| [1] |

Feng S C, Wang Y H, Ding R F. Application and prospect of powder metallurgy in steel enterprises. Powder Metall Technol, 2015, 33(4): 296 doi: 10.3969/j.issn.1001-3784.2015.04.011冯士超, 王艳红, 丁瑞锋. 粉末冶金在钢铁企业的应用及发展前景. 粉末冶金技术, 2015, 33(4): 296 doi: 10.3969/j.issn.1001-3784.2015.04.011

|

| [2] |

Tan Z Q, Zhang Q, Guo X Y, et al. New development of powder metallurgy in automotive industry. J Cent South Univ, 2020, 27(6): 1611 doi: 10.1007/s11771-020-4394-y

|

| [3] |

Vasanthakumar P, Sekar K, Venkatesh K. Recent developments in powder metallurgy based aluminium alloy composite for aerospace applications. Mater Today, 2019, 18(7): 5400

|

| [4] |

Shang F, Zhou H X, Qiao B, et al. Application of metal powder metallurgy technology in preparation of friction materials of the railway vehicles. Adv Mater Res, 2011, 1334(287-290): 2987

|

| [5] |

Bao C X, Cao Y, Yi J H. et al. Preparation processes of high density iron-based powder metallurgy parts. Powder Metall Technol, 2011, 2022, 40(5): 458包崇玺, 曹阳, 易健宏, 等. 高密度铁基粉末冶金零件制备技术. 粉末冶金技术, 2022, 40(5): 458

|

| [6] |

Guo B, Li Q, Wu H, et al. Influences of impact energy on the densification and mechanical properties of powder metallurgical Fe−C−Cu preforms during a powder-forged process. J Mater Res Technol, 2020, 9(6): 13914 doi: 10.1016/j.jmrt.2020.09.084

|

| [7] |

Rodriguez A K, Ayoub G A, Mansoor B, et al. Effect of strain rate and temperature on fracture of magnesium alloy AZ31B. Acta Mater, 2016, 112: 194 doi: 10.1016/j.actamat.2016.03.061

|

| [8] |

Guo Y, Zhou M X, Sun X D, et al. Effects of temperature and strain rate on the fracture behaviors of an Al−Zn−Mg−Cu alloy. Materials, 2018, 11(7): 1233 doi: 10.3390/ma11071233

|

| [9] |

He A, Xie G L, Zhang H L, et al. A modified Zerilli-Armstrong constitutive model to predict hot deformation behavior of 20CrMo alloy steel. Mater Des, 2014, 56: 122 doi: 10.1016/j.matdes.2013.10.080

|

| [10] |

Song B, Sanborn B. A modified Johnson-Cook model for dynamic response of metals with an explicit strain- and strain-rate-dependent adiabatic thermosoftening effect. J Dyn Behav Mater, 2019, 5(3): 212 doi: 10.1007/s40870-019-00203-0

|

| [11] |

Yin X Y, Luo J, Zhu J. Construction of high-temperature constitutive model of HAl61-4-3-1 alloy for synchronizer ring based on Hansel-Spittel mode. J Chongqing Univ Technol Nat Sci, 2021, 35(1): 111尹小燕, 骆静, 朱杰. 基于Hansel-Spittel模型的齿环用HAl61-4-3-1合金本构模型构建. 重庆理工大学学报(自然科学), 2021, 35(1): 111

|

| [12] |

Meng B, Wan M, Wu X D, et al. Constitutive modeling for high-temperature tensile deformation behavior of pure molybdenum considering strain effects. Int J Refract Met Hard Mater, 2014, 45: 41 doi: 10.1016/j.ijrmhm.2014.03.005

|

| [13] |

Zhu H F, Liu J, Wu Y, et al. Hot deformation behavior and workability of in situ TiB2/7050Al composites fabricated by powder metallurgy. Materials, 2020, 13(23): 5319 doi: 10.3390/ma13235319

|

| [14] |

Zyguła K, Wojtaszek M, Śleboda T, et al. The analysis of hot deformation behavior of powder metallurgy Ti−10V−2Fe−3Al alloy using activation energy and Zener-Hollomon parameter. Procedia Manuf, 2020, 50: 546 doi: 10.1016/j.promfg.2020.08.098

|

| [15] |

Qu F S, Dong X F, Liu J Y, et al. The research on vacuum isothermal bloom for powder metallurgy V−5Cr−5Ti alloy guiding by the constitutive models and the error analysis. Int J Refract Met Hard Mater, 2018, 72: 349 doi: 10.1016/j.ijrmhm.2018.01.007

|

| [16] |

Wang J, Zhao G Q, Chen L, et al. A comparative study of several constitutive models for powder metallurgy tungsten at elevated temperature. Mater Des, 2016, 90: 91 doi: 10.1016/j.matdes.2015.10.114

|

| [17] |

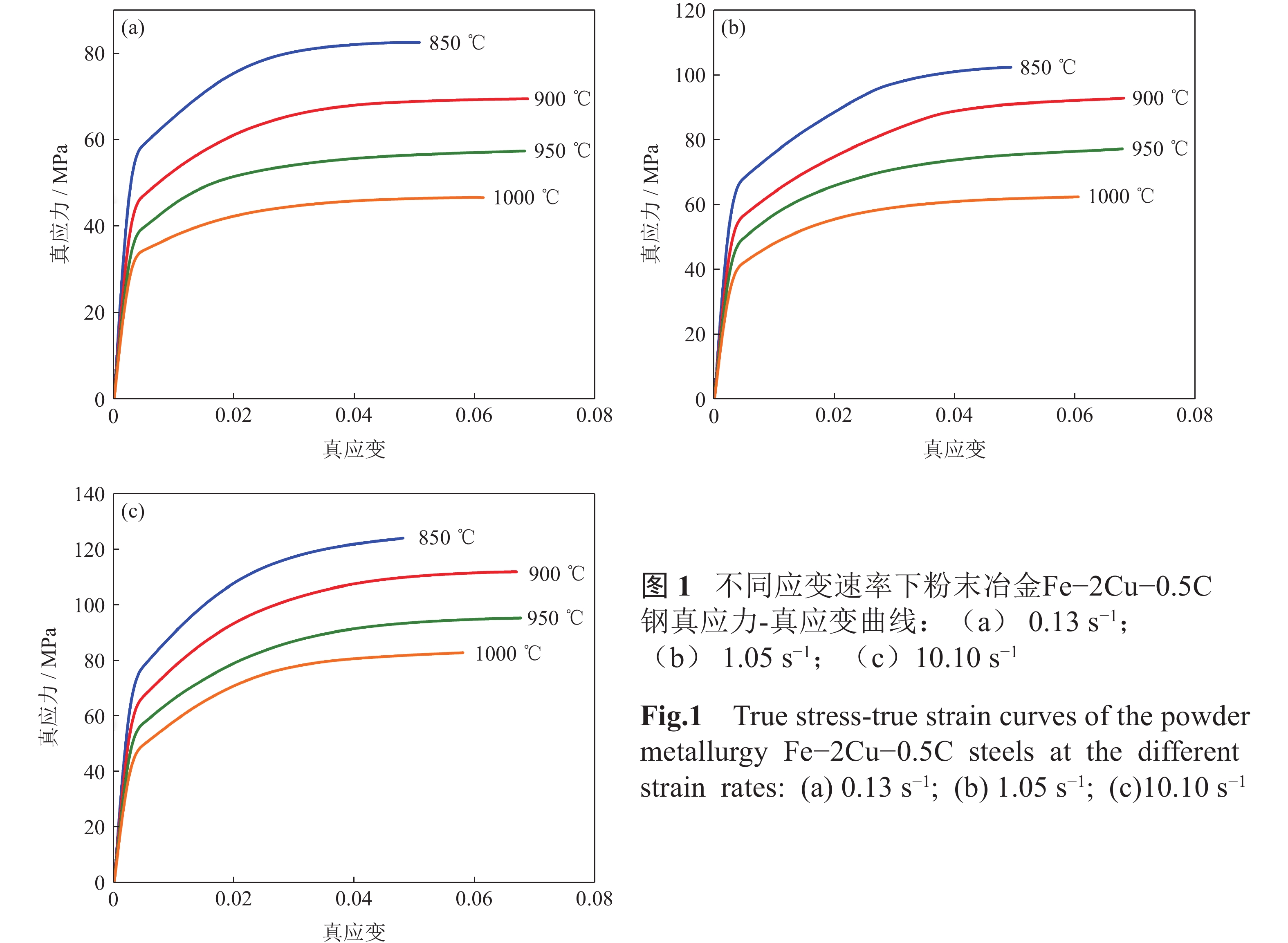

Li Q, Guo B, Wu H, et al. Flow stress and prediction on powder sintered steel Fe−2Cu−0.5C during high temperature tensile. Forg Stamp Technol, 2020, 45(8): 195李强, 郭彪, 吴辉, 等. Fe−2Cu−0.5C粉末烧结钢高温拉伸流变应力及预测. 锻压技术, 2020, 45(8): 195

|

| [18] |

Wu H, Wen S P, Huang H, et al. Hot deformation behavior and constitutive equation of a new type Al−Zn−Mg−Er−Zr alloy during isothermal compression. Mater Sci Eng A, 2016, 651: 415 doi: 10.1016/j.msea.2015.10.122

|

| [19] |

Wang H R, Wang W, Zhai R X, et al. Constitutive equations for describing the warm and hot deformation behavior of 20Cr2Ni4A alloy steel. Metals, 2020, 10(9): 1169 doi: 10.3390/met10091169

|

| [20] |

Qiao L, Deng Y, Liao M, et al. Modelling and prediction of thermal deformation behaviors in a pearlitic steel. Mater Today Commun, 2020, 25: 101134 doi: 10.1016/j.mtcomm.2020.101134

|

| [21] |

He J, Xiao Y, Liu J, et al. Model for predicting ductile fracture of SA508-3 steel undergoing hot forming. Mater Sci Technol, 2014, 30(10): 1239 doi: 10.1179/1743284713Y.0000000443

|

| [22] |

Xu R R, Li M Q, Li H. Kinetic analysis and strain-compensated constitutive models of Ti−42.9Al−4.6Nb−2Cr during isothermal compression. Prog Nat Sci Mater Int, 2020, 30(2): 260

|

| [23] |

Xiao X, Liu G Q, Hu B F, et al. A comparative study on Arrhenius-type constitutive equations and artificial neural network model to predict high-temperature deformation behaviour in 12Cr3WV steel. Comput Mater Sci, 2012, 62: 227 doi: 10.1016/j.commatsci.2012.05.053

|

| [24] |

Wang T X, Lu S Q, Wang K L, et al. Flow stress behavior and constitutive model base on artificial neural network of Ti60 alloy. Spec Cast Nonferrous Alloys, 2020, 40(9): 1019 doi: 10.15980/j.tzzz.2020.09.022王天祥, 鲁世强, 王克鲁, 等. Ti60合金的流变应力行为及人工神经网络本构模型. 特种铸造及有色合金, 2020, 40(9): 1019 doi: 10.15980/j.tzzz.2020.09.022

|

| [25] |

Zhou F, Wang K L, Lu S Q, et al. Flow behavior and neural network high temperature constitutive model of Ti−22Al−24Nb−0.5Y alloy. J Mater Eng, 2019, 47(8): 141周峰, 王克鲁, 鲁世强, 等. Ti−22Al−24Nb−0.5Y合金流动行为及BP神经网络高温本构模型. 材料工程, 2019, 47(8): 141

|

| [26] |

Murugesan M, Sajjad M, Jung D W. Microstructure evaluation and constitutive modeling of AISI-1045 steel for flow stress prediction under hot working conditions. Symmetry, 2020, 12(5): 782 doi: 10.3390/sym12050782

|

下载:

下载: