-

摘要: 为降低钛及钛合金制品的成本,以钛锭表面切削下来的钛屑(切削纤维)为原料,经过清洗、剪切、压制、高温约束烧结等工序制备成钛合金纤维多孔材料,观察材料微观结构,分析压制压力和孔隙率之间的关系,并研究烧结温度、纤维宽度、孔隙率对钛合金纤维多孔材料压缩性能的影响规律。结果表明,钛合金纤维多孔材料内部均为通孔,随着压制压力的增加,钛合金纤维多孔材料的孔隙率随之降低。纤维宽度为2 mm,孔隙率为56.0%,烧结温度为1200 ℃条件下制得的钛合金纤维多孔材料平台应力达17.34 MPa。本文实现了原材料零成本制备钛合金纤维多孔材料,可用于阻尼减振、冲击防护等领域。Abstract: To reduce the cost of Ti and Ti alloy products, the Ti chips (cutting fibers) from the surface of Ti ingots were used as the raw materials to prepare the Ti alloy fiber porous materials by cleaning, cutting, pressing, and high temperature confined sintering. The microstructures were observed, the influence of pressing pressure on porosity was analyzed, and the effects of sintering temperature, fiber width, and porosity on the compressive properties of the Ti alloy fiber porous materials were systemically studied. The results show that, the interior of Ti alloy fiber porous materials is the through-pore. As the increase of the pressing pressure, the porosity of the Ti alloy fiber porous materials decreases. The compressive platform stress of the Ti alloy fiber porous materials sintered at 1200 ℃ is up to 17.34 MPa with the fiber width of 2 mm and the porosity of 56.0%. The titanium alloy fiber porous materials are prepared at zero cost for the raw materials in this paper, which can be applied in the fields of damping, vibration reduction, and impact protection.

-

Key words:

- Ti alloy fibers /

- porous materials /

- high temperature sintering /

- porosity /

- compressive properties

-

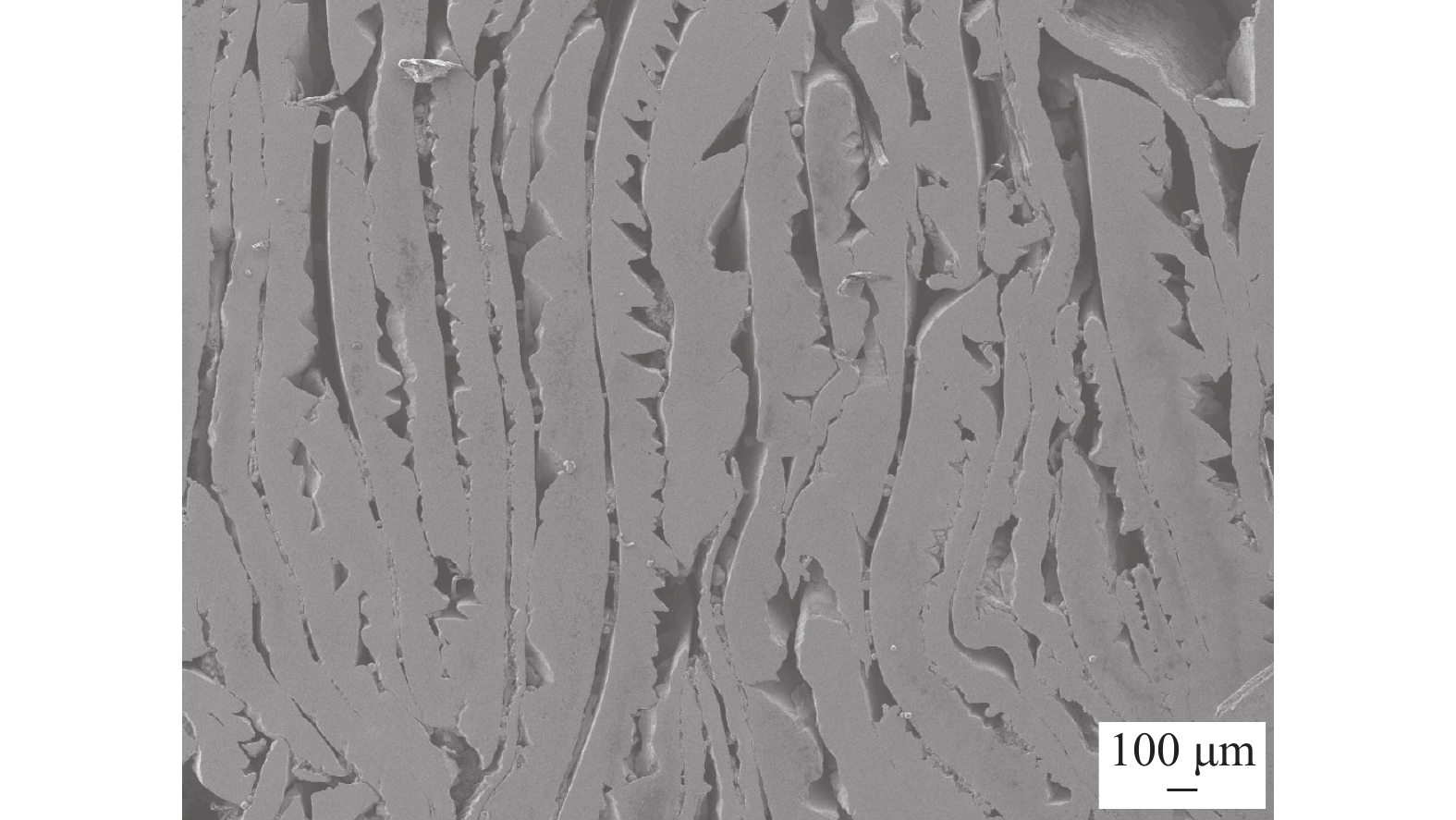

图 5 不同纤维宽度的钛合金纤维多孔材料微观形貌:(a)孔隙率63%,纤维宽度为2 mm;(b)孔隙率63%,纤维宽度为4 mm;(c)孔隙率57%,纤维宽度为2 mm;(d)孔隙率57%,纤维宽度为4 mm

Figure 5. Microstructures of the Ti alloy fiber porous materials with the different fiber width: (a) porosity of 63%, fiber width of 2 mm; (b) porosity of 63%, fiber width of 4 mm; (c) porosity of 57%, fiber width of 2 mm; (d) porosity of 57%, fiber width of 4 mm

表 1 压制压力与钛合金纤维多孔材料孔隙率的关系

Table 1. Relationship between the pressing pressure and porosity of the Ti alloy fiber porous materials

压制压力 / MPa 孔隙率 / % 20 66.2 40 64.0 60 60.1 80 56.7 表 2 不同孔隙率的钛合金纤维多孔材料平台应力

Table 2. Platform stress of the Ti alloy fiber porous materials with the different porosity

平台应力 / MPa 孔隙率 / % 2.24 70.8 4.91 65.6 10.61 63.0 13.74 60.4 17.34 56.0 -

[1] Guo L, He W X, Zhou P, et al. Research status and development prospect of titanium and titanium alloy products in China. Hot Working Technol, 2020, 49(22): 22 doi: 10.14158/j.cnki.1001-3814.20192060郭鲤, 何伟霞, 周鹏, 等. 我国钛及钛合金产品的研究现状及发展前景. 热加工工艺, 2020, 49(22): 22 doi: 10.14158/j.cnki.1001-3814.20192060 [2] Liu Y N, Wang Z X, Liu J P, et al. Research status and progress of titanium foams prepared by space holder technique. Powder Metall Technol, 2019, 37(4): 306刘永宁, 王智祥, 刘锦平, 等. 造孔剂法制备泡沫钛的研究现状与进展. 粉末冶金技术, 2019, 37(4): 306 [3] Ren J S, Zhang Y M, Tan J, et al. Current research status and trend of titanium alloys for biomendical applications. Mater Rev, 2016, 38(28): 384任军帅, 张英明, 谭江, 等. 生物医用钛合金材料发展现状及趋势. 材料导报, 2016, 38(28): 384 [4] Han J Y, Luo J H, Yuan S B, et al. Research status of dental titanium and titanium alloys. Titanium Ind Prog, 2016, 33(3): 1 doi: 10.13567/j.cnki.issn1009-9964.2016.03.001韩建业, 罗锦华, 袁思波, 等. 口腔用钛及钛合金材料的研究现状. 钛工业进展, 2016, 33(3): 1 doi: 10.13567/j.cnki.issn1009-9964.2016.03.001 [5] Wu Q C, Ji Z, Jia C C, et al. Research progress on titanium and titanium alloys used as implant materials for human body. Powder Metall Technol, 2019, 37(3): 225 doi: 10.19591/j.cnki.cn11-1974/tf.2019.03.011武秋池, 纪箴, 贾成厂, 等. 钛及钛合金人体植入材料研究进展. 粉末冶金技术, 2019, 37(3): 225 doi: 10.19591/j.cnki.cn11-1974/tf.2019.03.011 [6] Li X M, Liu L, Dong J, et al. Discussion on economic analysis and decreasing cost process of titanium and titanium alloys. Mater China, 2015, 34(5): 401李献民, 刘立, 董洁, 等. 钛及钛合金材料经济性及低成本方法论述. 中国材料进展, 2015, 34(5): 401 [7] Ren X M, Ma B Y, Zhang B W, et al. Research progress of porous titanium and titanium alloy. Rare Met Cement Carb, 2018, 46(1): 61任鑫明, 马北越, 张博文, 等. 多孔钛及钛合金的研究进展. 稀有金属与硬质合金, 2018, 46(1): 61 [8] Kuang M S, Hu W M, Guo A H, et al. Application of titanium and titanium alloys to ships of US navy. Torpedo Technol, 2012, 20(5): 331匡蒙生, 胡伟民, 郭爱红, 等. 钛及钛合金在美海军舰船上的应用. 鱼雷技术, 2012, 20(5): 331 [9] Wang J Z, Ao Q B, Ma J, et al. Sound absorption performance of porous metal fiber materials with different structures. Appl Acoust, 2019, 145: 431 doi: 10.1016/j.apacoust.2018.10.014 [10] Ao Q B, Wang J Z, Ma J, et al. Vibration-damping properties of stainless steel fiber porous materials. Hot Working Technol, 2021, 50(8): 30 doi: 10.14158/j.cnki.1001-3814.20190704敖庆波, 王建忠, 马军, 等. 不锈钢纤维多孔材料的阻尼减振性能. 热加工工艺, 2021, 50(8): 30 doi: 10.14158/j.cnki.1001-3814.20190704 [11] Wu Y L, Li Y G, Ma W X. Research progress of metal fiber blended electromagnetic shielding fabric. Prog Text Sci Technol, 2020(6): 1 doi: 10.3969/j.issn.1673-0356.2020.06.002吴依琳, 李永贵, 麻文效. 金属纤维混纺电磁屏蔽织物的研究进展. 纺织科技进展, 2020(6): 1 doi: 10.3969/j.issn.1673-0356.2020.06.002 [12] Xi Z P, Tang H P, Zhu J L, et al. Application of metal porous materials in energy and environmental protection. Rare Met Mater Eng, 2006, 35(Suppl 2): 413 doi: 10.3321/j.issn:1002-185X.2006.z2.101奚正平, 汤慧萍, 朱纪磊, 等. 金属多孔材料在能源与环保中的应用. 稀有金属材料与工程, 2006, 35(增刊 2): 413 doi: 10.3321/j.issn:1002-185X.2006.z2.101 [13] Ma J, Wang J Z, Ao Q B, et al. A Preparation Process of Low-Cost Titanium Based Porous Material with High Energy Absorption Characteristics: China Patent, 202011178503. X. 2020-10-29马军, 王建忠, 敖庆波, 等. 一种具有高能量吸收特性的低成本钛基多孔材料制备工艺: 中国专利, 202011178503. X. 2020-10-29 [14] Wang J Z, Tang H P, Ma Q, et al. Fabrication of high strength and ductile stainless steel fiber felts by sintering. JOM, 2016, 68(3): 890 doi: 10.1007/s11837-015-1803-z [15] Tang H P. Porous Metal Fiber Materials. Beijing: Metallurgical Industry Press, 2016汤慧萍. 金属纤维多孔材料. 北京: 冶金工业出版社, 2016 [16] Qiao J C, Xi Z P, Tang H P, et al. Compressive behavior of porous metal fibers. Rare Met Mater Eng, 2008, 37(12): 2173 doi: 10.3321/j.issn:1002-185X.2008.12.024乔吉超, 奚正平, 汤慧萍, 等. 金属纤维多孔材料的压缩行为. 稀有金属材料与工程, 2008, 37(12): 2173 doi: 10.3321/j.issn:1002-185X.2008.12.024 [17] Wang J Y, Tang H P, Zhu J L, et al. Effect of porosity on compressive properties of porous sintered stainless steel fiber media. Powder Metall Technol, 2009, 27(5): 323 doi: 10.19591/j.cnki.cn11-1974/tf.2009.05.001王建永, 汤慧萍, 朱纪磊, 等. 孔隙度对烧结不锈钢纤维多孔材料压缩性能的影响. 粉末冶金技术, 2009, 27(5): 323 doi: 10.19591/j.cnki.cn11-1974/tf.2009.05.001 [18] Wang J Z, Xu Z G, Ao Q B, et al. Status quo of mechanical properties of porous metal fibrous materials. Rare Met Mater Eng, 2016, 45(6): 1636王建忠, 许忠国, 敖庆波, 等. 金属纤维多孔材料力学性能研究现状. 稀有金属材料与工程, 2016, 45(6): 1636 [19] Wang J Z, Ao Q B, Ma J, et al. Quasi-static compressive performance of porous stainless steel fiber materials. J Funct Mater, 2018, 49(9): 107 doi: 10.3969/j.issn.1001-9731.2018.09.019王建忠, 敖庆波, 马军, 等. 不锈钢纤维多孔材料的准静态压缩性能. 功能材料, 2018, 49(9): 107 doi: 10.3969/j.issn.1001-9731.2018.09.019 -

下载:

下载: