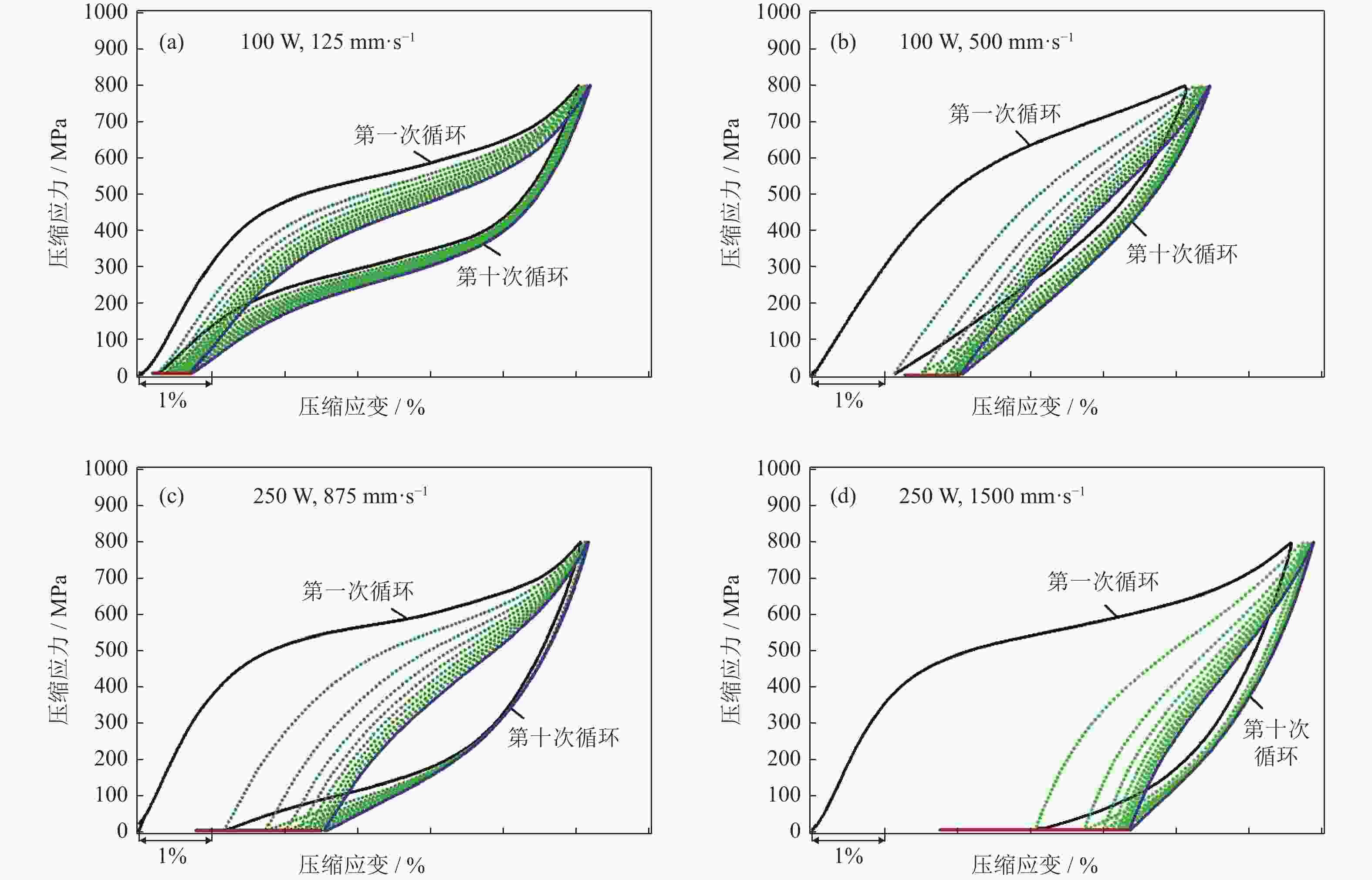

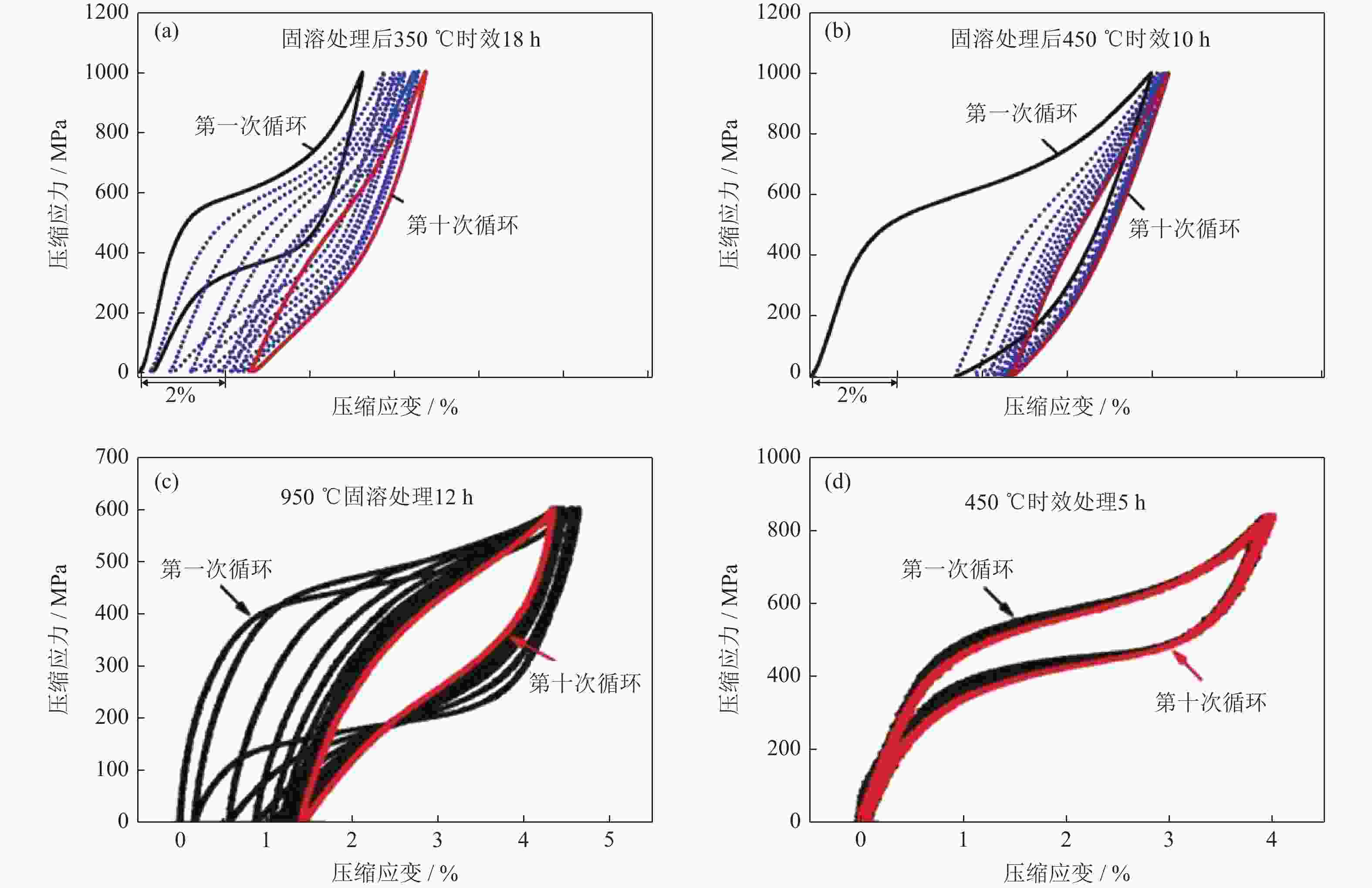

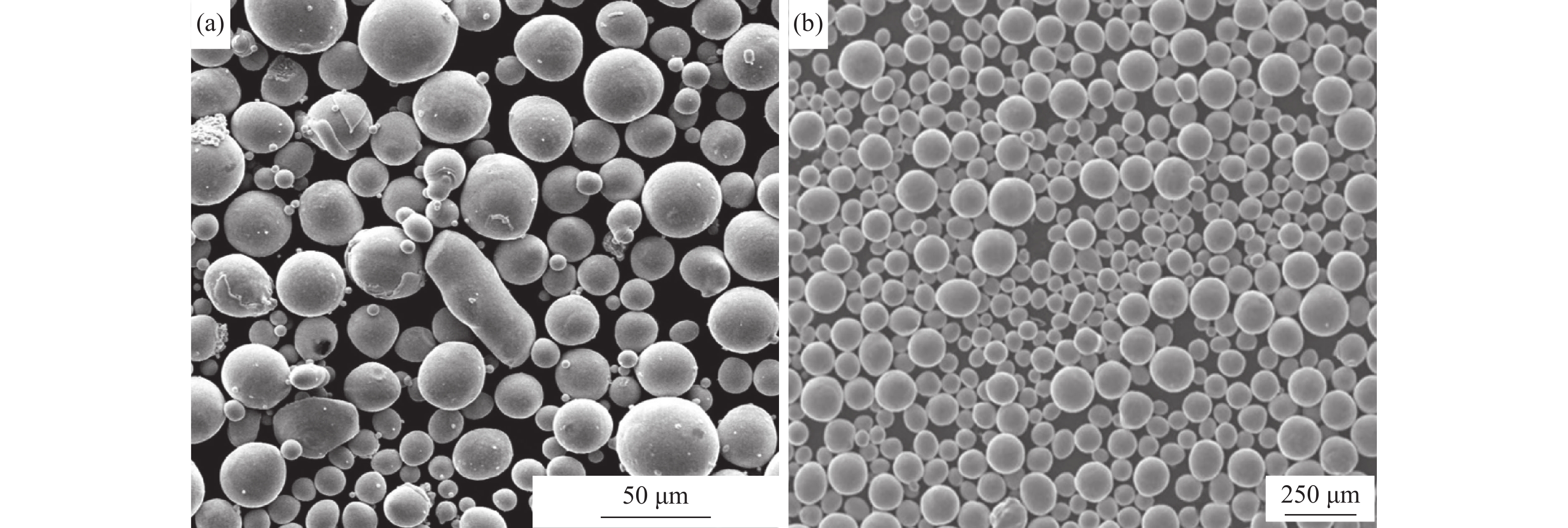

摘要: NiTi作为一种形状记忆合金,具有优异的形状记忆效应、超弹性、耐腐蚀性、生物相容性,在生物医用、航空航天、微机电等领域均有着广泛的应用。增材制造(additive manufacturing,AM)技术作为一种新兴的加工方式,能够提高NiTi合金加工效率,并扩展NiTi合金应用领域。本文介绍了近年来国内外增材制造NiTi合金的研究进展,主要包括增材制造加工过程中原料及工艺的选择,熔池、晶粒、析出物、缺陷等的组织特点,原料、工艺参数、热处理对增材制造NiTi合金力学性能、相变温度、形状记忆效应、超弹性、表面质量的影响。最后对增材制造NiTi合金的研究现状进行了总结,展望了未来的发展趋势。Abstract: As a kind of shape memory alloys, the NiTi alloys show the excellent shape memory effect, superelasticity, corrosion resistance, and biocompatibility, which have been widely used in the biomedical, aerospace, and micro electro mechanical fields. Additive manufacturing (AM) as the new processing method can enhance the manufacturing efficiency of the NiTi alloys and broaden the applications. The research progress of the NiTi alloys fabricated by additive manufacturing was reviewed in this paper, including the selections of raw materials and process, the microstructural characteristics of molten pool, grain, precipitates, and defects, the effects of raw materials, processing parameters, and heat treatment on the mechanical properties, phase transformation temperature, shape memory effect, superelasticity, and surface quality. Finally, the research status of the NiTi alloys fabricated by additive manufacturing was summarized, and the perspectives for the future research in this area were presented.

-

Key words:

- NiTi alloys /

- shape memory alloys /

- additive manufacturing /

- phase transformation /

- microstructure /

- properties

-

图 9 增材制造NiTi合金的应用:(a)右股骨髋关节的植入体[88];(b)口腔颌面修复的植入体;(c)增材制造NiTi合金在温度刺激下发生的形状变化[89];(d)可调节的喷嘴[4]

Figure 9. Applications of AM NiTi alloys: (a) hip implant for insertion into the right femur[88]; (b) implants for oral and maxillofacial restoration; (c) shape development stimulated under the various temperatures[89]; (d) adjustable serrated edge nozzle[4]

表 1 用于激光增材制造的粉末特性及工艺参数

Table 1. Powder properties and optimal processing parameters of the NiTi alloys by LAM

送给方式 文献 Ni原子数分数 / % 粒径 / μm P / W v / (mm·s‒1) h / μm t / μm E / (J·mm‒3) 铺粉 [24] 49.70 — 250 1250.0 120 30 55.5 [23] 50.00 — — 500.0~2000.0 100 50 20.0~80.0 [15] 50.06 25~45 250 160.0 75 30 111.0 250 1100.0 60 30 126.0 [47] 50.90 — 50 80.0 35

12030 — 送粉 [30] 50.00 Ni 20~63

Ti 45~105500

100016.7 15000 1000 — [48] 50.80 28~35 25 2.5 100 — — [49] 53.00 — 1000 10.6 1900 300 — -

[1] Atli K C. The effect of tensile deformation on the damping capacity of NiTi shape memory alloy. J Alloys Compd, 2016, 679: 260 doi: 10.1016/j.jallcom.2016.04.102 [2] Marattukalam J J, Singh A K, Datta S, et al. Microstructure and corrosion behavior of laser processed NiTi alloy. Mater Sci Eng C, 2015, 57: 309 doi: 10.1016/j.msec.2015.07.067 [3] Elahinia M, Moghaddam N S, Andani M T, et al. Fabrication of NiTi through additive manufacturing: A review. Prog Mater Sci, 2016, 83: 630 doi: 10.1016/j.pmatsci.2016.08.001 [4] Hartl D J, Lagoudas D C. Aerospace applications of shape memory alloys. Proc Inst Mech Eng G J Aerosp Eng, 2007, 221(4): 535 [5] Wadood A, Berthod P. Brief overview on nitinol as biomaterial. Adv Mater Sci Eng, 2016, 2016: 4173138 [6] Velmurugan C, Senthilkumar V, Dinesh S, et al. Machining of NiTi-shape memory alloys — A review. Mach Sci Technol, 2018, 22(3): 355 doi: 10.1080/10910344.2017.1365894 [7] Wu L Z, Wen Y J, Zhang B C, et al. Research status of selective laser melting aluminum alloy. Powder Metall Technol, 2021, 39(6): 549吴灵芝, 温耀杰, 张百成, 等. 选区激光熔化铝合金制备研究现状. 粉末冶金技术, 2021, 39(6): 549 [8] Zhang G X, Liu S F, Yang X, et al. Research progress on preparation of biological implant materials by additive manufacturing. Powder Metall Technol, 2019, 37(4): 312张光曦, 刘世锋, 杨鑫, 等. 增材制造技术制备生物植入材料的研究进展. 粉末冶金技术, 2019, 37(4): 312 [9] Zhou Q, Hayat M D, Chen G, et al. Selective electron beam melting of NiTi: Microstructure, phase transformation and mechanical properties. Mater Sci Eng A, 2019, 744: 290 doi: 10.1016/j.msea.2018.12.023 [10] Lu B, Cui X, Liu E, et al. Influence of microstructure on phase transformation behavior and mechanical properties of plasma arc deposited shape memory alloy. Mater Sci Eng A, 2018, 736: 130 doi: 10.1016/j.msea.2018.08.098 [11] Haberland H M C. Structural and functional properties of NiTi shape memory alloys produced by selective laser melting // International Conference on Advanced Research and Rapid Prototyping. Leiria, 2011: 291 [12] Li S, Hassanin H, Attallah M M, et al. The development of TiNi-based negative Poisson's ratio structure using selective laser melting. Acta Mater, 2016, 105: 75 doi: 10.1016/j.actamat.2015.12.017 [13] Saedi S, Moghaddam N S, Amerinatanzi A, et al. On the effects of selective laser melting process parameters on microstructure and thermomechanical response of Ni-rich NiTi. Acta Mater, 2018, 144: 552 doi: 10.1016/j.actamat.2017.10.072 [14] Wang X, Yu J, Liu J, et al. Effect of process parameters on the phase transformation behavior and tensile properties of NiTi shape memory alloys fabricated by selective laser melting. Addit Manuf, 2020, 36: 101545 [15] Dadbakhsh S, Speirs M, Kruth J, et al. Influence of SLM on shape memory and compression behaviour of NiTi scaffolds. CIRP Ann, 2015, 64(1): 209 doi: 10.1016/j.cirp.2015.04.039 [16] Safaei K, Nematollahi M, Bayati P, et al. Torsional behavior and microstructure characterization of additively manufactured NiTi shape memory alloy tubes. Eng Struct, 2021, 226: 111383 doi: 10.1016/j.engstruct.2020.111383 [17] Andani M T, Saedi S, Turabi A S, et al. Mechanical and shape memory properties of porous Ni50.1Ti49.9 alloys manufactured by selective laser melting. J Mech Behav Biomed Mater, 2017, 68: 224 [18] Zhao C, Liang H, Luo S, et al. The effect of energy input on reaction, phase transition and shape memory effect of NiTi alloy by selective laser melting. J Alloys Compd, 2020, 817: 153288 doi: 10.1016/j.jallcom.2019.153288 [19] Yang Y, Zhan J B, Sun Z Z, et al. Evolution of functional properties realized by increasing laser scanning speed for the selective laser melting fabricated NiTi alloy. J Alloys Compd, 2019, 804: 220 doi: 10.1016/j.jallcom.2019.06.340 [20] Chen W, Yang Q, Huang S, et al. Laser power modulated microstructure evolution, phase transformation and mechanical properties in NiTi fabricated by laser powder bed fusion. J Alloys Compd, 2021, 861: 157959 doi: 10.1016/j.jallcom.2020.157959 [21] Xiong Z, Li Z, Sun Z, et al. Selective laser melting of NiTi alloy with superior tensile property and shape memory effect. J Mater Sci Technol, 2019, 35(10): 2238 doi: 10.1016/j.jmst.2019.05.015 [22] Yang Y, Zhan J B, Li B, et al. Laser beam energy dependence of martensitic transformation in SLM fabricated NiTi shape memory alloy. Materialia, 2019, 6: 100305 doi: 10.1016/j.mtla.2019.100305 [23] Ren D C, Zhang H B, Liu Y J, et al. Microstructure and properties of equiatomic Ti‒Ni alloy fabricated by selective laser melting. Mater Sci Eng A, 2020, 771: 138586 doi: 10.1016/j.msea.2019.138586 [24] Farhang B, Ravichander B B, Venturi F, et al. Study on variations of microstructure and metallurgical properties in various heat-affected zones of SLM fabricated nickel‒titanium alloy. Mater Sci Eng A, 2020, 774: 138919 doi: 10.1016/j.msea.2020.138919 [25] Wen S, Liu Y, Zhou Y, et al. Effect of Ni content on the transformation behavior and mechanical property of NiTi shape memory alloys fabricated by laser powder bed fusion. Opt Laser Technol, 2021, 134: 106653 doi: 10.1016/j.optlastec.2020.106653 [26] Fu J, Hu Z, Song X, et al. Micro selective laser melting of NiTi shape memory alloy: Defects, microstructures and thermal/mechanical properties. Opt Laser Technol, 2020, 131: 106374 doi: 10.1016/j.optlastec.2020.106374 [27] Lu H Z, Ma H W, Luo X, et al. Influence of laser scanning speed on phase transformation and superelasticity of 4D-printed Ti‒Ni shape memory alloys. J Mech Eng, 2020, 56(15): 65 doi: 10.3901/JME.2020.15.065卢海洲, 马宏伟, 罗炫, 等. 激光扫描速度对4D打印钛镍形状记忆合金相转变和超弹性的影响. 机械工程学报, 2020, 56(15): 65 doi: 10.3901/JME.2020.15.065 [28] Hamilton R F, Bimber B A, Palmer T A. Correlating microstructure and superelasticity of directed energy deposition additive manufactured Ni-rich NiTi alloys. J Alloys Compd, 2018, 739: 712 doi: 10.1016/j.jallcom.2017.12.270 [29] Marattukalam J J, Balla V K, Das M, et al. Effect of heat treatment on microstructure, corrosion, and shape memory characteristics of laser deposited NiTi alloy. J Alloys Compd, 2018, 744: 337 doi: 10.1016/j.jallcom.2018.01.174 [30] Wang C, Tan X P, Du Z, et al. Additive manufacturing of NiTi shape memory alloys using pre-mixed powders. J Mater Process Technol, 2019, 271: 152 doi: 10.1016/j.jmatprotec.2019.03.025 [31] Hamilton R F, Bimber B A, Taheri A M, et al. Multi-scale shape memory effect recovery in NiTi alloys additive manufactured by selective laser melting and laser directed energy deposition. J Mater Process Technol, 2017, 250: 55 doi: 10.1016/j.jmatprotec.2017.06.027 [32] Kumar S S, Marandi L, Balla V K, et al. Microstructure‒property correlations for additively manufactured NiTi based shape memory alloys. Materialia, 2019, 8: 100456 doi: 10.1016/j.mtla.2019.100456 [33] Halani P R, Halani P R, Shin Y C, et al. In situ synthesis and characterization of shape memory alloy nitinol by laser direct deposition. Metall Mater Trans A, 2012, 43(2): 650 doi: 10.1007/s11661-011-0890-x [34] Shiva S, Palani I A, Mishra S K, et al. Investigations on the influence of composition in the development of Ni‒Ti shape memory alloy using laser based additive manufacturing. Opt Laser Technol, 2015, 69: 44 doi: 10.1016/j.optlastec.2014.12.014 [35] Hamilton R F, Palmer T A, Bimber B A. Spatial characterization of the thermal-induced phase transformation throughout as-deposited additive manufactured NiTi bulk builds. Scr Mater, 2015, 101: 56 doi: 10.1016/j.scriptamat.2015.01.018 [36] Bernard S, Krishna B V, Bose S, et al. Compression fatigue behavior of laser processed porous NiTi alloy. J Mech Behav Biomed Mater, 2012, 13: 62 doi: 10.1016/j.jmbbm.2012.04.010 [37] Biffi C A, Bassani P, Fiocchi J, et al. Microstructural and mechanical response of NiTi lattice 3D structure produced by selective laser melting. Metals, 2020, 10(6): 814 doi: 10.3390/met10060814 [38] Wang J, Pan Z, Carpenter K, et al. Comparative study on crystallographic orientation, precipitation, phase transformation and mechanical response of Ni-rich NiTi alloy fabricated by WAAM at elevated substrate heating temperatures. Mater Sci Eng A, 2021, 800: 140307 doi: 10.1016/j.msea.2020.140307 [39] Wang J, Pan Z, Yang G, et al. Location dependence of microstructure, phase transformation temperature and mechanical properties on Ni-rich NiTi alloy fabricated by wire arc additive manufacturing. Mater Sci Eng A, 2019, 749: 218 doi: 10.1016/j.msea.2019.02.029 [40] Lee A Y, An J, Chua C K. Two-way 4D printing: A review on the reversibility of 3D-printed shape memory materials. Engineering, 2017, 3(5): 663 doi: 10.1016/J.ENG.2017.05.014 [41] Shi Y S, Wu H Z, Yan C Z, et al. Four-dimensional printing — the additive manufacturing technology of intelligent components. J Mech Eng, 2020, 56(15): 1 doi: 10.3901/JME.2020.15.001史玉升, 伍宏志, 闫春泽, 等. 4D打印—智能构件的增材制造技术. 机械工程学报, 2020, 56(15): 1 doi: 10.3901/JME.2020.15.001 [42] Zheng D, Li R D, Song B, et al. Effect of NiTi powder gas atomization process on the selective laser melting moldability and alloys’ superelastic. J Mech Eng, 2020, 56(15): 104 doi: 10.3901/JME.2020.15.104郑聃, 李瑞迪, 宋波, 等. NiTi气雾化制粉工艺对选区激光熔化成型性、制件超弹性的影响. 机械工程学报, 2020, 56(15): 104 doi: 10.3901/JME.2020.15.104 [43] Ren D C. The Investigation of Ti‒Ni Alloy Fabricated by Additive Manufacturing Techonlogy [Dissertation]. Hefei: University of Science and Technology of China, 2020任德春. 增材制备Ti‒Ni合金及其性能研究[学位论文]. 合肥: 中国科学技术大学, 2020 [44] Shen L, Chen G, Zhao S Y, et al. Properties and microstructures of spherical NiTi powders prepared by plasma rotating electrode process. Mater Sci Eng Powder Metall, 2017, 22(4): 539 doi: 10.3969/j.issn.1673-0224.2017.04.013沈垒, 陈刚, 赵少阳, 等. PREP法制备球形NiTi合金粉末的特性及显微组织. 粉末冶金材料科学与工程, 2017, 22(4): 539 doi: 10.3969/j.issn.1673-0224.2017.04.013 [45] Chen G, Zhao S, Tan P, et al. Shape memory TiNi powders produced by plasma rotating electrode process for additive manufacturing. Trans Nonferrous Met Soc China, 2017, 27(12): 2647 doi: 10.1016/S1003-6326(17)60293-0 [46] Haberland C, Elahinia M, Walker J M, et al. On the development of high quality NiTi shape memory and pseudoelastic parts by additive manufacturing. Smart Mater Struct, 2014, 23(10): 104002 doi: 10.1088/0964-1726/23/10/104002 [47] Sam J, Franco B, Ma J, et al. Tensile actuation response of additively manufactured nickel-titanium shape memory alloys. Scr Mater, 2018, 146: 164 doi: 10.1016/j.scriptamat.2017.11.013 [48] Khademzadeh S, Bariani P F, Bruschi S. Textural evolution during micro direct metal deposition of NiTi alloy. Met Mater Int, 2018, 24(4): 869 doi: 10.1007/s12540-018-0104-9 [49] Bimber B A, Hamilton R F, Keist J, et al. Anisotropic microstructure and superelasticity of additive manufactured NiTi alloy bulk builds using laser directed energy deposition. Mater Sci Eng A, 2016, 674: 125 doi: 10.1016/j.msea.2016.07.059 [50] Khoo Z X, Liu Y, Low Z H, et al. Fabrication of SLM NiTi shape memory alloy via repetitive laser scanning. Shape Memory Superelast, 2018, 4(1): 112 doi: 10.1007/s40830-017-0139-7 [51] Guo W, Sun Z, Yang Y, et al. Study on the junction zone of NiTi shape memory alloy produced by selective laser melting via a stripe scanning strategy. Intermetallics, 2020, 126: 106947 doi: 10.1016/j.intermet.2020.106947 [52] Zhang Q, Hao S, Liu Y, et al. The microstructure of a selective laser melting (SLM)-fabricated NiTi shape memory alloy with superior tensile property and shape memory recoverability. Appl Mater Today, 2020, 19: 100547 doi: 10.1016/j.apmt.2019.100547 [53] Tan C, Li S, Essa K, et al. Laser powder bed fusion of Ti-rich TiNi lattice structures: Process optimisation, geometrical integrity, and phase transformations. Int J Mach Tools Manuf, 2019, 141: 19 doi: 10.1016/j.ijmachtools.2019.04.002 [54] Dadbakhsh S, Vrancken B, Kruth J P, et al. Texture and anisotropy in selective laser melting of NiTi alloy. Mater Sci Eng A, 2016, 650: 225 doi: 10.1016/j.msea.2015.10.032 [55] Shayesteh M N, Saghaian S E, Amerinatanzi A, et al. Anisotropic tensile and actuation properties of NiTi fabricated with selective laser melting. Mater Sci Eng A, 2018, 724: 220 doi: 10.1016/j.msea.2018.03.072 [56] Bayati P, Jahadakbar A, Barati M, et al. Toward low and high cycle fatigue behavior of SLM-fabricated NiTi: Considering the effect of build orientation and employing a self-heating approach. Int J Mech Sci, 2020, 185: 105878 doi: 10.1016/j.ijmecsci.2020.105878 [57] Nematollahi M, Saghaian S E, Safaei K, et al. Building orientation-structure-property in laser powder bed fusion of NiTi shape memory alloy. J Alloys Compd, 2021, 873: 159791 doi: 10.1016/j.jallcom.2021.159791 [58] Peduk G S A, Dilibal S, Harrysson O, et al. Comparison of the production processes of nickel-titanium shape memory alloy through additive manufacturing // International Symposium on 3D Printing (Additive Manufacturing). Istanbul, 2017: 1 [59] Zheng D, Li R, Yuan T, et al. Microstructure and mechanical property of additively manufactured NiTi alloys: A comparison between selective laser melting and directed energy deposition. J Cent South Univ, 2021, 28(4): 1028 doi: 10.1007/s11771-021-4677-y [60] Bormann T, Müller B, Schinhammer M, et al. Microstructure of selective laser melted nickel‒titanium. Mater Charact, 2014, 94: 189 doi: 10.1016/j.matchar.2014.05.017 [61] Resnina N, Palani I A, Belyaev S, et al. Structure, martensitic transformations and mechanical behaviour of NiTi shape memory alloy produced by wire arc additive manufacturing. J Alloys Compd, 2021, 851: 156851 doi: 10.1016/j.jallcom.2020.156851 [62] Saedi S, Turabi A S, Andani M T, et al. Texture, aging, and superelasticity of selective laser melting fabricated Ni-rich NiTi alloys. Mater Sci Eng A, 2017, 686: 1 doi: 10.1016/j.msea.2017.01.008 [63] Gan J, Duan L, Li F, et al. Effect of laser energy density on the evolution of Ni4Ti3 precipitate and property of NiTi shape memory alloys prepared by selective laser melting. J Alloys Compd, 2021, 869: 159338 doi: 10.1016/j.jallcom.2021.159338 [64] Wang J, Pan Z, Wang Y, et al. Evolution of crystallographic orientation, precipitation, phase transformation and mechanical properties realized by enhancing deposition current for dual-wire arc additive manufactured Ni-rich NiTi alloy. Addit Manuf, 2020, 34: 101240 [65] Shen C, Reid M, Liss K, et al. In-situ neutron diffraction study on the high temperature thermal phase evolution of wire-arc additively manufactured Ni53Ti47 binary alloy. J Alloys Compd, 2020, 843: 156020 doi: 10.1016/j.jallcom.2020.156020 [66] Guan K. Fundamental Study of NiTi Shape Memory Alloy Fabricated by Selective Laser Melting [Dissertation]. Wuhan: Huazhong University of Science and Technology, 2017关凯. 激光选区熔化成形NiTi形状记忆合金技术基础研究[学位论文]. 武汉: 华中科技大学, 2017 [67] Bayati P, Safaei K, Nematollahi M, et al. Toward understanding the effect of remelting on the additively manufactured NiTi. Int J Adv Manuf Technol, 2021, 112(1-2): 347 doi: 10.1007/s00170-020-06378-4 [68] Li R D. Research on the Key Basic Issues in Selective Laser Melting of Metallic Powder [Dissertation]. Wuhan: Huazhong University of Science and Technology, 2010李瑞迪. 金属粉末选择性激光熔化成形的关键基础问题研究[学位论文]. 武汉: 华中科技大学, 2010 [69] Saedi S, Turabi A S, Taheri Andani M, et al. The influence of heat treatment on the thermomechanical response of Ni-rich NiTi alloys manufactured by selective laser melting. J Alloys Compd, 2016, 677: 204 doi: 10.1016/j.jallcom.2016.03.161 [70] Oliveira J P, Cavaleiro A J, Schell N, et al. Effects of laser processing on the transformation characteristics of NiTi: A contribute to additive manufacturing. Scr Mater, 2018, 152: 122 doi: 10.1016/j.scriptamat.2018.04.024 [71] Khalil-Allafi J, Amin-Ahmadi B. The effect of chemical composition on enthalpy and entropy changes of martensitic transformations in binary NiTi shape memory alloys. J Alloys Compd, 2009, 487(1-2): 363 doi: 10.1016/j.jallcom.2009.07.135 [72] Malukhin K, Ehmann K. Material characterization of NiTi based memory alloys fabricated by the laser direct metal deposition process. J Manuf Sci Eng, 2006, 128(3): 691 doi: 10.1115/1.2193553 [73] Speirs M, Wang X, Van Baelen S, et al. On the transformation behavior of NiTi shape-memory alloy produced by SLM. Shape Memory Superelast, 2016, 2(4): 310 doi: 10.1007/s40830-016-0083-y [74] Farber E, Zhu J, Popovich A, et al. A review of NiTi shape memory alloy as a smart material produced by additive manufacturing. Mater Today Proc, 2020, 30: 761 doi: 10.1016/j.matpr.2020.01.563 [75] Khoo Z X, Liu Y, An J, et al. A review of selective laser melted NiTi shape memory alloy. Materials, 2018, 11(4): 519 doi: 10.3390/ma11040519 [76] Wang X, Kustov S, Van Humbeeck J. A short review on the microstructure, transformation behavior and functional properties of NiTi shape memory alloys fabricated by selective laser melting. Materials, 2018, 11(9): 1683 doi: 10.3390/ma11091683 [77] Cao Y, Zhou X, Cong D, et al. Large tunable elastocaloric effect in additively manufactured Ni‒Ti shape memory alloys. Acta Mater, 2020, 194: 178 doi: 10.1016/j.actamat.2020.04.007 [78] Dutkiewicz J, Rogal Ł, Kalita D, et al. Superelastic effect in NiTi alloys manufactured using electron beam and focused laser rapid manufacturing methods. J Mater Eng Perform, 2020, 29(7): 4463 doi: 10.1007/s11665-020-04938-z [79] Halani P R, Kaya I, Shin Y C, et al. Phase transformation characteristics and mechanical characterization of nitinol synthesized by laser direct deposition. Mater Sci Eng A, 2013, 559: 836 doi: 10.1016/j.msea.2012.09.031 [80] Zeng Z, Cong B Q, Oliveira J P, et al. Wire and arc additive manufacturing of a Ni-rich NiTi shape memory alloy: Microstructure and mechanical properties. Addit Manuf, 2020, 32: 101051 [81] Bagheri A, Mahtabi M J, Shamsaei N. Fatigue behavior and cyclic deformation of additive manufactured NiTi. J Mater Process Technol, 2018, 252: 440 doi: 10.1016/j.jmatprotec.2017.10.006 [82] Deng H B, Chen Y H, Li S H, et al. Research progress on the laser additive manufacturing technology of NiTi shape memory alloys. Rare Met Mater Eng, 2019, 48(12): 4119邓怀波, 陈玉华, 李树寒, 等. NiTi形状记忆合金激光增材制造研究进展. 稀有金属材料与工程, 2019, 48(12): 4119 [83] Singh S, Resnina N, Belyaev S, et al. Investigations on NiTi shape memory alloy thin wall structures through laser marking assisted wire arc based additive manufacturing. J Manuf Process, 2021, 66: 70 doi: 10.1016/j.jmapro.2021.04.004 [84] Khademzadeh S, Zanini F, Rocco J, et al. Quality enhancement of microstructure and surface topography of NiTi parts produced by laser powder bed fusion. CIRP J Manuf Sci Technol, 2020, 31: 575 doi: 10.1016/j.cirpj.2020.08.009 [85] Safdel A, Elbestawi M A. Distortion and printability of stent structures in laser powder bed fusion processing of NiTi alloys. Mater Lett, 2021, 300: 130163 doi: 10.1016/j.matlet.2021.130163 [86] Zhao M, Qing H, Wang Y, et al. Superelastic behaviors of additively manufactured porous NiTi shape memory alloys designed with Menger sponge-like fractal structures. Mater Des, 2021, 200: 109448 doi: 10.1016/j.matdes.2021.109448 [87] Yang Y, Zhan J B, Sui J B, et al. Functionally graded NiTi alloy with exceptional strain-hardening effect fabricated by SLM method. Scr Mater, 2020, 188: 130 doi: 10.1016/j.scriptamat.2020.07.019 [88] Dadbakhsh S, Speirs M, Van Humbeeck J, et al. Laser additive manufacturing of bulk and porous shape-memory NiTi alloys: From processes to potential biomedical applications. MRS Bull, 2016, 41(10): 765 doi: 10.1557/mrs.2016.209 [89] Ma J, Franco B, Tapia G, et al. Spatial control of functional response in 4D-Printed active metallic structures. Sci Rep, 2017, 7(1): 46707 doi: 10.1038/srep46707 -

下载:

下载: