Porous titanium prepared by metal injection molding based on space-holder technique

-

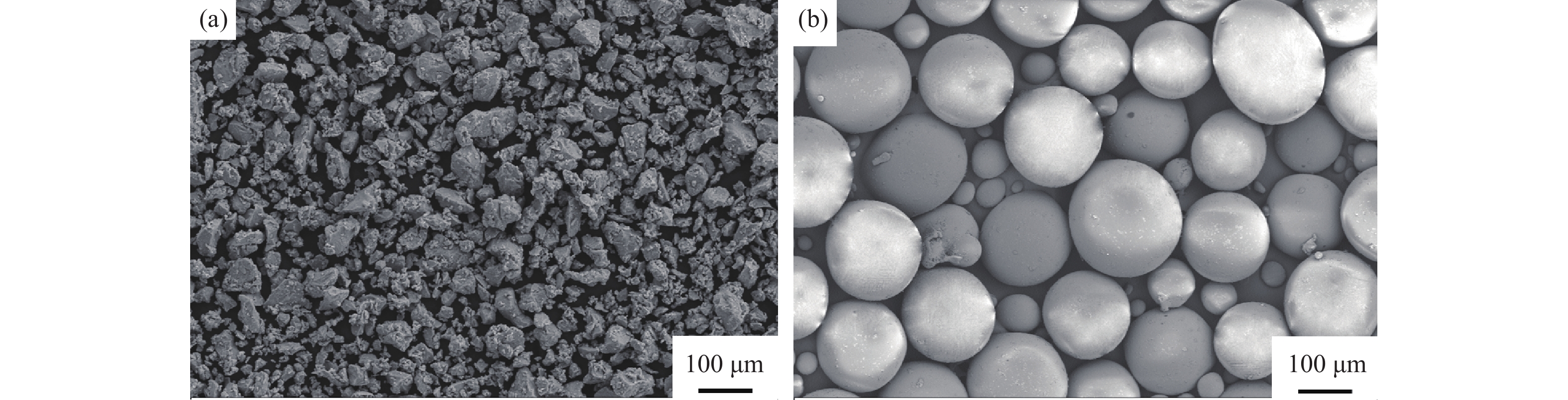

摘要: 以聚甲基丙烯酸甲酯(PMMA)为造孔剂,聚甲醛(POM)为主要粘结剂,通过金属注射成形和高真空烧结制备了多孔钛。研究了PMMA在金属注射成形中对多孔钛孔隙特征的影响及烧结温度对多孔钛孔隙特征的影响。结果表明,密炼过程中PMMA与POM等有机粘结剂混合在一起,失去其原有颗粒特征(粒径与形状);热脱脂过程中PMMA集中在350~420 ℃区间先于高密度聚乙烯(HDPE)分解,起到造孔作用,但孔隙形状不可控且孔径远小于其原始颗粒尺寸;在1100~1250 ℃烧结区间内,提高烧结温度时多孔钛的开孔率与孔径均呈下降趋势,当烧结温度为1150~1200 ℃时,多孔钛开孔率为34%~35%,孔径为9.1 µm。Abstract: Porous titanium was prepared by metal injection molding (MIM) and high vacuum sintering using polymethyl methacrylate (PMMA) particles as pore forming agent and polyformaldehyde (POM) as main binder. The effects of PMMA and sintering temperature on the pore characteristics of porous titanium were investigated in detail. The results showed that PMMA particles are melted and mixed with organic binder together and lose their original particle characteristics (particle size and shape) during kneading. In the process of thermal debinding, PMMA decompose before high-density polyethylene (HDPE) in the temperature range of 350~420 ℃, which play the role of pore formation, but the shape of pores was irregular and the pore sizes are much smaller than the original PMMA particle sizes. In the sintering temperature range of 1100~1250 ℃, the opening porosity and pore sizes of porous titanium decrease with increasing of sintering temperature. When the sintering temperature is 1150~1200 ℃, the opening porosity of porous titanium is 34%~35%, and the pore size is about 9.1 μm.

-

组分 熔融温度 / ℃ 热分解温度 / ℃ POM 175~180 280 HDPE 139 410~550 EVA 99 230 SA 150~176 350~380 PMMA >160 >270 表 2 不同烧结温度制备的多孔钛的孔隙特性

Table 2. Pore properties of porous titanium at different sintering temperatures

烧结温度 / ℃ 开孔率 / % 孔隙容积 / (mL·g−1) 比表面积 / (m2·g−1) 平均孔径 / μm 1100 40.08 0.1519 0.067 9.117 1150 35.57 0.1221 0.054 9.073 1200 34.70 0.1170 0.051 9.183 1250 26.69 0.0799 0.038 8.465 -

[1] Zhang E L, Wang X Y, Han Y. Research status of biomedical porous Ti and its alloy in China. Acta Metall Sin, 2017, 53(12): 1555 doi: 10.11900/0412.1961.2017.00324张二林, 王晓燕, 憨勇. 医用多孔Ti及钛合金的国内研究现状. 金属学报, 2017, 53(12): 1555 doi: 10.11900/0412.1961.2017.00324 [2] Wang P, Yang L J, He F. Review on technology of surface micro-nano structure and biological properties on titanium and titanium alloy implant surface. Titanium Ind Progr, 2020, 37(6): 41王培, 杨理京, 何飞. 钛及钛合金植入体表面微纳结构制备技术及生物性能研究进展. 钛工业进展, 2020, 37(6): 41 [3] He X, Wang X F, Wang X L, et al. Research progress in the preparation process of porous titanium materials. Light Ind Sci Technol, 2020, 36(9): 69何喜, 王晓峰, 王小炼, 等. 多孔钛材料制备工艺研究进展. 轻工科技, 2020, 36(9): 69 [4] Ren Y J, Liu S F, Li X J, et al. Preparation and research status of porous metal fiber materials. Mater China, 2019, 38(8): 800 doi: 10.7502/j.issn.1674-3962.201805027任垚嘉, 刘世锋, 李香君, 等. 金属纤维多孔材料的制备和研究现状. 中国材料进展, 2019, 38(8): 800 doi: 10.7502/j.issn.1674-3962.201805027 [5] Ren X M, Ma B Y, Zhang B W, et al. Research progress of porous titanium and titanium alloy. Rare Met Cement Carb, 2018, 46(1): 61任鑫明, 马北越, 张博文, 等. 多孔钛及钛合金的研究进展. 稀有金属与硬质合金, 2018, 46(1): 61 [6] Feng D. Application of metal porous materials in environmental treatment. Tianjin Metall, 2020(1): 41 doi: 10.3969/j.issn.1006-110X.2020.01.012冯丹. 金属多孔材料在环境治理领域的应用. 天津冶金, 2020(1): 41 doi: 10.3969/j.issn.1006-110X.2020.01.012 [7] Cao F, Zhang W Y, Zhang S S, et al. A technological and performance review of chemically prepared porous metallic materials. Mater Rep, 2017, 31(21): 139 doi: 10.11896/j.issn.1005-023X.2017.021.020曹凤, 张文彦, 张思思, 等. 多孔金属材料的化学制备方法及性能研究进展. 材料导报, 2017, 31(21): 139 doi: 10.11896/j.issn.1005-023X.2017.021.020 [8] Xiao J, Qiu G B. Research progress in preparation methods of titanium foams or porous titanium. Rare Met Mater Eng, 2017, 46(6): 1734肖健, 邱贵宝. 泡沫或多孔钛的制备方法研究进展. 稀有金属材料与工程, 2017, 46(6): 1734 [9] Li F F, Zhang F. Preparation method and application of porous metal material. China Foundry Mach Technol, 2021, 56(1): 82 doi: 10.3969/j.issn.1006-9658.2021.01.015李斐斐, 张芳. 多孔金属材料的制备方法及应用. 中国铸造装备与技术, 2021, 56(1): 82 doi: 10.3969/j.issn.1006-9658.2021.01.015 [10] Lhadi S, Chini M, Richeton T, et al. Micromechanical modeling of the elasto-viscoplastic behavior and incompatibility stresses of β-Ti alloys. Materials, 2018, 11(7): 1227 doi: 10.3390/ma11071227 [11] Liu C L, Zhang Q P, Wu J W, et al. Preparation and property characterization of Ti-6Al-4V feedstock by metal powder injection molding. Hot Work Technol, 2020, 49(6): 98刘春林, 张钱鹏, 邬均文, 等. Ti-6Al-4V金属粉末注射成形喂料的制备与性能表征. 热加工工艺, 2020, 49(6): 98 [12] Liu C, Kong X J, Wu S W, et al. Research progress on metal injection molding of titanium and titanium alloys. Powder Metall Technol, 2017, 35(2): 150 doi: 10.3969/j.issn.1001-3784.2017.02.012刘超, 孔祥吉, 吴胜文, 等. 钛及钛合金金属粉末注射成形技术的研究进展. 粉末冶金技术, 2017, 35(2): 150 doi: 10.3969/j.issn.1001-3784.2017.02.012 [13] Zhao L M, Qu X H, He X B, et al. Sintering of TiAl injection molding. Chin J Rare Met, 2008, 32(2): 180 doi: 10.3969/j.issn.0258-7076.2008.02.011赵丽明, 曲选辉, 何新波, 等. 粉末注射成形钛铝烧结工艺研究. 稀有金属, 2008, 32(2): 180 doi: 10.3969/j.issn.0258-7076.2008.02.011 [14] Hu K, Zou L M, Shi Q, et al. Effect of titanium hydride powder addition on microstructure and properties of titanium powder injection molding. Powder Technol, 2020, 367: 225 doi: 10.1016/j.powtec.2020.03.059 [15] Li Y, Zhang X Q, Zhu J, et al. Study on debinding process of Ti-Mo getter matertial by powder injection molding. J Funct Mater, 2014, 45(2): 02110李洋, 张心强, 朱君, 等. Ti-Mo吸气材料注射成形脱脂工艺的研究. 功能材料, 2014, 45(2): 02110 [16] Li T, Li Y M, Chen L J, et al. Fabrication of bioactive porous titanium by metal injection molding and its properties. Rare Met Mater Eng, 2011, 40(2): 335李挺, 李益民, 陈良建, 等. 注射成形制备多孔钛及其性能. 稀有金属材料与工程, 2011, 40(2): 335 [17] Cui X M, Chen L J, Zheng Y. Preparation of a new porous titanium implant. Sci Technol Rev, 2012, 30(28-29): 71 doi: 10.3981/j.issn.1000-7857.2012.h1.012崔晓明, 陈良建, 郑遥. 一种新型多孔钛种植体的制备与研究. 科技导报, 2012, 30(28-29): 71 doi: 10.3981/j.issn.1000-7857.2012.h1.012 [18] Engin G, Aydemir B, Özkan Gülsoy H. Injection molding of micro-porous titanium alloy with space holder technique. Rare Met, 2011, 30(6): 565 doi: 10.1007/s12598-011-0430-2 [19] Liu W. Research on Powder Injection Molding of Pure Titanium Porous Filter Cartridge [Dissertation]. Harbin: Harbin Institute of Technology, 2014刘伟. 纯钛多孔滤筒的粉末注射成形研究[学位论文]. 哈尔滨: 哈尔滨工业大学, 2014 -

下载:

下载: